- Calculation of the required performance of the grease trap

- Industrial grease trap

- Household grease trap

- The device and principle of operation of the grease trap

- Homemade grease trap

- Biofor 0.5-40 "pro" - from 5,000 rubles

- Sink grease trap: DIY creation and installation

- Grease traps: device and principle of operation

- Making a do-it-yourself grease trap

- Features of the installation of the structure

- Overview of popular grease trap manufacturers

- Varieties of fat traps

- By destination

- By type of material used

- By installation option

Calculation of the required performance of the grease trap

In order for the device to be useful, it is necessary to correctly calculate the performance of the grease trap. In this matter, it is best to turn to professionals involved in the installation and maintenance of filters, but you can do the calculation yourself.

There are two methods for selecting instruments.

Industrial grease trap

The calculation is based on data on the work of a particular institution. The quantity of manufactured products and the estimated volume of fats and oils in the wastewater are important. This method is optimal for catering establishments and is in no way suitable for choosing a household grease trap.

In this case, the nominal capacity of the device can be found by multiplying the known maximum wastewater flow rate by the coefficient of detergents used.

The following formula is used to calculate wastewater consumption:

Qs = M*Vm*F/(3600*t), where

- Qs is the required value;

- M is the average number of prepared meals per day;

- Vm is the consumption of liquid necessary for the preparation of one dish;

- F - peak flow;

- t is the operating time of the enterprise.

Household grease trap

Calculation based on data on the number of baths, sinks and their throughput. For a correct calculation, you will need to determine the type of equipment used. They can flow and storage.

To choose a household grease trap, you will need to calculate the volume of each sink. You can do this by multiplying its length, width and height.

Further, the number of sinks in the house is multiplied by the obtained value and we get the required indicator.

When using flow-through washers, the formula for finding the optimal separator size looks like this:

P \u003d n * ps, where

- n is the number of washes;

- ps is the rate of water flow from the tap.

As a rule, the latter value is 0.1 l/s.

In order to correctly calculate the required performance of the grease trap yourself, it is enough to have basic mathematical skills and know exactly the parameters of the downcomer installed in the room.

