- How to install?

- How does it work?

- What are they made of?

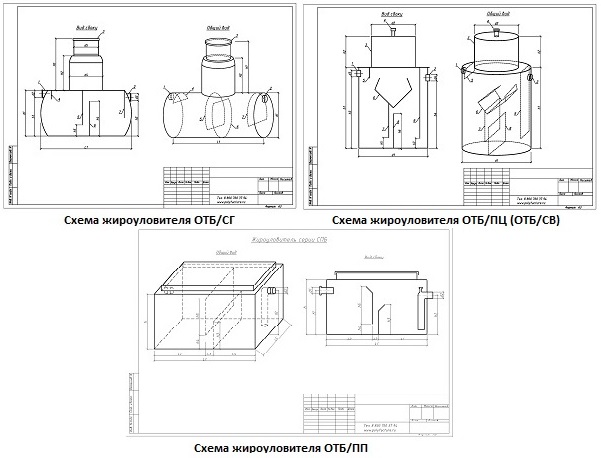

- Types

- Performance

- Equipment installation technology

- Installation of a street grease trap

- Installing the grease trap indoors

- Care and maintenance of the instrument

- Care and maintenance of the instrument

- Exploitation

- Cleaning frequency

- How and what to clean

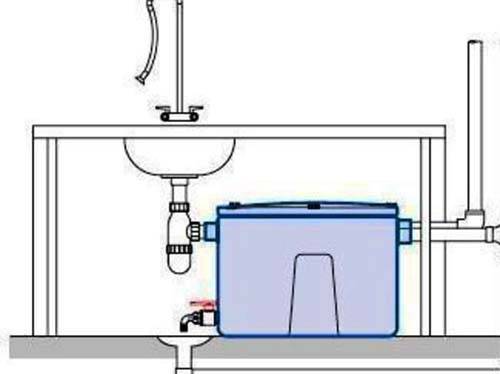

- Installing a grease trap indoors

- How to choose a device for the home

- The device and principle of operation of the grease trap

- Selection criteria and main manufacturers

- What is a grease trap, its device and principle of operation

- Where is used

- under the sink

- For sewerage

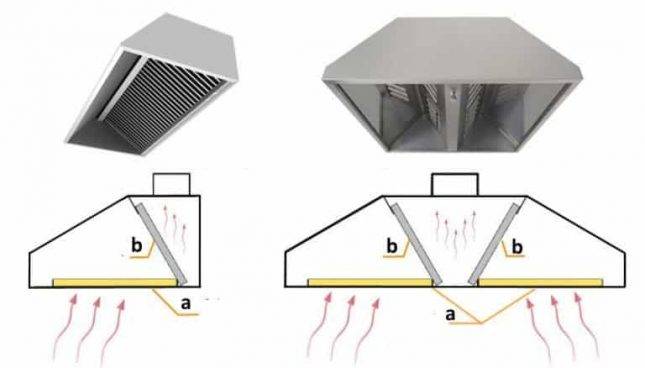

- for hood

- The principle of operation of the device

- Overview of popular manufacturers of grease traps under the sink

- "Fifth Element"

- Flotenk

- Evo stock

- How to choose?

- The principle of operation of the device

How to install?

It is not difficult to install a grease trap, this work can be done independently. When performing installation, you must adhere to certain rules:

- first determine the installation location and check if there is enough space for installation. So, plumbing can interfere with placement under the sink. Keep in mind that the grease trap will need to be cleaned periodically, so it should be freely accessible;

- prepare the levelness of the surface where the grease trap will be installed;

- check the completeness, all pipes and fasteners necessary for assembly must be present;

- now you can install and connect the grease trap, following the instructions;

- during installation, it is necessary to seal all joints with plumbing sealant or sealing tape;

- carry out tests to ensure that the installation is leak-tight.

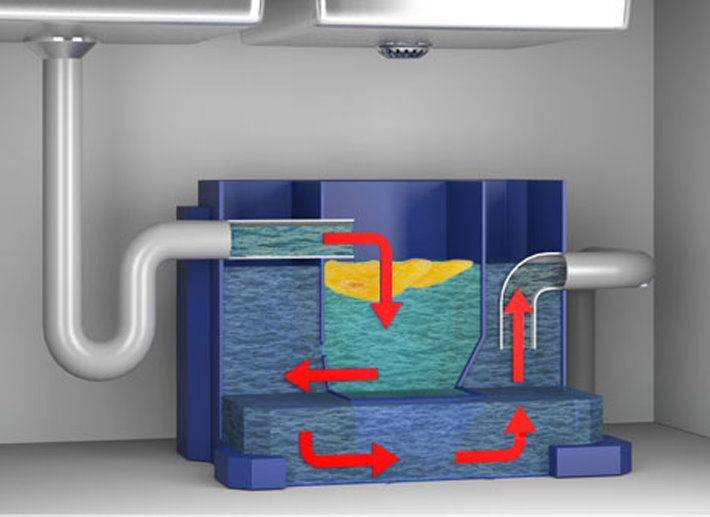

How does it work?

