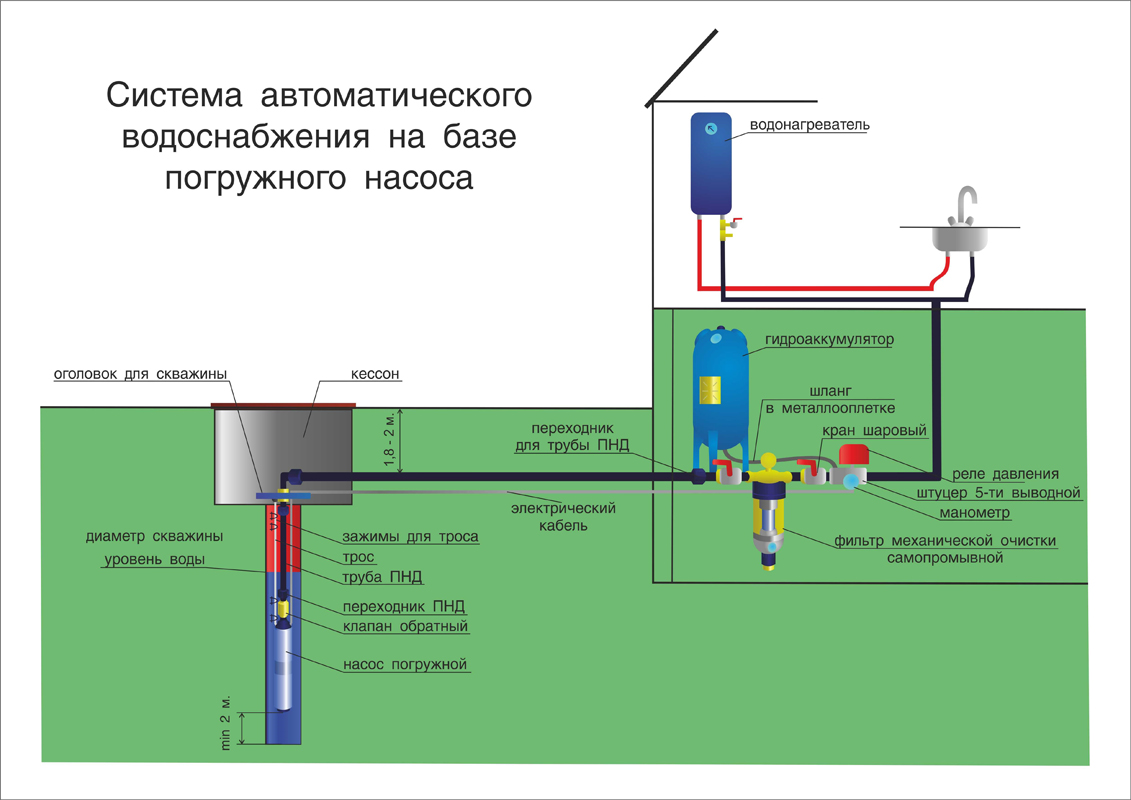

- Deep pump installation

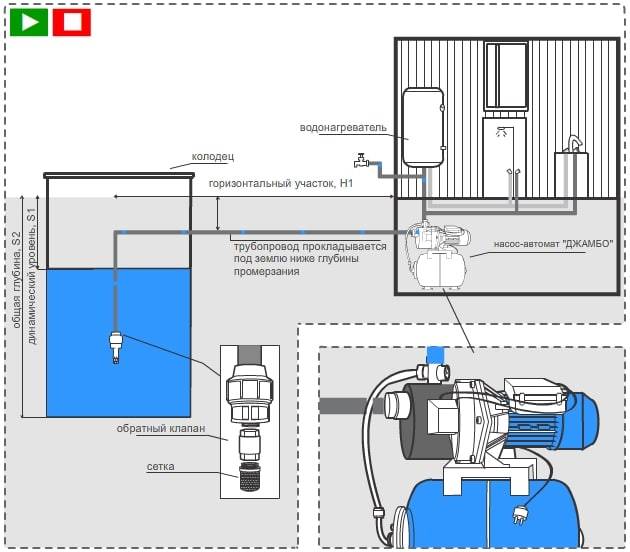

- Water supply system

- Main elements of the system

- Pipeline laying

- System installation

- Laying pipes below the freezing depth of the soil

- Do-it-yourself automation for a well or with the help of professionals

- General principle of operation of automation

- Types of automation for borehole pumps

- First generation ↑

- Second generation ↑

- Third generation ↑

- Do-it-yourself automatic block ↑

- Basic assembly schemes ↑

- Installation Tips ↑

- Providing hot water

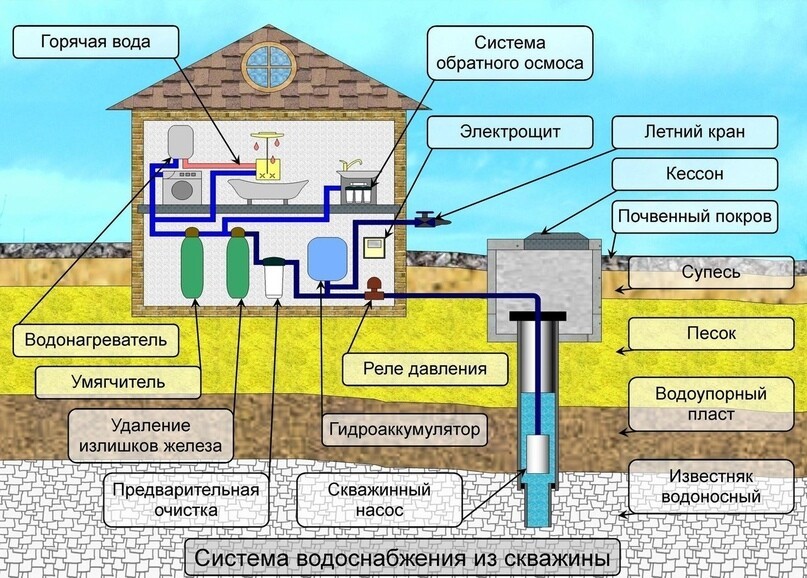

- What is an autonomous water supply

- The main nodes of the system

- Pipe laying

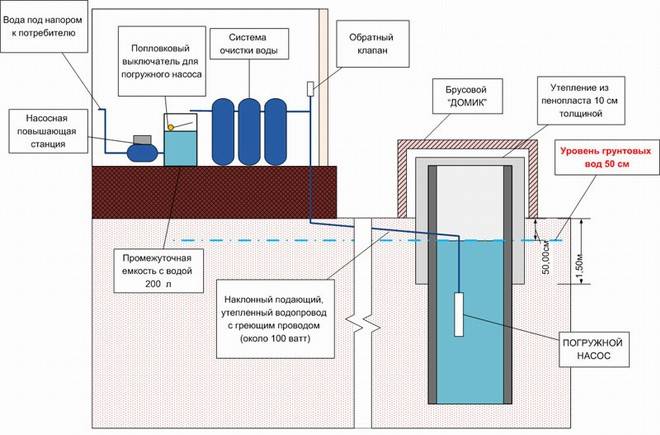

- Well insulation methods

- Installation of expanded polystyrene

- Manufacture of a well house

- Polyurethane spraying

- Main components and system design

- Pump selection

- Hydraulic accumulator

- drain valve

- Pressure switch

- Where to get water, or how to choose a source of water supply

- Centralized water supply

- mine well

- Well

Deep pump installation

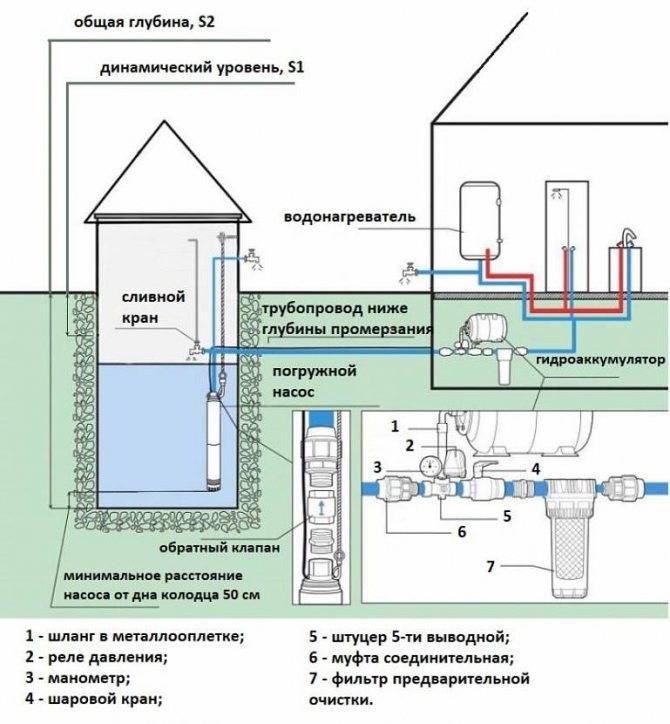

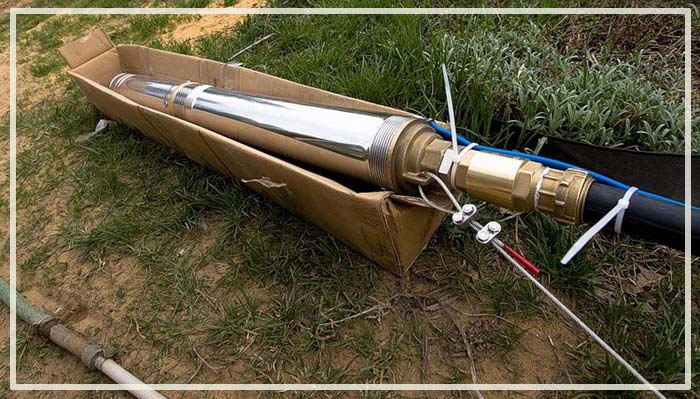

In order for water to be pumped out of the well, you will need to install a deep-type hydraulic pump in this structure. Usually for its installation, a variant with suspension on a cable is used. To do this, a special design is welded from steel corners, which is laid on the concrete rings of the well. It is attached to them with anchors.

Work on installing and connecting the pump is carried out in the following order:

- The pump is installed at the end of the pipe section, with which it will be connected to the corner.

- Then the power cable of the device is unwound.

- A special valve is installed on the outlet, which will protect the system from backflow of water.

- A coupling is attached to the valve, and a pipe is attached to it.

- The power cable is attached to the pipe with electrical tape.

- The entire structure is immersed in the intake structure.

- The safety cable is attached to the frame of steel corners.

- Then the pipeline is joined with the help of a corner element with the pipe of the unit, and the power cable is brought out from above or fits into the trench.

If you plan to use not a deep pump, but a pumping station, then for the operation of the system in winter, the connection of the pump to the pipeline is arranged in a special pit. Its dimensions are 0.75x0.75 m and a depth of 100 cm. The bottom of the pit must be carefully tamped and covered with crushed stone or concreted, and the walls reinforced with bricks or boards. Pipes are brought into the pit and there they are connected to the installed pump. To protect against the cold, the pit must be thoroughly insulated.