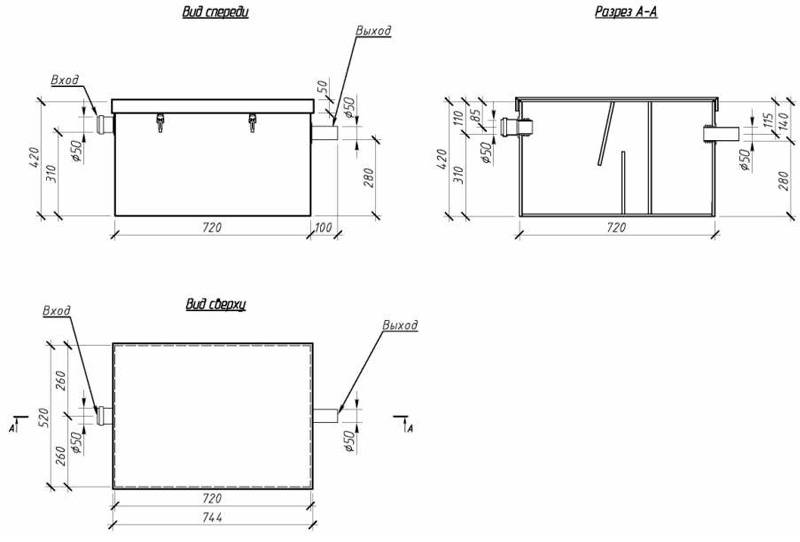

The device and principle of operation of the grease trap

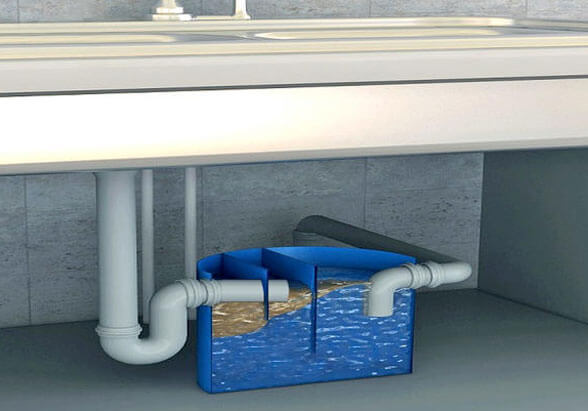

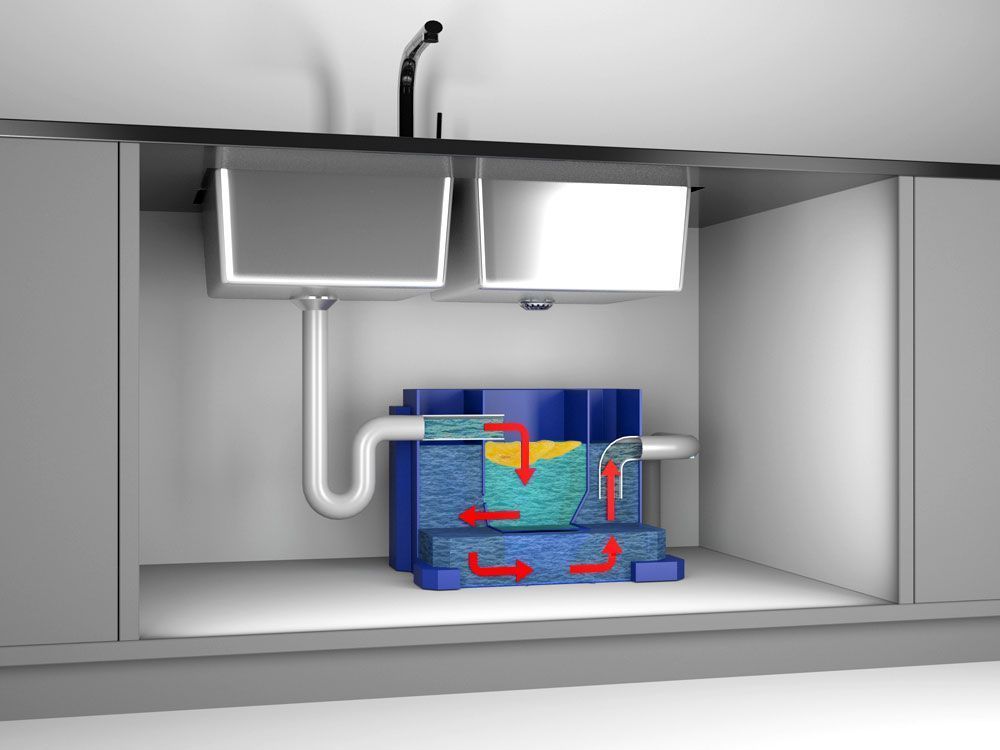

The grease trap performs the function of cleaning wastewater from fats and solid waste, catching them and collecting them in a special tank. It is compact and fits easily under the sink. The body of household models is made of polypropylene or stainless steel.

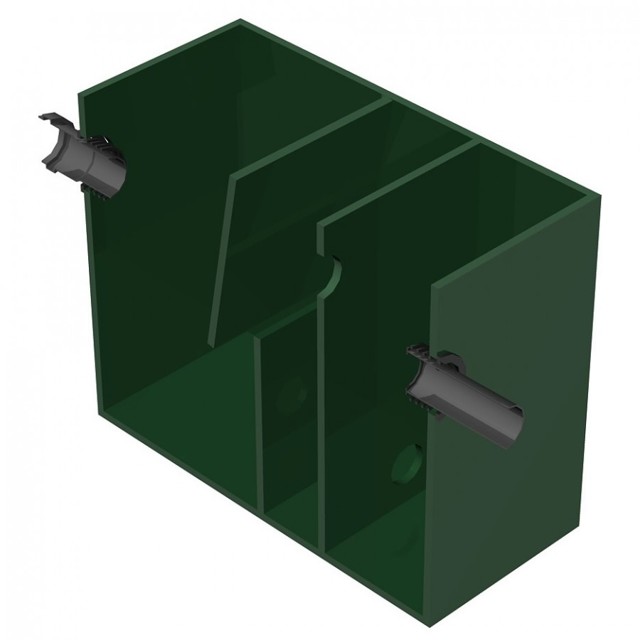

The separator device is simple, consists of the following elements:

• a rectangular body with 2-3 holes (2 holes for the inlet and outlet of drains, one more is not available in all models for ventilation);

• internal partitions acting as traps;

• cover with a rubber seal to prevent the penetration of odors into the room;

• inlet pipe (short in the form of a knee);

• exhaust pipe (in the form of a tee).

