- Copper faucet connection: aesthetics and reliability

- The structure and service life of flexible piping

- Flexible water supply: how to choose the right one in the store

- What are the characteristics of a flexible faucet hose?

- Pros and cons of flexible piping

- Common Problems

- Security measures

- Mounting

- Installation with metal-plastic pipes

- Security measures

- Tap Hard Line Video

- Kitchen faucet installation

- Assembly

- Installation on the sink

- Washing installation

- Connecting hoses and siphon

- Types and designs

- Benefits of bellows liners

- Cons of bellows hoses

- How to choose the diameter of a flexible eyeliner, taking into account its type

Copper faucet connection: aesthetics and reliability

There are only two ways to connect the mixer with copper pipes. Copper tubes are very flexible and the master who deals with this type of connection will easily make the device on site. For such manufacture, connecting parts are required, namely: accessories nuts, rings and adapters

And when choosing additional components, it is important to consider the installation method. The installation method can be either threaded or crimped.

Connections with fittings with ferrules do not differ in complexity from the connections of metal-plastic pipes with fittings, but require a little more effort

Connections with fittings with ferrules do not differ in complexity from the connections of metal-plastic pipes with fittings, but require a little more effort

Well-known manufacturers produce products with a set of copper tubes. And in this case, only the lower connections need to be made. At the same time, you can install a swivel mechanism for convenience. Such an eyeliner has an aesthetic appearance.

Copper plumbing can be used for bathroom sinks, kitchens and even toilets. The grohe brand is in great demand, its installation does not take much time, and the eyeliner itself can be either open or closed.

To make a final decision about whether you need a hard eyeliner, you need to familiarize yourself with the disadvantages and positive aspects of such an eyeliner and determine what is best for you.

Positive aspects of hard eyeliner:

- Compared to a flexible analogue, such an eyeliner is elastic;

- The term of use is more than 20 years;

- Ease of assembly and installation;

- The material is made with anti-corrosion quality;

- Reliable eyeliner;

- The smoothness of the coating, which does not allow dirt to accumulate;

- Resistance to chemical and mechanical stress, the ability to withstand pressure drops and high temperatures.

The 7 advantages of such an eyeliner are listed above, but, despite the fact that the number 7 is happy, such a connection also has disadvantages.

The dispute about the installation of a rigid or flexible type of eyeliner is a minus. The complexity of this installation lies in the limited movement of the eyeliner, which sometimes needs to be moved for another installation. The rigid method is not subject to change and does not bend, and this does not allow for optimal connection.

To perform hard eyeliner on your own and without any problematic moments, it is enough to perform work according to the rules and recommendations of specialists.

The procedure for installing a hard liner should be as follows:

Before starting, you need to choose a place where the sink with a mixer will be placed.

It is necessary to prepare a wall for placing pipes. To do this, mark the placement of pipes on the wall and make strobes. Installation of pipes can be done internally, that is, in the wall or externally on the surface of the wall.

We make preliminary marks in the place where the knee of the system will be installed.

We assemble pipes

This stage is most often performed by specialists, but if you are still a fan of independent work, then it is important not to forget to wind a fum tape or other winding on the pipe thread to remove possible leaks.

We proceed to fixing the old mixer in order to be completely convinced of the correct location of the system. Almost all mixers have the same distance from the seat to the required connection.

We double-check the work performed for smoothness, evenness and correctness.

Next, we close the strobes, with a solution

But at the same time, it is important to ensure that the solution is enough to seal the tile.

After the solution has dried, you can dismantle the old mixer and install a new one. It happens that the old mixer is not very smooth and does not turn out. To dismantle such a mixer, you just need to saw it off, leaving a small area for eversion.

To connect a new faucet, you can use angle valves based on a flare nut, which makes it possible to provide a sealing gasket.

And at the end, it is necessary to check all connections, namely their reliability and for leaks. After this check, you can proceed with the installation of tiles.

The most common mistake when installing hard piping is incorrectly installing a rubber gasket. The gasket must be positioned across the taper of the fitting and the flat washer. To correct this error, you can apply a sealant to seal the valve.

It happens that when installing a hard connection, it is necessary to bend the pipe, and for this, use a pipe bender. If you decide to bend pipe without pipe bender, then this leads to a bend in the pipe, less water flow through it and can even lead to a leak.

