- Varieties of sewer rings and their scope

- Ring prices

- Concrete rings for sewerage: sizes, prices and varieties

- Advantages and disadvantages of using concrete wells for sewerage

- The main types and general sizes of sewer rings

- Pros and cons

- Which are better and how to determine the quality

- Scope of concrete rings

- Application features

- Areas of use

- The main types of reinforced concrete rings for sewers, sizes, prices

- How much do concrete rings for wall-type sewers cost without a lock

- Buying sewer rings: how much do products with a lock connection cost

- Assortment of reinforced concrete rings for sewerage: prices for filtration products

- At what cost can you buy reinforced concrete rings for sewerage: prices for products with a blank bottom

- Deepening a well by digging

- Carrying out preparatory work

- Deepening works

- Final work in the well

- What are the rings for building wells

- How to mount correctly, and what tool is needed

- Concrete septic tank: installation features

- Mixing concrete

- The ratio of ingredients in concrete mortar

- How is the amount of water calculated?

- Methods for mixing concrete mortar

Varieties of sewer rings and their scope

To drain sewage, pipes are usually used, which are made of polymeric materials, cast iron, ceramics, asbestos cement, reinforced concrete, mainly these products have a small diameter, with the exception of structures made of lightweight plastic components. If a large pipeline diameter is required for laying underground utilities, the weight of long pipes becomes too large for transportation and installation of the line, so it is constructed from short rings.

Due to the cheapness, wide sewer rings are made only from concrete, and this material has no competitors today. With the development of modern technologies and the trend of using polymers in all areas, analogues of concrete products have appeared on the market relatively recently - polymer sand rings, which are used only for the construction of vertically installed structures.

If in the urban planning sphere, underground horizontal communications are laid from reinforced concrete rings for transporting organic waste, storm and gray wastewater, they are used as protection for water supply and gas pipelines, then in the household economy their use is of a different nature. In individual sections, reinforced concrete sewer rings serve as the main elements in the construction of the following structures:

Water wells. Installation of wells for the intake of drinking water from reinforced concrete rings is one of the most popular ways of supplying water to individual residential buildings in urban and rural areas. The shaft is dug out manually or mechanized, after which sewer wall rings with a lock are immersed in it.If a well is made of concrete rings on the site, the depth of the structure can reach 30 m - in this case, a submersible electric pump is used to draw water.

Septic tanks. From do-it-yourself sewer rings, some homeowners build septic tanks or settling tanks using structures with a closed bottom and top.

Drainage wells. Installation of reinforced concrete rings for sewerage in households is one of the most common areas of their application. The sewage waters purified in individual septic tanks are disposed of at their site, using aeration fields or drainage wells for additional purification and directing the effluents underground. Many people mount the drainage chamber with their own hands from reinforced concrete rings, installing several elements with a locking connection on top of each other in a vertical position.