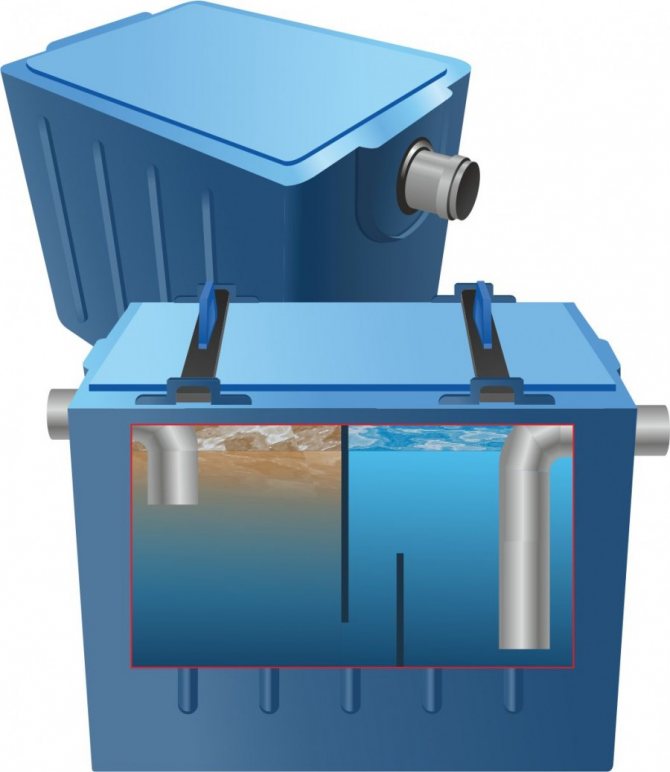

The principle of operation of the device consists in the ingress of effluents into the receiving zone of the separator and their passage through partitions, where solid particles and fats are cut off from the liquid. The difference in the density of fats and water raises the former to the top, where they accumulate. Behind all the partitions there is a second chamber, where the treated drains go, getting into the sewer system. As the fat builds up in the upper part of the tank, the mass is excavated with subsequent disposal.

Homemade grease trap

It is not difficult to assemble a cleaning module of this type for a sink with your own hands. The main thing is to know how it should work. Everything else is purely technical. But there is one point that must be taken into account. This is the volume of the container.

In order to understand what is at stake, it is necessary to give an example of the calculation. First of all, it is necessary to determine the performance of the device. In fact, this is a value that is determined by multiplying the number of sinks for which a grease trap is installed and the speed of the water in the water supply. If the unit is installed under one sink, then the first value is "1". The second position is standard - 0.1 l / s. Multiplying one by the other, that is: 1x0.1 \u003d 0.1. This is performance.

Secondly, it is the volume of the tank that is determined.Here is another formula: V=60 x t x N, where:

t is the time for which the separation of water from fat occurs, it is considered that it is equal to 6 minutes;

N is the performance that was calculated above.

Now we substitute the values \u200b\u200bin the formula: V \u003d 60x6x0.1 \u003d 36 l

Under this value it will be necessary to find a sealed container. It can have a different shape, the main thing is the volume is not less than the calculated one. By the way, the photo below shows a homemade round cross-section grease trap made from a metal barrel. It has only one partition and a small first compartment. But this design is enough to remove grease and oils from under one sink in the kitchen. The only requirement for it is a hermetically sealed lid.

It should be noted that the variety of homemade grease traps is huge. As practice shows, the shape of the product is not important here, the properly organized passage of drains through the partitions is important here. Exactly the same as described above in the article.

A few words about how to properly clean the device from accumulated greasy contaminants. Everything is quite simple.

- You need to remove the cover.

- Oil accumulations floating on the surface of the water in the compartments must be removed with any not very deep volumetric object. It might even be a cup. The main thing is to collect pollution as much as possible.

- All this is collected in a bucket or basin.

- After that, the cover is installed in place.

The cabinet on which the sink is installed is not always voluminous. Therefore, you may encounter difficulties in the process of cleaning the device. But you should not disconnect it from the sink and sewer, it is better to do everything inside the cabinet. It will take a little time, so be patient.