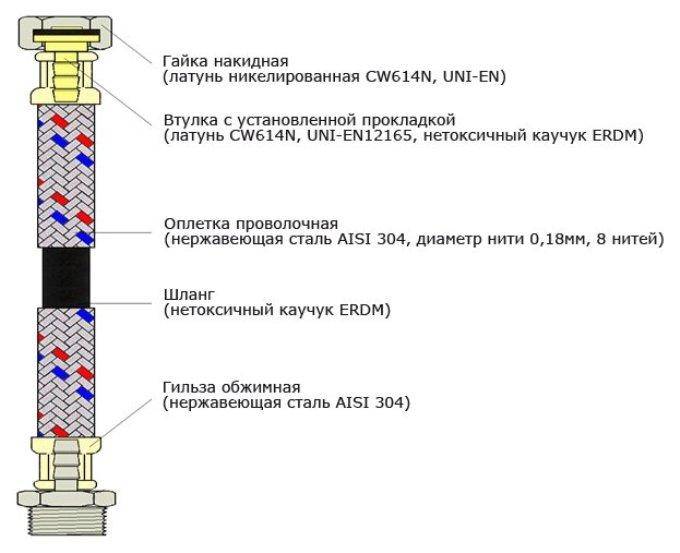

The structure and service life of flexible piping

Many manufacturers use non-toxic rubber hose during the production of high-quality flexible braids, which makes them absolutely safe for health. In low-quality eyeliners, technical rubber is used, which has a peculiar smell. The rubber hose braid can be made of galvanized steel, aluminium, stainless steel or nylon. As a rule, eyeliners covered with aluminum braid fail much earlier than their counterparts - on average after 36 months of operation. This type of eyeliner is designed for operating pressure up to about 5 atmospheres. In the case of braids made of galvanized steel, the situation is much worse. If the first can last up to 3 years, then from galvanization, it will fail after a few weeks of operation.

Metal eyeliners (aluminum and galvanized) are afraid of condensate. When it becomes covered with condensate in a room that is poorly ventilated, it undergoes oxidation and the reinforcement eventually disappears.As a result, the hose explodes. Because of this, the owners of the apartment have to make unplanned repairs to the bathroom, and these are additional financial costs and wasted time. To protect yourself from such unexpected "surprises" you need to approach the choice of material wisely. It will be much easier to overpay a little for quality products than to pay a lot of money for repairs later. This rule applies not only to eyeliners, but to all repairs.

Flexible water supply: how to choose the right one in the store

The easiest way to choose a flexible hose, like any other product, is to read the label that comes with the product.

In addition, you should pay attention to the weight of the product. Clearly light eyeliner can be braided with aluminum, which significantly reduces its service life.

The material of the fittings is also a mandatory check point. If they are made of silumin, then such an eyeliner is not worth your attention, since already at the installation stage the connecting elements can crumble in your hands:

The same applies to plastic fittings:

The flexibility of the eyeliner is one of the main criteria for its quality, otherwise the tube will quickly become unusable

Pay attention to the quality of the crimping of the fittings, the material of the sleeves (only stainless steel is used in high-quality specimens) and the fit of the connectors. The photo below shows an example of a sleeve without crimping:

After installation, such an eyeliner will soon simply disconnect from the pipe or mixer:

Do not forget about the thickness of the union nuts.The thinner the walls of the metal nut, the more likely it is to deform. The weight of the product can also tell a lot about the quality of nuts, if the walls of the nut look thick enough, but the product itself is very light, then you most likely have a plastic fitting. If it is visually difficult to determine the material of manufacture of the nut, then it can be scratched a little. The color that appears on the scratch will tell you what material we are talking about: yellow is a sign that the nut is brass, and the absence of a color change or darkening of the nut indicates that you have silumin in front of you. In the photo below, the silumin nut is the third from the left:

Quality samples should not have a characteristic rubber smell. If one is present, then the product uses cheap technical rubber, known for its toxicity. Usually, in the most inexpensive mixers, this flexible connection option comes with the product. The photo shows an example of the reaction of such rubber to a fracture:

If seals are made of the same rubber, then they will soon become unusable:

Below is an example of a quality seal after a long period of operation:

Read the material on the topic: How to choose a water supply

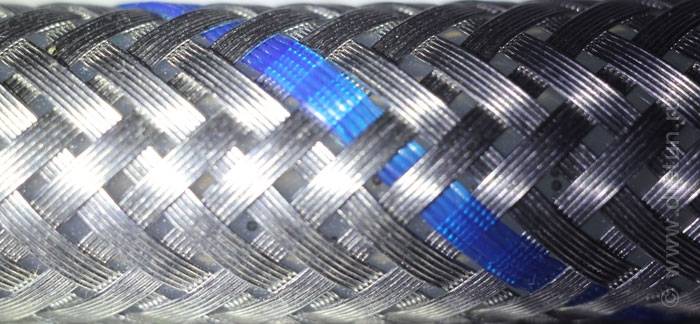

For what purposes this or that eyeliner serves, you will be prompted by the color of the tape integrated into the sheath: blue for cold water, red for hot water, and both colors are a sign of the versatility of this type of flexible eyeliner:

If you did not find any multi-colored ribbons on the flexible eyeliner braid, then you have a very cheap copy, which you should refuse to buy:

In high-quality flexible hose models, the nuts are already equipped with good gaskets and do not require additional sealing.

When installing flexible piping, you need to follow a simple rule: do not tighten the hose. It is better to immediately determine the approximate length of the hose and, if necessary, purchase additional corners for the correct installation of the flexible hose. The photo above just shows an example of an unwanted bend in the liner, which could be solved by using angles during installation or by choosing a longer hose.

Do not overtighten the union nuts, as the seal (gasket) can easily be torn and leakage will immediately occur in this place.

Do not make sharp bends of the eyeliner during installation. In the situation shown in the photo below, it is better to use a longer hose, making a larger loop with a smaller bend radius:

What are the characteristics of a flexible faucet hose?

Pros and cons of flexible piping

The advantages of a flexible hose for a water mixer include the following characteristics:

-

safety in use;

-

reliability (provided that a quality product is installed);

-

better practicality than hard liner and generally more comfortable to use;

-

long service life;

-

installation and dismantling of a flexible faucet hose is very simple and is carried out with two open-end wrenches;

-

the flexibility of the eyeliner allows it to be displaced relative to the mixer without fear of damage;

-

the possibility of installation in a designer interior, since it is convenient to hide the flexible hose for the mixer during installation.

Flexible piping for faucets could be an ideal way to connect, if not for a number of disadvantages:

-

twisting, tension and strong bends will lead to deformation of the flexible liner, which is fraught with leakage;

-

use near open fire is not allowed;

-

flexible hose for the mixer is not designed to work with very hot water;

-

metal braid can corrode over time;

-

if a bellows flexible hose is used for the mixer, then when opening water taps in different rooms, a rumble will be heard in such a hose.

Common Problems

Flexible faucet hoses can loosen over time, leading to some problems. There are three reasons why flexible liner can fail:

-

poor or weak crimping of the flexible hose braid;

-

flexible hose for the mixer has nuts, fittings, bushings and other connecting elements of inadequate quality;

-

low-quality rubber and braided flexible hose for the mixer.

These breakdowns usually occur when a flexible faucet hose is purchased from an unverified seller or supplied by an unknown manufacturer.

Manufacturers who are interested in their customers will not go for the use of cheap components or low-quality raw materials. On the contrary, the quality of their products will be constantly improved, specially treated rubber will be used for hoses, connectors will be made of high quality brass, and the braid will be made of a material that is resistant to corrosion and water.

A flexible connection for a modern-type mixer eliminates the problems of older analogues, which had one weak point - seals. Modern flexible piping does not have seals, which have been replaced by fittings.

Read the material on the topic: Mixer design: we understand the intricacies of the issue

Security measures

Do not forget that the flexible hose for the mixer is under constant load, as it is located in the working area of the pipeline.

Therein lies the potential danger. Leaving your home for a long time, you may find a small (or large) flood upon your return, as the flexible piping has burst due to a pressure surge. The consequences of such an event can be the saddest.

To prevent such situations, it is necessary to turn off the water supply in the house. This will relieve the flexible hose for the mixer from the load, and eliminate the possibility of its rupture and subsequent flooding of everything around.

Despite their obvious advantages, such unpleasant situations reduce consumer confidence in flexible faucet hoses. However, it is worth noting that, as a rule, products of low quality and from unverified suppliers fail.

Thus, you should not save on a flexible faucet connection when equipping a water supply system in your home. If you have chosen a flexible faucet hose, the characteristics of which leave much to be desired, then only you are responsible for its operation and condition. By spending a little more on a flexible faucet hose, you can be sure of its reliable service.

Mounting

You can install the bellows liner, as we have already noted, on your own. To do this, follow the simple instructions.

