- Main types

- Sink grease trap: DIY creation and installation

- Grease traps: device and principle of operation

- Making a do-it-yourself grease trap

- Features of the installation of the structure

- What is a fat separator

- The principle of operation of the grease trap

- Types of grease filters

- Grease trap installation

- Installing a grease trap under the sink

- Installation of a grease trap in the garden

- Equipment installation technology

- Installation of a street grease trap

- Installing the grease trap indoors

- Selection criteria and main manufacturers

- KS-Zh-2V - from 45,000 rubles

- Selection criteria and main manufacturers

- Filter classification

- Installation

- Where to install

- How to install

- Selection Tips

- Varieties

- Why install filters on the exhaust system

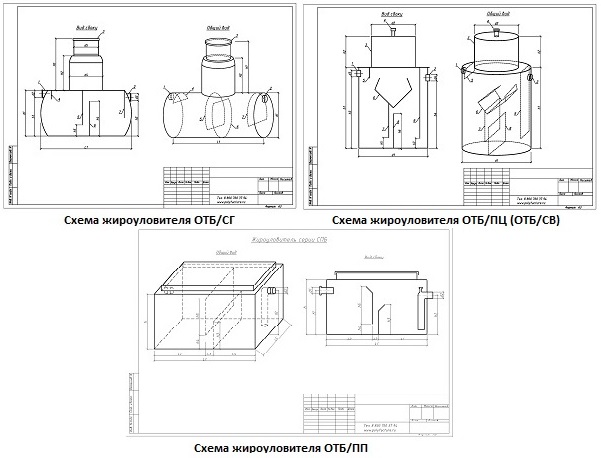

Main types

Devices of this type are classified according to the principle of cleaning, it can be performed in three ways:

- Mechanical. This most common option has been described above, its main disadvantages are:

- during operation, it is necessary to regularly clean the device from the accumulation of fat;

- low efficiency and level of purification, part of the impurities still remains in the effluents.

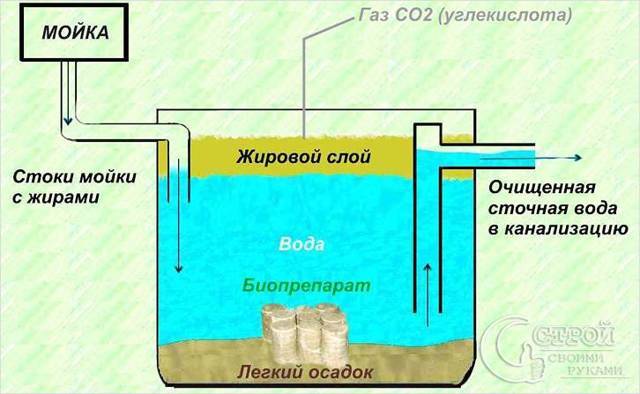

- Gravitational. The design of such separators and the principle of operation resembles the previous type (see Fig. 3), the only difference is in the technological process of cleaning.Drains are given time to settle (about a day), which allows almost all impurities to collect near the surface. Often, in these devices, special chemicals are used that bind fatty impurities, forming heavy conglomerates from them that precipitate.

The principle of operation of the gravitational grease trap Evo Stok

The principle of operation of the gravitational grease trap Evo Stok

Such devices have a much higher cleaning percentage, about 98%, but there are also characteristic disadvantages:

- manual cleaning and subsequent disposal of fat is necessary;

- in the precipitated organic matter, the process of decay may begin, which manifests itself in the form of an unpleasant odor.

- Biological. Such separators are called biological destructors. The difference from previous types also lies in the cleaning technology. It is produced by adding biological products (special cultures of microorganisms), which feed on fat and convert it into a neutral precipitate.

Grease trap tablets Custom GT

Grease trap tablets Custom GT

The advantages of this method are obvious, after the decomposition of fat there is no unpleasant odor and a less difficult cleaning process.

Concluding the topic about the types of grease traps, we should mention devices for ventilation systems, for example, a kitchen hood, which also has special devices for separating fats.

Grease traps in the kitchen hood: a - grate filters; b - labyrinth type

Passing through the filters, grease vapors settle on them, which reduces the pollution of duct ventilation systems.

Sink grease trap: DIY creation and installation

Grease traps: device and principle of operation

The installation of grease traps at industrial and food facilities is due to the presence of relevant sanitary norms and rules, but as for domestic use, is this device really necessary in the house? To do this, you need to understand what effect fatty substances have on the sewer system:

- When cooled, fatty acids turn into a flaky mass, which settles on the walls of pipes and eventually leads to clogging, reducing the flow of water. Over time, the system becomes completely impassable and must be cleaned (in the worst case, repaired).

- Fats lead to the gradual formation of caustic substances that have a persistent fetid odor.

- Over time, fatty deposits oxidize and corrode the sewer system from the inside, completely rendering it unusable.

