- The preparatory stage for the arrangement of the SZHBK

- How the vibroform works

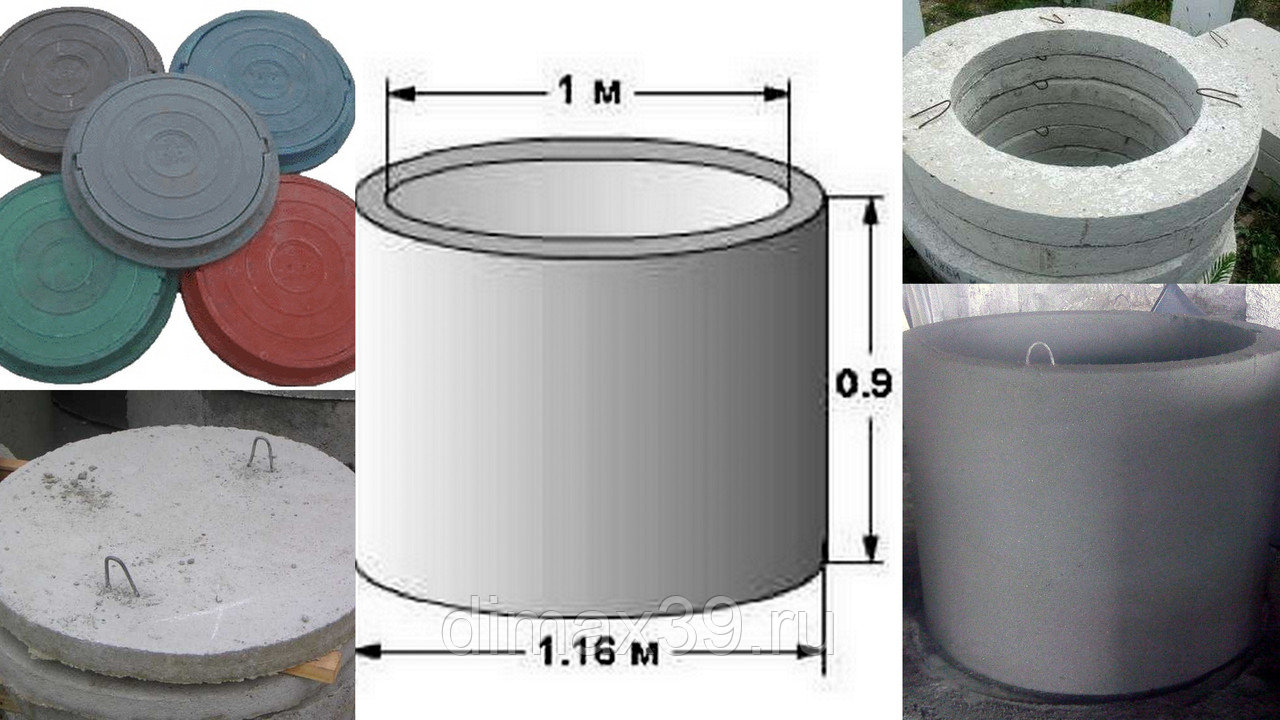

- Typical dimensions of reinforced concrete rings

- Which are better and how to determine the quality

- Additional elements for reinforced concrete wells

- Additional elements for wells

- Water well from reinforced concrete elements

- Concrete concrete rings for the construction of a water well structure

- Other reinforced concrete elements for construction

- Advantages of a reinforced concrete well

- What can wells be?

- Functions of water wells

- Construction stages

- Video description

- How to choose the best place for a septic tank

- Pit preparation

- Installation of rings and sewer pipes

- Sealing and waterproofing

- Manhole installation and backfill

- How does the septic tank start up

- What rules must be observed when maintaining a septic tank

- How to calculate the cost of a well from reinforced concrete rings

- Manufacturing process

- Required equipment

- Ring mold

- Manufacturing technology

- Mounting Recommendations

- Useful video on the topic

- All about sizes

The preparatory stage for the arrangement of the SZHBK

We carry out the following works:

We determine the place in which the well will be equipped. There are several methods: using frames, based on surveys of a geodetic nature and electro-vertical sounding. It is best to use all methods in combination.

On a note! The optimal time for arranging a well is August-September. They are also dug in winter, after 3 weeks of frost, when the upper layers of the soil freeze through and they do not feed the aquifer.

- We free the territory from shrubs, trees, debris and old buildings.

- We select the type and size of reinforced concrete rings (ZhBK), and also calculate their number.