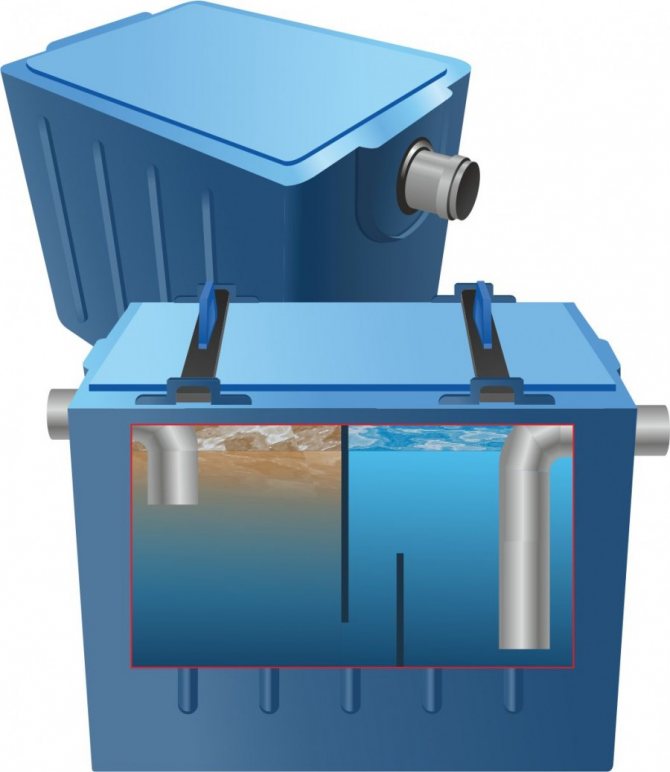

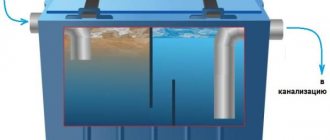

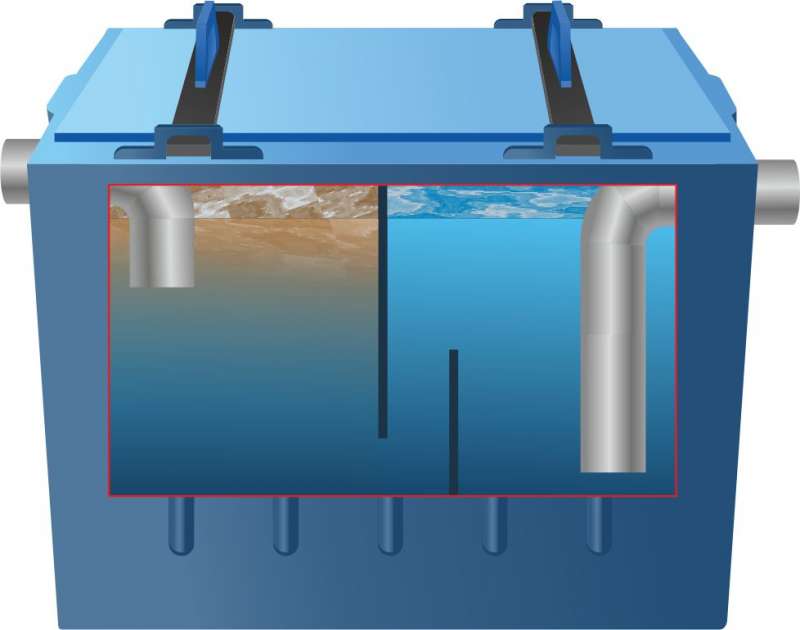

Grease traps work on the principle of gravitational settling. A household grease separator is a plastic container divided inside by partitions into chambers. In the first and last compartment there are branch pipes for connecting pipes.

The design has a removable cover. The principle of separation is based on the fact that during settling, the liquid is divided into layers depending on the density. The process goes like this:

- the polluted liquid entering the sink drain enters the first chamber of the grease trap through the inlet pipe;

- separators installed in the transverse direction separate part of the fatty impurities rising up;

- the water flow moves to the next compartment, where fat removal continues;

- the collected fat is moved to the drive;

- from time to time the storage chamber must be freed from fat.

What are they made of?

Grease traps can be made from different materials:

- stainless steel;

- plastic;

- fiberglass.

Household models are made mainly from polymeric materials (polypropylene), since this material is the cheapest and most practical. Industrial grease traps can also be made of steel.

Types

According to the place of installation, the following options are distinguished:

- models for installation under the sink;

- grease traps for installation in the next room;

- option for installation at the outlet of the sewer from the house;

- outdoor devices.

Performance

An important criterion for choosing a grease trap is the performance of the model. The greater the water flow, the greater the throughput of the grease trap should be. In domestic conditions, installations with a capacity of 0.1-2 liters per second are used. Models of higher productivity are classified as industrial.

Equipment installation technology

The installation process of the fat separator can be carried out in various ways. It is necessary to choose the optimal type of installation depending on the type and characteristics of the fat trap. Consider several options for mounting separators.

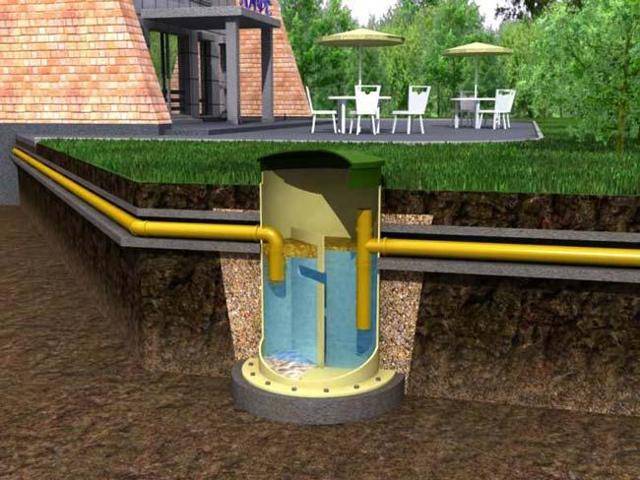

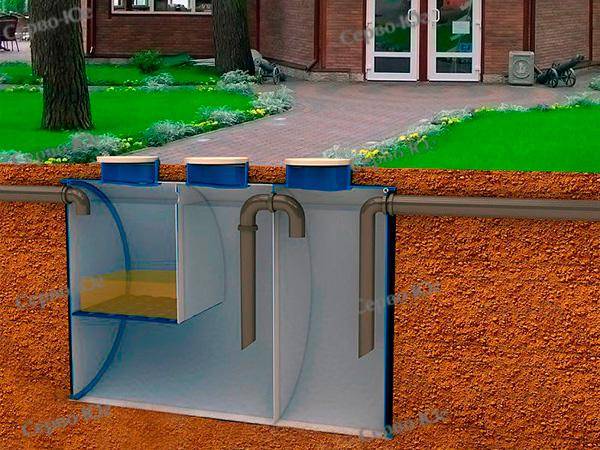

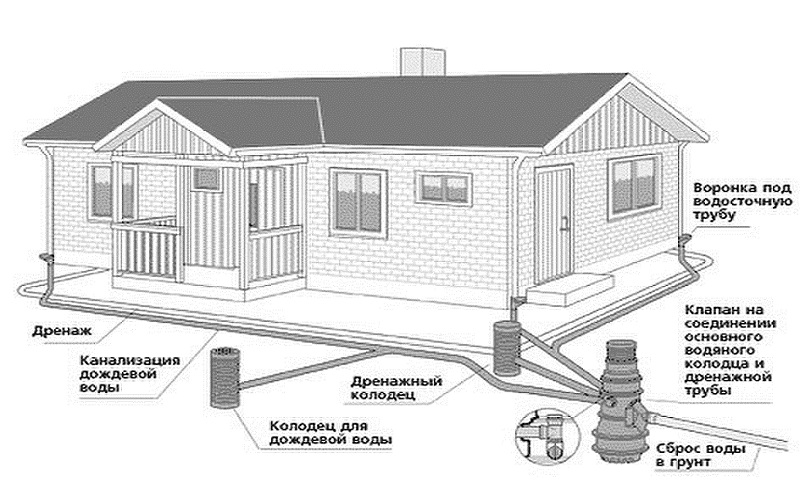

Installation of a street grease trap

The procedure for mounting an industrial fat trap is complex and time-consuming. Therefore, most trap buyers prefer to entrust the installation of equipment to specialists.