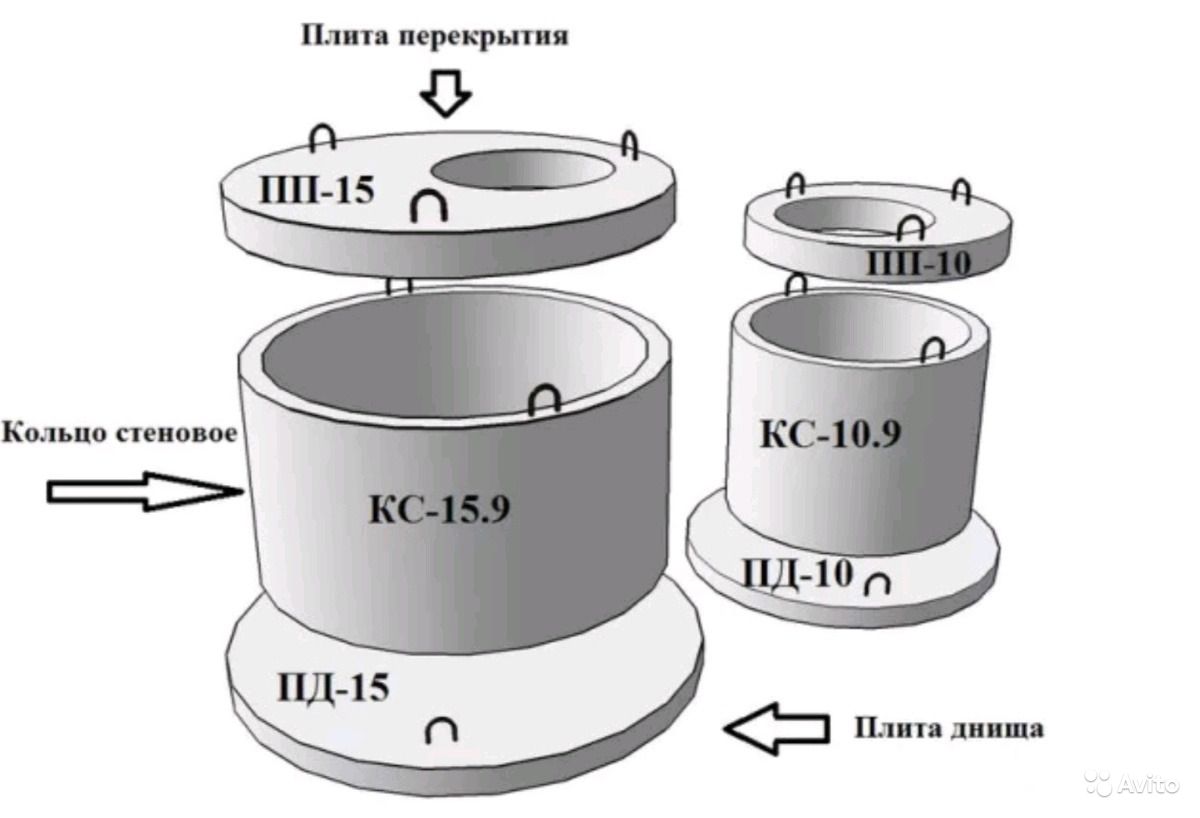

Rice. 2 Engineering structures from reinforced concrete rings

Viewing wells. Engineering structures of this type are needed for sewers in a private house in cases where the underground main has a large length or branches. For cleaning, preventive maintenance and inspection, wells of small diameter are placed along the sewer pipeline. They are designed to access inspection hatches installed in pipes for cleaning them in case of blockages and monitoring the state of the line.

Caisson wells. A well made of reinforced concrete rings is often used to place pumping equipment in it, to protect a well water source from freezing and precipitation when it is taken by a submersible electric pump or a surface pumping station. Depth such structures are not usually exceeds 2 m, during installation they often use rings with a finished bottom or top floor with a hole for the hatch, another installation option is to install separate round plates for the bottom and top manhole. Also for caisson wells, experienced users purchase ready-made structures with built-in metal running brackets located along the entire height of the wall.

Settling tanks. Often in private households, especially in rural areas, residents deprived of access to centralized sewerage share waste disposal. They install a separate toilet for faeces on the street, and gray water after washing dishes, washing, cleaning rooms and other household needs is drained through sewer pipes into a drainage sump built of concrete rings.

Cellars. Concrete rings with a bottom can be used in a private area for the construction of cellars designed to store fruits and vegetables deep underground in winter and summer.

horizontal passages. When laying utilities under roads, for transferring water masses to the other side of highways and railways, reinforced concrete rings of large diameter are often used, which are easier and easier to lay one after another than to immediately stretch a heavy long pipe.

Rice. 3 Excavation for wells with special equipment

Ring prices

The price policy is formed by the market, and therefore in different regions the same product will cost differently, but everywhere its price is directly dependent on the size. And if for KS 7.3 you have to pay from 700 rubles, then for KS 20.9 - already about 4.5 thousand rubles. Buying from the manufacturer gives a savings of 5-15% compared to the construction markets.But, when making an estimate, in addition to spending on rings, the customer must keep in mind other costs:

- for digging a foundation pit for a structure;

- for the delivery of products;

- for installation work;

- construction of a well house (optional);

- for additional materials, for example, cement for sealing joints or pebbles for a seepage bottom of a well.

It makes sense to cooperate with one supplier. In many cases, this will bring additional benefits in the field of service, delivery and information support.

Concrete rings for sewerage: sizes, prices and varieties

In private and suburban construction, sewer systems based on concrete rings are often used. This type of sewage is considered one of the most economical. After all, the price of concrete rings for sewerage is low, and the process of their installation does not require a lot of time. As a result, the owner of a summer cottage has the opportunity to create comfortable conditions for living outside the city.

Concrete ring with a blind bottom

Along with bricks and polymer rings, concrete elements are also used for the construction of sewers in the country without pumping. Each of these materials is characterized by its own advantages and disadvantages, however, concrete structures are significantly superior to the parameters of other system options.