- Provide easy access to the places where the eyeliner attachments are provided. If necessary, you will quickly carry out repairs, carry out preventive measures.

- Inspect the product, make sure that it is intact, that there are no defects. Even if you bought a normal eyeliner in a store, problems may arise during transportation or during storage.

- Check how well the end fitting is crimped. Many Chinese low-end products only look durable, although in reality the quality leaves much to be desired.

- Read the installation instructions supplied by the responsible manufacturers. You also need to know about the outer diameter of the eyeliner, which appears in the passport.

- In no case do not overtighten or unscrew the eyeliner during installation and upon its completion. The product should be mounted as evenly and accurately as possible.

- After verifying the consistency of the new liner, turn off the water at the main valves. Unscrew the old eyeliner, install the purchased items. To do this, just use a simple key.

- Start the system. Make sure there are no leaks. To do this, leave the water on for a while. As a rule, factory seals cope with the task of sealing, but an extra layer of sealant has not hurt anyone yet.

- Another point - do not use gas wrenches. They are theoretically suitable for mounting the liner, however, they can damage the union nuts. It is unlikely that you will want to eliminate the consequences of such troubles.

Installation with metal-plastic pipes

Such pipes carry out both open and hidden installation.

When open - you can use press fittings (not collapsible) and clamping (collapsible).

When hidden - only press fittings.

This is due to the fact that clamp fittings weaken over time, and twisting with a wrench is required.

Metal-plastic pipes are sold in coils of great length, therefore, when laying pipes under a screed or plaster, it is advisable to use a single pipe.

Metal-plastic pipes are sold in coils of great length, therefore, when laying pipes under a screed or plaster, it is advisable to use a single pipe.

Installation of connections using threaded fittings.

Pipes and press fittings.

Security measures

Be sure to take into account the fact that the eyeliner is under constant load. They occupy the working area of the pipeline. This leads to potential danger.

If you are not at home for a long time, the water pressure may increase, the product will not withstand the stress, it will burst. As a result, you will flood yourself and your neighbors. The consequences are difficult, long and financially costly to eliminate.

This leads to potential danger. If you are not at home for a long time, the water pressure may increase, the product will not withstand the stress, it will burst. As a result, you will flood yourself and your neighbors. Eliminating the consequences is difficult, time-consuming and financially costly.

As you can see, flexible eyeliner has its undeniable advantages, but it is also characterized by disadvantages. In fact, the main reason flexible systems are not fully trusted is because many products are of poor quality.

An attempt to save on the arrangement of the water supply system often entails much more serious financial losses. It makes no sense to blame the manufacturers of cheap eyeliners, since you alone are responsible for repairing your home. Do not spare money, buy a quality product right away. The eyeliner, in turn, will answer you with a long and reliable service.

Tap Hard Line Video

In the video, the flexible hoses of the mixer are replaced with metal ones:

Despite the fact that due to the cheapness, practicality and ease of installation, in most cases flexible versions of the eyeliners are chosen, the rigid one will always be in demand. This is due to its indicators of reliability and durability.

At objects of increased responsibility, in places with large and sharp pressure drops, for example, in the basements and first floors of buildings, for trouble-free operation, preference is given to a metal rigid eyeliner. Such products are more expensive than flexible ones, but even their most budgetary options win in terms of price and quality.

Kitchen faucet installation

Replacing the faucet in the kitchen is nearing completion. Now we assemble the crane and install it in place. It is much more convenient if the work can be carried out on a removed sink. If this is not possible, all manipulations will have to be carried out reclining in the closet. Approximately as in the photo.

Not the most comfortable position

Assembly

First, we fasten flexible hoses to the mixer. They are screwed in by hand, then tightened a little with a key - no more than 2 turns.

We screw the flexible hose into the holes on the mixer body, tighten it slightly with a wrench

Now you need to put a rubber gasket on the body, which seals the junction of the mixer and the sink surface. This rubber ring of decent diameter is included in the kit. It is pulled through the installed supply hoses, placed on the body.

Install gasket on body

In modern kitchen faucets, there are two different forms of attachment to the sink. The first - with the help of a nut - you saw in the part where it was about dismantling the mixer. It's just an "older" system. The second provides for the presence of rods and spacers-clamps in the form of a horseshoe. The rod is usually one, but there may be two.If there are such rods, they are screwed into the appropriate socket. If a nut is screwed on it, it is removed.