In order to perform the installation yourself, you need to carry out a number of preparatory work:

- We select a place for installation. When choosing, one should take into account the features of the layout of the site, as well as the possibility of performing landscape work in the future.

- We determine the size of the pit for mounting the device - its depth should be such that the fat trap cover is about 4 cm higher than the ground surface.

- We dig a hole. At the very bottom, we equip a solid formwork into which we pour a mixture of sand and cement. For sandy soils and loams, a solution prepared in a ratio of 1: 5 is optimal.

- We wait until the solution hardens, at a minimum it is 14 days.

When the preparation of the base for installation is completed, you can proceed directly to the installation of equipment.To do this, we install the body of the fat trap on a concrete base and securely fasten the device to the loops embedded in a home-made concrete slab during the pouring period. If you forgot to put the hinges, then they can be fixed with anchor bolts.

Now we are building peculiar plywood walls around the equipment installed in the pit. This process is necessary to prevent soil shedding. If it is planned to operate the separator in a cold climate, then it must be covered with thermal insulation material. For this, mineral wool or polystyrene is suitable.

It remains to connect the fat trap to the communication networks. To do this, the outlet pipe of the equipment must be connected to the drainage system. Joints must be treated with sealant. And we connect the inlet pipe of the device to the sewer pipe. We coat the place of joining of the elements with sealant.

All free space formed between around the body of the grease trap is covered with soil. Backfilling is usually used, during which it is necessary to fill the opening with soil excavated from this place at the stage of digging a hole.

We must not forget about the need to install a fan riser. It is required to remove excess gases accumulated in the sewer system. If there is a heavy load on the wastewater disposal system, it is better to install several risers at once. The fat accumulation sensor, which is installed inside the equipment, will warn you about the need for a cleaning procedure.

Street grease traps are more often cleaned by specialists of specialized companies using pumps or special equipment

Installation and installation of industrial fat traps is recommended to be carried out with the involvement of professional installers.They must also have permits to carry out the entire range of work.

Also, professional specialists have the necessary construction equipment for installation, so they can perform the necessary procedures for stable and long-term operation of the equipment.