Brick is less durable and requires a significant amount of time to make masonry, unlike ready-made elements that just need to be placed on the bottom of the pit and fixed. In addition, it is extremely difficult to make wells of great depth on the basis of brickwork. The price of sewerage from turnkey concrete rings slightly exceeds the cost of manufacturing a brick system.Given the simplicity of installation work and the minimum time required, such a small overpayment is fully justified.

Prices for the installation of sewerage from concrete rings on a turnkey basis:

| Number of rings | Capacity, m³ | Number of consumers | price, rub. |

| 3+2 | 3,5 | 1-3 | 35990 |

| 3+3 | 4,2 | 2-4 | 39990 |

| 4+2 | 4,2 | 3-4 | 39900 |

| 4+3 | 4,9 | 3-5 | 45990 |

| 4+4 | 5,6 | 4-6 | 49900 |

| 3+3+3 | 6,3 | 4-6 | 59990 |

| Installation of a septic tank in areas with a high level of groundwater | |||

| 2+2 | 2,8 | 1-2 | 30990 |

| 2+2+2 | 4,2 | 3-4 | 43990 |

Advantages and disadvantages of using concrete wells for sewerage

Many summer residents prefer to buy concrete sewer rings for arranging the system at their summer cottage, the prices of these products are far from the only advantage confirming the benefits of such a purchase.

Advantages of concrete structures:

- the possibility of installation in areas with any type of soil (due to the increased margin of safety, concrete rings are able to withstand natural pressure, which is formed during the displacement of groundwater or seasonal movement of soil);

- it is possible to use any materials for waterproofing;

Concrete sewer ring with ladder

- even if do-it-yourself installation work is supposed to be done, this process will not take too much time;

- due to the smooth inner surface, the speed and quality of cleaning concrete wells increases;

- the material is more accessible than brick or stone;

- long service life without the need for repair work.

A wide variety of sizes and prices of concrete rings for sewerage allows you to create septic tanks of any capacity and depth. This type of material is highly hygroscopic, so contaminated effluents can partially seep through the walls into the surrounding soil.However, this problem can be easily solved with waterproofing.

The main types and general sizes of sewer rings

On sale there are concrete products for the construction of sewers of two types:

- Additional (from 670 rubles).

- Wall (from 990 rubles).

Wall sewer rings

Wall view elements are used to form the neck of the structure. Additional options for products have an extended range of sizes, and non-standard ones. They are used in cases where the height of the storage tanks according to the project cannot be formed from elements with standard sizes. With the help of additional rings, you can adjust the height of any septic tank design.

Concrete rings used for the construction of country sewage systems are elements of a regular rounded shape. The internal diameter of the products is in the range from 70 to 200 cm. The standard wall thickness is 70-100 microns. Most often, for the manufacture of drain pits and country septic tanks, a size of 1-1.5 m is used, the price of concrete rings of this diameter is 1500-2500 rubles. for the product.

For the manufacture of rings, manufacturers use metal fittings and concrete grades with different characteristics. Metal, as a reinforcing component, increases the strength of products and reliability. In addition, the possibility of stretching the structure made of rings is excluded. In turn, concrete provides corrosion protection to the metal. As a result, the design of the septic tank is not subjected to deformation changes under the influence of compressive loads.

Dimensions of concrete wall rings

Pros and cons

Well rings have a number of positive aspects for which the consumer chooses them, for example:

- High strength.We said that the production is based on reinforced concrete technology. This is what creates long-term strength, which will only grow stronger in the next 50 years. This is due to the fact that concrete gets stronger for 50-70 years. Water and even dampness, which always happens at a depth, will help him in this. The most important thing is the absence of violations in the production technology, namely, high-quality concrete should be used and vibrocompression technology should be applied.

- Wide range of applications. Previously, we already knew that rings are used for wells, septic tanks, equipment installation sites and pits near the drain pit, for laying cables, pipes (plumbing, sewage, water), as well as other infrastructure. The device of a well from concrete rings will turn out to be simple and reliable.

- Convenient for transportation and installation. The same manipulator or truck, followed by unloading with a crane, can solve all the problems of arrangement. On KAMAZ, the body of which has dimensions of 2.5 by 6 meters, you can place up to 8 rings with a diameter of 1 meter, 4 rings of 1.5 meters and 2 rings of 2 meters. KAMAZ with a manipulator function has similar characteristics.