Water supply system

Main elements of the system

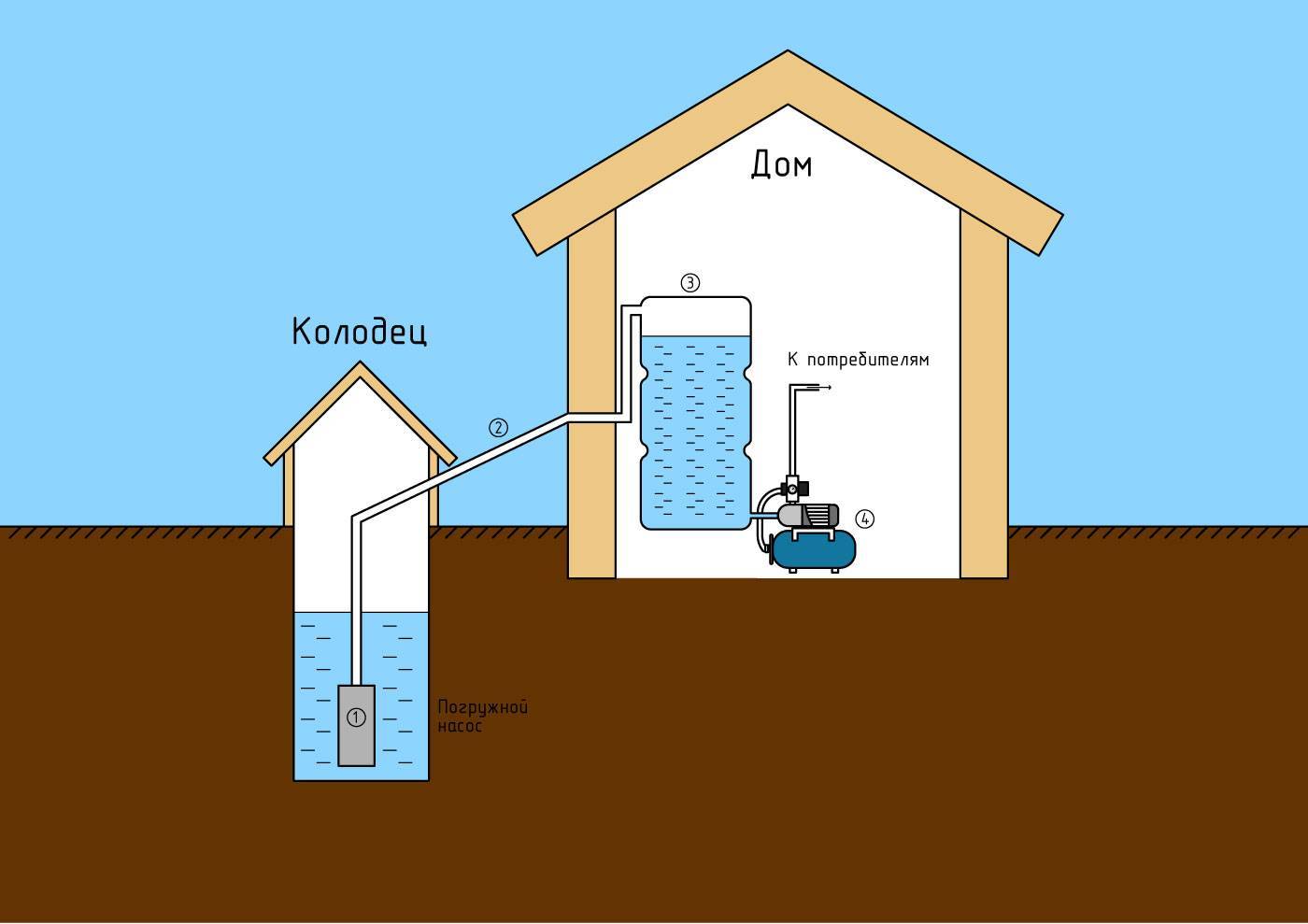

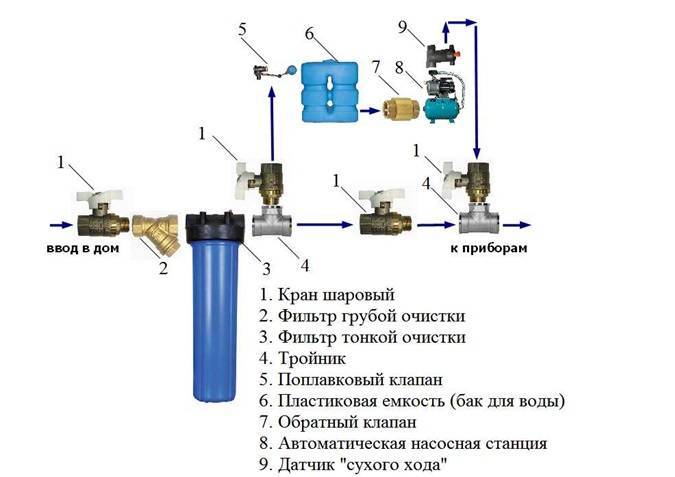

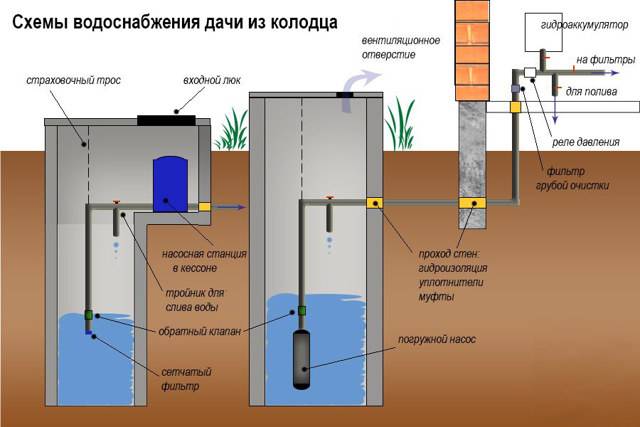

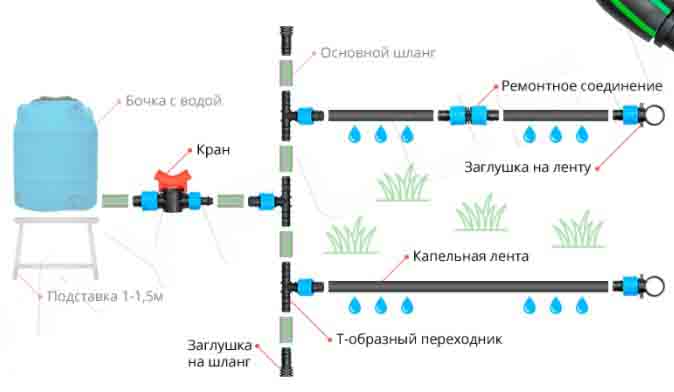

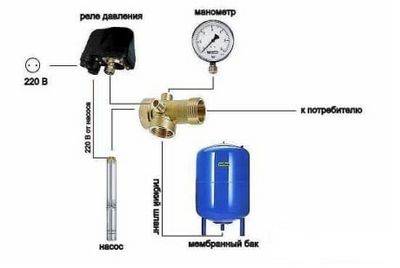

Details of the water supply system for shallow wells

As we noted above, in addition to properly installed and correctly operating water-lifting equipment, we will need many details to provide the house with water from the well.

Among them:

- The supply pipeline through which water from the well will flow to the house.

- A hydraulic accumulator, which is a water tank that maintains a stable pressure inside the system.

- A relay that turns the water pump on and off depending on the level of pressure in the tank.

- Dry running relay (if water stops flowing into the pump, the system is de-energized).

- Well filter system for cleaning and optimizing water parameters. As a rule, it includes filters for coarse and fine cleaning.

- Pipelines and shut-off equipment for wiring in rooms.

Also, if necessary, the water supply scheme from the well to the house includes a branch for the water heater. This makes it possible to provide hot water.