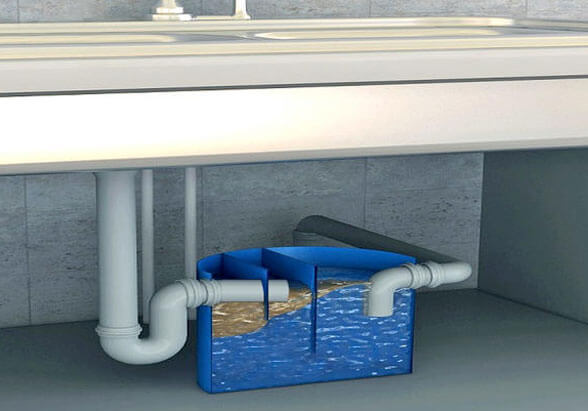

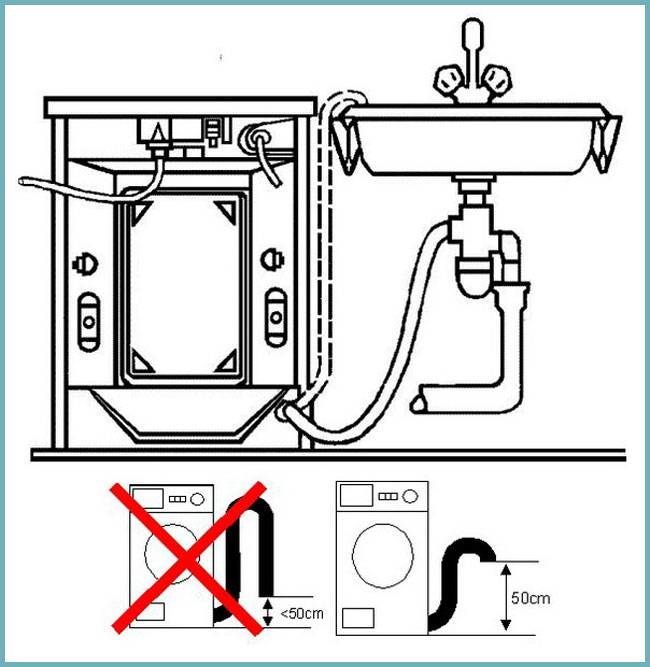

Installing the grease trap indoors

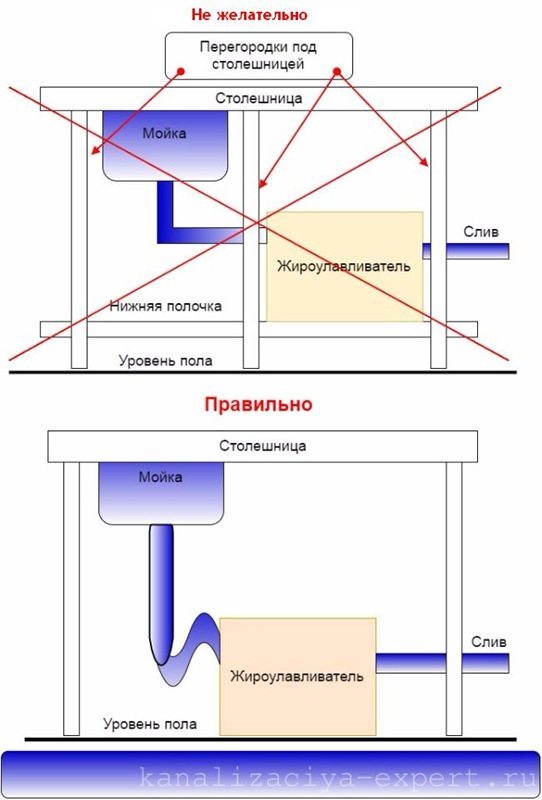

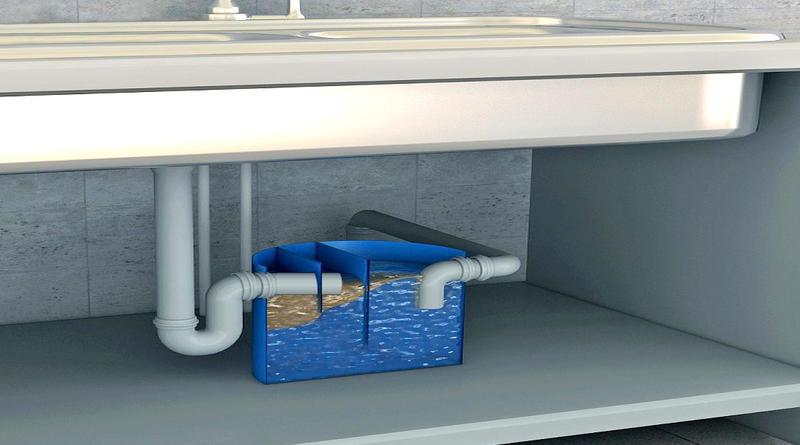

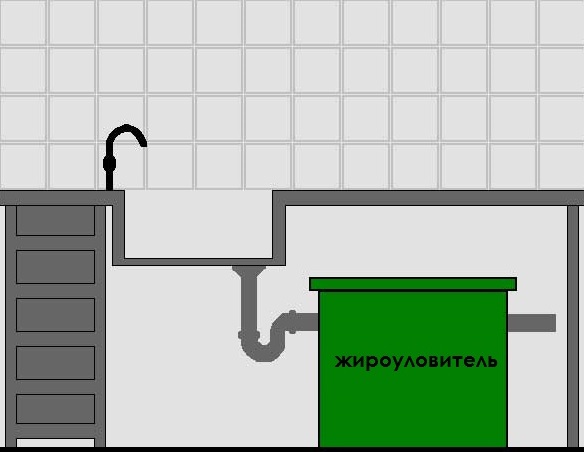

Installing a domestic separator under the sink is an easier process than installing equipment outside. To do this, you first have to choose the optimal place for mounting the equipment.

It should be located on an easily accessible, hard and as level surface as possible, close to plumbing fixtures.

It remains to perform a series of sequential actions:

- We bring the outlet pipe of the equipment into the sewerage system. At the connection point, you need to install a rubber gasket that comes with the device.

- We connect the inlet pipe of the trap to the outlet pipe of the plumbing equipment or to the pipeline (at the junction of the sink and washing equipment), not forgetting to put a special gasket.

- We collect the required amount of water in the grease trap to check the device for leaks.

If the test was successful, you can install a cover on the fat trap. With the installation of the cover, the installation of the equipment can be considered complete.

For more information on how to choose and install a grease trap under the sink, read this material.

Care and maintenance of the instrument

With intensive use of the grease trap, it may be necessary to perform operations to remove grease from the cleaning plant every couple of weeks. The accumulation of contaminants is controlled by opening the top cover of the container. The fat clot accumulated in the upper part of the container must be removed.For this, a special cage is suitable, which is included in the factory equipment of some devices. You can also use a suitable size ladle or an ordinary mug. Dietary fat mixed with dirt, which formed a clot, is dense enough, so it easily collects, like foam from the surface of a liquid, and is thrown into the trash.

In order for the grease trap unit installed under the sink not to create emergency problems, and also to effectively work for at least the period declared by the manufacturer, it needs a simple annual preventive maintenance. To do this, it is disconnected from the siphon supply and sewer communications and washed thoroughly to get rid of heavy bottom sediments.

Care and maintenance of the instrument

With intensive use of the grease trap, it may be necessary to perform operations to remove grease from the cleaning plant every couple of weeks. The accumulation of contaminants is controlled by opening the top cover of the container. The fat clot accumulated in the upper part of the container must be removed. For this, a special cage is suitable, which is included in the factory equipment of some devices. You can also use a suitable size ladle or an ordinary mug. Dietary fat mixed with dirt, which formed a clot, is dense enough, so it easily collects, like foam from the surface of a liquid, and is thrown into the trash.

In order for the grease trap unit installed under the sink not to create emergency problems, and also to effectively work for at least the period declared by the manufacturer, it needs a simple annual preventive maintenance.To do this, it is disconnected from the siphon supply and sewer communications and washed thoroughly to get rid of heavy bottom sediments.

Exploitation

Like all household appliances, the separator needs regular maintenance for many years of flawless operation. It must be regularly cleaned of fat accumulations and washed with its components (including corrugated pipes). The life of the trouble-free service of the installation and sewage depends on this.

It is necessary to check periodically the presence and amount of fat deposits. Fat, accumulating and stagnating, hardens and can disable the grease trap. First, the effectiveness of the device decreases, the passed particles of fat slip into the sewer and settle there already. Then it may happen that cleaning the grease separator will no longer help - only replacement. Long-term fat accumulations are a breeding ground for bacteria that emit disgusting odors. You also need to regularly get rid of such neighbors.

Cleaning frequency

The required frequency of revisions and pumping out (cleaning) of grease separators also depends on the model, volume, performance and degree of wastewater contamination with fats. Small grease traps fill up faster than larger units and need to be cleaned more frequently. It is good when there is a level control sensor available. If this is not the case, you need to track the accumulations in the installation, at least visually.

In addition, many models of grease separators need maintenance 3-4 times a year. Complete maintenance of the separator is enough to carry out 1-2 times a year. In catering places, grease traps are checked and serviced with a professional cleaning complex more often:

- once every seven days, household grease traps under the sink are cleaned;

- up to three times a month, most of the catering grease separators are cleaned;

- Large industrial installations are cleaned 2-4 times a year.

Prevention of equipment together with the pipeline should be carried out at least once every three months. At catering establishments, it is recommended to change the water in the device at the end of the work shift.

How and what to clean

Homemade grease traps are easy to clean. For this you need:

- disconnect the corrugated hoses from the body of the grease trap;

- with a special spatula (or other convenient tool) remove fats and solid waste;

- rinse the parts with hot water (to eliminate strong odors, steam the installation);

- reinstall the grease separator in its place;

- connect to the sink and sewerage.

Grease traps of large industrial installations are serviced automatically. The work is carried out by specialists of companies with the necessary equipment and qualifications. As a rule, enterprises enter into an agreement with such companies for the maintenance of grease trapping equipment. The list of services includes works of various levels of complexity. For medium (workshop) grease traps, a pumping standard is produced. This is a complex of works, which includes pumping out with a portable vacuum extractor. To clean industrial grease traps, pumping is carried out with a vacuum machine.

Installing a grease trap indoors

Installing a filtering device inside a building is a simple process and can be done independently.