- If necessary, we equip temporary access roads for lifting equipment that delivers the necessary materials, as well as digging a pit (if you decide to drill a mine using a mechanized method).

Important! We do not recommend tilting (that is, rolling) reinforced concrete rings over long distances. This is fraught with the fact that chips and cracks may form on the surface of the product.

How the vibroform works

The device of this form is simple: there are two metal cylinders, one of which has a cone with a mounting loop. The core is located in the inner part. Vibrators are installed in the second cylinder. The form itself is a metal sheet with an additional reinforcement profile. The core is reinforced at the bottom and the outer cylinder at the top

The device of this form is simple: there are two metal cylinders, one of which has a cone with a mounting loop. The core is located in the inner part. Vibrators are installed in the second cylinder. The form itself is a metal sheet with an additional reinforcement profile. The core is reinforced at the bottom and the outer cylinder at the top

The device of this form is simple: there are two metal cylinders, one of which has a cone with a mounting loop. The core is located in the inner part. Vibrators are installed in the second cylinder. The form itself is a metal sheet with an additional reinforcement profile. The core is reinforced at the bottom and the outer cylinder at the top.

Vibrators are installed on special platforms. Before pouring the concrete mix, the mold is assembled. To do this, the core is installed in the center of the outer cylinder and fixed with metal pins.

The standard sample of the vibroform is designed for the manufacture of rings for wells with already mounted lugs for loading and installation. These are loops that can be made of durable metal and rigidly connected to the elements reinforcing the frame of the ring. However, with this manufacturing option, the manufacture of a ring with a lock is excluded. There are more modern versions of forms, where openings are installed on the side walls of the form. Their purpose is to create a through eye in the wall of the product, which will be used to attach slings to move the ring. During the construction of the well, these holes are muffled.

The price of the mold for the production of reinforced concrete rings is constant, regardless of the presence or absence of opening formers. For the manufacturer, the most important thing is to have a clear idea of which version of the reinforced concrete - with locks, with eyes or with loops - will be more in demand in his region.

The video will help you to get acquainted with the vibroform device in more detail.

Typical dimensions of reinforced concrete rings

If for some reason it is impossible to use finished products, then the owner of a suburban or summer cottage should think about options for their self-production.

To do this, it is necessary to make a form from improvised materials, install a reinforcing mesh in it, and then pour concrete mortar, mixed in strictly defined proportions.

At factories producing reinforced concrete products and structures, special marking of products is used. Typical dimensions of well rings:

- height is standard and is 900 mm;

- thickness - 70-140 mm;

- diameter - 100-200 mm.

The wall thickness of the cylinder and its diameter can be different.

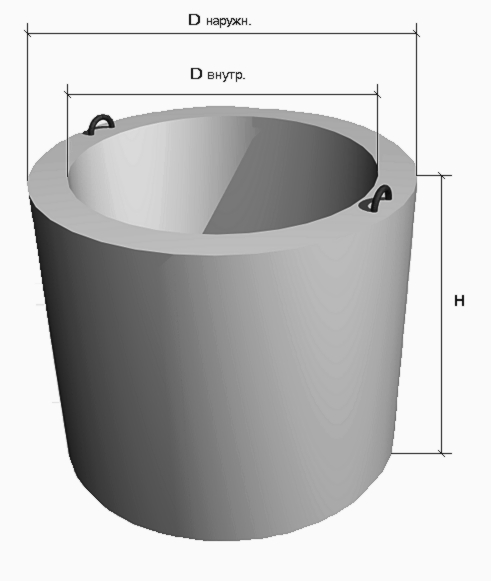

The main dimensional parameters of the reinforced concrete ring for the well: Dv - inner diameter, Dn - outer diameter, H - height (+)

The main dimensional parameters of the reinforced concrete ring for the well: Dv - inner diameter, Dn - outer diameter, H - height (+)

With an increase in the diameter of the ring and the thickness of its walls, the consumption of concrete increases. The weight of the product also depends on these dimensions. To reduce the mass of the finished product, they try to reduce only the height of the reinforced concrete ring, and the walls are made as thick as possible.

On sale you can see products with a height of 350, 450 or 500 mm. They are also called additional rings and are installed at the end of the work, when the product of standard sizes is no longer entirely included in the dug well.

Another way to “legitimately” reduce the mass of the well ring is to use a reinforcing mesh. In this case, the wall thickness can be 6-8 cm, which does not impair the strength characteristics of the product. Therefore, it is better to make reinforced concrete rings with reinforcement for the construction of a well on the site with your own hands.

