- The process of pouring sealant

- Types of sealants for heating systems

- based on oligomers

- Acrylic

- Thiokolovye

- Silicone

- Polyurethane

- Liquid sealant for heating system

- How to choose?

- Scope of application

- Steps to fix leaks with liquid sealant

- Preparing the heating system

- Sealant preparation

- Pouring sealant

- Liquid sealant for home heating system and pipes

- Types of sealants

- How to choose a sealant for heating?

- Fixing leaks in the heating system

- About the pros and cons of glycol antifreeze

- What to look for when choosing?

- How to use liquid sealant

- Features of heat-resistant sealants

- Applications for sealants

- The main properties of sealants

- Additional features of sealants

- Sealing threaded connections

- Anaerobic sealants

- Sealant selection

- Silicone sealants

- Acrylic sealants

- Recommendations for use

- How to fix leaks in hidden pipes

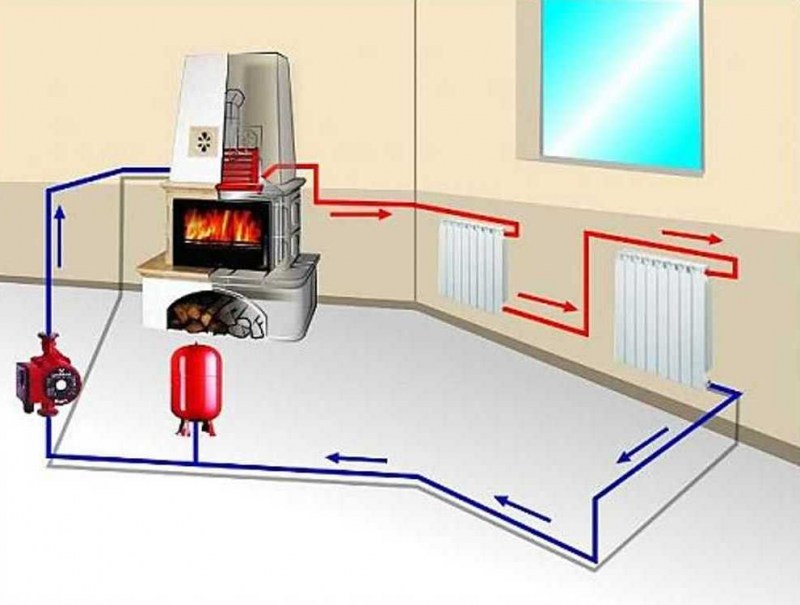

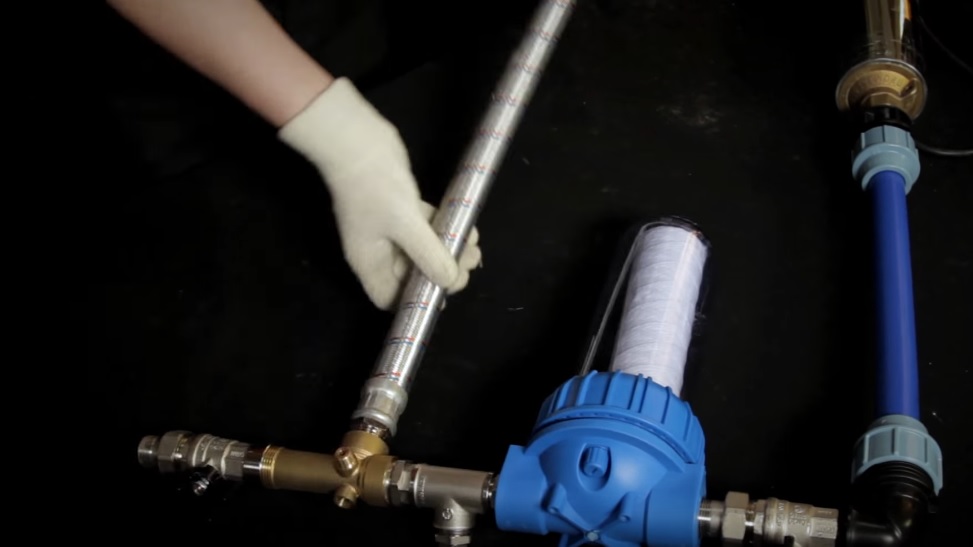

The process of pouring sealant

A bucket of hot coolant is poured into a previously prepared container. Another half a bucket is taken separately, for subsequent washing of the container, in order to get all the components into the heating system. The sealing compound is shaken and added to the bucket of drained liquid. The solution should not be in contact with open air for a long time, therefore it is immediately pumped into the system by a pump.The procedure for removing air from the pipes is repeated.