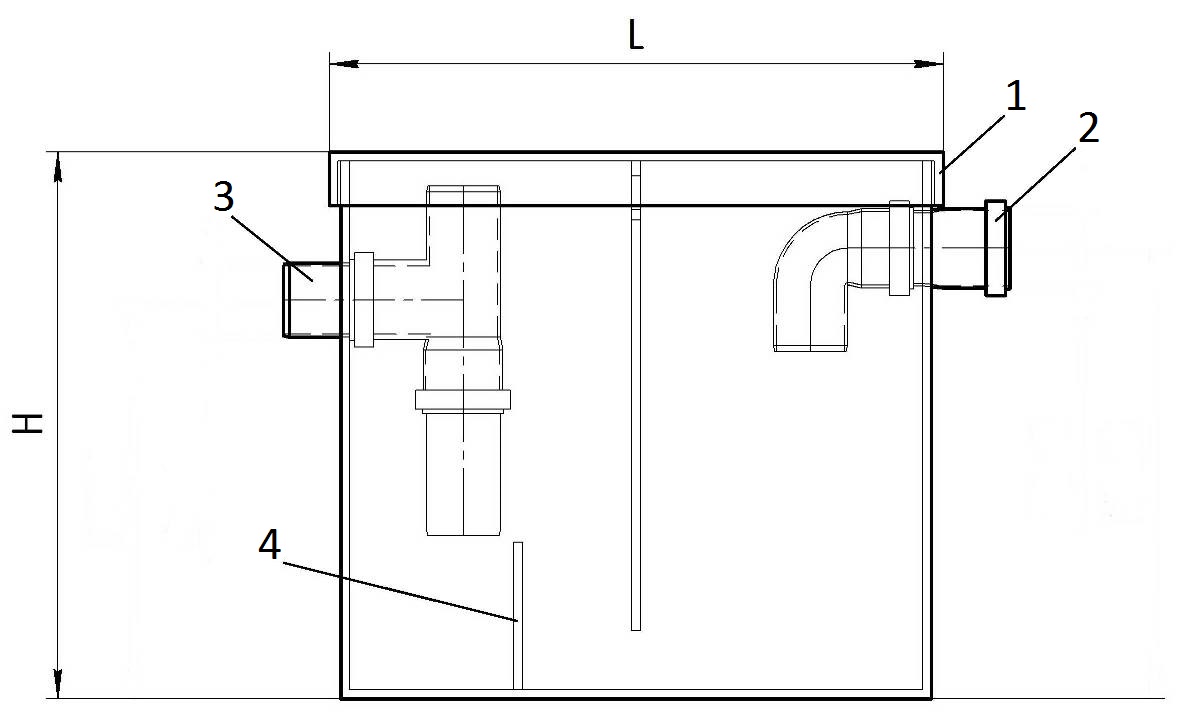

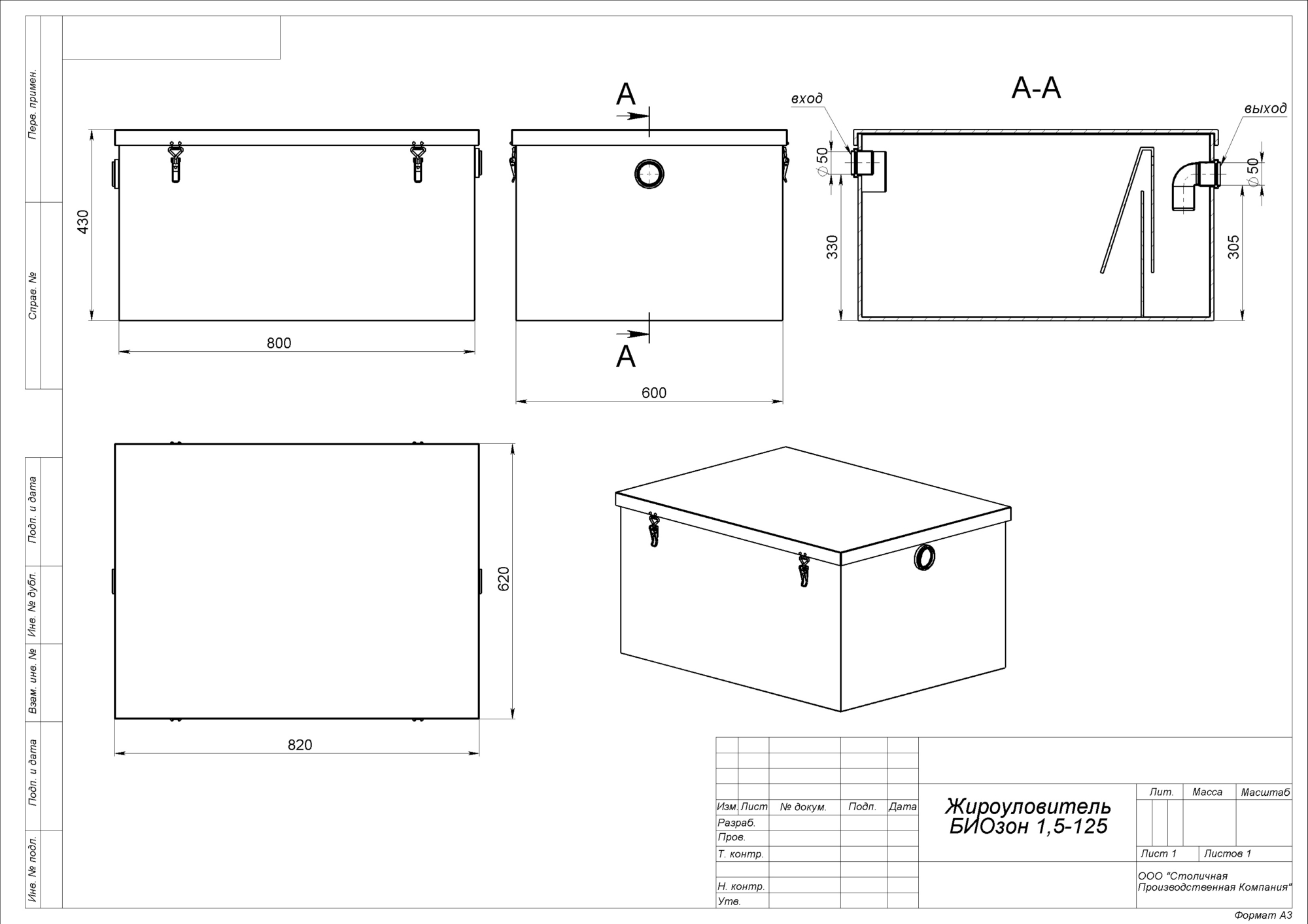

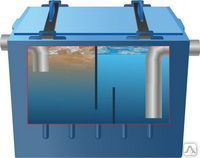

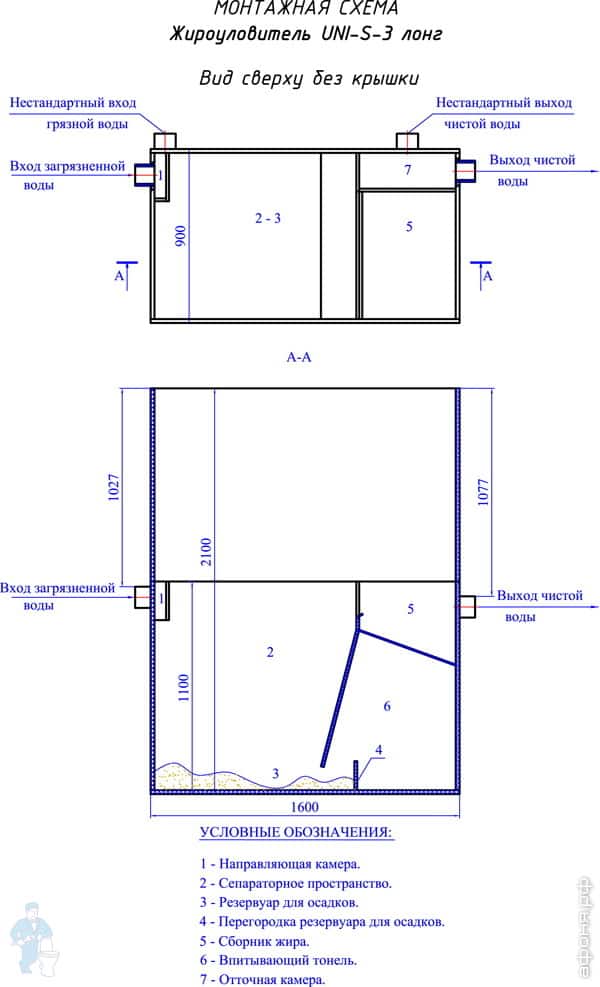

As you can see, the use of a grease trap is quite justified even at home. Let us briefly consider the device of a household installation. The grease trap is a completely sealed container with a removable lid, made of food-grade plastic and divided into several sections. Branch pipes are connected to the extreme ones, which cut into the sewer pipeline. Installed under the sink.

The grease trap is classified as a septic tank. All used water passes through it. The basic principle of operation of the installation is the difference between the densities of water and fat. First, the effluents enter the tank through the inlet pipe. Since fat is less dense, its particles float on the water surface and, thanks to the partitions installed across them, are removed from there to a special storage tank. The accumulated fat in the household grease trap can only be removed manually.

Making a do-it-yourself grease trap

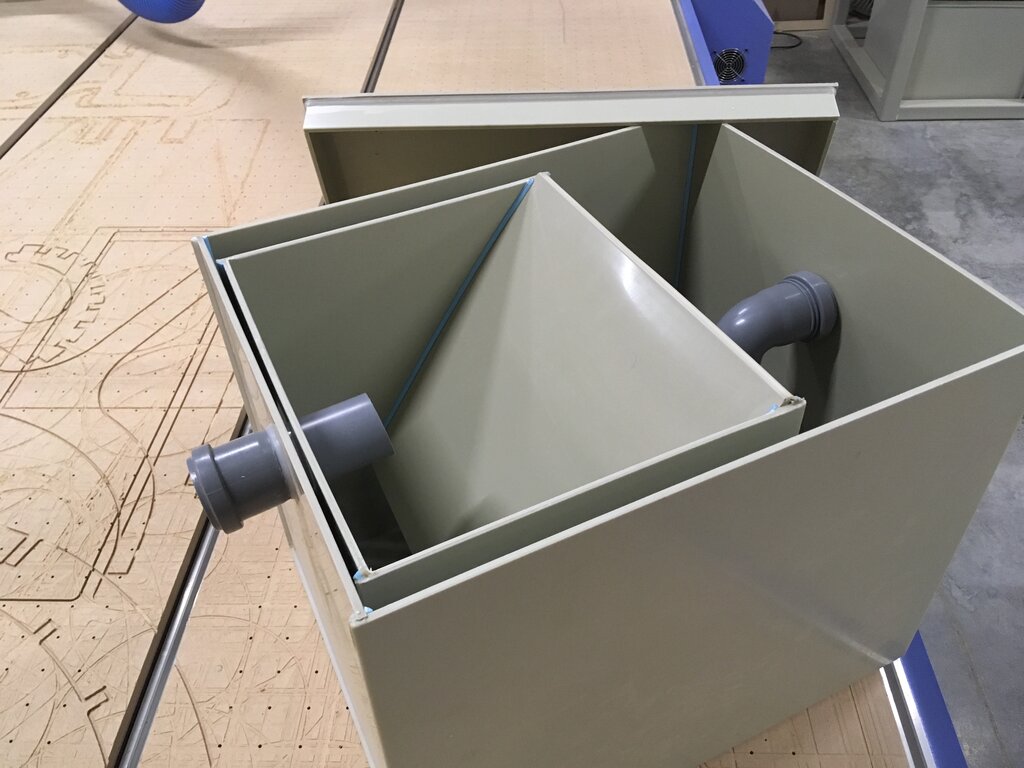

Most often, materials such as steel, food-grade plastic, fiberglass and polypropylene are used for the manufacture of this unit. We will consider the simplest option - the manufacture of a plastic device.