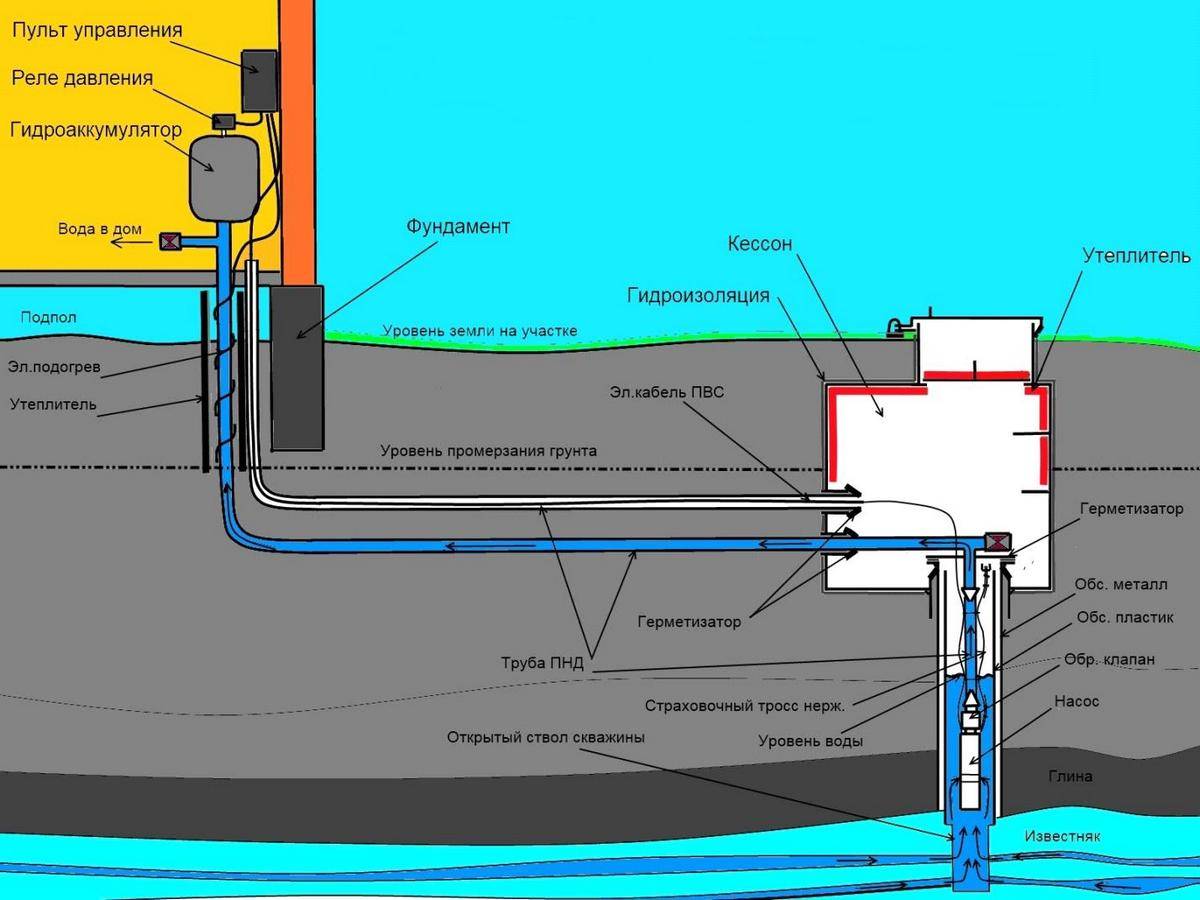

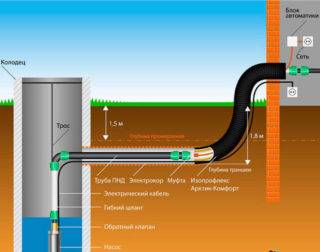

Pipeline laying

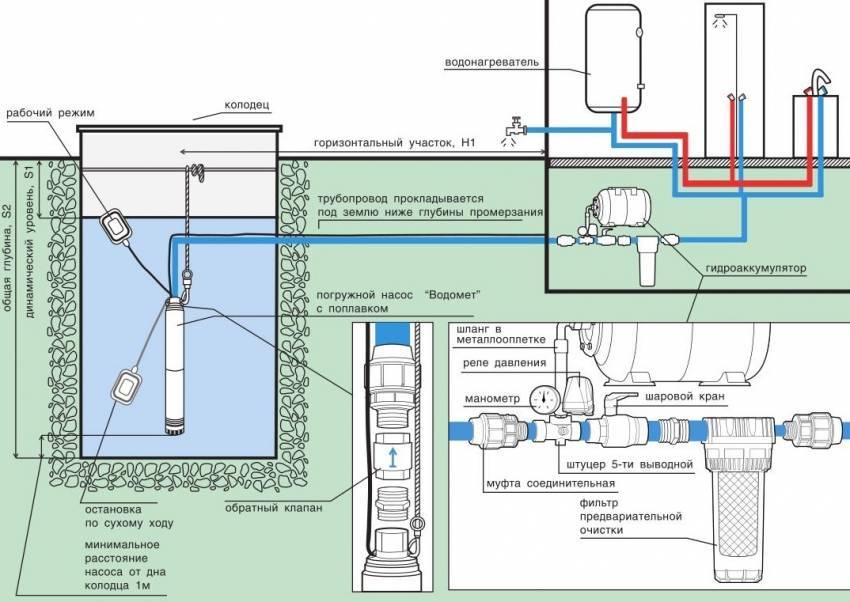

If you have certain skills, the system itself can be assembled by hand.

We do it like this:

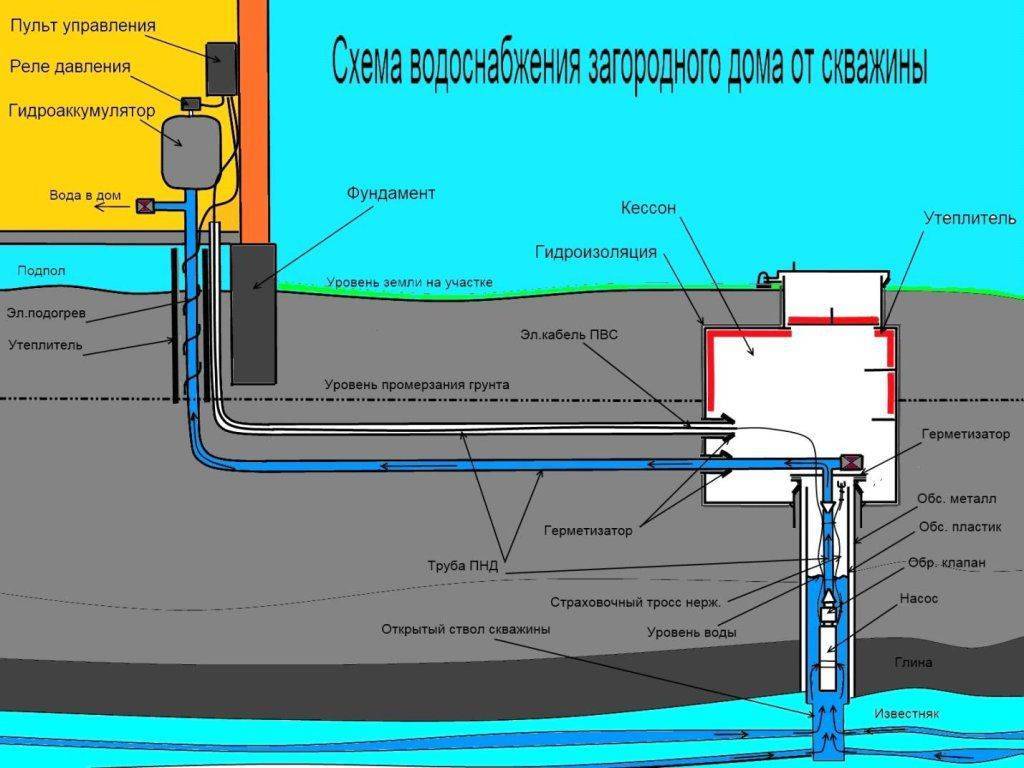

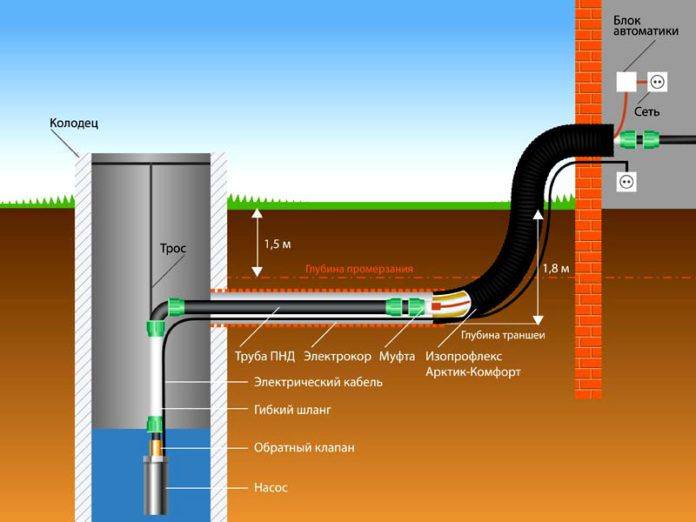

- To lay a pipe from the mouth of the well to the house, we dig a trench. It is desirable that it passes below the freezing level of the soil.

- We lay a pipe (preferably polyethylene with a diameter of 30 mm or more). If necessary, we wrap the pipeline with heat-insulating material.

- We lead the pipe into the basement or underground space through a special vent. This part of the pipeline must be insulated!

Trench from well to house

System installation

Next, we proceed to the construction of the accumulator:

- We install the hydraulic accumulator (a plastic container with a volume of up to 500 liters) as high as possible - this will provide us with a natural pressure adjustment. At the inlet we mount a pressure switch, which, when the tank is filled, will turn off the water supply.

- In some cases this is not enough. Then we additionally install an automatic pumping station - a complex of several relays, pressure gauges and a membrane receiver tank.

Pumping station with a receiver that can be used instead of a hydraulic accumulator or together with it

The receiver, equipped with a separate pump, provides a smooth change in pressure in the accumulator, which has a positive effect on the performance of all systems. Without this part, the downhole pump motor starts up with each turn on of the crane, which, of course, leads to its early wear.

- After assembling the system from a hydraulic accumulator and a pumping station, we proceed to the installation of piping. For it we use polyethylene pipes. When water supplying a cottage or a country house, a diameter of 20 mm is enough.

- We cut pipes using special devices. To connect them, we use a soldering iron with a set of bushings. The use of this technology allows to achieve maximum tightness.

- Alternatively, steel or multilayer pipes can be used. They are distinguished by greater mechanical strength, but it is more difficult to mount them. Yes, and detachable connections are still inferior in tightness to soldered seams.

We bring the pipe wiring to the points of consumption and attach it to the taps. To ensure safety, we fix the pipes on the walls with clamps.

The most common scheme

Separately, it is worth taking care of the drainage system.

When designing it, it is important to place a cesspool or septic tank in such a way as to completely eliminate the filtration of runoff into aquifers. First of all, this applies to sand wells, which are characterized by shallow water.

Laying pipes below the freezing depth of the soil

Most often, difficulties arise with the choice of pipes: low-pressure polyethylene pipes cannot be used, since the mass of the soil will lead to cracking of the material, and the metal will corrode. Other disadvantages:

- When installing the system, a large amount of land work is required.

- Difficulties in finding damaged sections of the autonomous highway.

- If the depth of the trench is less than the level of soil freezing, the likelihood of damage to the integrity of the pipeline increases significantly.

To minimize the likelihood of a leak, it is necessary to make as few joints between pipes as possible during the construction phase.

Do-it-yourself automation for a well or with the help of professionals

General principle of operation of automation

Despite the difference in price and functionality, modern automatic units work according to the same scheme - various sensors monitor the pressure level and adjust it as necessary.

A good example is the principle of operation of the simplest pressure switch:

- The device is installed in two positions - the maximum and minimum pressure in the system - and is connected to the accumulator.

- The accumulator membrane reacts to the amount of water, that is, to the pressure level.

- When the minimum allowable level is reached, the relay turns on, which starts the pump.

- The pump stops when the top sensor is triggered.

More advanced systems that operate without a hydraulic accumulator can be equipped with additional options, but the main principle of operation of automation for a borehole pump remains unchanged.

Types of automation for borehole pumps

First generation ↑

The first (simplest) generation of automation includes the following devices:

- Pressure switch;

- Hydraulic accumulator;

- Dry run sensors-blockers;

- Float switches.

The pressure switch was mentioned above. Float switches react to a critical drop in the liquid level by turning off the pump. Dry running sensors prevent the pump from overheating - if there is no water in the chamber, the system stops functioning. As a rule, such a scheme is used in surface models.

The simplest automation for a borehole pump can be easily installed with your own hands. The system is also suitable for drainage equipment.

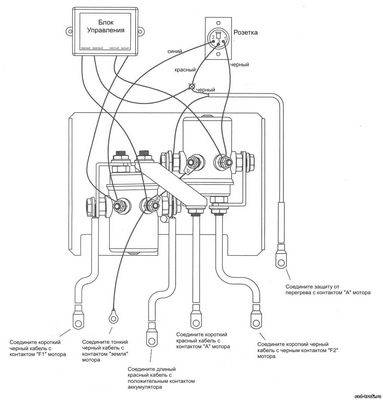

Second generation ↑

Block machines of the second generation are more serious mechanisms. It uses an electronic control unit and several sensitive sensors fixed in different places of the pipeline and pumping station. The signals from the sensors are sent to the microcircuit, which maintains full control over the operation of the water supply system.

The electronic "watchman" reacts in real time to any deviations from the norm. In addition, it can be equipped with additional features:

- Temperature control;

- Emergency shutdown of the system;

- Checking the liquid level;

- Dry run blocker.

Important! The big disadvantage of such an automation scheme for borehole pumps is the need for fine-tuning, a tendency to breakdowns and a rather high price.

Third generation ↑

Important! If you do not have experience in water supply, you will not be able to install automation for a well with your own hands. Only a specialist can determine which algorithm is better to program the system

Do-it-yourself automatic block ↑

Do-it-yourself automation for a borehole pump is often cheaper than a factory set of equipment.When buying units separately, you can always choose the best option for the purchased pump model without overpaying for unnecessary additional options.

Important! Such amateur performance requires a certain level of knowledge. If you cannot call yourself an expert, it is better to purchase pumping equipment with pre-installed automation.

Basic assembly schemes ↑

Among the automation schemes for borehole pumps, the following types have proven themselves well:

All automation nodes are assembled in one place. In this case, the accumulator can be located on the surface, and water is supplied to it through a pipe or flexible piping. The scheme is suitable for both surface and deep-well pumps.

Control unit on hydraulic accumulator

With this arrangement, it is recommended to connect the system manifold to the pump supply pipe. It turns out a distributed station - the unit is located in the well, and the control unit with a hydraulic accumulator is installed in the house or utility room.