The algorithm for carrying out assembly robots involves the following steps.

Choosing a place for device installation. The device is often located directly under the kitchen sink or next to the dishwasher.

It is important to remember that there must be a free space of at least 3 cm between the furniture sanitary ware and the separator.

Compliance with this requirement will provide quick access to communication in case of need.

Grease trap installation. The surface for placing the mechanism must be perfectly smooth, even and solid.

Fulfillment of this condition will ensure reliable fixation of the device and exclude the possibility of overflow of contaminants through the sides of the sump.

- Connecting the inlet pipe of the device to the sewer pipe of the sink. At the same time, the junction of plumbing is sealed with a rubber gasket.

- Removal of the outlet socket of the separator into the drainage system. Additional insulation is installed at pipe joints.

- Checking the tightness of the structure. The device is filled with water and the joints are inspected to identify possible leaks. In case of their absence, the product should be tightly closed with a special lid.

Remember, during the installation of the filter device, fire safety rules must be observed. It is strictly forbidden to install a grease trapping structure near flammable plumbing equipment.

Currently, wastewater treatment can be done in a variety of ways, ranging from simple water filtration to complex designs with bacterial colonies. However, the most popular device today is the standard sewer grease trap.

Proper selection and installation of the device will help to avoid losses associated with the removal of blockages, repair and replacement of pipelines in which grease gradually accumulates.Timely cleaning of the separator tanks and adjacent drains will guarantee stable and long-term operation of the entire sewer system.

How to choose a device for the home

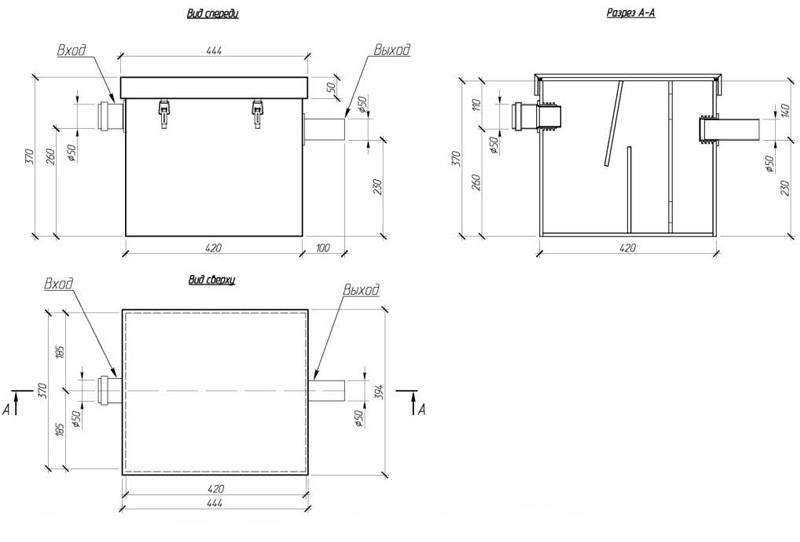

The initial stage of choosing a grease trap is not carried out in a hardware store or on the Internet, but in the planned place of its installation. Before buying a device, you need to decide on a number of parameters that will help narrow down your options to a few models.

First of all, it is worth evaluating:

- Dimensions of free space under the sink. It should be borne in mind that there should be space on top for removing the cover, and on the sides for connecting pipes.

- The diameter of the sewer pipes in the kitchen. It is better to buy a grease trap with the same hole size so as not to use additional plastic adapters.

- Number of car washes served. When calculating the performance, it is necessary to take into account the simultaneous flow of effluents from all open taps.

- Stock characteristics. With a large amount of solid particles in the drained water, it is recommended to install grease trap models with several partitions.

- The presence of a sewer riser or a fan pipe near the sink - the channel is necessary to prevent the failure of the water seal on the siphon. Models with an air duct are preferred, but not every apartment or house has the ability to connect them to a sewer riser.

- Availability of free space for equipment maintenance work. When removing fat, waste with an unpleasant odor can fall behind the body of the grease trap, so it must be possible to clean this space

- Body material.For installation under the sink, a conventional plastic grease trap will suffice, but if it is open for viewing, then you can buy a more expensive and aesthetic stainless steel model.

- Wash volume. Sometimes it is required to dump water from a fully filled sink in one gulp. This amount of liquid is one of the characteristics of the grease trap and must be indicated in the instructions.

After taking into account all the above nuances, you can proceed to the direct selection of a suitable device from the options offered on the market.

The price of a budget plastic grease trap roughly corresponds to the cost of washing along with furniture, a tap and a siphon, so you need to plan its purchase in advance (+)

The price of plastic models depends mainly on the volume of the tank and the complexity of the internal structure. With the same parameters, it is better to choose the cheaper option, because a more expensive model is unlikely to be of better quality.

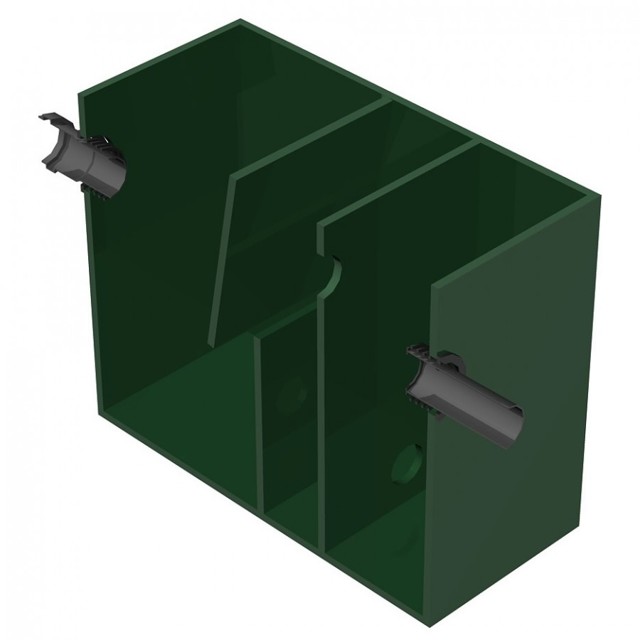

The device and principle of operation of the grease trap

The grease trap performs the function of cleaning wastewater from fats and solid waste, catching them and collecting them in a special tank. It is compact and fits easily under the sink. The body of household models is made of polypropylene or stainless steel.

The separator device is simple, consists of the following elements:

• a rectangular body with 2-3 holes (2 holes for the inlet and outlet of drains, one more is not available in all models for ventilation);

• internal partitions acting as traps;

• cover with a rubber seal to prevent the penetration of odors into the room;

• inlet pipe (short in the form of a knee);

• exhaust pipe (in the form of a tee).