It is necessary to reduce the weight of the well ring in order not to use lifting equipment during installation work

This is important for summer residents and gardeners who decide not only to make products with their own hands, but also to move them around the site without the involvement of special equipment.

Homemade rings are a practical and affordable solution not only for arranging a well, but also for solving other problems. For example: creating a drainage well or drain pit.

Which are better and how to determine the quality

There are two technologies for the production of concrete rings: vibrocasting and vibrocompression. In the first case, concrete is poured into collapsible forms, compacted with a submersible vibrator and left to set. This usually happens after 6-8 hours.Then the molds are removed and the rings are left to “ripen” so that they gain strength sufficient for sale - 50%. You can mount them after 28 days, so it’s better not to buy “fresh” rings. Another point: in the last days of aging, cracks may appear. So it is best to purchase well rings “aged” in the warehouse. As you can see, the technology is simple, except for the molds there is no equipment. This allows you to open small workshops that make these products. In this case, the quality depends entirely on who kneads and fills the molds.

It is necessary to choose according to the quality of the walls and edges, the absence of marriage and deviations in size

For the manufacture of well rings by vibrocompression, special equipment is required. Not only forms, but also the vibropress itself. It creates a certain pressure and vibration frequency at each stage of the process. The result is a more uniform concrete, smooth and even edges, a perfectly formed edge or lock. But the price is higher - more expensive equipment.