- Are convenient in work. If you need to bring electricity into the ring, pull out a hose with water or do other work, then it's easy. You can use a perforator and make a hole.

- You can buy a complete set. According to the diameter of the ring, there is a base and a cover for sale. Together they are part of a single whole, which allows you to make the septic tank airtight, protect children and pets from accident, and make access convenient. The through hole for the hatch in the cover is standardized, regardless of the fact that there are different sizes of rings.

- Big weight.This property applies to reinforced concrete products. Weight plays into the hands when there is groundwater near a septic tank or well. In the case of plastic rings, they could float when the soil heaves. This does not happen with concrete products.

The disadvantages of reinforced concrete rings can only be attributed to a lot of weight. It is difficult to roll them with your hands, it is even more difficult to lower them into the pit. Therefore, you will need to rent special equipment, for which you will have to pay. Not only installation, but also dismantling can not be done manually.

Which are better and how to determine the quality

There are two technologies for the production of concrete rings: vibrocasting and vibrocompression. In the first case, concrete is poured into collapsible forms, compacted with a submersible vibrator and left to set. This usually happens after 6-8 hours. Then the molds are removed and the rings are left to “ripen” so that they gain strength sufficient for sale - 50%. You can mount them after 28 days, so it’s better not to buy “fresh” rings. Another point: in the last days of aging, cracks may appear. So it is best to purchase well rings “aged” in the warehouse. As you can see, the technology is simple, except for the molds there is no equipment. This allows you to open small workshops that make these products. In this case, the quality depends entirely on who kneads and fills the molds.

For the manufacture of well rings by vibrocompression, special equipment is required. Not only forms, but also the vibropress itself. It creates a certain pressure and vibration frequency at each stage of the process. The result is a more uniform concrete, smooth and even edges, a perfectly formed edge or lock. But the price is higher - more expensive equipment.

Scope of concrete rings

When choosing rings, the purpose of the sewer well should also be taken into account:

- Concrete rings are suitable for creating storage wells. The large diameter and high strength make it possible to create a structure with a large displacement index from them. Therefore, if the throughput of the sewer system is high, then this type of material is often chosen.

- Gradient structures are designed to change the level of wastewater flow. In areas with difficult terrain, it is quite often necessary to change the level of the pipeline, and for this, overflow wells are often installed. Concrete rings can also be used to create a similar design: they can withstand a large load, the surface does not wear out under the influence of drains.

- Rain wells are designed to store rainwater. If it is necessary to divert wastewater from the site, storage structures can be installed.

In general, we can say that concrete rings are suitable when you need to get a reliable and durable structure.

Application features

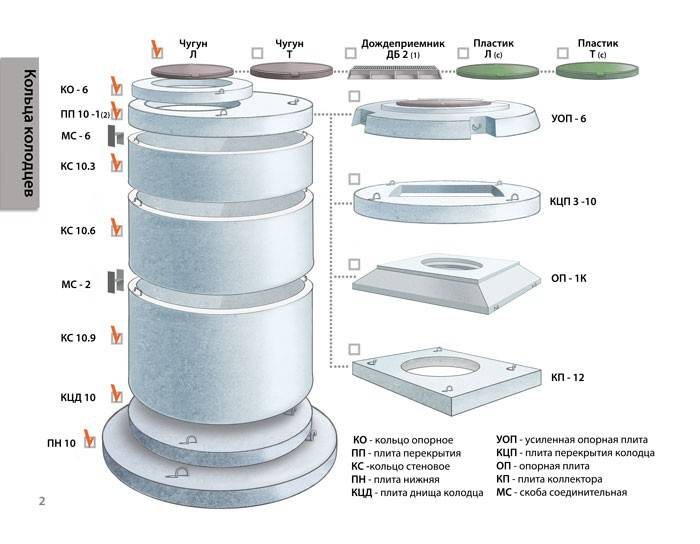

Depending on the design and area of use, there are several design options. Their characteristics should be studied before purchase.

- Support. If the well is planned to be equipped with a hatch, the supporting structures are installed in front of the floor slab.

- Wall. These models are indispensable in the construction of water intake and sewer wells.

- working chambers. Such structures have found application in the construction of sewers, the construction of water and gas pipelines.

- Additional. These custom-sized products are made to order.They are necessary if, for some reason, the depth of standard rings is not enough for well equipment. Additional elements are installed at the bottom.

- With lock. The tongue-and-groove connection ensures maximum tightness of the adjoining sections to each other. If there is no lock, staples and concrete mortar are used when installing products.