The principle of operation of the device consists in the ingress of effluents into the receiving zone of the separator and their passage through partitions, where solid particles and fats are cut off from the liquid. The difference in the density of fats and water raises the former to the top, where they accumulate. Behind all the partitions there is a second chamber, where the treated drains go, getting into the sewer system. As the fat builds up in the upper part of the tank, the mass is excavated with subsequent disposal.

Selection criteria and main manufacturers

To select the necessary device, first of all, it is necessary to proceed from its purpose. The operating parameters of the separators depend on this. For example, for domestic purposes, performance will be sufficient in the range of 0.1-2 liters per second. But these characteristics are completely unsuitable for treating wastewater entering the canteen drain, cafes or restaurants, this task will require industrial models with the appropriate technical characteristics.

It is worth noting that many industrial models (for example, for workshops where the production of dairy products is established) are equipped with additional equipment that increases service efficiency. These can be automatic pumps for pumping wastewater, fill sensors, etc.

An important factor is the material from which the tank body is made, it can be plastic, fiberglass or stainless steel. In industrial devices, the well is often made of concrete.

Household cleaners are usually made of plastic, which is explained by the low cost of the material, as well as its following useful properties:

- light weight, which greatly simplifies installation and maintenance;

- long service life (at least 30 years);

- harmlessness to humans.

Such devices are designed for domestic use or installation in small catering establishments.

Fiberglass separators. A distinctive feature of such cases is high mechanical strength and resistance to aggressive chemicals.

Such characteristics are excellent for industrial models, especially taking into account the fact that outdoor installation is allowed.

Fiberglass hulls are weather resistant, lightweight and easy to clean.

Stainless steel housings are typically used for industrial separators. Characteristics:

- long service life;

- high hygienic properties;

- presentable appearance.

These characteristics, as well as possible, meet the requirements of public catering establishments.

The only drawback that limits the use of such a case is the high price.

When choosing a manufacturer, we recommend giving preference to well-known brands, such as Ecoline, Alta, The Fifth Element, Thermite, etc. We also note that domestic products are not inferior in quality to foreign ones, but are significantly cheaper. As for unknown manufacturers from the Middle Kingdom, here, as always, the quality must be checked on the spot.

When choosing a separator model, it is necessary to take into account the place of its installation. There are models designed for installation indoors and/or outdoors.

There are three home installation options:

- under the sink or sink;

- in the basement;

- in the space provided for this purpose.

In everyday life, as a rule, use the first option. Briefly describe the sequence of actions when installing a household separator:

- Choose where the device will be located. For this, any surface with a smooth and hard coating is suitable. Since the grease trap requires regular cleaning during operation, it is necessary to provide free access to it. The best option is a place under the sink or next to it.

- We install the separator in the selected place.

- We connect the sink drain hose to the inlet pipe. To ensure the sealing of the joint, we use rubber gaskets (usually supplied with the device), as an additional security measure, you can use silicone sealant.

- We connect the drain pipe to the sewer (it is best to use a corrugated hose of the appropriate diameter for this purpose), without forgetting about rubber seals.

- We fill the structure with water in order to check the tightness. If a leak is found, fix it.

- Close the top cover, after which the device is ready for use.

An outdoor vertical or conventional grease trap is mounted in the ground according to the same principle as a septic tank, a description of this process can be found on our website.

