- How to make a reinforced concrete ring yourself.

- The headband is beautiful and functional

- ring requirements.

- How to make a formwork for a reinforced concrete ring

- Characteristic features of the device of wells

- Varieties of reinforced concrete modules

- Well rings

- What can you make a mold out of?

- Construction stages

- Video description

- How to choose the best place for a septic tank

- Pit preparation

- Installation of rings and sewer pipes

- Sealing and waterproofing

- Manhole installation and backfill

- How does the septic tank start up

- What rules must be observed when maintaining a septic tank

- Buy ready-made or make your own?

- Useful video on the topic

- How and from what to make molds for concrete rings

- From barrels with thick walls

- sheet metal

- From wooden boards or bars

- Basic Information

- Postulate 1. Position correctly

- Postulate 2. Look at the GWL

- Postulate 3. Calculate the volume of the septic tank with a margin

- Postulate 4. Hire people to develop the pit

- Postulate 5. Order rings with delivery and installation

- Postulate 6. Use only red pipes

- Postulate 7. The filtration field occupies a large area

How to make a reinforced concrete ring yourself.

Every homeowner has desires to improve their housing and the territory on which personal possessions are located

An important place among the general plans is the desire to be independent from the general communal systems of the regional municipality, or to improve everything in its own way if there are no common communal systems. Who will refuse a personal water supply, a well dug with their own hands or an equipped septic tank, which not only receives sewage sewage, but also, for example, produces gas for a stove?

The main participating element in the listed structures is the reinforced concrete ring familiar to us.

It is good when there are conditions for the purchase of rings and their delivery to the house. And what about the rest, who do not have financial and delivery opportunities?

You can buy a ready-made formwork for making rings, or you can make a formwork for a reinforced concrete ring.

In the beginning, you need to decide on the dimensions of future rings: diameter, height. The thickness recommended everywhere should be at least 7-10 centimeters. And this is an important recommendation.

The technology is simple and there are no difficulties if everything is done carefully and slowly. A successful result is obtained even for those who have done this for the first time.

The headband is beautiful and functional

The final stage of the construction of any well will be the installation of a cap - a beautiful and functional detail. The head is based on a primitive lifting mechanism, but it is also designed to protect the source from contamination. In a beautiful design, it can be an excellent decor element on the site. Also, at the construction stage, it is advisable to think over the organization of the water supply to the outdoor shower, if it is available on your site.

The head of the well is drawn up at the discretion of the owner of the site

The head of the well is drawn up at the discretion of the owner of the site

To organize the head, the upper ring of the well should protrude 60-80 cm above the surface. But in the first year after construction, it is not recommended to arrange the site, since the earth can still subside a little. Build a temporary lift with a good roof. A head or a house for a well can be made independently or purchased ready-made. As a rule, they are sold unassembled, but assembling all the parts is not much more difficult than a children's designer.

ring requirements.

The existing wells intended for drinking water must be isolated from the ingress of polluted water.

More:

- Sewer wells are used to collect polluted effluents. Protecting the discharge of sewage into the ground is unacceptable. For this, they are waterproofed.

- For maintenance of underground communications, technical inspection rooms were installed. The ingress of water into these wells is unacceptable.

Letters and numbers are used to mark rings:

- The letter index shows the purpose of the ring.

- The numbers indicate the diameter and height of the ring.

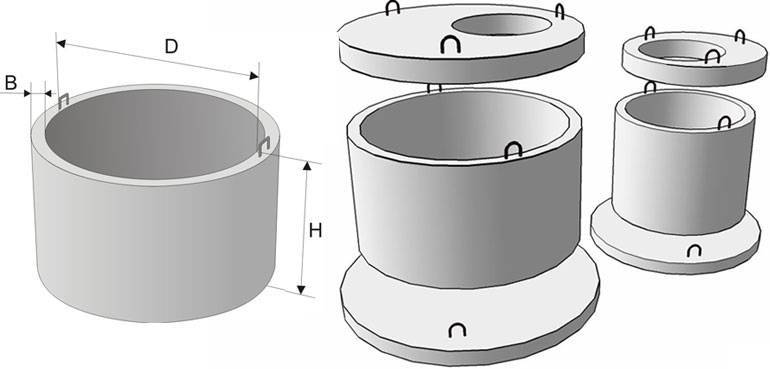

The photo shows all types that are used in water supply facilities.

How to make a formwork for a reinforced concrete ring

For the manufacture of such formwork, you can use the ‘Advice from Maksimych, or you can use ingenuity. Who does not have enough time for this, I offer my proven option, which turned out to be the most convenient for me. It will suit you - decide for yourself.