A bucket of hot coolant is poured into a previously prepared container. Another half a bucket is taken separately, for subsequent washing of the container, in order to get all the components into the heating system. The sealing compound is shaken and added to the bucket of drained liquid. The solution should not be in contact with open air for a long time, therefore it is immediately pumped into the system by a pump.The procedure for removing air from the pipes is repeated.

To distribute the sealant over the heating fluid, the temperature is up to 60 °C and the pressure is up to 1.5 bar for several hours. The seal is created by polymerization of the sealant. This process takes 3-4 days of continuous operation of the heating system. On the fifth day, pressure and leaks are checked.

Characteristic features of a properly functioning heating system are always warm in the house, stable coolant pressure in the circuit, no leaks. Reliability is laid down at the installation stage, which depends on the skills and qualifications of the installer. But sometimes leaks still happen, giving users a lot of problems. Let's see how to get rid of the leak and achieve tightness of the system even at the stage of its construction.

- What is the best way to seal pipe joints?

- How to get rid of a visible leak.

- How to get rid of a hidden leak.

We will provide detailed instructions for each question.

Types of sealants for heating systems

The choice of sealant is determined not only by the material of the pipes, but also by the type of coolant used, the presence of a heat exchanger. If you choose the wrong product, blockage of pipes can occur anywhere in the heating system. Various substances can be used as a heat carrier, and the sealant must not react or break down from contact with them. On this basis, the funds are divided into those that can contact:

- with water (ordinary, softened by complexones or magnetized);

- with antifreeze;

- with oils;

- with gas or steam.

A separate line is a sealant for cold water pipes, which is also applied to the threads of taps, used to seal joints.The consistency of sealants can be fluid and pasty. Another pipe sealant can be classified according to physical properties:

- Drying Compounds. As polymerization becomes completely dry. If the application and drying technology has been violated, the products can shrink and crack quickly.

- Non-drying formulations. Ideal for removing small leaks, sealing threads, although they can be squeezed out at the joints under pressure.

based on oligomers

Depending on the functional group used in the production, such agents are divided into polysulfide and polysiloxane. Sealants made from polysulfide oligomers are used much more often to work with heating systems. They have a unique set of properties: oil resistance, petrol resistance, gas impermeability, weather resistance, the ability to operate for a long time in different temperature ranges.

Acrylic

Most of the acrylic products are not suitable for repairing CO in a private house or apartment. Only a few brands are able to withstand temperature extremes and can boast of heat resistance. For example, anaerobic sealants are suitable for sealing pipes and radiators - a kind of acrylic compounds that, when released into an airless environment, fill the entire closed volume (crack, chip) and form a homogeneous polymer mass.

Such products withstand high temperatures, they are very durable, elastic. Seams and joints are subsequently allowed to be cleaned with acidic and alkaline substances, since the sealants are sufficiently resistant to chemicals.And yet they have one drawback: the dismantling of the structure will be very difficult, as it becomes monolithic.

Thiokolovye

Such materials can be used at temperatures of -20 ... +40 degrees, that is, they do not belong to the number of heat-resistant ones. Therefore, they are used only in construction for sealing interpanel joints, double-glazed windows, plumbing equipment and are not used for repair of CO.

Silicone

Such funds are considered universal and most in demand. Most of the silicone sealants are high temperature, therefore suitable for work in CO. They can be liquid and pasty, the latter having thixotropic properties (do not flow after application). The technical characteristics of silicone compounds are as follows:

- possibility of operation at -60…+300 degrees;

- penetration even into the smallest cracks, depressions;

- adhesion to any surfaces;

- solidification at room temperature;

- resistance to moisture, aggressive chemicals;

- elasticity;

- environmental Safety;

- strength;

- durability.

Polyurethane

Means based on polyurethane are produced as one-, two-component. The first ones are inexpensive, but they dry much longer. The latter, after reacting with the hardener, quickly undergo polymerization, resulting in a strong, elastic connection. Polyurethane compounds are suitable for all types of materials, including metals, they do not provoke corrosion, on the contrary, they protect parts from damage. Sealants are durable, resistant to aggressive chemicals, mechanical stress, and are characterized by low consumption.