Advice. If you have unnecessary products made of harmless plastic on the farm, then you can safely use them to create the capacity of the unit.

Before proceeding directly to the creation of the design, it is important to make basic calculations that will help calculate the optimal installation volume for a particular water supply system. First, let's calculate the performance of the created unit

So, we use the following formula: Р=nPs, where

- P - performance of the septic tank, l / s;

- n is the number of sinks in the room;

- Ps - water supply rate (usually equal to 0.1 l / s).

After we know the capacity of the unit being designed, we determine the required volume of the structure using the formula: V=60Pt, where

- t is the average duration of fatty acid sedimentation (about 6 minutes);

- P is the performance of the unit already known to us.

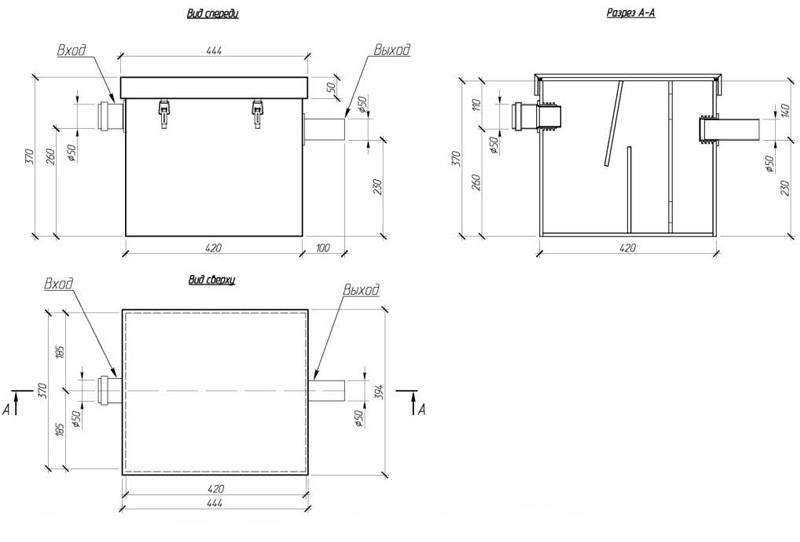

We make a drawing of the installation according to the dimensions obtained. Now you can start preparing the tool and materials:

- material for the body of the installation (in our case, food grade plastic);

- sanitary silicone;

- building glue;

- a piece of thermoplastic pipe with a diameter of 5 cm;

- thermoplastic elbow with a diameter of 5 cm;

- thermoplastic tee with a diameter of 5 cm.