- Bottom. A monolithic ring with a bottom facilitates installation and ensures the tightness of the structure.

- With perforation. With the help of such products, a drainage system is arranged.

- Additional elements. When constructing wells, it is often necessary to use bottom slabs, floor slabs or hatches with covers.

Areas of use

What this or that type of such products is intended for can be judged by the same marking, therefore, when choosing rings, their purpose must be taken into account. For example:

- if it is necessary to build a well for drinking water, then the concrete products must be clean;

- if a container is being built for sewage, then rings made of contaminated material may well be suitable;

- for the construction of a well with drinking water, it is necessary to use cylinders that do not have a bottom. Otherwise, water simply cannot come from underground sources;

- for sewer wells, the bottom, on the contrary, is necessary, since it does not allow waste to penetrate into groundwater.

READ Do-it-yourself concreting of a platform for a car

The scope of application is quite extensive, and it is not limited to the construction of wells. They can be used in the construction of gas pipelines and filtration systems.They may also be required in the construction of tunnels and when laying communication networks, such as telephone lines and electrical cables.

The main types of reinforced concrete rings for sewers, sizes, prices

Manufacturers produce different types of rings. Each type of product has its own parameters and a specific purpose.

Buyers can buy reinforced concrete rings for sewerage of the following types:

- elements without a lock;

- filtration details;

- elements with a blind bottom;

- locking components or with a quarter.

Dimensions of reinforced concrete rings for sewers

How much do concrete rings for wall-type sewers cost without a lock

Wall rings for septic structures without a lock are considered a working part of the storage system. This segment of the sewer is formed from three elements, including wall, support and additional type products. The dimensional parameters of the rings, as well as their number, are selected in accordance with the design data. Manufacturers label products of this type with a combination of the letters "KS".

Selling price of concrete rings for wall-type sewers without a lock:

| Product name KS | Diameter, mm | Height, mm | price, rub. |

| 7-3 | 700 | 290 | 675 |

| 7-6 | 700 | 590 | 1050 |

| 7-9 | 700 | 890 | 1275 |

| 10-8 | 1000 | 800 | 1520 |

| 10-9 | 1000 | 900 | 1650 |

| 15-9 | 1500 | 900 | 2570 |

Straight rings without a lock are installed one on top of the other. The joints are treated with cement mortar, which fixes these elements. It is allowed to use special brackets to secure these rings.

Buying sewer rings: how much do products with a lock connection cost

Rings with a quarter or lock connection greatly simplify the process of assembling the well.The result is a tight and reliable connection of parts without additional processing of seams with a sealant. In addition, the special structure of these elements allows compact storage of products on the construction site.

In the lower part of these parts, special recesses are formed. There are protrusions at the top of the rings. Such a specific structure allows the elements to be placed on top of each other during installation. As a result, the rings are securely fixed with the help of a locking connection, which excludes the possibility of shifting the septic tank structure or displacement. After installation, the elements will retain their original position throughout the entire operational life.

The cost of concrete rings for sewerage: prices for products with a quarter:

| Product name KS h | Diameter, mm | Height, mm | price, rub. |

| 7-3 | 700 | 300 | 530 |

| 7-5 | 700 | 500 | 710 |

| 7-6 | 700 | 600 | 755 |

| 7-10 | 700 | 1000 | 1130 |

| 8-3 | 800 | 300 | 700 |

| 8-5 | 800 | 500 | 1125 |

| 8-10 | 800 | 1000 | 1370 |

| 10-3 | 1000 | 300 | 715 |

| 10-5 | 1000 | 500 | 955 |

| 10-6 | 1000 | 600 | 980 |

| 10-9 | 1000 | 900 | 1375 |

Assortment of reinforced concrete rings for sewerage: prices for filtration products

Filtration rings for the construction of septic tanks are concrete elements covered with perforation. In other words, the surface of the product is covered with a plurality of holes of the same size. They are evenly distributed along the perimeter of the ring at an equal distance from each other. Through these holes, purified water in the septic tank enters the soil. Based on these elements, filtration wells for sewage are constructed.

To fix the drainage rings, special H-shaped fasteners are used. They are made of metal and securely fix structural elements in case of soil movement. To secure a pair of rings to each other, about 3-4 fixing elements will be required.