Biofor 0.5-40 "pro" - from 5,000 rubles

Biofor 0.5-40 is a plastic container with two nozzles and a tight-fitting lid. The working space of the device is divided into 2 parts by a removable and a fixed block.

The upper edges of the blocks are located 50-70 mm above the nozzles, so nothing interferes with the removal of fat. The removable tray makes it easy to get rid of debris that settles under the inlet. Locks on the body securely press the lid to the seal - unpleasant odors remain in the grease trap.

The design of the working space stops the directional flow of the drain. This is a necessary measure, because in a calm state, the separation of fat suspension is much more efficient than in the process of flow. But one has only to make a mistake in the calculations and the last advantage turns into a significant drawback - the fats do not have time to rise and go into the sewer network. The intensity of the removal of dirty water, directly from sanitary appliances, is also violated.

It is recommended to clean the tank before starting work - the cooled fat is well removed from all surfaces.

| Productivity, m³/h | 0.5 |

| Peak discharge, l/min | 40 |

| Weight, kg | 8 |

| Dimensions (LxWxH), mm | 470x360x390 |

| Branch pipe height (inlet/outlet), mm | 285/265 |

| electrical equipment | non-volatile |

| Producing country | Russia |

The device of the Biofor 0.5-40 model is shown in the video:

Sink grease trap: DIY creation and installation

Grease traps: device and principle of operation

Installation of grease traps industrial and food facilities is due to the presence of relevant sanitary norms and rules, but as for domestic use, is this device really necessary in the house? To do this, you need to understand what effect fatty substances have on the sewer system:

- When cooled, fatty acids turn into a flaky mass, which settles on the walls of pipes and eventually leads to clogging, reducing the flow of water. Over time, the system becomes completely impassable and must be cleaned (in the worst case, repaired).

- Fats lead to the gradual formation of caustic substances that have a persistent fetid odor.

- Over time, fatty deposits oxidize and corrode the sewer system from the inside, completely rendering it unusable.

As you can see, the use of a grease trap is quite justified even at home. Let us briefly consider the device of a household installation. The grease trap is a completely sealed container with a removable lid, made of food-grade plastic and divided into several sections. Branch pipes are connected to the extreme ones, which cut into the sewer pipeline. Installed under the sink.

The grease trap is classified as a septic tank. All used water passes through it. The basic principle of operation of the installation is the difference between the densities of water and fat. First, the effluents enter the tank through the inlet pipe. Since fat is less dense, its particles float on the water surface and, thanks to the partitions installed across them, are removed from there to a special storage tank. The accumulated fat in the household grease trap can only be removed manually.

Making a do-it-yourself grease trap

Most often, materials such as steel, food-grade plastic, fiberglass and polypropylene are used for the manufacture of this unit. We will consider the simplest option - the manufacture of a plastic device.

Advice. If you have unnecessary products made of harmless plastic on the farm, then you can safely use them to create the capacity of the unit.

Before proceeding directly to the creation of the design, it is important to make basic calculations that will help calculate the optimal installation volume for a particular water supply system. First, let's calculate the performance of the created unit

So, we use the following formula: Р=nPs, where

- P - performance of the septic tank, l / s;

- n is the number of sinks in the room;

- Ps - water supply rate (usually equal to 0.1 l / s).

After we know the capacity of the unit being designed, we determine the required volume of the structure using the formula: V=60Pt, where

- t is the average duration of fatty acid sedimentation (about 6 minutes);

- P is the performance of the unit already known to us.