Distributed pumping station

The automation unit is located near the cold water collector, maintaining a constant pressure level in it. The pressure pipe departs from the pump itself. With such a scheme, it is better to use surface models.

Installation Tips ↑

In order for automatic equipment to serve you faithfully, you need to take care of the correct place for its installation in advance:

- The room must be heated all year round.

- The closer to the well is the remote unit, the better. The ideal option is to equip a small boiler room near the caisson.

- To avoid pressure losses, install the pumping station in close proximity to the collector.

- If the equipment will be located in the house, carry out high-quality soundproofing of the room.

Providing hot water

If you need to provide hot water, you can complete your plumbing system with a water heater. There are accumulative and flowing varieties of such equipment. In summer cottages, it is most convenient to use storage tanks.

The installation of the water heater is carried out according to the standard scheme for such equipment.

Now you know in what order the installation of the plumbing system is carried out and what needs to be taken into account for the successful implementation of all related activities. Do everything in accordance with the provisions of the above guide, and your plumbing will work properly for many years.

What is an autonomous water supply

When you were able to clearly answer all the questions above and made a rough plan of action, you need to figure out what constituent engineering elements the plumbing consists of. In fact, these are the pipes themselves, as well as the mechanisms for their injection to the surface:

Pipes of different diameters

Cranes and fittings (connecting parts) for the installation of pipes as a whole

Mechanisms for pumping water various types of pumps (their choice mainly depends on the required volumes of water supply

Electric motors for pumps

If it is necessary to heat water (for using it at home) - water heaters

Filters for mechanical (coarse) and deep water purification (you can’t do without them if the water is used for drinking purposes)

You will also need working tools and materials for attaching pipes to surfaces, additional protection (insulation) of pipes for using them in the winter.

In general, do-it-yourself country water supply from a well as a single system should look like this.

A schematic diagram of the system looks something like this

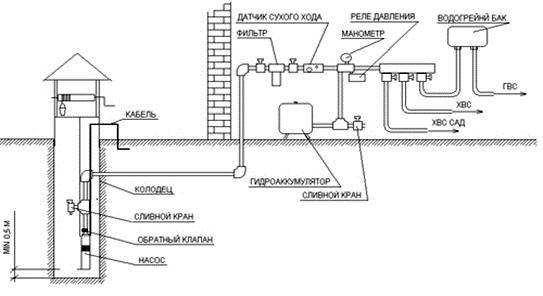

The main nodes of the system

Main elements water supply systems of the cottage from the well:

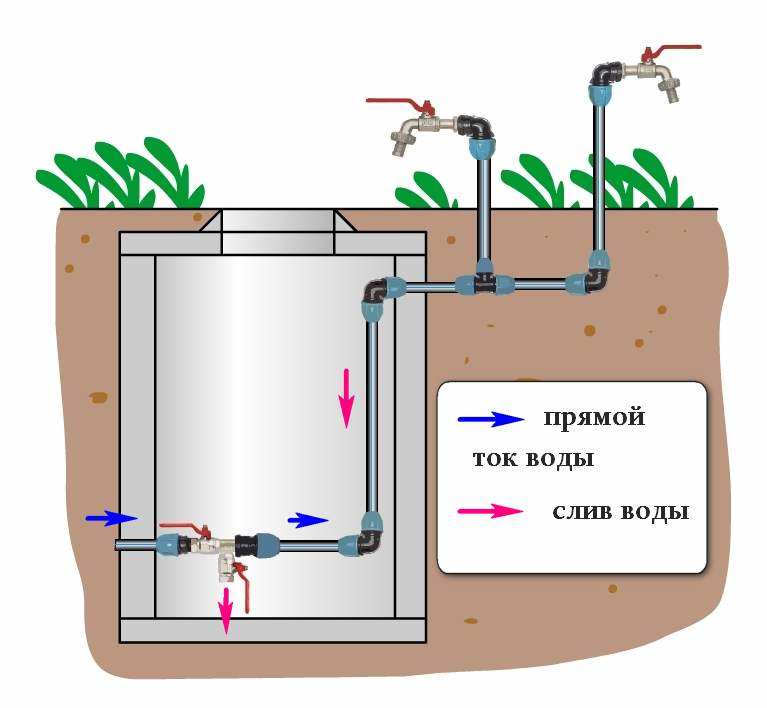

-

Pump. There are surface pumps and those that are completely submerged in water on a steel cable. A cable is connected to the pump, and a water hose departs from the pump.

-

Hydro accumulator. Provides control over water pressure.

-

Water drain valve. Necessary for the conservation of the system for the winter

-

Heating boiler or boiler. Provide water heating.

-

Wiring and pipes – ensure the distribution of water and deliver it to the necessary points of the room (kitchen, shower, lavatory, etc.)

The main elements of the plumbing are located in one place

The layout of the wiring and pipe laying depends on the specific room. The final cost of the project will depend on the needs of homeowners.

The main elements of the water supply system

Pipe laying

Water from the well will be transported to the house through pipes. You can use metal, metal-plastic or polymer products. It is better to choose metal-plastic pipes, as they are more durable and resistant to aggressive environments.

The pipe trench is dug below the freezing mark in your climate region. This will keep the water from freezing in the pipes in winter. However, it is possible to make the trench less deep by using a heating cable and a thorough insulation of the pipe, which will prevent the water from freezing during the cold season.

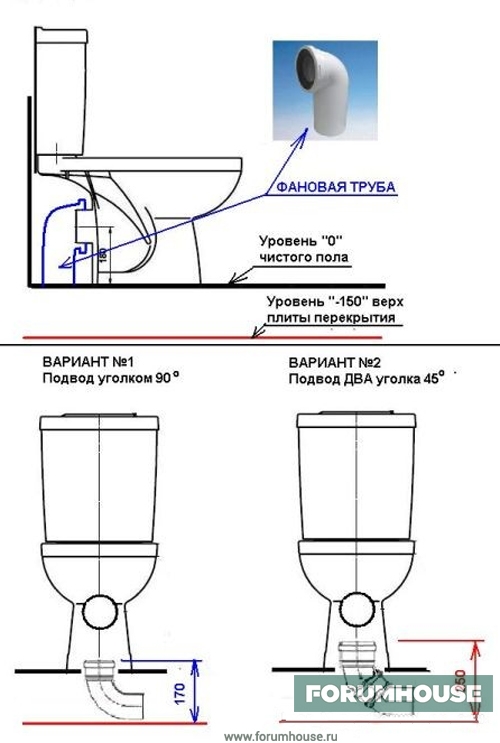

Before laying pipes in places of rotation, divergence or deepening of the branch, it is necessary to make manholes:

- To do this, first dig a pit measuring 100x100 mm. The bottom of the pit should be 400 mm below the freezing mark. The bottom is covered with a layer of sand 100-150 mm high.

- Then a concrete strip or slab foundation is constructed. It must be such that it can withstand a brick wall.

- After that, you can lay out the walls of brick. The thickness of the walls of the manhole is 250 mm.