Average price of reinforced concrete rings with perforation:

| Product name KS | Diameter, mm | Height, mm | price, rub. |

| 7-9 | 700 | 890 | 2410 |

| 10-9 | 1000 | 890 | 2520 |

| 15-6 | 1500 | 590 | 3255 |

| 15-9 | 1500 | 890 | 3730 |

| 20-6 | 2000 | 510 | 5180 |

| 20-9 | 2000 | 890 | 6250 |

At what cost can you buy reinforced concrete rings for sewerage: prices for products with a blank bottom

Well elements with a blind bottom in the form of rings are used for the construction of sedimentation tanks. In this part of the sewer system, sludge gradually accumulates during operation, which can be removed using a fecal sewage pump in a private house or special equipment equipped with equipment with similar functionality.

This type of product is considered by experts as the best option for the construction of an autonomous, as well as an overflow sewer system for wastewater treatment.

The average cost of concrete rings for sewerage with a blind bottom:

| Product name KCD | Diameter, mm | Height, mm | price, rub. |

| 7-3 | 700 | 300 | 1075 |

| 7-5 | 700 | 500 | 1115 |

| 7-6 | 700 | 600 | 1195 |

| 7-9 | 700 | 900 | 1289 |

| 7-10 | 700 | 1000 | 1289 |

| 8-6 | 800 | 600 | 1215 |

| 8-9 | 800 | 900 | 1289 |

| 8-10 | 800 | 1000 | 1420 |

| 10-3 | 1000 | 300 | 1200 |

| 10-5 | 1000 | 500 | 1289 |

| 10-6 | 1000 | 600 | 1545 |

| 10-9 | 1000 | 900 | 1610 |

| 10-10 | 1000 | 1000 | 1740 |

Deepening a well by digging

This method differs from the one described above in that the well is built up with repair rings from above. Moreover, their diameter does not differ from those that have already been installed.

In fact, this is a continuation of the work begun many years ago with the initial digging of the well. The main danger in using this method is the possibility of the old column getting stuck in the ground, especially if the well is located on clay rocks.

Carrying out preparatory work

We start by fixing the rings. At each joint we fix at least 4 staples. We drill holes for them, put metal plates 0.4x4x30 cm and fix them with 12 mm anchor bolts.

Thus, the casing string will be able to withstand possible ground movements. We pump out water from the well and completely remove the bottom filter, if it was present in the structure.

Deepening works

A worker descends on the belay and begins to dig.First, he selects the soil from the middle of the bottom of the structure, then from the periphery. After that, he begins to dig under two opposite points from the edges of the lower ring with a depth of 20-25 cm.

It is no longer necessary, otherwise there is a danger of an uncontrolled descent of the element. Then the tunnel is gradually expanded to the annular area.

During operation, the column must settle under its own weight. New rings are placed on the space vacated on top. Undermining is carried out until the water begins to arrive very quickly.

It should be noted that column subsidence does not always occur, especially if the well is “older” than 1-2 years. In difficult cases, the side digging method can be used as a way to lower a stuck ring.

It looks like a spatula, which is used for lateral digging of rings. The handle, longer than 40 cm, should be bent for comfort and precision

Consider it on the example with the lower ring. We carry out the digging as already described. Then we take three hemp or strong supports from a bar and place them under the ring so that there is a distance of about 5 cm between them and the bottom edge.

These supports will subsequently take on the entire weight of the settled structure. Then, in two opposite sections, we remove the sealing solution from the annular gap.

We insert nail pullers into the resulting gaps, and two people, simultaneously acting as a lever, can try to lower the ring. If all else fails, we take a special spatula for undermining the side walls.

For its handle, fittings 10 cm long and 14 mm in diameter are used. The cutting part measuring 60x100 mm is made of 2 mm sheet iron.We insert the spatula 2-3 cm from the outer wall of the ring and proceed to hollowing out the clay.

To do this, hit the handle with a sledgehammer from the bottom up. Thus, we pass the entire ring except for the sections under which there are supports. We managed to remove the clay to a height of 10-15 cm from the lower edge of the ring.

Now you can try again the lowering attempt with the nail pullers or any other levers. If not, take the next blade. The length of its handle should be 10 cm longer. We perform similar steps.

At the end of the repair work, you should once again inspect all the seams and carefully seal them, then cover them with sealant

A small note: when the length of the shovel handle reaches 40 cm or more, it will need to be bent a little. So it will be more convenient to work. With proper lateral digging, the outer wall of the ring is gradually released, and it settles down. Similarly, work is carried out on other rings.