Liquid sealant for heating system

Liquid sealant has to be used where there are hidden leaks, there is no access to the place where the defect appears. The material is poured into the damaged pipe along with the coolant. In the area of the crack, the sealant inevitably comes into contact with air and begins to polymerize, sealing the defect. Among the liquid options are those that work in water, antifreeze, suitable for metal or plastic pipes.

How to choose?

It is important not just to choose a sealant for the radiator, but heat-resistant options to fix leaks. If you notice that a joint is leaking somewhere near the batteries, you need to decide which sealant will help, and reviews can help in this matter

The choice of sealant is carried out, starting from the tasks that it must solve to fix a leak in the heating system. If it will be used to seal the joints of the heating system, then paste-type silicone sealant is perfect for these cases.

It can be drying and non-drying option.

Differences between sealants can be as follows:

- Drying compounds. After the composition applied to the surface dries, it has the ability to shrink, but this happens if the drying technology is violated. So, deformation of the composition may occur, cracks and streaks will appear.

- Non-drying compositions. Ideal for removing small cracks and can also be used to seal heating system joints. But such compounds can be squeezed out if the pressure in the system exceeds the normal value.

Aerobic-based compounds, which are considered a type of acrylic sealant, are used in some situations to eliminate defects and leaks in heating.This type of sealant is able to withstand temperature changes, is resistant to mechanical stress and is resistant to alkali and acid solutions. If it is applied to the place of the defect, then it quickly fills the flaw and dries.

Scope of application

Liquid sealant has a wide range of applications and can be used in various types of work.

- Fixing various surfaces. In this case, the sealant is similar to "liquid nails". It allows you to fasten together various, including materials of different textures. The resulting layer of the composition is transparent, invisible, but very durable - it can withstand up to 50 kg. Suitable for bonding ceramic, glass, textile, plastic and silicate substrates.

- Plumbing work. Allows you to eliminate leaks that are not visible to the eye or located in hard-to-reach places in heating systems, gas supply, water supply, sewer pipes. It is used for sealing the joints of sinks and pipes, pipes and radiator systems, boilers. It can be used both at home and in public institutions.

- Car repair. Suitable for filling gaps in various auto systems, can be used when replacing gaskets, in the car's cooling system.

- Sealants working on the principle of "liquid plastic". Suitable for eliminating cracks in plastic windows, as well as other PVC-based surfaces. They contain adhesive components, including PVA, due to which the solidity of the material is formed.

- Operations and operation involving harsh environments.For these purposes, polyurethane foam compositions are used, which are characterized by increased resistance to moisture, high and low temperatures, and chemical reagents. Such solutions are called "liquid rubber", since the resulting seam is similar to this material.

- The scope of application of liquid sealants based on polyurethane foam is also roofing - filling joints and cracks. In this regard, the composition is sometimes called "sprayed waterproofing."

- Polyurethane foam sealant can repair a puncture in a car tire. The inner surface of the wheels of vehicles operated in harsh conditions can also be filled with this sealant. In this case, it plays the role of a protective layer.

Steps to fix leaks with liquid sealant

Before you start sealing possible leaks in the heating system, you need to make sure that the expansion tank is working.

The procedure for using liquid sealants for system repair Heating a home can seem quite daunting. In some cases, clots of sealing fluid cause partial blockage and prevent the movement of the coolant. Therefore, in order not to harm the heating equipment due to your inexperience, it is better to invite a specialist. In any case, you need to study the instructions for using a particular type of sealant for radiators and strictly follow it.

Having decided to use a liquid sealant to fix a problem in the heating system, you need to make sure that:

- the cause of the pressure drop is precisely the leakage of the coolant, and is not associated with a malfunction of the expansion tank;

- the selected type of sealant for heating systems corresponds to the type of coolant in this system;

- the sealant is suitable for this heating boiler.