- Now you can lay a floor slab on the walls with a hole for servicing the water supply.

Well insulation methods

Timely insulation of the winter well will help to avoid problems with freezing of the underground section of the mine. The formation of an ice crust leads to negative consequences:

- the pump and other equipment fails;

- ice exerts pressure on the walls of the concrete rings, causing cracks to form.

Installation of expanded polystyrene

The structure can be insulated with expanded polystyrene plates or other material with similar properties. For insulation efficiency, the rings are dug to a depth of up to 1.5 m, and then pasted over with insulation and covered with earth. This option has several advantages:

- affordable cost;

- durability;

- foam is resistant to moisture and decay.

Expanded polystyrene is used to insulate the well

Manufacture of a well house

Installation of a wooden well house is an effective, but expensive method of insulation. The tree serves as a good heat insulator, eliminating the risk of freezing of the upper part of the shaft. The original wooden structure, in addition to practical use, serves as a decorative decoration for a summer cottage.

Such a house is one of the options for insulating a source of water supply.

Polyurethane spraying

One of the methods to protect the source from winter frosts is to spray polyurethane foam on the outer part of the barrel. It turns out a strong monolithic layer that reliably protects concrete rings from the cold. The work is quite laborious, you will have to dig a shaft 1.5-2 m, and after the foam has hardened, fall asleep again.

Polyurethane spraying

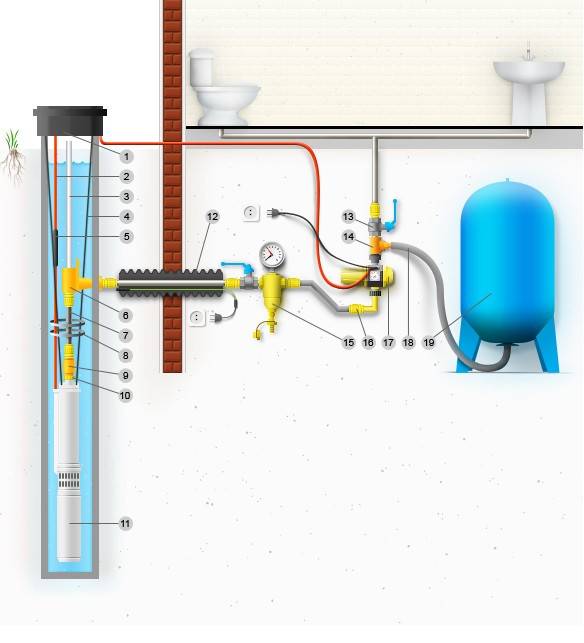

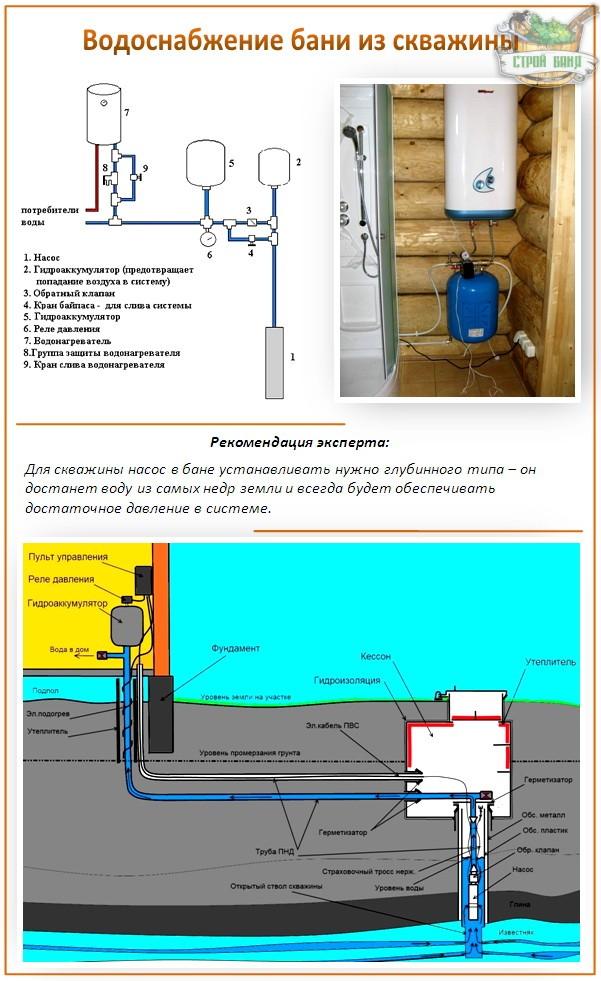

Main components and system design

Any water supply scheme from a well includes several basic elements:

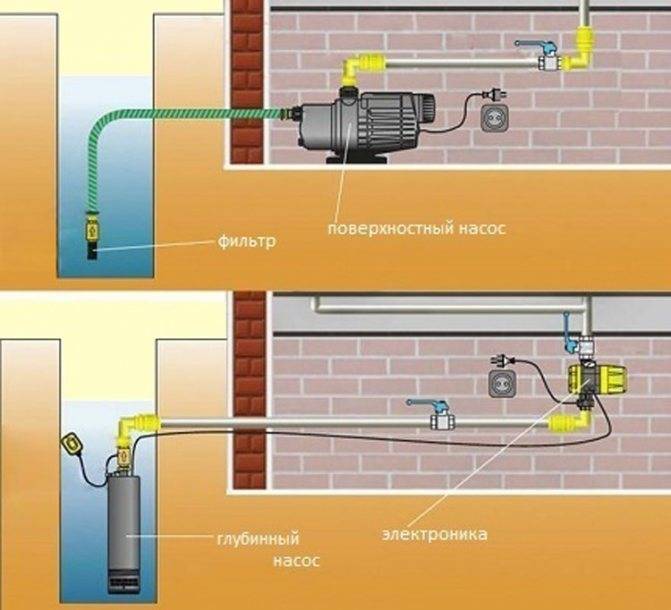

Pump selection

The device can be both submersible and surface. Experts recommend choosing submersible devices. They have high performance, can work at great depths, are economical and have low noise levels. The brand of the device and its power are selected depending on the depth at which it will work.

Hydraulic accumulator

The equipment is necessary to protect the system from water hammer and stabilize the pressure in the water supply. A hydro-storage tank with a membrane accumulates water, so even in the event of power outages, its supply will continue for some time.

Tank size may vary. When choosing it, it must be taken into account that the amount of water that will be in the tank is much less than the nominal volume of the device.

drain valve

The design is installed at the lowest point of the system, that is, immediately after the pump. Used to drain water from the system during conservation.If the well has a depth of no more than 8 m and is located near the dwelling, another device can be installed instead of a drain valve. A non-return valve is mounted in the house, and directly in front of it is a bypass system with a tap. As soon as the faucet opens, the vacuum created by the non-return valve leaves, and all the water from the system is drained.