Final work in the well

Upon completion of the deepening works, all contaminated water is removed from the structure. All seams between the rings are securely sealed and sealed. If damage to old seams is noticed, they are also eliminated.

At the bottom of the structure we lay a new bottom filter of the desired design. Then we disinfect the walls of the mine with a solution of chlorine or manganese. The well is ready for use.

Do not forget that the normal operation of the water intake mine working and the preservation of its water abundance is directly related to competent arrangement, the rules for the implementation of which will be introduced by the article we have proposed.

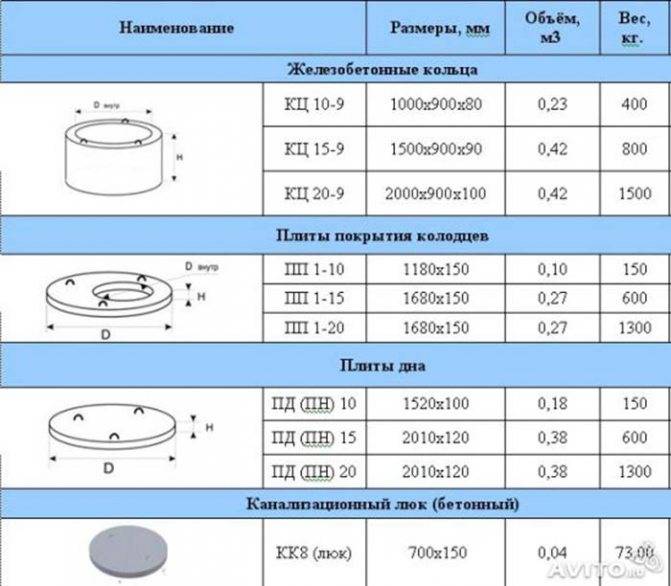

What are the rings for building wells

For professional fastening of the internal base of any well, only reinforced concrete rings should be used.

High-quality building materials are made from concrete grade M200 - M500. When casting rings, steel rods are used for reinforcement.

This is optional, but there is nothing better for improving structural strength.

well rings

They are widely used in the construction of all types of wells, mines and drainage structures.

bottom rings

Produced to provide a normal, monolithic bottom in many well-type structures.

Rings with a "mechanical" lock

This type of rings ensures the reliability of the design. The connection of rings with a mechanical lock is carried out at the expense of folds at the joints.

They are applicable for the tightness of the complete base of the well. Horizontal displacement is almost impossible with this kind of reinforced concrete structure.

Rings with a "mechanical" cover

This element is used on the outer crown of a well-type structure. It is a folded ring with a concrete cover, in the cavity of which there is an opening for convenient use.

Additionally.

Additional elements are used to form a correct and integral well-type structure. In particular:

- Concrete covers for wells.

- Concrete bottoms for wells.

Both elements are convenient when repairing or restoring wells.

How to mount correctly, and what tool is needed

It is difficult to mount reinforced concrete rings with your own hands, but sometimes this is done due to the impossibility of accessing special equipment to the territory.Otherwise, you buy reinforced concrete rings at the construction site, hire a manipulator, it performs loading, delivery to the customer's site and unloading. Unloading can be understood as direct installation.

Before installation, experts recommend deepening to the required amount, tamping the bottom, and filling in a pillow of sand. Concrete will draw moisture from the ground, so a pillow is simply necessary. Do not save on this layer, and fill up to 10 centimeters of sand, inclusive. To some extent, this will level the base. Already lay the concrete bottom on the sand, and then begin the phased installation of the rings.

Each of them has special hooks. They serve to fix the slings of the manipulator, and to tie the rings together. After the first reinforced concrete product is lowered, the slings are released, the metal hooks are bent, and the second product is mounted. Then, all screams can be linked together using a welding inverter. The work is not difficult and even a novice welder can handle it.

When the well is being arranged and the work is done manually, it is not always possible to use the services of a manipulator. In this case, install the first ring and gradually dig inside it, which allows the rings to go down.

Further, when 1 is first lowered to its own height and stands parallel to the ground at the top, a reinforced concrete product is installed 2 and work continues in the same way. Experts recommend using a hole drill, with the ability to drill to a depth of 10 meters or more.

This will allow you to drill the entire inner diameter, install the ring and manually dig under its walls only.You will save the right amount of time, do the job professionally. In order to facilitate your work manually, you need a powerful winch. It must be firmly fixed, which will facilitate the process of lifting and lowering products.