The first step is to cut the parts for the body. We use a hacksaw for metal / jigsaw. First, we glue the sides (body) of our design, only after that we fix the bottom. Then we install internal partitions (their height should be 2/3 of the height of the side walls).Joints are sealed with silicone.

We install an elbow in the assembled structure (it will act as an inlet pipe). From a piece of pipe and a tee we make an outlet pipe. It remains the case for small - the top cover for the design. In places of its contact with the body, we fix the rubber seal. You can proceed to the installation of the unit in the working area.

Features of the installation of the structure

Installing a grease trap is a fairly simple process, but it requires certain rules to be followed:

- First of all, we determine the place for installing the unit.

- We check and prepare the surface on which we will install the structure (it must be absolutely horizontal).

- We prepare all fasteners for fixing the unit to the pipeline (clamps, fittings, etc.).

- We bring the inlet pipe to the sewer drain, and the outlet pipe to the drainage system.

- We are testing the installation, waiting for the first cleaning. If the unit has passed the test, you can close the installation.

That, in fact, is all. In fact, as you can see, it is quite easy to build and install a grease trap for home use. The main thing is to be careful, attentive and accurate. Good luck!

What is a fat separator

A fat separator is needed to treat wastewater that flows through pipes. It can be installed both indoors and outdoors. In this case, the fat will not get into the sewer pipes, and there will be no bad odors.

The fat separator is made from different materials. Most often, stainless steel and polyethylene are used, as these are cheap and at the same time durable materials.

The design of the separator consists of two components:

- sump;

- Special filter device.

In the sump, during the operation of a household grease trap, all the fat that goes into the water accumulates, for example, after dirty dishes.

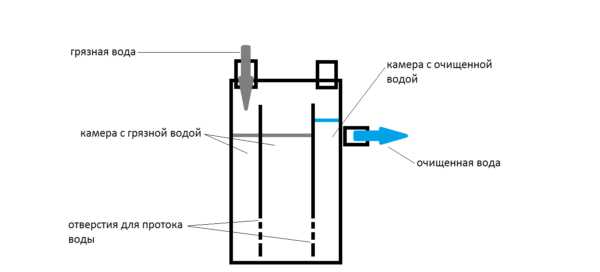

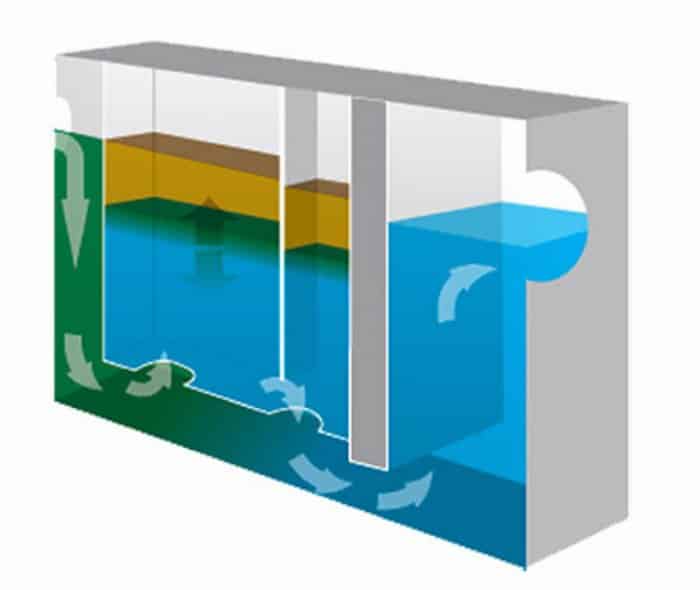

The principle of operation of the fat separator is based on the physical and chemical properties of various substances. Light substances during draining, such as fat and oil, are collected in the upper layer of the container. Heavy substances immediately go to the bottom. The material of the tank itself does not react to an aggressive environment in the form of fats and oils, and the ventilation lid prevents the penetration of stinky odors that are deposited inside the grease trap.

If you own a bar, cafe, canteen, restaurant, or just want to keep pipes from clogging up in your house, then get a grease separator. It will help you stop the grease before it enters the sewer pipes.

The principle of operation of the grease trap

Proper installation and operation of the separator is impossible without understanding the principles of its operation, as well as choosing the model that is best for you. Let's consider these questions in more detail.

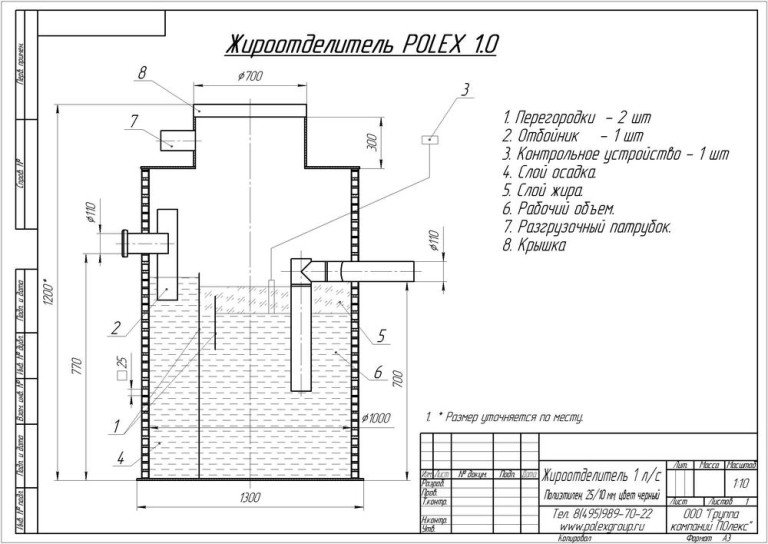

Despite the fact that grease traps designed for domestic use have appeared relatively recently, they are direct "descendants" of their old industrial counterparts. For example, for many decades grease traps have been operating in the technological chains of urban wastewater treatment plants, food and chemical industries. Regardless of the configuration, power or installation location, separators often differ in their simplicity of design, as well as their energy independence. In the simplest case, this is a two-section tank (see the figure below), in which wastewater is stratified into a liquid and fatty phase.