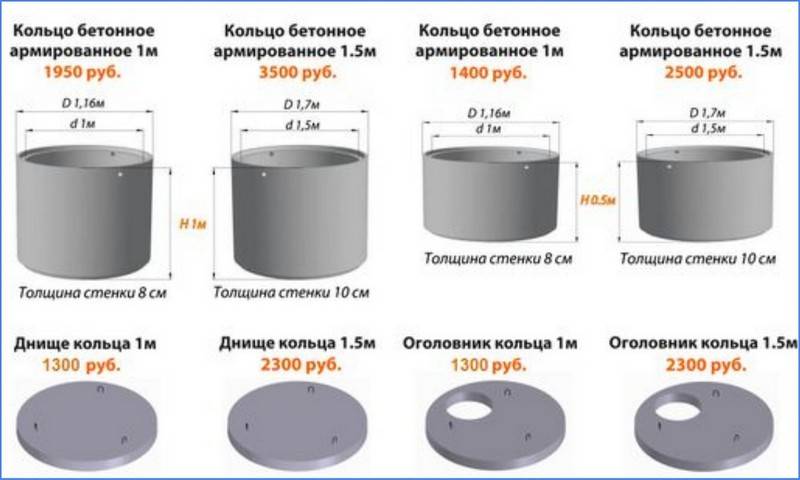

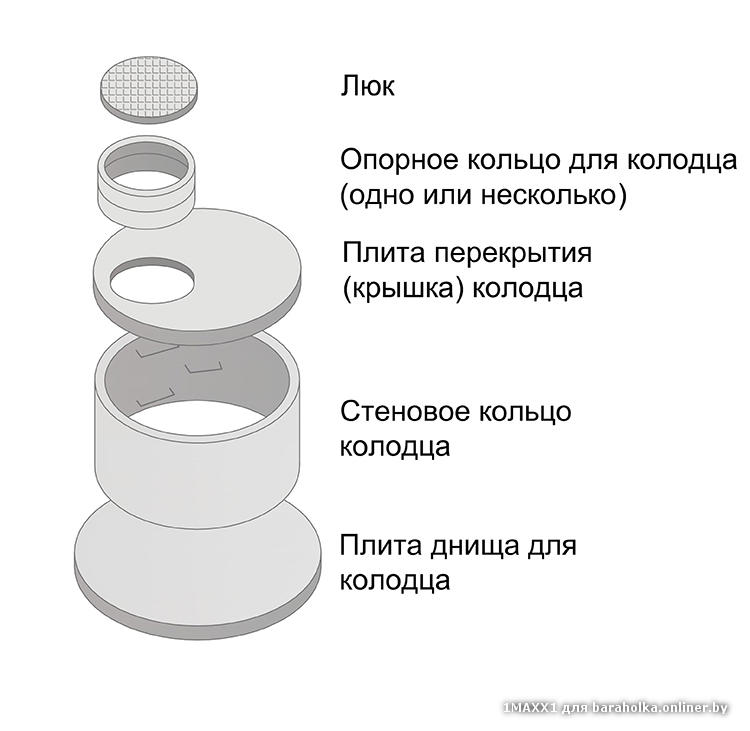

Additional elements for reinforced concrete wells

It is clear that well rings are just a part of the entire well structure. Of course, much will depend on the purpose of the structure itself. For example, if this is a prefabricated well for sewage, then it must be built as a sealed tank. That is, not only the walls of the barrel, but also the bottom must be hermetically sealed. Such wells are also supplied with manhole covers. There are also perforated bottoms, which are used in septic tanks for the unhindered passage of water into the ground. Therefore, it is worth considering all the accessories for reinforced concrete wells.

Reinforced concrete ring, lid with hole and blind bottom

So, two options for the bottoms have already been said. Although it should be noted that many summer residents, when constructing wells for sewer systems, manage with a bottom, which is poured at the place where the rings are installed in the form of a flat foundation that repeats the shape of the well section.

- Reinforced concrete well covers. In principle, this is a standard plate in which a hole is made for the hatch. It can be located in the center of the plate or slightly to the side.

- Support ring. This is an intermediate element that is installed on the neck of the barrel. Usually it is used only if the upper ring, which forms the head of the structure, protrudes too little above the ground level. That is, the height of the head increases with the support ring. Its height is only 18 cm, which makes it possible to raise the upper part of the trunk by a small size. By the way, such rings are used mainly in the construction of wells that fall on roads. They are installed to align the level of the structure with the level of the road surface.

- Houses for wells. Their main purpose is to protect the open mouth from dirt, dust, plates and small animals, as well as precipitation from getting inside the mine. But many suburban developers give them decorative content, sometimes making a work of art out of an ordinary canopy. Such houses are mainly installed on wells, from which water is raised for drinking and domestic needs. For other types, they do not apply.

- Floor slabs. In fact, these are all the same covers with holes for the hatch.They can also be used as a final element installed on the neck of the structure, or they can also be mounted inside the well shaft, as an element that equalizes the load on the entire height of the shaft.

Additional elements for wells

Regardless of the purpose of the well, it will not be possible to do with rings alone during installation.

In order for the entire system to function correctly and not fail in the future, the following elements will certainly be needed:

- Bottom plates (bottoms) - fit into the base of the structure, level the base surface and give stability to the entire well shaft.

- Support floors - are a concrete circle with a hole closed by a standard manhole cover. They take on and evenly distribute the external load over the surface. Ensure the safety of the entire well and protect it from collapse and cracking.

- Additional rings - have a standard diameter, but a smaller thickness. Designed to raise the current height of the well to a higher level.

- Well hatches (covers) - are produced in the form of a regular circle. Depending on the operating conditions, they are divided into sidewalk and main. Differ in high durability and good resistance to intensive loadings.

The presence of additional accessories provides the system with complete tightness, prevents sewage from entering the network, protects pipes from freezing in winter and prolongs the service life of communications.

To equip and protect the well from destruction, you will need a base plate. For use in private construction, a product that can withstand a load of up to 1,000 tons is suitable.Reinforced modules that are not afraid of the current pressure of 1550 tons will perform better at industrial facilities, highways and streets with heavy traffic.

To equip and protect the well from destruction, you will need a base plate. For use in private construction, a product that can withstand a load of up to 1,000 tons is suitable.Reinforced modules that are not afraid of the current pressure of 1550 tons will perform better at industrial facilities, highways and streets with heavy traffic.

All additional elements must be selected, focusing on the conditions in which the system will be operated. This approach allows you to create a stable, sealed network with a large working resource.

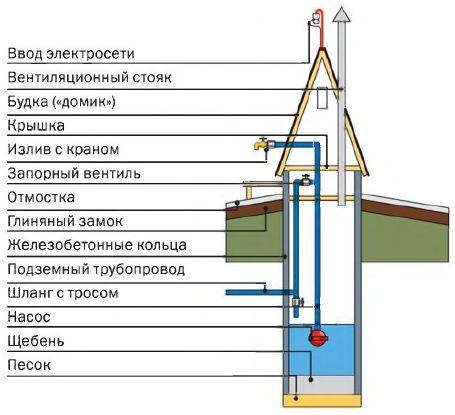

Water well from reinforced concrete elements

Water supply in the house can be performed using wells or boreholes. Wells are pipe wells that require finishing with plastic pipes. Shaft wells are more practical and do not require large expenditures for their construction.