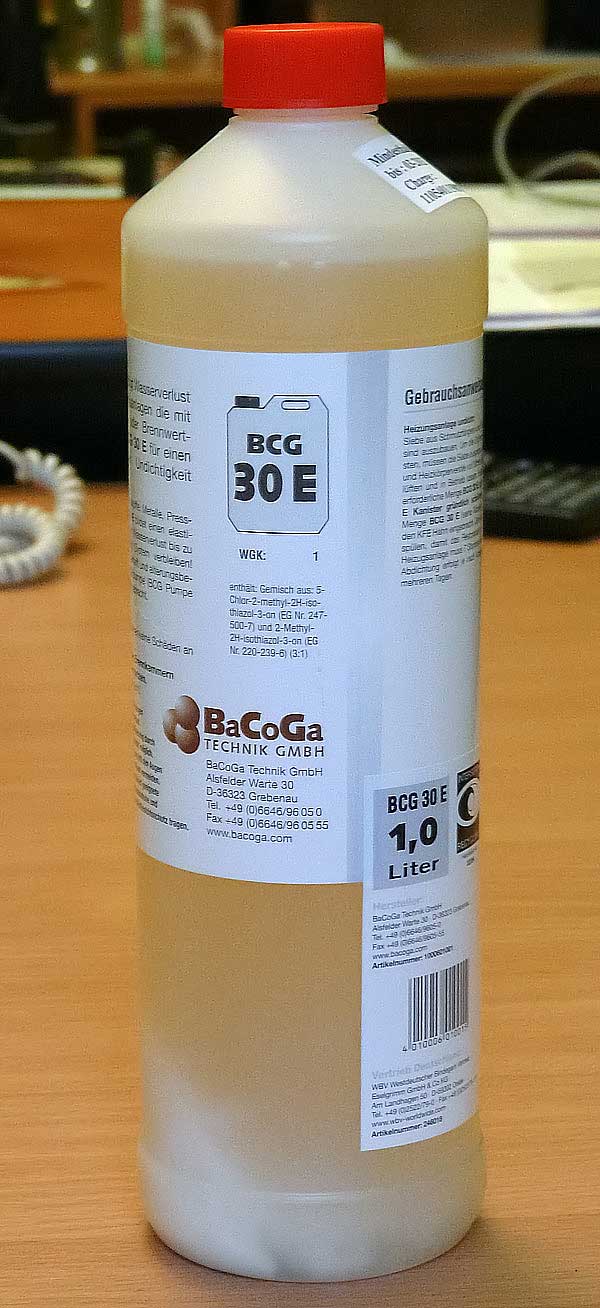

German sealant liquid type BCG-24 is used to eliminate leaks in heating systems

When using liquid sealant for pipes and radiators it is important to maintain the correct concentration. On average, its values range from 1:50 to 1:100, but it is desirable to determine the concentration more accurately, since factors such as:

- coolant leakage rate (up to 30 liters per day or more);

- the total volume of water in the heating system.

If the volume does not exceed 80 liters, 1 liter of sealant will be enough to fill the heating system. But how to more accurately calculate the volume of water in the system? You need to calculate how many meters of pipes and what diameter were laid in the house, and then enter this data into one of the online calculators. To the resulting volume of pipelines, you must also add the passport characteristics of the volumes of all radiators and the boiler.

Preparing the heating system

- Dismantle or cut off all filters with taps so that they are not clogged with a viscous solution of sealant for heating systems;

- Unscrew the Mayevsky tap from one radiator (the first in the direction of the coolant) and connect a pump to it (such as "Kid");

- Start the heating system and let it warm up for an hour to a temperature of 50–60 ° C at a pressure of at least 1 bar;

- Open all valves on pipelines and radiators for free passage of sealant through them;

- Remove air from the entire system, including radiators and circulation pump.

Sealant preparation

-

It is possible to pour liquid sealant into the heating system, including using a manual pressure pump

Drain about 10 liters of hot water from the system into a large bucket, most of which should be used to prepare the sealant solution, and leave a few liters for subsequent flushing of the pump;

- Shake the canister (bottle) with sealant for radiators and heating pipes, then pour its contents into a bucket;

- Rinse the canister thoroughly with hot water so that all the sediment remaining in it gets into the prepared solution.

Sealant solutions for heating systems must be prepared immediately before use so that the liquid does not come into contact with atmospheric air for too long.

Pouring sealant

Liquid sealant for heating systems must have time to mix with the coolant before it reaches the boiler, so it is more expedient to fill it into the supply:

- Introduce a solution of liquid sealant into the system using a pump;

- Pump the remaining hot water through the pump so that absolutely all of the sealant residue enters the system;

- Release the air from the system again;

- Raise the pressure to 1.2–1.5 bar and maintain the system operating cycle for 7–8 hours at a temperature of 45–60°C. This period is needed for the complete dissolution of the sealant in the coolant.

Liquid sealant for home heating system and pipes

Usually, with the correct and high-quality installation of heating systems, a substance such as a sealant for a home heating system is used. Such substances belong to the category of vulcanizable. These are polymer components that serve to seal joints between surfaces.