Rod for additional fixation

Installation on the sink

Now the kitchen faucet can be installed on the sink. First, flexible hoses are inserted into the hole, then the body is placed in the center of the hole. Further actions depend on the type of fastener. If this is an ordinary nut, they simply tighten it, trying not to overtighten it.

The nut is screwed onto the body

If it is a model with rods, the appearance is different, although the meaning is the same. First, the gasket is put on (it is also in the shape of a horseshoe), then the pressure plate. Next, the nuts are screwed onto the rods. The nuts are slightly tightened with a wrench. TODE nothing complicated.

Faucet attachment with rods

Turn the sink over and turn on the faucet. He must be dead. There shouldn't be any loopholes. If there is movement, tighten the mount.

Washing installation

Now the sink with the mixer installed on it is placed in the prepared place. First, a silicone sealant is applied from the back of the sink around the perimeter (not acrylic - it quickly turns yellow). Then the sink is installed in place, the fixing bolts are tightened.

Preparing the sink for installation

Then everything is simple: put in place, align with the edges of the table, tighten the fasteners. It is made in the form of petals that attract the sink to the countertop when you tighten the nuts. The sink must stand firmly, without shifts.

Connecting hoses and siphon

With a siphon, everything is simple - they pulled the corrugated hose to the nozzle, tightened the nut by hand until it stops. All. Do not use the keys - everything is made of plastic.

With the connection of the water supply is not much more difficult. Just be sure not to confuse the place of connection of cold water. Its entrance is on the right.After making sure that there is a rubber gasket in the union nut of the flexible liner, we bring it to the pipe, tighten the nut as much as possible with our fingers. Then we take the key and tighten it one or two turns. Do not pull hard - you can cut through the gasket and then the connection will flow.

But what about tow, winding and paste? When using hoses of normal quality, they are not needed. Connection without them is reliable and tight. It will be possible to rewind a lot if, after a test run, drops of water appear from under the nuts. But this shouldn't be. There is no need to wind tow or fum-tape just like that. Extra time and extra pressure on the union nut.

After connecting to the hot pipeline, we can assume that the independent replacement of the faucet in the kitchen is over. It remains to turn on the water and check if everything is working properly and if the connections are leaking. To do this, the joints are wiped with a dry cloth, and then carried out several times by hand.

Types and designs

rubber product

There are three types of flexible eyeliners, which differ in material.

- Polyethylene hoses for water. Their advantage is high flexibility.

- Rubber hoses that are braided with stainless steel, nylon or reinforced with aluminum.

- Flexible stainless steel piping (corrugated tube).

Each type of eyeliner has its pros and cons. Aluminum reinforced rubber hoses will last up to three years. The boundary pressure is 0.5 MPa, and the temperature resistance is up to 80 degrees. The main disadvantage of aluminum reinforcement is poor corrosion resistance. The hose covered with stainless steel is much more reliable than the previous one. It can withstand pressure up to 1 MPa, and the maximum temperature is 95 degrees. Such models will last up to ten years.Rubber hoses braided with nylon can be used for up to 15 years, withstand pressure up to 2 MPa and temperatures up to 110 degrees. Polyethylene liners, despite the strict operating temperature limits, are considered reliable due to their high corrosion resistance.

There are two types of bellows hoses - seamless and welded. The wall thickness of the eyeliners is about 0.3 mm in both cases. The hoses come with union nuts, which are made from the same steel as the hoses themselves. In rare cases, the material is different and the nuts may be brass or bronze with a chrome or nickel finish. Connecting nut diameters can be 1.2 inches, as well as ½, 3/4, 11/4, 11/2 inches. The allowable pressure ranges from 10 to 20 bar.

Flexible design

Flexible connections for the mixer are mounted using a retaining ring. This is a special additional element that ensures high-quality joining of the fold with a pipe or fitting during installation.

Brass or steel adapters are used to properly mate the bellows pipe to the fitting equipment. They are especially necessary if the cross section of the pipes differs from the diameter of the liner.

An important and reliable part that is in the bellows eyeliner is a sealing gasket. It can be made from fluorine-containing polymer, copper or paronite. This element can withstand the same pressure as the tube itself, so its minimum thickness must be at least 2.5-3 mm.

Stainless steel is a high-quality and reliable material that will serve for many years. It is resistant to corrosion, aggressive chemicals, temperature extremes.The service life of bellows connections reaches 20 years, and the operating temperature can vary from -40 to +200 degrees. Such products withstand pressure up to 3 MPa.