The cleaning effect is manifested as a result of the processes of flotation and coalescence of fatty impurities. The consequence of these physical phenomena is that oily substances are concentrated in the upper part of the tank, forming clots, while solid inclusions under the action of gravity settle to the bottom. Such a simple technological scheme allows, even for household equipment, to provide clarification of drains:

The cleaning effect is manifested as a result of the processes of flotation and coalescence of fatty impurities. The consequence of these physical phenomena is that oily substances are concentrated in the upper part of the tank, forming clots, while solid inclusions under the action of gravity settle to the bottom. Such a simple technological scheme allows, even for household equipment, to provide clarification of drains:

- for the fat component, not less than 50-60%;

- for solid suspensions - about 50%.

Types of grease filters

Two types of devices can be used for extracting, they can be fat-absorbing or coal. The latter types perform fine cleaning, remove odor, steam or harmful gas. The main substance that is part of this model is activated carbon. If the exhaust system removes air, then such filters are not used.

The grease filter performs rough cleaning, retains grease or soot, it serves as a good protection for the internal elements of the hood, this makes the system more durable. Such an element of trapping fat is divided into three types.

- There are single-use models, they can be paper, synthetic winterizer or non-woven. On the surface of the device there are special marks that disappear when the filter needs to be replaced.

- The acrylic look is reusable, being washed about once a month with soapy, lukewarm water. It is forbidden to wring out the element, as it can be damaged.

- The aluminum filter can also be washed or cleaned, meaning it is also considered reusable.

Grease trap installation

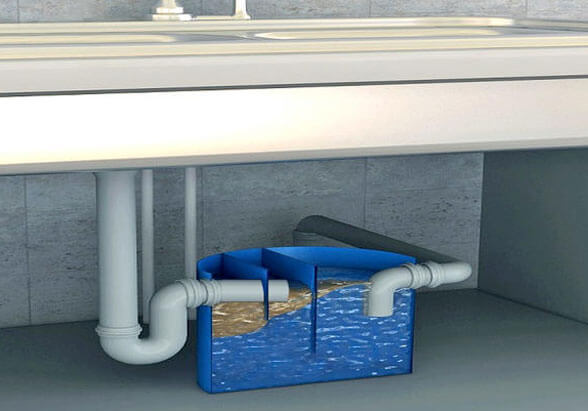

Installing a grease trap under the sink

Installing the grease trap is quite simple.To mount the device with your own hands, you must follow the following instructions:

- The place for installation of a separator is chosen. It should be a level and solid surface that is easy to access. Most often, the grease trap is installed directly under the sink or near the dishwasher.

- A grease filter is installed.

- The inlet pipe of the separator is connected to the sewer pipe of the sink or the pipe where the sink and washing equipment are connected. At the connection point, a rubber gasket is used, which is supplied with the device.

- The outlet pipe is discharged into the sewer. To connect pipes, in the same way as in the previous paragraph, a gasket is used.

- The grease trap is filled with water to check the tightness of its connections with pipes.

- The system is closed by the lid of the device.

Example of a correctly installed instrument

The separator is connected and tested. The device can be used.

Installation of a grease trap in the garden

Installing a separator on a personal plot is a more difficult task than installing a device at home. In order to install it yourself, you must perform the following steps:

Initially, choose a place to install the filter

It is important to take into account the further planning of the site and possible landscape work.

A hole of the required size is dug. When carrying out this work, it should be taken into account that at the bottom of the recess there should be a solid backfill and the separator cover should protrude 3-4 cm above ground level.

At the bottom of the pit, a solid formwork is made from a mixture of sand and cement. If the site has sandy or loamy soils, then the mixture used is diluted in a ratio of 1: 5

If the soil is more unstable, then the amount of cement in the solution needs to be increased. After the prepared base has completely hardened, you can proceed with the further installation of the device.

The body of the grease trap, for stability and avoiding distortions, is attached to a solid base with anchor bolts.

Plywood formwork is constructed around the grease trap to prevent soil shedding. Use of the instrument in cold climates will require the use of any thermal insulation material such as mineral wool or foam.

If the site has sandy or loamy soils, then the mixture used is diluted in a ratio of 1:5. If the soil is more unstable, then the amount of cement in the solution needs to be increased. After the prepared base has completely hardened, you can proceed with the further installation of the device.

The body of the grease trap, for stability and avoiding distortions, is attached to a solid base with anchor bolts.

Plywood formwork is constructed around the grease trap to prevent soil shedding. Use of the instrument in cold climates will require the use of any thermal insulation material such as mineral wool or foam.

Mineral wool and foam plastic are suitable thermal insulation materials

- The inlet pipe of the device is connected to the sewer pipe. After connection, the joint is recommended to be treated with a sealant.

- The outlet pipe of the separator is connected to a further drainage system. The junction of the pipes is also treated with a sealant.

- The remaining space of the pit is covered with excavated soil (the backfilling method is used, in which the earth extracted from this particular place is used).

Outdoor grease trap installation

When installing the grease trap on the street, fan risers are required. These pipes are used to remove excess gas accumulations from the sewer system that can damage the equipment. If it is planned to spend a lot of time on the plot and in a large company, that is, there will be a lot of wastewater, then it is recommended to use not only the main, but also an additional fan pipe.

If during the installation of the grease trap all the basic rules and requirements are observed, then there will never be any problems with the operation and further maintenance of the device.

Equipment installation technology

The installation process of the fat separator can be carried out in various ways. It is necessary to choose the optimal type of installation depending on the type and characteristics of the fat trap. Consider several options for mounting separators.