Sealants for home heating system

Types of sealants

To date, the highest quality and most common is a universal heat-resistant sealant for heating pipes. Usually, the owners of heating systems use it, since this substance has all the necessary qualities for an insulating material. It is also used in everyday life and in industry. This is a viscous mass that can withstand high temperatures and quickly hardens.

Silicone sealant is also common. It is resistant to moisture and mold, as well as to temperature extremes. Such a sealant is often used in everyday life to seal the seams of various surfaces.

Silicone sealants for heating pipes

Less common types are urethane and polysulfide sealants for home heating systems. But such sealants may not be used everywhere, so you need to carefully study their characteristics and capabilities before use.

Very often you can find the use of such a sealant as heat-resistant. Such a sealant is able to penetrate even those gaps that are hard to reach.

Also, this sealant has increased ductility and excellent elasticity. Heat-resistant sealant for the heating system is used to glue metal, rubber and other materials. The main task of this substance is that it protects individual elements of the heating system from moisture.

The quality of the heat-resistant sealant is monitored by specialists who constantly test it, checking for strength and extensibility.That is why such a sealant perfectly fulfills the functions assigned to it, it is resistant to various factors - sunlight, water, and it is practical and easy to use.

We also note that heat-resistant sealant is currently produced in a wide range of colors and by a variety of manufacturers.

Of course, it is better to give preference to proven brands that guarantee quality.

How to choose a sealant for heating?

Chimney Sealant

The main criterion for choosing a sealant for heating systems is resistance to deformation. A good option is silicone sealant for the heating system (acidic or neutral). If you purchase an acrylic sealant, then only one that will be resistant to high temperatures.

There are sealants that can withstand temperatures above 1000 degrees Celsius. They are commonly used to seal targets and cracks in fireplaces, around chimneys and pipes.

Do not try to use one universal sealant for everything. It is better if these are specialized formulations for specific materials.

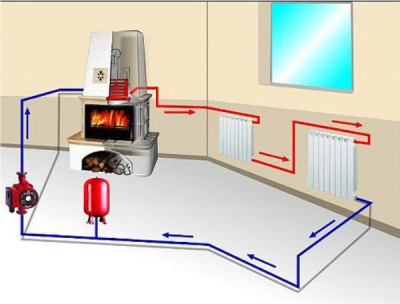

Fixing leaks in the heating system

Many owners of heating systems will sooner or later find out what a leak problem is. Using a sealant for heating, you can easily get rid of it.

First you need to fill the system with water as much as possible, remove all air from it and warm it up to operating temperature. Mud and other filters are preliminarily removed. Mix the sealant well until smooth and pour into a container convenient for you.The volume of water that corresponds to the volume of sealant must be drained from the system. The sealant must be pumped into the system using a pump that is connected to any available inlet to the system. The pump hose is connected, then the valve opens and the pump turns on. After pumping the sealant, the system must work for at least 7 hours with a temperature of 45-60 degrees Celsius and a pressure of 1.1-1.6 bar.

Remember that when working with a substance such as liquid heating sealant, you must follow all the safety precautions that are standard for working with chemicals. If suddenly this substance gets into your eyes or on your skin, then wash it off with plenty of water. If the sealant gets inside - rinse your mouth and drink plenty of water, then call a doctor! Do not store sealant near acid.

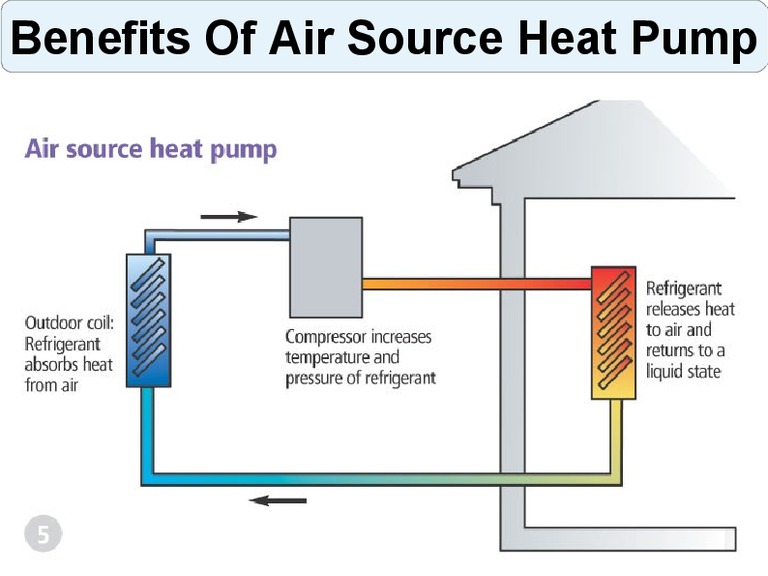

About the pros and cons of glycol antifreeze

The main advantage of artificial coolants based on glycols is the preservation of the liquid phase at low temperatures. We list other positive aspects from the use of antifreezes in closed water heating systems:

- heat carriers do not contain calcium and magnesium salts, which form scale inside heat exchangers;

- due to the penetrating ability of glycols, the effect of lubrication of moving parts occurs, ball valves and thermostatic valves do not turn sour, fittings last longer;

- the boiling point of antifreeze 103-106 ° C postpones the moment of vaporization and airing in case of overheating of the solid fuel boiler;

- when the temperature falls below freezing, the glycol solutions turn into a gel mass.

When frozen, glycol mixtures form a slurry that is not capable of breaking pipes and heat exchangers

Let's clarify the last 2 points.Ordinary water, often poured into the heating system of country houses, begins to boil at 96-98 ° C, actively releasing steam. If the circulation pump is on the TT-boiler supply, the vapor phase enters the chamber with the impeller, the water pumping stops, the boiler overheats completely. A higher boiling point of antifreeze will allow you to push back the moment of the accident.

Unlike water, freeze-hardened glycol does not expand or rupture pipe walls. In the event of freezing, the only unit affected is the forced circulation pump. The crystallizing gel will jam the impeller and burn out the motor.

Unfortunately, non-freezing substances have plenty of disadvantages:

Ethylene glycol is poisonous and requires careful handling and disposal of the solution. Glycerin and polypropylene glycol are harmless.

The heat capacity of the "anti-freeze" is 15% less

To deliver the required amount of heat to the batteries, the flow rate of the liquid will have to be increased.

The viscosity of antifreeze creates additional hydraulic resistance. You will need a more powerful and expensive circulation pump.

Good fluidity is a double-edged sword. Glycols penetrate through the slightest leaks, from where plain water will not flow.

Heat carriers and additives decompose during operation, losing their frost-resistant properties and precipitated in flakes. The maximum service life of 1 gas station is 5 years, then the heating is flushed and replaced.

When using antifreeze, many manufacturers of gas boilers deprive the purchased product of the warranty.

Glycol fluids are not compatible with electric boilers.Instructions for the use of various antifreezes categorically do not recommend filling systems that work in conjunction with electrolysis heaters with antifreeze. That is, for electrode boilers of the Galan type, a special coolant developed by the specified company is needed.

Under rare circumstances, antifreeze is capable of releasing flammable gas that breaks through an automatic air vent. Example: the heat source is an electric boiler, the heaters are aluminum radiators made in China. Heating the glycol causes a complex chemical reaction and gas formation. The fact is shown in the video:

What to look for when choosing?

- Heading to the store, you should already have an idea for what kind of work you need a sealant. This is the first thing the seller will ask you.

- In addition, try to study in detail the instructions (it should be on the package) of what you will be offered.

- Determine whether the composition is for interior or exterior use.

- There should be an indication of the type of work (plumbing, roofing, etc.).

- Sealant properties - whether it has heat resistance or elasticity.

- Check if it matches your color.

- If there is an indication on the packaging that it belongs to the professional group, please note that it is more difficult to work with this, additional knowledge of the features is required.

- Is it possible to use a pistol.

How to use liquid sealant

For general information, you can consider the process of pouring sealant into the radiator

Here it is important to follow certain instructions:

- The system should be shut off and the coolant drained.

- Then you need to dismantle the damaged heater.

- Pour some hot water into the bucket, about 5 liters.

- To this water is added a concentrated sealing compound and mixed well, trying to achieve a uniform consistency.

- The finished solution is poured into the heating device using a purge pump or funnel.

- If a pump was used during the filling process, then it is necessary to additionally prepare several liters of hot water in order to subsequently rinse the parts of the pump that come into contact with the polymer composition.

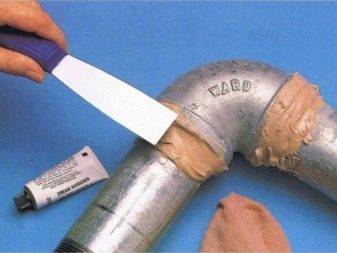

- Next, close the top and bottom plugs on one side of the radiator, and on the other side, these holes are left open. The prepared sealing compound is poured into one of these holes.