They are characterized by the following features:

- Ease of assembly design.

- Small depth, which can reach 10 m.

- Strength with the correct installation of each structural element.

It will be mandatory to install on them:

- Water pumps.

- filter stations.

Water well

Mine wells are dug using:

- Improvised tool: shovels. The earth is raked out with buckets or other large containers.

- Special equipment: machines with buckets.

Forms can be different:

- Square.

- Round.

- Rectangular.

This does not prevent the use of reinforced concrete elements of wells, which have a round shape, in the design.

Concrete concrete rings for the construction of a water well structure

Concrete concrete rings and other elements for the construction of a well for water

Concrete concrete wells for water have always been very popular.

This is due to:

- High strength rings.

- Various sizes of structural elements.

- Possibility of deepening and installation of well rings and other elements.

Concrete concrete rings are made using:

- Solution of concrete.

- Special strengthening agents.

- Reinforcing meshes of different sizes, which help to make the rings stronger and more durable.

- Rubble or gravel. Only such material should be small in size in order to ensure a reliable bonding of all elements of the solution.

The price of rings depends on their type and the functions they perform. There are several types of rings that are used in the construction of a structure.

It:

- Wall rings (support). Their purpose is to organize the walls of the structure, and they subsequently serve to support the floor slab.

- Rings with locks. At the moment, they are used most often in construction, since they have special locks on their walls at the end, which make it possible to make the structure durable due to the reliable fastening of each element to each other.

- Bottom rings. They are used to organize the bottom.

- Rings with a floor slab that complete the structure.

- Neck rings. They are mounted on support rings and serve as a support for the floor slab.

What is it for?

Concrete solution allows:

- Securely fasten each element of the structure.

- Protect against displacement of soils, which can cause deformation of the structure and, as a result, water pollution.

- Seal the seams from the ingress of metal impurities, ground and melt water.

You can make a concrete solution for such work with your own hands.

For this you will need:

- Cement brand 400.

- Water.

- Sand (cleaned).

The dimensions of the reinforced concrete rings for the well may be different.

There are the following ring options:

- The inner diameter starts from 70 cm and ends at 1 m.

- The outer diameter starts at 110 cm and ends at 126 cm.

- The height of the rings is 10-70 cm.

- The thickness of the walls reaches 10 cm.

Dimensions of reinforced concrete rings and other structural elements

Other reinforced concrete elements for construction

Concrete concrete well can be made not only with the help of standard rings. There are also plates for arranging the structure.

They are used in case:

- The design has a square or rectangular shape.

- The soil does not allow the use of round plastic or reinforced concrete rings due to the very frequent displacement.

The following structural elements are installed using:

- A solution of concrete, which processes the joints of the sheets.

- Special equipment, since manually mounting the structure will not work due to the large weight of the material itself.

Plate sizes can be:

- 1x1 m.

- 1.25x1.50 m.

- 1.25x1.25 m.

Advantages of a reinforced concrete well

The main advantage will be that it can be built on any type of soil.

Reinforced concrete wells:

- Durable and reliable.

- Serve for a long time.

- Concrete is not able to emit harmful substances that can affect the quality of well water.

- The walls of the structure in case of clogging can be cleaned with their own hands using any special means.

What can wells be?

At the moment, there are three types of wells that are used in suburban areas:

- Water pressure.

- Lookouts.

- Sewer.

Functions of water wells

The main function of this design is to provide water to a residential building. can be different, since the aquifer is located differently in each area. As a rule, wells with water supply are mine and various materials are used for their arrangement inside:

- Wood, which is laid out around the entire perimeter of the internal walls of the structure.

- Stone (brick or natural agglomerate), which is used in a similar way.

- Rings. Here the choice of such material for arrangement is quite wide.

Construction stages

Installation is carried out in the following order:

- A place is selected, an installation scheme is built, and the parameters of the septic tank are calculated.

- A hole is being dug.

- Rings are installed, pipes are connected.

- Sealing and waterproofing works are underway.

- Covers are installed.

- Backfilling is underway.

Video description

The order of work and the installation of a septic tank from concrete rings on the video:

How to choose the best place for a septic tank

The structure is mounted above the groundwater level. The best location is at the maximum distance from the house (at least 7 meters, but not more than 20, so as not to increase the cost of pipeline construction). It is logical to have a septic tank on the border of the site, next to the road. This will reduce operating costs, since the cost of leaving the tanker-vacuum truck is affected by access to the system and the length of the hose. In addition, with the correct location, the sewage truck does not need to drive into the yard, and the hoses will not roll on the beds or paths (otherwise, when the hose is rolled up, the waste can get into the garden).