For water supply from a well, you can choose a submersible or surface pump

Pressure switch

It is installed next to the hydraulic accumulator to maintain optimal pressure values in the structure. The relay reduces or increases the pressure in the pipeline while the pump supplies water to the accumulator tank. As soon as the maximum pressure is reached, the device turns off the pump. When the value decreases to a minimum, the relay closes the contacts and water pumping starts.

In addition to these devices, water pipes will be needed. Professionals recommend using polypropylene parts, which are durable, reliable, environmentally friendly, easy to install and affordable. You may also need a water heating cable that will prevent pipes from freezing during the cold season. If the amount of water in the well is small, it is recommended to install a dry-running switch that will protect the pump in the event of a sharp drop in water level.

Another nuance: the water supply from the well to the house must be installed under a slope that is directed towards the drain valve. Thus, it is possible to completely drain the water from the structure without any problems. Inside the house, all wiring is also arranged with a mandatory slope towards the supply pipe, which becomes a drain pipe during the conservation of the system.

Where to get water, or how to choose a source of water supply

After you have studied all the elements of the future water supply system, as well as drawn a diagram specifically for your site, you need to decide on the source of water supply. In the country, unlike a city apartment, there are several options:

Centralized water supply

The most convenient and obvious option is centralized water supply. This option is the cheapest, because you do not need to install a pump or purchase additional tools to pump water and control its pressure level.

In fact, you need to dig recesses, lay pipes, strengthen them in the ground, connect them together, and the system is ready for irrigation. There are, of course, the central water supply and weaknesses:

- usually this is a summer option - it does not function in winter;

- ordinary water is poorer in terms of the content of nutrients than artesian water (if you have a well on the site);

- finally, the central source may be too far away, and it will become more expensive to pull pipes, and even through neighboring fields, than to make a water pipe in the country with your own hands from a well.

Often there is no centralized water supply nearby at all - and then it is not necessary to consider this possibility.

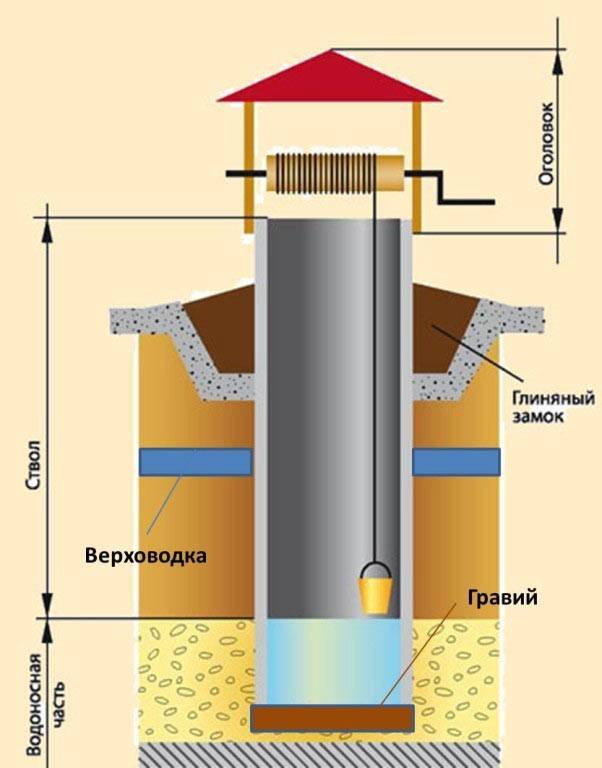

mine well

If you have a well with a source of good, clean water on your site or a neighbor, you can consider yourself very lucky. Such sites are not very common, and they are usually more expensive.

The well, in addition to the outer part with a gander and a stone support, has an inner base. This is a trunk that opens access to water to the surface and the aquifer itself, where natural water is contained.

The well itself can be located at different depths, and depending on this parameter, the following are distinguished:

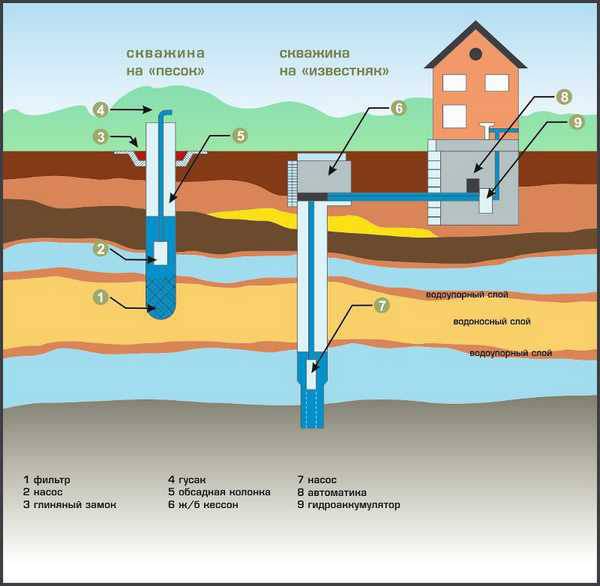

- The well "on limestone" - it lies deeper and is reliably separated from groundwater. In this case, it is required to filter the water much less, and in terms of the content of microelements it is much richer than a well “on sand” and even more so chlorinated city water.

- Well "on the sand" - located higher, most often contains a lot of mechanical impurities (sand, small stones, soil). However, this does not prevent it from being used for irrigation. But for drinking, a filtering process is required.

Well

The well provides the rise of water, which lies shallow (usually up to 12 meters). In all other cases, a well is required to be drilled on the site. This option is much more costly in terms of both strength and money, and of course, in time. However, the result is worth it - thanks to the well, it will be possible to provide year-round water supply to both the site and the country house.

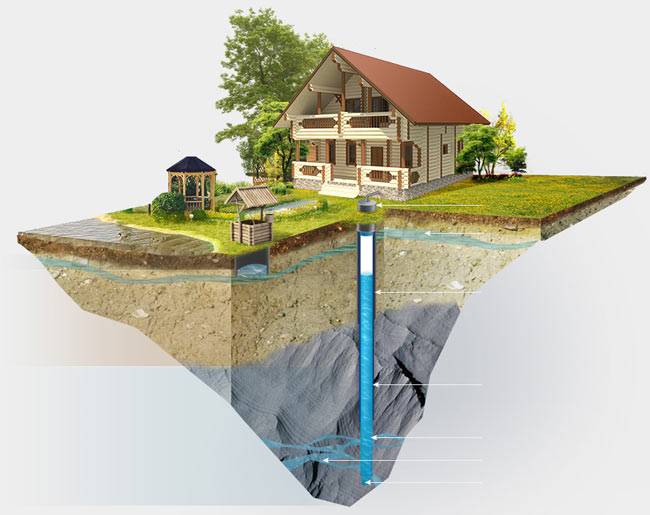

You can compare a well and a well and feel the difference in this diagram.

Indeed, usually the depth of the well is several times greater than the well. But there is a lot of water there, and it is much cleaner and healthier.