- The heating device is turned, trying to deliver the sealant to the damaged area.

It is very important to use the solution immediately after preparation, since during the polymerization process, which begins after a while, a dense film forms on the surface.

You can see the process of filling the damaged area with sealant for the heating system after 3 days.

Features of heat-resistant sealants

A sealant is a special composition that can create a durable insulating layer on the surface to be treated or between parts. Thermal sealant is the most reliable means, and the requirements for it are very serious. The material is made on the basis of heat-resistant silicone - a polymer, which is a transparent elastic mass. Also, other substances are introduced into the composition that enhance the operational properties of the sealant (minerals, metal powder, etc.). There are also high-temperature epoxy adhesives - two-component products, the components of which are mixed before application.

Applications for sealants

Materials are widely used in everyday life, industry. Sealants are involved in the installation of heating pipes, cold and hot water supply pipelines, because they withstand not only heating, but also temperature extremes down to minus. heat resistant sealants suitable for ovens, chimney in the bath, sauna, private house. A special automotive composition is useful in strengthening and sealing gaskets, engine seams, headlights, a car muffler, and an exhaust pipe.

With the help of sealants, it is possible to repair heating household appliances - a kettle, a hob, an oven, and even a moonshine still. Usually, a food-grade thermal sealant is used for this purpose, which is harmless in contact with food, taking into account the heat. The same type of material is used in the repair of equipment in food production, factories, catering establishments.

Other applications for sealants:

- protection of stainless steel products, alloys from moisture penetration;

- prevention of damage to complex equipment operating in the air, aggressive conditions;

- restoration of electrical engineering, radio electronics for pouring elements and electrical insulation;

- protection of car parts from corrosion;

- sealing of welded seams of gas boilers;

- repair of fireplaces, ventilation, fire structures.

The main properties of sealants

Silicone sealant is a heat-resistant material, the ability to withstand high temperatures is its hallmark. Conventional heat-resistant sealants are used up to +350 degrees, but there are compounds that can withstand +1500 degrees, therefore they are considered refractory. Materials are non-flammable, non-flammable, non-explosive.

Other properties of sealants:

- the ability to withstand high loads without loss of sealing qualities;

- plasticity and elasticity (due to this, the seam does not crack after drying);

- good adhesion with any materials (subject to a dry surface at the time of application);

- moisture resistance;

- long service life and long storage period;

- non-toxic, safety for humans, the environment and animals.

Almost any sealant is oil-resistant or gasoline-oil-resistant - it does not deteriorate from contact with petroleum products. Also, most products are immune to the action of weak acids, alkalis, other chemicals and household chemicals.

The negative properties of sealants include the fact that they do not adhere well to wet surfaces, the level of adhesion drops sharply. Also, before use, the base should be treated from small debris, otherwise the seam will not serve for a long time. Some products do not harden quickly, and several days will pass before the moment of operation. The sealant cannot be painted, the paint does not adhere to it, although there are colored products (red, black, and others) on sale. It is not recommended to seal too large gaps with thermal sealant, since the material may not harden in depth.

Additional features of sealants

Thermal sealants also have a number of related properties, which are sometimes no less in demand. So, most of them are resistant to UV radiation, therefore they are suitable for outdoor work, for example, for sealing a defect in a chimney, roof passages.Sealants are frost-resistant, which makes them indispensable for the repair of baths, stoves and fireplaces in country houses that are not heated all year round. The compositions after application do not crack during vibration, due to which they are used for the restoration of machinery and equipment.

Sealing threaded connections

Anaerobic sealants

Anaerobic sealant represents a separate group. Resistance to temperature fluctuations, mechanical stress, good leakage neutralization made it possible to use an anaerobic solution even in rocket science. In heating systems, the main advantage is the resistance of the substance to compounds containing acid and alkali. Due to this property, the anaerobic sealant in the system does not interfere with cleaning with chemical compounds and the use of various heat transfer fluids.

In a liquid state, an anaerobic solution exists only in the presence of air. Being in a closed place between the parts, it easily fills all the remaining free space and quickly hardens. The latter quality gives the reliability of threaded fixation and relieves from great physical effort when screwing parts.

Sealant selection

Maximum sealing when assembling sewer, heating or plumbing systems can only be achieved by using the right sealant.

For the assembly of pipelines, two types of sealants are used:

- silicone;

- acrylic.

Silicone sealants

At the heart of silicone sealant is silicone rubber, to which are added:

- compositions to increase adhesion;

- compositions to increase strength;

- impurities to accelerate vulcanization.