Pit preparation

Ground work using an excavator takes 2-3 hours. The size of the pit should be slightly larger than the dimensions of the wells. This is necessary for the smooth installation of rings and their waterproofing. The bottom is covered with rubble and concreted.

Preparing a pit for a septic tank from concrete rings

Installation of rings and sewer pipes

Rings for a septic tank are installed using lifting equipment, which saves a lot of time (when compared with manual installation). Fixation of the seams is provided with cement mortar, metal ties (brackets, plates) are additionally placed.

The crucial moment is the process of installing rings

Sealing and waterproofing

Sealing the seams of the septic tank from concrete rings is carried out on both sides of the structure. For this, cement and coating protective solutions are used. Inside the well, you can install ready-made plastic cylinders. Such additional costs will make the system 100% hermetic.

In the process of waterproofing concrete rings for a septic tank, the joints are treated with liquid glass, mastic based on bitumen or polymer, concrete mix. To prevent freezing (and destruction) of the structure in winter, it is recommended to insulate it with a layer of polystyrene foam.

Sealing joints and waterproofing a septic tank from concrete rings

Manhole installation and backfill

The wells are covered with concrete slabs, with holes for manholes. In the first two wells, ventilation is necessary to remove methane (gas appears as a result of the vital activity of anaerobic bacteria). To backfill the installed floors, use the soil taken out of the pit (backfill).

Backfilling of finished wells

How does the septic tank start up

In order for the system to begin to function effectively, the erected septic tank must be saturated with anaerobic microflora. The natural accumulation process takes several months, so it is accelerated by saturating the septic tank with imported microflora. You can do this in two ways:

- A new septic tank is filled with wastewater and defended for 10-14 days.Then it is loaded with sludge from an operating anaerobic septic tank (2 buckets per cubic meter).

- You can buy ready-made bioactivators (bacterial strains) in the store (the main thing here is not to confuse them with aerobes that are intended for other treatment systems).

Ready to run septic tank from the rings

What rules must be observed when maintaining a septic tank

There are simple rules that support the quality of the system.

- Cleaning. Twice a year, in addition to cleaning the drains, the septic tank must be inspected and the pipelines cleaned. Once every 5 years (and preferably in 2-3 years), bottom heavy fats are cleaned. The volume of sludge must not exceed 25% of the volume of the tank. During cleaning, part of the sludge is left to restore the microflora.

- Quality of work. Effluent at the outlet of the system must be cleaned by 70%. Analysis of wastewater in the laboratory will determine the acidity index, which will allow you to know the quality of the drainage system.

- Security measures:

- Work inside the septic tank is allowed only after enhanced ventilation and using a safety belt (gases formed inside can be dangerous to human life).

- Increased safety measures are required when working with power tools (wet environment).

A septic tank made of concrete rings makes private housing more autonomous and, despite its shortcomings, it is one of the most reliable and durable options for treatment facilities for suburban real estate.

How to calculate the cost of a well from reinforced concrete rings

The cost of a well made of reinforced concrete rings consists not only of spending on the rings themselves. Additionally, the estimate includes the cost of:

- digging holes for rings

- product delivery

- assembly structure

- construction of a well house (if necessary)

- additional materials, such as cement to fill the joints between the rings or pebbles for the filter layer

It is important to take into account its main profile. It is more profitable when it is the production of rings - the main cost item

If the company specializes in the installation and digging of wells, the material for them is overbought, and therefore overpriced.

Installation of rings and digging a well from ring manufacturers is a related service, so the price tag for it is acceptable, comparable to the requests of intermediary firms. Calculating the required number of rings, take into account the depth of the well. It depends on the water level. Experts help you find out. You also have to pay for their challenge and verdict.

Also, the cost of the well depends on its diameter and shape. More concrete is used for square reinforced concrete rings, and therefore the price tag is higher. All this must be taken into account in the question of how to calculate the cost of a well from reinforced concrete rings.

Manufacturing process

The production of concrete rings begins with preparatory work.

Required equipment

To begin with, we assemble equipment for the manufacture of concrete rings:

| Name | Purpose |

| Concrete mixer | Brings the cement mortar to the required homogeneity |

| Blanks for rings | They are a kind of removable formwork that allows you to give the product the desired shape. |

| Vibrator | Provides vibration shrinkage of the concrete mix to avoid air pockets |

| Winch with tripod | Facilitates the movement of rings, the mass of which can exceed 500 kg |

| Reinforced frame | Provides the necessary strength to the concrete structure |

Sample vibrator for concrete

In more detail, you should dwell on the workpiece.