Concrete septic tank: installation features

The construction of a sewer system from concrete rings goes through several stages:

-

Drawing up a project. The place and scheme of construction is selected (in this case, the number of chambers) and the location of the septic tank. The capacity of the structure is determined (based on the average daily consumption of one person, 150-200 liters). The brand, size and number of rings are determined (products of different sizes and volumes may be required).

- Procurement and delivery of materials.

-

Excavation. In accordance with the calculations, a pit is dug out, a concrete pad is poured to the bottom.

-

Installation of wells. Concrete rings with the help of lifting equipment are installed in a given place and fastened with steel brackets. The joints are additionally cemented and waterproofed with resin. To increase the service life, the outer surface is treated with hot bitumen.

-

System installation. Pipes are connected, covers are installed, ventilation and thermal insulation are arranged.

- The structure is covered with earth.

Installation of a filtration well

Mixing concrete

To prepare concrete, which will later be used to make rings, you will need:

- cement (binder);

- sand (fine aggregate);

- crushed stone (large aggregate);

- water.

To obtain high-quality concrete, they buy cement of the 400 brand, packed in paper bags of 25 kg. If you do not intend to use the building material right away, then take care of its proper storage.

The bags are stored in a dry place. It is even better to pour cement into closed iron containers. If possible, use purchased cement immediately after purchase.

Use of a tripod for lowering reinforced concrete rings into the well, as well as lifting soil to the surface from the mine

To mix concrete, stock up on quartz sand, which is considered an ideal fine aggregate. Silty, clay and other types of impurities contained in the imported bulk material will adversely affect the quality of the concrete mixture. Therefore, such sand is washed with water, ridding it of unnecessary impurities.

Not every crushed stone is suitable for mixing concrete for casting rings. Granite crushed stone with grains having a cubic shape is chosen, which contributes to better adhesion of the material with other ingredients of the concrete mixture.

Crushed stone of a lamellar (needle) shape should not be used. Crushed stone contaminated with clay is also washed with water before kneading.

For casting reinforced concrete rings, crushed granite is purchased with a fraction size not exceeding a quarter of the thickness of the product. For a ring with a 10-centimeter wall, crushed stone is suitable, the grain size of which will not exceed 20 mm.

Types of crushed stone: crumb, small, medium, large. Medium-sized crushed stone with a fraction of up to 5 to 20 mm is suitable for the manufacture of concrete.

The ratio of ingredients in concrete mortar

The properties of a concrete solution directly depend on the number of components included in its composition, as well as on their volume and mass. When drawing up the ratio between the three main ingredients necessary to obtain high-quality concrete, it is assumed that the amount of cement is equal to one.

For casting well rings, a concrete mixture is closed, taking cement, sand and gravel in a proportional ratio of 1:2:3 by volume or 1:2.5:4 by weight.

For example, a bucket of cement, two buckets of sand and three buckets of gravel are poured into a container. Add half a bucket of water. Or take 100 kg of cement (4 bags), add 250 kg of sand and 400 kg of crushed stone. Add 50 liters of water.

The preparation of one cubic meter of concrete takes 300 kg of cement M-400, 750 kg of sand and 1200 kg gravel. The mixture is diluted with 150 liters of water.

How is the amount of water calculated?

Water affects the mobility of the concrete mixture and the strength of the products after it hardens. The ratio of water and cement in the solution is called the water-cement ratio and denoted W / C.

For reinforced concrete rings, this value should be no more than 0.5-0.7. In the examples discussed above, the W/C was 0.5. In this case, the mass or volume of cement taken is divided in half and the required volume of water is obtained.

A thinner solution is easier to pour into molds and tamp, but it will have to be kept longer in the workpiece. The time for the initial hardening of the solution increases.

The mixture, which does not spread after squeezing it into a lump with the palm of your hand, allows you to immediately remove the workpiece and use it for stamping the next product. True, it is more convenient to ram it with the help of vibrators.

Methods for mixing concrete mortar

The manual method of mixing the components of the concrete mixture is now rarely used. Concrete mixers of factory and handicraft production are better able to cope with this time-consuming task.

Loading the concrete mixer manually with the components necessary to prepare the concrete solution of the desired consistency

Sand and cement are poured into the concrete mixer, then water is added, and then crushed stone, previously moistened with water. Having received a homogeneous mass, the equipment is turned off and the solution is poured into a container on wheels. This allows you to bring heavy concrete to the place of pouring the ring.