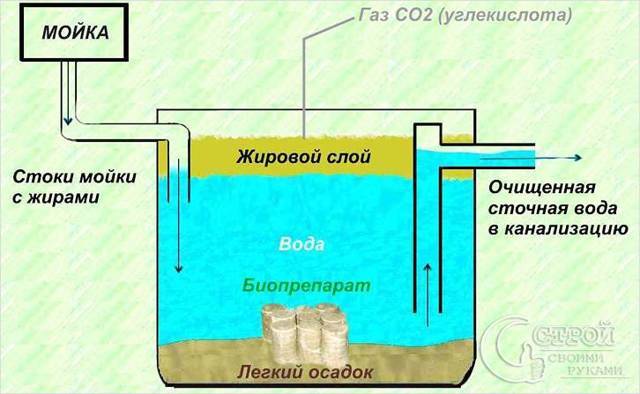

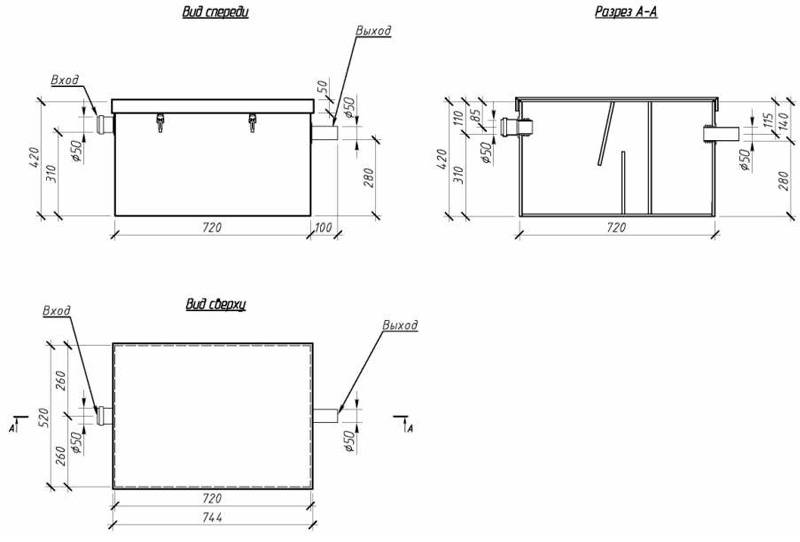

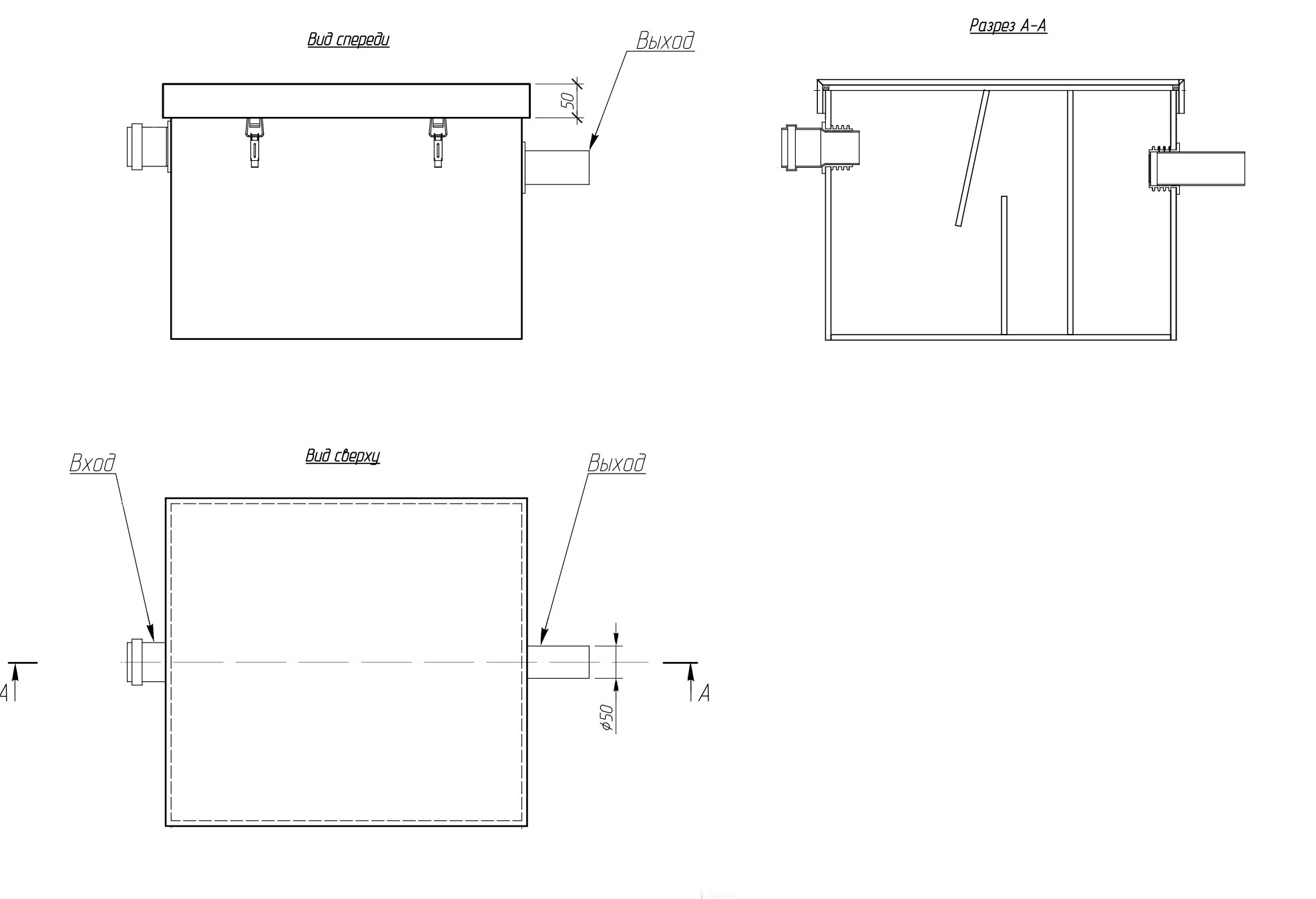

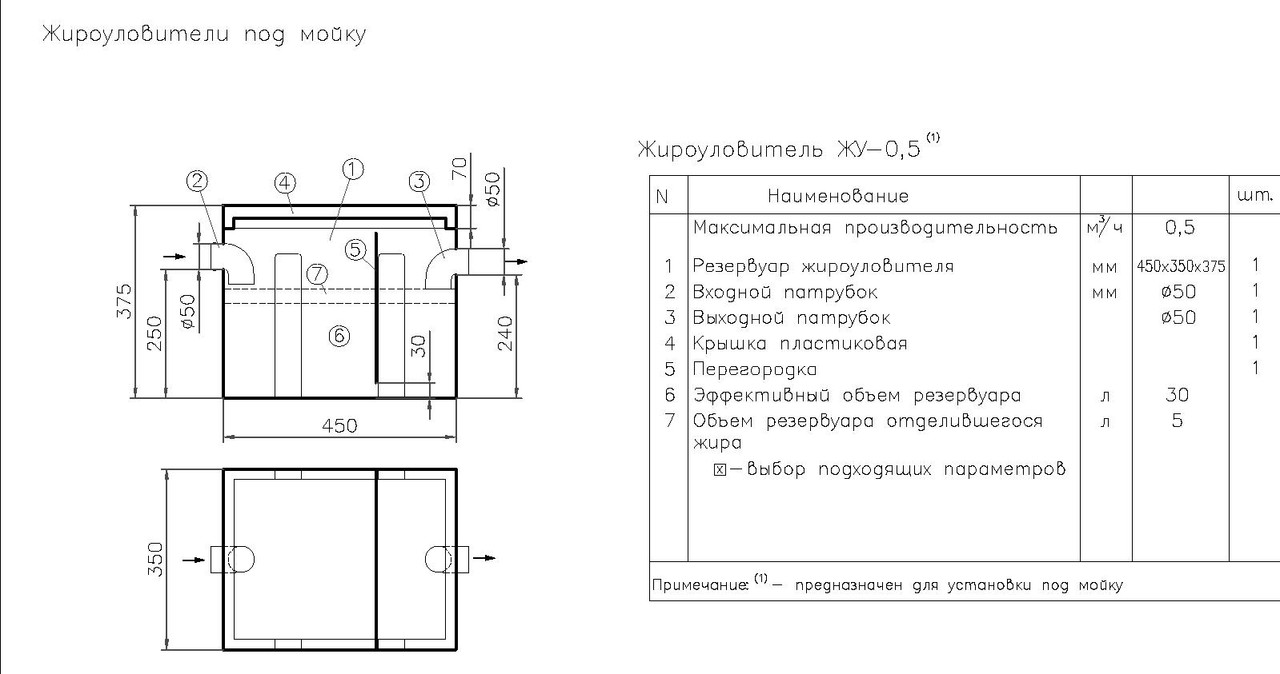

What is a grease trap, its device and principle of operation

These are special tanks used to remove fats contained in drains. A simplified drawing of such a device is shown below.

Grease trap design

Designations:

- A - pipe installed at the inlet;

- B - partition, plays the role of a flow damper;

- C - the first separation partition;

- D - separation chamber;

- E - the second separation partition;

- F - settling compartment;

- G - output distribution compartment;

- H - branch pipe for the removal of treated wastewater;

- I - a sealant that ensures the tightness of the structure;

- J - reservoir cover.