Ring mold

This is the most important equipment for concrete rings, without which everything else is useless. And you can either buy it ready-made or build it yourself.

Such a blank consists of the following elements:

- Metal or plastic circles equal to the outer and inner diameters of the poured ring. When hand-made, sections of pipes or barrels, as well as thin curved sheets of tin or polyvinyl chloride, fastened together by door canopies or other connecting elements, will fit in this capacity. In the most hopeless situation, you can lay out the desired contours from the boards.

Purchased forms for greater ease of use can be divided into component parts

- Cone-shaped "cap" for the central glass. It will allow the solution poured from above to drain into the right direction.

Conical lid

Tip: if the production of concrete rings takes place in the open air, then it is recommended to add special covers to the structure that cover the mortar.

This will prevent the ingress of various debris into it.

Manufacturing technology

The operating instructions for the listed equipment are as follows:

- We set the form on a solid, even and moisture-resistant base.

Cement screed is the ideal platform for pouring rings

- We create a frame from reinforcement by twisting steel bars with soft wire.

Tip: be sure to bring a few metal loops around the perimeter of the ring up beyond the fill.

A cable will cling to them during transportation, and they will also prevent products from sliding during installation.

- We mix the solution in a concrete mixer. For this we need the following ingredients:

| Component name | Purpose | Share ratio |

| Cement | Stones by bonding fine and coarse aggregates | 1 |

| Sand | Fills pores to reduce moisture absorption | 2 |

| Gravel | Gives the finished product high compressive strength | 4 |

| Water | Carries out a chemical reaction with cement, causing it to petrify | 3,5 |

Tip: it is recommended to use cement not lower than grade M400.

So you guarantee a sufficient level of setting.

400 grade cement

- We lay concrete in layers of twenty centimeters, carefully tamping with a metal rod.

- After the mold is completely filled, we turn on the vibration unit to maximize the compaction of the mixture and fill all the pores with it.

- Add concrete if necessary.

- After two weeks, we remove the formwork for the concrete product by removing the central part first, and then the outer one.

- We transport the structure to the place of installation.

Transportation of the finished concrete product

Mounting Recommendations

The installation of concrete rings is carried out manually using a winch with a tripod, which we leave from production work, and a shovel:

- We dig a hole under the first ring and install it.

Pit for the installation of the first reinforced concrete product

- Then we dig already inside it, deepening twenty centimeters.

- Then we take out the soil directly from under the structure, leaving small earthen supports.

- We knock out the remaining soil, after which the concrete ring settles.

- Using this method, we create a mine of the required size.It is noteworthy that concrete fences during the entire procedure will protect you from a possible collapse of the earth.

Digging inside a well

Useful video on the topic

In the video clip, the master independently assembles a metal mold, coats its walls with used oil, prepares a concrete solution and fills the formwork. With the help of special equipment, the mixture in the form is carefully compacted so that there are no defects in the walls of the well.

The video shows how easy it is to remove the formwork starting from the inner ring. By the way, the well ring is made without a reinforcing frame, so the thickness of the product is at least 15 cm.

In this video, the mold is designed for casting a thinner reinforced concrete ring. The master uses steel wire as reinforcement. The plot shows in more detail the process of putting ingredients into a concrete mixer.

As you can see, any healthy man can make reinforced concrete rings for a well. Special skills in making molds and mixing concrete mortar are not required.

Little tricks can be seen in the video stories on this topic. In a month, a person on his own can cast up to ten reinforced concrete rings using one mold. This is quite enough to equip the well shaft. Its depth depends on the level of the aquifer in your area.

Do you have experience in making concrete rings? Please share information with our readers, tell us about the features of your method. You can leave comments and ask questions on the topic of the article in the form below.