Benefits of bellows liners

Advantages of using stainless steel bellows connections for a mixer:

- Safety for health due to the environmental friendliness of stainless steel;

- Fire resistance of the material;

- Resistance to oxygen diffusion;

- Good wear resistance.

During installation, the bellows hose is not pinched during bending, does not lose its cross-sectional shape. Therefore, the pressure indicators along the length of the hose remain unchanged.

Cons of bellows hoses

Low flexibility is the main disadvantage of bellows pipes. If mounting space is limited, flexible rubber water hoses are a better fit. However, the poor flexibility of the bellows pipes allows installation without additional fasteners - the product itself holds its shape.

Another drawback is the extraneous noise from the vibrations of the corrugated tubes, which is amplified if several water consumers are turned on at the same time. This problem is easily solved by installing a plastic sleeve - the vibration sound will be muffled.

The disadvantages can also be attributed to the high price of the bellows eyeliner. But this is offset by a long service life compared to other products.

How to choose the diameter of a flexible eyeliner, taking into account its type

Flexible water supply consists of rubber hoses in a metal or nylon sheath and a bellows connection. The flexible water inlet has two ferrules (one for each end of the hose) that provide the ability to connect on a nipple-nipple, nut-nut and nipple-nut principle to pipes with a diameter of 1, 1/2, 3/4 and 3/8 inches.The inner diameter of the flexible hose affects the capacity of the hose.

A flexible hose in a metal or nylon braid is a hose made of ethylene-propylene rubber (non-toxic rubber) braided on the outside with stainless steel or nylon thread. This braid protects the hose from water hammer and increases its mechanical resistance.

The material used in the production of flexible hoses is safe for health (non-toxic), therefore it is often used in drinking water supply systems. This eyeliner is resistant to high temperatures up to +95 degrees Celsius. These characteristics allow it to be used in heating systems and in hot water supply.

The high mechanical resistance of the flexible hose allows it to withstand hydraulic shocks (working water pressure up to 20 atm). Depending on the required water flow, the diameter of the flexible piping (flow area) can be different. In water supply systems, an eyeliner with an internal diameter of 8 mm is most often used. The blue thread in the braid indicates the possibility of its use in cold water supply systems, and the red one - hot.

The stainless steel sleeve provides a secure connection between the metal-braided hose and the nickel-plated brass sleeve. For a more convenient installation of this type of connection, there are two types of fittings equipped with gaskets for a tight connection: a threaded fitting (for reliable connection with an internal thread on the connected equipment) or union nuts (for connecting to a pipe with an external thread). When installing a flexible hose in a metal winding, it is recommended to use hoses no longer than 2.5 m. The service life is no more than 5 years.

When purchasing a flexible eyeliner, you must carefully examine the products. The presence of dents, bulges and other flaws on the nut and winding is not allowed. Braid threads must be even, without protrusions, etc. The fitting elements must be aligned with the hose. The sealing gasket must not be wrinkled and detached. Defects on the decorative coating are also unacceptable. When choosing a product, ask for a product passport and specify the warranty period. If possible, purchase eyeliner only from authorized dealers.

Bellows eyeliner - a sleeve (hose) made of stainless steel in the form of a corrugation. For the production of this type of eyeliner, a stainless steel tape is twisted into a tube and welded with a laser beam along its entire length, and then compressed into a corrugation. Rolled sleeves are welded to the bushing. The service life of such an eyeliner is higher than that of a hose in a metal winding, and can be up to 25 years. Due to the corrugated structure, the bellows liner is able to withstand large pressure drops, water hammer and absorb thermal expansion (it is able to maintain its properties in the temperature range from -50 °C to + 250 °C).

During operation, microcracks form on the metal from variable pressure, which contributes to destruction. Under extreme conditions, a protected version is used - a bellows eyeliner in a metal braid. It is easy to install, has excellent flexibility and does not disturb the flow area (at least 11 bends per point).

In addition to the advantages, the bellows eyeliner also has disadvantages. With the simultaneous use of plumbing in the bathroom and in the kitchen, vibration and buzz of the corrugated hose are heard, which increase with increasing water pressure.For this reason, it is recommended to select a flexible liner with a larger diameter. For high water consumption, it is recommended to use a 3/4" flexible hose diameter. Another way to combat vibration and hum is to use a plastic-coated bellows, which also protects the bellows from damage.

Read the material on the topic: How to choose a flexible eyeliner