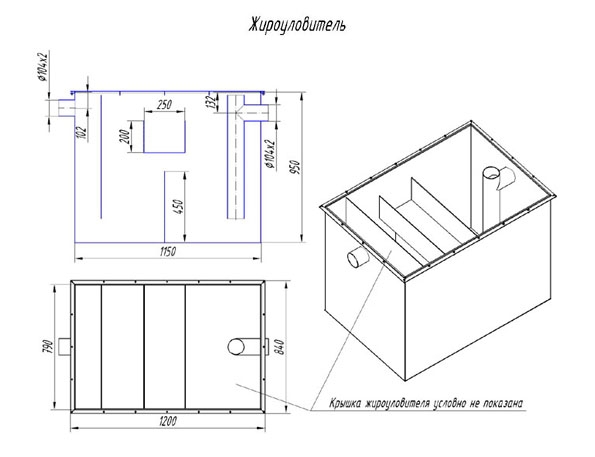

Installation of a street grease trap

The procedure for mounting an industrial fat trap is complex and time-consuming. Therefore, most trap buyers prefer to entrust the installation of equipment to specialists.

In order to perform the installation yourself, you need to carry out a number of preparatory work:

- We select a place for installation. When choosing, one should take into account the features of the layout of the site, as well as the possibility of performing landscape work in the future.

- We determine the size of the pit for mounting the device - its depth should be such that the fat trap cover is about 4 cm higher than the ground surface.

- We dig a hole. At the very bottom, we equip a solid formwork into which we pour a mixture of sand and cement. For sandy soils and loams, a solution prepared in a ratio of 1: 5 is optimal.

- We wait until the solution hardens, at a minimum it is 14 days.

When the preparation of the base for installation is completed, you can proceed directly to the installation of equipment. To do this, we install the body of the fat trap on a concrete base and securely fasten the device to the loops embedded in a home-made concrete slab during the pouring period. If you forgot to put the hinges, then they can be fixed with anchor bolts.

Now we are building peculiar plywood walls around the equipment installed in the pit. This process is necessary to prevent soil shedding. If it is planned to operate the separator in a cold climate, then it must be covered with thermal insulation material. For this, mineral wool or polystyrene is suitable.

It remains to connect the fat trap to the communication networks. To do this, the outlet pipe of the equipment must be connected to the drainage system. Joints must be treated with sealant. And we connect the inlet pipe of the device to the sewer pipe. We coat the place of joining of the elements with sealant.

All free space formed between around the body of the grease trap is covered with soil. Backfilling is usually used, during which it is necessary to fill the opening with soil excavated from this place at the stage of digging a hole.

We must not forget about the need to install a fan riser. It is required to remove excess gases accumulated in the sewer system. If there is a heavy load on the wastewater disposal system, it is better to install several risers at once. The fat accumulation sensor, which is installed inside the equipment, will warn you about the need for a cleaning procedure.

Street grease traps are more often cleaned by specialists of specialized companies using pumps or special equipment

Installation and installation of industrial fat traps is recommended to be carried out with the involvement of professional installers. They must also have permits to carry out the entire range of work.

Also, professional specialists have the necessary construction equipment for installation, so they can perform the necessary procedures for stable and long-term operation of the equipment.

Installing the grease trap indoors

Installing a domestic separator under the sink is an easier process than installing equipment outside. To do this, you first have to choose the optimal place for mounting the equipment.

It should be located on an easily accessible, hard and as level surface as possible, close to plumbing fixtures.

It remains to perform a series of sequential actions:

- We bring the outlet pipe of the equipment into the sewerage system. At the connection point, you need to install a rubber gasket that comes with the device.

- We connect the inlet pipe of the trap to the outlet pipe of the plumbing equipment or to the pipeline (at the junction of the sink and washing equipment), not forgetting to put a special gasket.

- We collect the required amount of water in the grease trap to check the device for leaks.

If the test was successful, you can install a cover on the fat trap. With the installation of the cover, the installation of the equipment can be considered complete.

More details on how to choose and install sink grease trap, read in this material.

Selection criteria and main manufacturers

To select the necessary device, first of all, it is necessary to proceed from its purpose.The operating parameters of the separators depend on this. For example, for domestic purposes, performance will be sufficient in the range of 0.1-2 liters per second. But these characteristics are completely unsuitable for cleaning wastewater entering the sewer from a canteen, cafe or restaurant; industrial models with the appropriate technical characteristics will be required for this task.

It is worth noting that many industrial models (for example, for workshops where the production of dairy products is established) are equipped with additional equipment that increases service efficiency. These can be automatic pumps for pumping wastewater, fill sensors, etc.

An important factor is the material from which the tank body is made, it can be plastic, fiberglass or stainless steel. In industrial devices, the well is often made of concrete.

Household cleaners are usually made of plastic, which is explained by the low cost of the material, as well as its following useful properties:

- light weight, which greatly simplifies installation and maintenance;

- long service life (at least 30 years);

- harmlessness to humans.

Grease traps made of polypropylene "Termite"

Grease traps made of polypropylene "Termite"

Such devices are designed for domestic use or installation in small catering establishments.

Fiberglass separators. A distinctive feature of such cases is high mechanical strength and resistance to aggressive chemicals.

Such characteristics are excellent for industrial models, especially taking into account the fact that outdoor installation is allowed.

Fiberglass grease traps Flotenk

Fiberglass grease traps Flotenk

Fiberglass hulls are weather resistant, lightweight and easy to clean.

Stainless steel housings are typically used for industrial separators. Characteristics:

- long service life;

- high hygienic properties;

- presentable appearance.

These characteristics, as well as possible, meet the requirements of public catering establishments.

Stainless steel separator manufactured by ACO Group

Stainless steel separator manufactured by ACO Group

The only drawback that limits the use of such a case is the high price.

When choosing a manufacturer, we recommend giving preference to well-known brands, such as Ecoline, Alta, The Fifth Element, Thermite, etc. We also note that domestic products are not inferior in quality to foreign ones, but are significantly cheaper. As for unknown manufacturers from the Middle Kingdom, here, as always, the quality must be checked on the spot.