Sealing compound based on silicone

The advantages of silicone-based sealants are:

ease of use. The sealing material is applied to the surface of the pipe with a special gun or squeezed out by hand (small packages of material);

Easy sealant applicator

- durability. Due to such qualities as elasticity, excellent adhesion, resistance to deformation, water resistance and heat resistance, the service life of silicone sealant is 15 - 20 years;

- wide scope. Silicone-based sealants can be used in the assembly of pipelines from various types of pipes. The sealing composition is suitable for the construction of an internal or external pipeline, as the sealant is resistant to aggressive media and direct exposure to sunlight.

Among the disadvantages of the sealing material can be noted:

- seams treated with sealant cannot be coated with paint, since its composition negatively affects the sealant, reducing the period of operation;

- it is not recommended to use a sealant during the construction of a pipeline in cold weather, since the low temperature regime significantly reduces the vulcanization (hardening) period of the composition;

- sealant must not be used on pipes larger than 4 inches (100 mm) in diameter.

To increase strength, silicone sealant can be used in combination with linen thread.

Silicone sealants, depending on the chemical composition, can be:

- acidic. This type of sealing composition is not suitable for sealing pipes made of non-ferrous metals, as a chemical reaction occurs between the materials;

- neutral.

Acrylic sealants

For sealing pipes for water supply, heating, and so on, a separate type of acrylic sealant is most often used - anaerobic.

Anaerobic sealant is used for sealing threaded connections. When contact with metal, the sealant hardens. The final polymerization of the substance, which gives strength to the junction, is carried out after the assembly of the pipeline system assembly without air access.

Sealing compound for threaded connections

The advantages of anaerobic sealant for heating systems, sewerage, water supply and so on are:

ease of use. The sealing composition is applied to the thread (flanged connection) without the use of additional devices;

Use of sealant

- resistance to vibration, which allows extending the service life of the threaded connection by 4-5 years;

- resistance to high temperatures and high pressure;

- no need to use additional sealing materials;

- additional protection of the metal surface of the thread from corrosion.

However, this type of sealant has its drawbacks, which include:

- Can only be used on metal surfaces. For plastic pipes connected to a socket, such a composition will not work;

- dismantling difficulty. If a section of pipeline needs to be replaced, then preheating will be required to separate the pipes and remove the sealant;

- the possibility of using sealant for pipes whose diameter does not exceed 8 cm;

- high price.

Depending on the strength of the resulting joint, all anaerobic sealants are divided into three groups:

- standard strength.The composition is used in the manufacture of a pipeline with low pressure and not subject to vibration;

- medium strength. Such a sealant is used for the construction of a pipeline with average operating parameters;

- increased strength. Used to seal joints under high pressure and do not require constant dismantling.

For the construction of domestic pipelines, it is sufficient to use sealants of standard or medium strength.

When choosing an anaerobic sealant, it is also worth considering the composition of the mixture and the diameter of the pipes, which may vary depending on the product line or manufacturer.

Selection of sealant according to parameters

Recommendations for use

To begin with, remember that each manufacturer has its own instructions for applying a sealant.

But there are a few general principles and rules that are found on almost all sealants.

- First, determine if there is a leak in the radiator. This can be done using a special sensor, in a puddle under the car, or in a gradually falling coolant level;

- In case of leakage, turn off the engine and wait for it to cool;

- Next, open the radiator cap and start gradually pouring or pouring the agent. Here fully rely on the recommendations of the manufacturer;

- After that, the engine starts and runs for several minutes;

- Now turn off the engine again and check if the leak is gone or not;

- If used correctly, the leak should be plugged.

But it happens that the sealant does not give any result. This happens due to too large a hole, or in violation of the technology for using the product.

How to fix leaks in hidden pipes

For quick sealing of hidden heating pipelines, mustard powder or ready-made special sealant is used. The available substance is added to the expansion boiler and the system is put into operation. After a few hours, the sealant (or mustard powder particles) will seal the damaged area, eliminating the leak.

Such repairs will give time to prepare a complete restoration of the heating circuit. However, if a large damage has formed in a hidden area, then an internal sealant is unlikely to help. The heating circuit will have to be drained and repaired immediately.

Affordable repairs begin with proper design and installation of the heating system. All detachable connections must be accessible for inspection. Hidden areas should be made of high-quality, durable materials, not have detachable connections. Timely replacement of worn-out equipment will allow you to live in peace in cold weather, enjoying warmth and comfort.