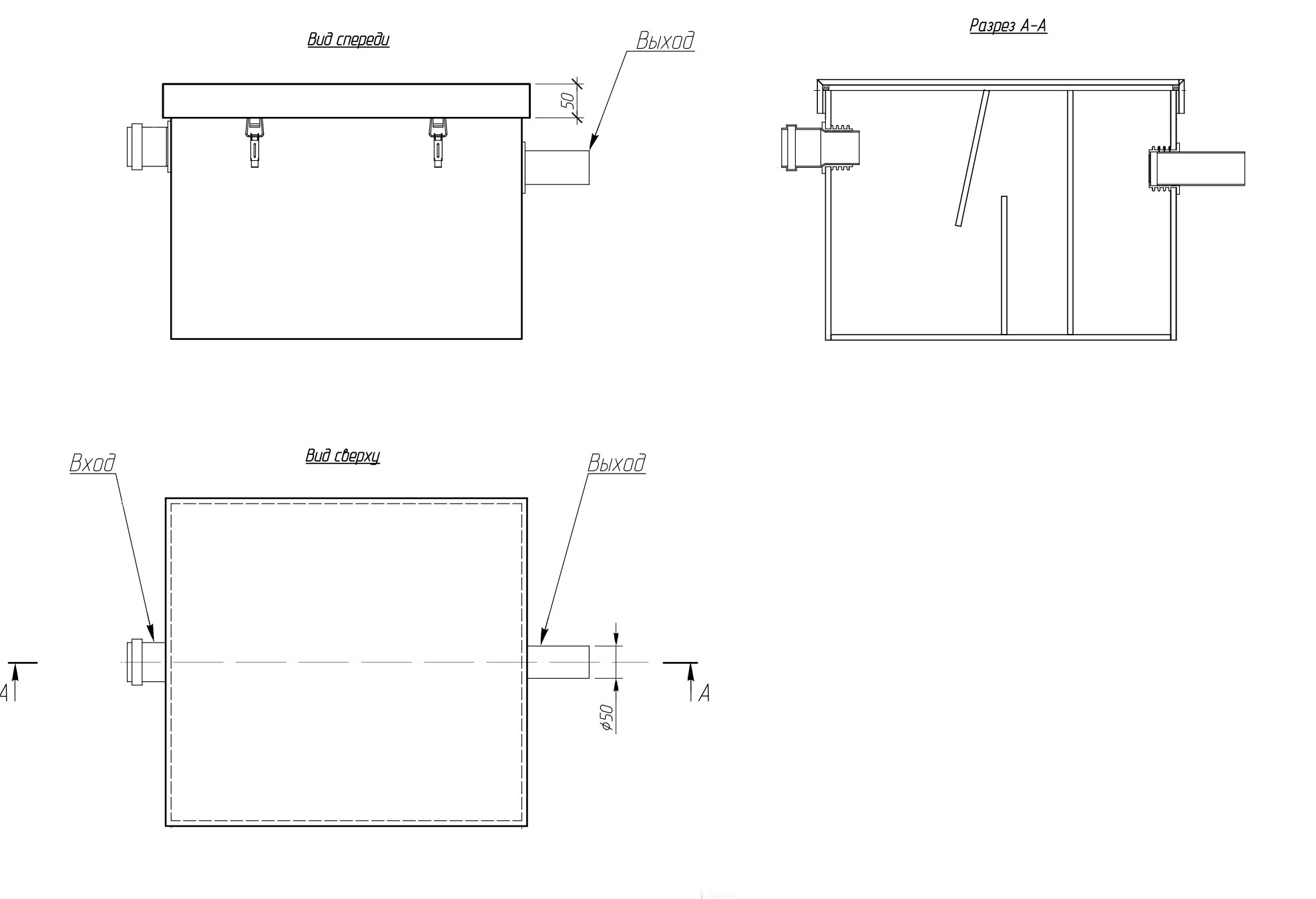

We make a drawing of the installation according to the dimensions obtained. Now you can start preparing the tool and materials:

- material for the body of the installation (in our case, food grade plastic);

- sanitary silicone;

- building glue;

- a piece of thermoplastic pipe with a diameter of 5 cm;

- thermoplastic elbow with a diameter of 5 cm;

- thermoplastic tee with a diameter of 5 cm.

The first step is to cut the parts for the body. We use a hacksaw for metal / jigsaw. First, we glue the sides (body) of our design, only after that we fix the bottom.Then we install internal partitions (their height should be 2/3 of the height of the side walls). Joints are sealed with silicone.

We install an elbow in the assembled structure (it will act as an inlet pipe). From a piece of pipe and a tee we make an outlet pipe. It remains the case for small - the top cover for the design. In places of its contact with the body, we fix the rubber seal. You can proceed to the installation of the unit in the working area.

Features of the installation of the structure

Installing a grease trap is a fairly simple process, but it requires certain rules to be followed:

- First of all, we determine the place for installing the unit.

- We check and prepare the surface on which we will install the structure (it must be absolutely horizontal).

- We prepare all fasteners for fixing the unit to the pipeline (clamps, fittings, etc.).

- We bring the inlet pipe to the sewer drain, and the outlet pipe to the drainage system.

- We are testing the installation, waiting for the first cleaning. If the unit has passed the test, you can close the installation.