KS-Zh-2V - from 45,000 rubles

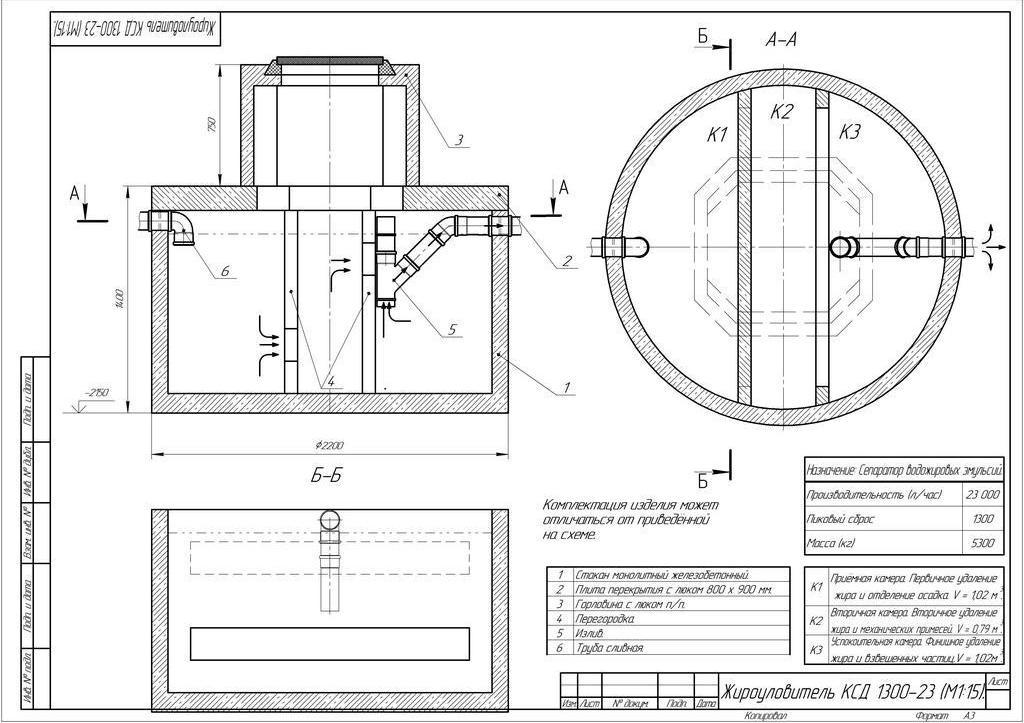

KS-Zh - a line of non-volatile well-type grease traps. Designed to treat industrial wastewater before being discharged into the city sewer. "2V" - vertical layout of the device. Installed in the ground, cleaned through the hatch.

The advantages of the "younger" model of the KS-Zh line are the performance and working volume of the device. Thanks to which the flow up to 300 liters per minute is effectively processed. The minimum service interval of the device is six months.

Of the minuses - constant investments will be required: for the calculation - to the designer, for the preparation of the site and installation of the device - to specialized craftsmen, for cleaning - to a professional vacuum cleaner.

To control the current level of fat, it is best to use a customizable sensor, which is offered by the manufacturer as an option.

| Productivity, m³/h | 7.2 |

| Peak discharge, l/min | 300 |

| Dimensions (height/diameter), mm | 1300/800 |

| electrical equipment | Non-volatile, medium density sensors are optionally mounted. |

| Producing country | Russia |

Industrial KS-Zh in the video from the manufacturer:

Selection criteria and main manufacturers

To select the necessary device, first of all, it is necessary to proceed from its purpose. The operating parameters of the separators depend on this. For example, for domestic purposes, performance will be sufficient in the range of 0.1-2 liters per second. But these characteristics are completely unsuitable for cleaning wastewater entering the sewer from a canteen, cafe or restaurant; industrial models with the appropriate technical characteristics will be required for this task.

It is worth noting that many industrial models (for example, for workshops where the production of dairy products is established) are equipped with additional equipment that increases service efficiency. These can be automatic pumps for pumping wastewater, fill sensors, etc.

An important factor is the material from which the tank body is made, it can be plastic, fiberglass or stainless steel. In industrial devices, the well is often made of concrete.

Household cleaners are usually made of plastic, which is explained by the low cost of the material, as well as its following useful properties:

- light weight, which greatly simplifies installation and maintenance;

- long service life (at least 30 years);

- harmlessness to humans.

Such devices are designed for domestic use or installation in small catering establishments.

Fiberglass separators. A distinctive feature of such cases is high mechanical strength and resistance to aggressive chemicals.

Such characteristics are excellent for industrial models, especially taking into account the fact that outdoor installation is allowed.

Fiberglass hulls are weather resistant, lightweight and easy to clean.

Stainless steel housings are typically used for industrial separators. Characteristics:

- long service life;

- high hygienic properties;

- presentable appearance.

These characteristics, as well as possible, meet the requirements of public catering establishments.

The only drawback that limits the use of such a case is the high price.

When choosing a manufacturer, we recommend giving preference to well-known brands, such as Ecoline, Alta, The Fifth Element, Thermite, etc. We also note that domestic products are not inferior in quality to foreign ones, but are significantly cheaper. As for unknown manufacturers from the Middle Kingdom, here, as always, the quality must be checked on the spot.

When choosing a separator model, it is necessary to take into account the place of its installation. There are models designed for installation indoors and/or outdoors.

There are three home installation options:

- under the sink or sink;

- in the basement;

- in the space provided for this purpose.

In everyday life, as a rule, use the first option. Briefly describe the sequence of actions when installing a household separator:

- Choose where the device will be located. For this, any surface with a smooth and hard coating is suitable. Since the grease trap requires regular cleaning during operation, it is necessary to provide free access to it. The best option is a place under the sink or next to it.

- We install the separator in the selected place.

- We connect the sink drain hose to the inlet pipe. To ensure the sealing of the joint, we use rubber gaskets (usually supplied with the device), as an additional security measure, you can use silicone sealant.

- We connect the drain pipe to the sewer (it is best to use a corrugated hose of the appropriate diameter for this purpose), without forgetting about rubber seals.

- We fill the structure with water in order to check the tightness. If a leak is found, fix it.

- Close the top cover, after which the device is ready for use.

An outdoor vertical or conventional grease trap is mounted in the ground according to the same principle as a septic tank, a description of this process can be found on our website.

Filter classification

As for the varieties, the devices are divided into different types depending on a number of criteria. The general classification is as follows:

1. Based on the material of use:

- plastic;

- fiberglass;

- stainless steel;

- polypropylene;

- food plastic.

2. According to the installation method:

- under the sink;

- for basements;

- for designated areas.

3. Given the manufacturer:

- "Alta". Suitable for sewer pipes of small cross section, and the cost on the Russian market is one of the best.