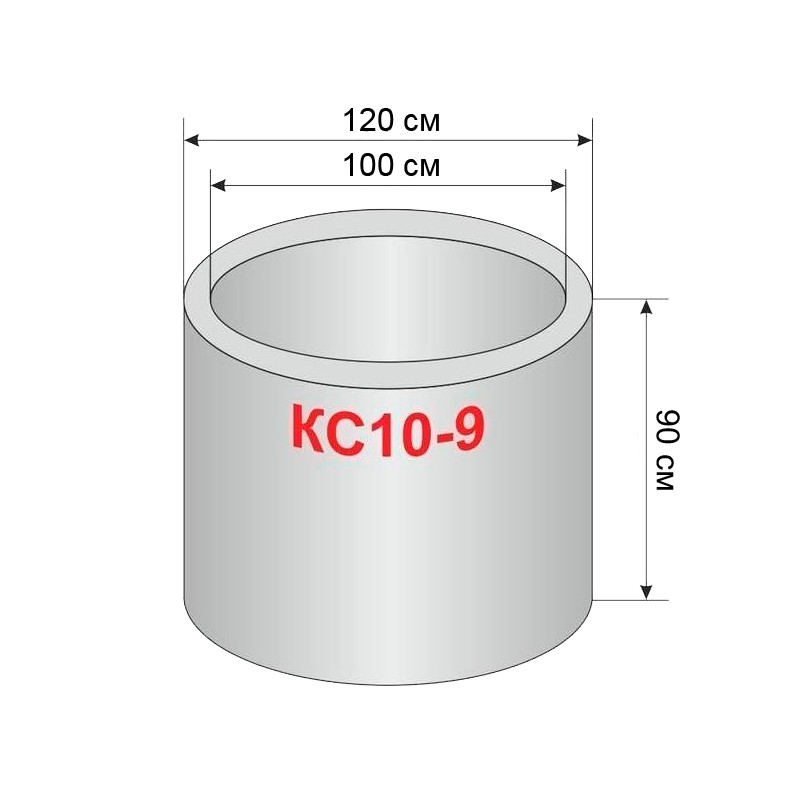

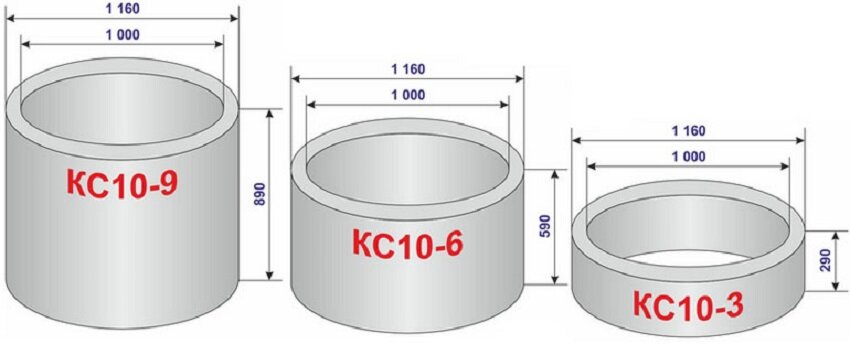

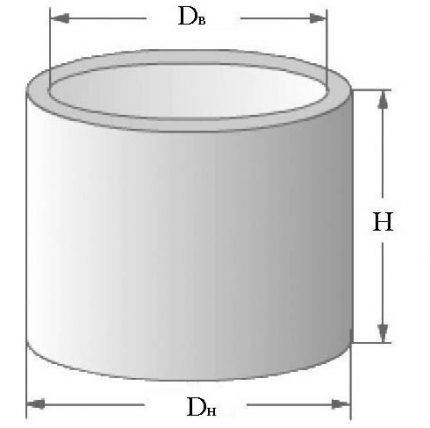

All about sizes

The dimensions of reinforced concrete rings for wells are regulated by GOST 8020-90 "Concrete and reinforced concrete structures for wells of sewer, water and gas networks." The products we are interested in are marked KS, followed by numbers indicating the inner diameter of the well rings and their height in decimeters.

The most popular rings used for the construction of individual wells are KS10, KS15 and KS20 with a height of 90 cm. Shafts with a diameter of less than a meter are difficult to dig manually, and making them more than two meters is not economically viable, since the cost of rings for a well directly depends on the number used for their production materials.

The table shows the size of the well rings and the corresponding mass and volume of the product

As can be seen from the table, in addition to those listed, rings and other sizes are also available. They are called additional or auxiliary and are used for repair, deepening of wells, and installation of above-ground heads of the required height.

They can have a height of 10 to 70 cm and a diameter of at least 70 cm.

Main and additional rings

The wall thickness is also of great importance. The larger it is, the stronger the product and the higher the cost of well rings.

The thickness is selected taking into account the type of soil, its ability to frost heaving, so that during operation the walls of the shaft do not collapse from a compressive load or move relative to each other, violating the tightness of the column.