That, in fact, is all. In fact, as you can see, it is quite easy to build and install a grease trap for home use. The main thing is to be careful, attentive and accurate. Good luck!

Overview of popular grease trap manufacturers

A wide range of fat separators manufactured by foreign and domestic manufacturers is presented on the modern market. It should be noted that there are no significant differences in the equipment of different companies.

Devices of any brand work on the same principle - they function due to the force of gravity.Many manufacturers offer additional equipment in addition to traps, such as a stand.

The stand is designed for use with fat traps, which are installed directly under the sink in restaurants, canteens, cafes and cutting shops of large supermarkets

When choosing the optimal model, it is worth focusing on the purpose of the fat trap, as well as on the prestige and reputation of the manufacturer.

Grease traps from companies are in particular demand:

- helyx;

- Wavin Labko;

- Evo stock;

- Flotenko;

- UE "Polymerconstruction".

Helyx is a popular manufacturer that manufactures mainly industrial vertical and horizontal grease traps. The separator is used as the initial treatment system.

It is installed at the site of the release of industrial sewage, which contains contaminated and fatty drains.

Wavin Labko is a Finnish developer and manufacturer of innovative electronic fat accumulation level meters and traps made of fiberglass and polyethylene.

Wavin-Labko's EuroREK grease traps are used in restaurants, cafes, canteens, gas stations, meat processing plants and slaughterhouses.

The Russian manufacturer Evo Stok manufactures equipment for various purposes from heat-resistant reinforced plastic that is resistant to corrosion.

The devices are equipped with hermetic seals, which effectively prevent the penetration of unpleasant odors into the room.

Flotenk manufactures industrial and domestic appliances from durable fiberglass reinforced plastics.

The advantages of Flotenk fat traps are aesthetics, the presence of a level indicator, the degree of purification is up to 50 mg / l, and durability. The manufacturer manufactures vertical and horizontal grease traps.

The fat trap from UE "Polymerconstruction" is a container made of a spiral pipe, with inlet and outlet nozzles.

The discharge pipe is located at a considerable depth, due to which the leakage of fat is not allowed.

Varieties of fat traps

Modern grease traps are divided into several

categories in which their characteristics are taken into account.

By destination

According to their purpose, devices can be:

- Household. Such grease traps are installed in apartments and

private households. In addition, household devices include traps,

used for wastewater treatment in public catering establishments.

By the way, the grease trap for

sewerage from the dining room is an indispensable fixture when

equipment of such an establishment. Although these devices are mounted

grease trap directly under the sink

for sewerage from the dining room, according to the norms, it can also be located

apart from her. The household grease trap can only be cleaned manually

way. - Industrial. Such fat traps are installed on

production, where in wastewater there is an admixture of oil and any fat-containing

liquids. By the way, industrial grease traps are cleaned automatically.

This is facilitated by special mechanisms. Except for them, in the design

there are no differences between the two device categories.

By type of material used

The next division of grease traps can be carried out according to materials,

used in the manufacturing process of devices.

- Plastic. These devices are lightweight and

price. They are installed immediately on the pipe, and the installation process does not cause

difficulties. - Fiberglass. A distinctive feature of such traps

is increased resistance to aggressive environments. Thanks to

fiberglass housing is very rigid. Devices of this type can

be used as a grease trap

for outdoor sewerage. - Metal. The main material used in production,

is stainless steel. Its main advantages lie in the maximum

degree of resistance to chemicals and mechanical damage.

Such devices have become widespread in industry, since it is easy

cope with any aggressive substance and are able to filter drains even under

exposure to high temperature. Naturally, the price of such devices

significantly higher.

By installation option

In this classification, everything depends on the place of installation:

- Under the sink or sink. Such devices have compact dimensions and a maximum of two compartments for filtering. The performance of the grease trap is at the level of two liters within a second. Most often they are mounted in apartments.

- Separately installed device. Compared with the previous version, the dimensions of such a device differ upwards. The productivity of the trap also increases, which will not exceed fifteen liters per second. Such a sewer grease trap can be mounted in catering establishments where increased throughput is required.

- Buried device. The most powerful device that can be installed even underground.This option is used in industry. The throughput of such devices is equal to several hundred liters. There are models that, in their design, are absolutely different from the usual grease traps and have several stages of wastewater treatment at once.