- Flotenko.This household grease trap can be installed not only indoors, but also outside. Due to their reliability, such devices are popular among owners of small cafes and restaurants.

- Labko. They are very popular among catering professionals.

- Evo stock. Models in which the separator is made of reinforced plastic and polypropylene. Appropriate for home use.

- helyx. Filters are designed primarily for industrial applications.

- "5th element". In addition to ordinary consumers, these filters are ideal for industrial facilities.

The prices of these models are about the same. The same can be said about the principle of action.

Installation

Installing a grease trap is a simple process, especially if you think through everything in advance and create the conditions necessary for the operation of the device.

Where to install

Household grease separation devices can be installed in a building or on the street (in a country house - in front of an external sewage septic tank. In a cafe, restaurant or canteen, separators can be installed in a separate room, in a dishwasher, in a basement or on a street. Industrial - in workshops and on OS.

For outdoor installation of the separator, it is required to equip the place - dig a recess, level and concrete the area for the grease separator. This device requires careful preparation. For the installation of a street separator, they usually turn to specialists.

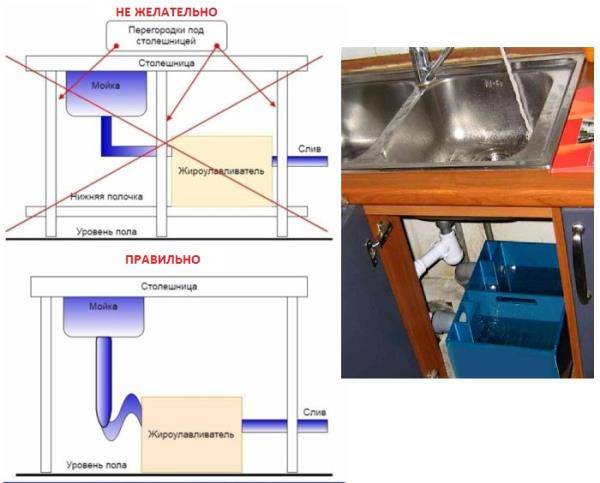

To install a grease separator under the sink, you must first accurately measure the location of furniture, sewerage units in order for the device to fit optimally. It is necessary to provide a gap between the separator and the furniture walls of at least 3-4 cm, and also provide for free access to the grease separator for its maintenance.

How to install

To install a grease trap, you must correctly select and prepare a place. The place for installation should be as flat as possible. It must be remembered that the device is filled with water during operation, therefore, instead of a light PVC housing, you need to rely on a heavy unit weighing at least 40 kg. This is only a static load. It is necessary to add a dynamic load to it, because the water entering the separator body in batches invariably generates vibrations. A light shelf or a shelf on weak fastenings will not withstand this shaking monster.

Enough space must be provided so that the separator and its pipes fit in one compartment (cupboard) and not connected to each other through the walls of the furniture. After all, the displacement of a heavy separator (for one reason or another) will cause a breakdown of pipes, the freedom of which is limited by a hole in the walls of the furniture. Therefore, the correct installation option with a lack of space under the sink, see the picture.

The assembly process is written in the instructions. Installation of the grease trap is not difficult. The main thing is to make sure that everything is in order inside the device (you can make sure even when buying). Further required:

- Install the body in the chosen place,

- connect it to the sink drain using a corrugated pipe,

- connect the outlet of the housing to the sewerage system.

The main thing is to make sure that all rubber gaskets are installed during installation, and not to confuse where the grease trap has an inlet and an outlet. It is possible to lubricate the gaskets with silicone before installation, and after installation, coat the joints with silicone or other sealant from the outside.

Selection Tips

Proper operation of the device and reliable protection of sewer pipes and from fat deposits and blockages depends on the correct choice of grease trap.

The principle of operation of the device

For domestic use, it is enough to purchase a device whose performance is from 0.1 to 2 l / s. Dimensional grease traps are equipped with large restaurants and enterprises for the production of food fat-containing products. Here they focus on the specifics of production. So, at enterprises for the manufacture of dairy products, grease traps are equipped with tank filling sensors and pumps that pump wastewater into the tank.

Tank cleaning

You can get rid of the specific unpleasant smell in the catering area by installing an automatic, compact grease trap. Place it directly under the sink. The modification of many models provides for the withdrawal of drains to a separate receiver. Maintenance of such devices does not require much and time - it is enough to periodically clean the nozzles from large particles, and use any detergent to remove sediment.

Compact device for a small dining room

To prevent the formation of blockages, sewer pipes are periodically washed with hot water.

Varieties

Conventionally, grease traps can be divided into several categories depending on the manufacturer, equipment use parameters, installation method and materials manufacturing.

For the manufacture of grease traps, stainless steel, plastic and fiberglass are used. The advantages of plastic products are as follows:

- under the order, it is possible to manufacture tanks that meet certain criteria - with a certain throughput, dimensions and shape;

- a PVC product is easy to use and maintain - it is enough to periodically clean the tank;

- The material is environmentally friendly and has a long service life.

plastic product

Fiberglass products are more often used for industrial purposes, as the material is particularly resistant to chemically active environments. The equipment assumes both internal and external type of installation - the body is durable, not afraid of environmental influences, easy to clean and has a low weight.

Fiberglass tanks

In large enterprises, grease traps in a steel case are used. Such equipment has a high cost, but it is justified by the operational properties of the material. It is characterized by high anti-corrosion properties, universal installation - inside and outside and a long service life.

Stainless steel product

Why install filters on the exhaust system

The oil filter is an indispensable part for air purification. Since it cleans the flow of outgoing air from fats and soot. In the absence of a filter device, the inside of the exhaust system will be covered with an oil coating, and it will be difficult to carry out maintenance. Also, the hood motor can quickly become unusable, as it will be under heavy load.

If the hood is placed strictly above the surface of the burners, then the accumulation of a large amount of fat can lead to a fire. Therefore, the use of a special filter is mandatory, but it must be replaced or cleaned in a timely manner, as the device will not work well, and dirt will settle on the kitchen surfaces.

A fat-type filter is necessary to purify the air from various contaminants that can settle on kitchen surfaces during cooking. Such an element prevents global grease contamination inside the exhaust system. When using such a device, the cleaning process is quick and convenient.