The most common method of separating fats is mechanical. Separator partitions are installed in the tank, which help to slow down the movement of effluents and cool them. As a result, the fatty formations contained in them, due to the transition to a non-emulsified state, are collected on the surface of the water. With the accumulation of a certain amount of fat, cleaning is performed. A visual diagram of the operation of the device is shown below.

Scheme of operation of the grease trap

Designations:

- A - supply of wastewater to the tank;

- B - sediment from heavy pollution;

- C - fat accumulated on the surface of the water;

- D - separation partitions;

- E - water level line;

- F - outlet to the sewer.

The main technical characteristics of separators are determined by their dimensions, performance, peak discharge volume and installation method.

Where is used

According to sanitary standards, grease traps are required in cafes and restaurants

The principle of operation of the grease trap is based on the difference in density between fat and water. Fat is lighter and always floats on the surface of the water. Liquid from the drain enters the plastic container, solid particles settle to the bottom, and fats float and accumulate on top. The partition divides the container into two parts and has a gap at the bottom. Water from below flows into the second part of the tank, and the fat remains on top, floating in the first half or flowing into a special fat collecting tray.At the outlet to the sewer pipe, purified water is obtained, which flows freely through the pipes and does not clog them.

Manufacturers produce special grease traps for installation at key points:

- in the hood;

- under the sink;

- dishwasher;

- sewerage.

Devices are divided into two main ways of draining wastewater:

- volley discharge, in which a full wash of water is collected, the drain hole is closed with a cork, and after washing the dishes, all the liquid quickly drains;

- uniform discharge, when water flows from the tap in a stream, this is how dishes are usually washed at home.

The design of the grease trap is simple, the price is quite affordable, installation is possible with your own hands, the factory kit includes all the necessary seals.

under the sink

The performance of a small plastic device is up to 2 liters per second

When installing a grease trap under a sink, it is often hidden in a cabinet or a lower cabinet, you should immediately leave 3–5 cm on each side of the container. Then, during cleaning and inspection, access to the device will be open. Even small plastic models require a solid base, the total weight together with water reaches 30–40 kg, slight vibration and shift of the body are possible. We connect the drain hose tightly to the inlet pipe of the device, and connect the drain pipe to the sewer using gaskets and sealant. Then you need to check the system for leaks, if everything is in order, then install the cover. The grease trap is ready to go.

Easy to take care of:

- Remove the lid and remove the layer of accumulated fat from above with a shallow wide container or spatula. A small plastic disposable container is fine.

- Remove solid particles and sediment from the bottom and from the nozzles.

- Rinse with hot water and detergent, replace the cover.

For sewerage

The unit is made of high strength plastic.

Another installation option involves the collection of wastewater from several sinks into a common pipe and connection to a grease trap, and then to the sewerage system. In this case, devices of larger volume and productivity are used, approximately 15 liters per second. Such dimensions cannot be hidden under the sink, they are installed in a separate room or in the basement. During filtration, additional waste splitting can be applied with the help of chemicals available in the form of tablets. This method gives a high degree of purification, up to 98%, but when organic matter decomposes, an unpleasant odor may appear, which will remain outside the residential part of the house.

for hood

Some grease traps can be made from acrylic

The steam rising from the hob and gas stove contains a significant amount of fat and soot, which, settling on the air ducts along with dust and cobwebs, contribute to the gradual overgrowth of the pipe. To capture and retain these particles, special filter devices are built into the hood. When dirty, the filters can be removed and washed with hot water and regular dishwashing detergent.

The principle of operation of the device

The grease trap is a filter unit designed to separate oil contaminants from the drainage system.

The principle of operation of the mechanism is based on the method of simple gravity. Fat particles in waste water are usually in a liquid state and have a temperature above 40 degrees.Due to this property, they easily float to the surface and penetrate into special equipment sumps that are designed to remove them.

Any type of grease trap consists of the following elements:

- flasks for settling sewage;

- an inlet pipeline that is connected to a sink;

- exhaust manifold connected to the drainage network;

- compartment for collecting fat;

- sealed lid to prevent odors from spreading.

To increase the service life of plumbing and increase the interval between the processes of its cleaning, bio-enzymes are added to the appliance, which contribute to the breakdown of accumulated fat.

Overview of popular manufacturers of grease traps under the sink

Now there are no difficulties with buying a "trap" for fat. The device is produced not only by foreign, but also by Russian manufacturers. Of course, you can always add something new to the design of the device, but in most cases the design is almost identical. Therefore, we intend to focus on the reputation and fame of the manufacturer.

A popular Russian company under whose name, as a rule, industrial equipment is produced.

"Fifth Element"

An enterprise that produces very inexpensive PP grease traps, which are intended not only for industrial, but also for domestic use.

Flotenk

Another Russian company engaged in the production of domestic / industrial equipment for sewers. In the manufacture of fiberglass is used, the service life of which can reach 50 years.

Evo stock

A company from Russia specializing in polypropylene grease separators for domestic/industrial use.Reinforced plastic can also be used in the manufacture.

A Finnish company that produces high-quality polyethylene grease traps under the EuroREK Omega brand.

How to choose?

Before you install a grease trap with your own hands, you first need to choose a good model. First of all, it is determined where the equipment will be installed. Next, you need to choose the performance of the model.

So, if you plan to install a grease trap under the kitchen sink, it is enough to use a model with a capacity of 0.1 liters per second. If the model will be installed in the basement, then you need to take into account the number of drains (from the bath, shower, etc.).

Having decided on the main criteria, you can choose the right model. You can purchase a variant of domestic or imported production, since the design is so simple that there is no particular difference in the products of different manufacturers.

The principle of operation of the device

The scheme for organizing a cleaning system with a grease trap is quite simple, so it can be implemented even by an ignorant specialist. The main thing is to purchase high-quality components and arrange them in the required order.

Grease traps operate according to the following principle:

- Water from the sink enters the inlet pipe of the treatment system, the first tank begins to fill;

- Due to the low density, fat particles begin to rise above the surface of the water;

- As the tank fills, the fat moves to a special trap, where it remains;

- Water moves to the second compartment, where it undergoes secondary treatment, and then goes into the sewer.

During the operation of the system, solid particles also accumulate in the first compartment, which periodically need to be removed from there.For these purposes, the tank must be completely pulled out and washed thoroughly. On average, this procedure is carried out once a week.

In large enterprises where a large amount of contaminated water passes through the sewer every day, it is recommended to install mechanical coarse filter. It is he who will prevent premature failure of the grease trap.