According to the diameter of the future ring you have chosen, pick up two metal barrels. Extruded stiffeners on the walls of the barrels will not affect the process of making rings.

You can find the desired diameter of air ducts or pipes.Or you can assemble formwork cylinders by connecting individual sheets to each other. A good result is shown by formwork made from plastic barrels.

Characteristic features of the device of wells

Before building a well from concrete rings, it is important to know its device. There are two elements in the well: an underground element and an element located above the ground. Before starting work, they are determined with the location of the well

They begin to dig the earth to a depth that allows you to install water filtration, which is required to purify water from clay, dust and other contaminants. The hydraulic structure must be protected from the ingress of sewage, precipitation and sewage

Before starting work, they are determined with the location of the well well. They begin to dig the earth to a depth that allows you to install water filtration, which is required to purify water from clay, dust and other contaminants. The hydraulic structure must be protected from the ingress of sewage, precipitation and sewage.

The construction of the well structure consists of 3 parts:

Installation of the head of the hydraulic structure, which is the upper part in the wells, located above the ground. The above-ground structural element performs the function of protection against the ingress of sewage and precipitation, which can contaminate drinking water. It consists of a roofing part, a blind area, a canopy and a lifting mechanism. Decorate the head: with wood, stone, plaster or other facing materials

It is important to provide an element for draining rainwater, which is installed outside the head.

Arrangement of trunks of a hydraulic structure.This is a place located underground in the gap between the head and the bottom. Water is lifted along the trunk using a bucket and a rope or other lifting device.

The shaft of the mine has a casing, the function of which is to protect the concrete well from destruction and the penetration of groundwater into the middle of the structure.

The construction of a water intake part, which is designed to store water, filter it and settle it.

Water is lifted along the trunk using a bucket and a rope or other lifting device. The shaft of the mine has a casing, the function of which is to protect the concrete well from destruction and the penetration of groundwater into the middle of the structure.

The construction of a water intake part, which is designed to store water, filter it and settle it.

The water intake part includes a casing string, a filter and can be of 3 types:

- Incomplete - this concrete structure has no difficulties in execution, in it the casing string does not reach the layer of impermeable rocks and water comes from below. The imperfect design has a small volume of water and is suitable for small families.

- The complete water intake part is complex in execution and has a casing string abutting against a layer of impermeable rocks. The volume of part of the accumulation of water is average, and the liquid is supplied through the walls of the well.

- Perfect water intake with sump. The depth reaches one and a half meters of water reserves. It is applied in case of a large amount of water consumption.

Varieties of reinforced concrete modules

The simplest standard models are produced without additional fasteners. They have a smooth and flat rim both at the top and at the bottom.

When laying, they are placed one on top of the other and fastened with metal staples. The joint area is covered with cement mortar or dry repair mortar.

As a sealant for well rings, you can use a hydraulic seal. The material consists of special grade cement and quartz sand. Dries quickly and expands over time. Protects the reinforced concrete line from the ingress of sewage

After such processing, the system acquires optimal integrity and tightness. Proper insulation in the zone of contact of concrete elements extends the operational period of the mine and almost completely eliminates water leakage through the gaps between the concrete elements.

Although reliable and durable, standard rings without a lock are suitable for installation in regions with weak seismicity. Strong soil movements can lead to displacement of modules and cracking of cement in the joint area

Eurorings are available with a practical flange type locking connection. In the upper part of such products there are protrusions, and in the lower part there are deep recesses.

During installation, the elements are inserted into each other, thus providing a monolithic and strong connection that does not require additional processing in the docking area.

When purchasing well rings with flanges, you should carefully monitor their quality. Poorly molded mating parts will complicate the work and require the use of diamond cutting to eliminate errors and imperfections

This facilitates and speeds up the process of creating a communication system and reduces the overall financial costs of the project.

A well shaft made of eurorings with a lock is not afraid of seismic activity with shifts and maintains the integrity of the structure even on very active soils prone to subsidence.

A monolithic glass is a one-piece construction of a wall ring and a bottom. It is used in places with increased requirements for tightness, for example, for sewer tanks.

Provides a high level of environmental friendliness and does not allow the contents of the well to seep into the ground or get into groundwater.

Well rings

The well is used for water intake, laying of communications and wires, sewerage devices. Its presence is mandatory for multi-storey buildings. The treatment system of a country house also needs a hydraulic structure.

It is subject to sanitary and hygienic standards, the structure must be strong and durable. To meet these requirements, ring elements are used in the construction of the well.

The purpose of the hydraulic structure directly affects which parts are best used. There are several varieties of it:

- Drinking - for the intake of drinking water, equipped with appropriate mechanisms. Water should be as free as possible from impurities and dirt;

- plumbing - part of the plumbing system, it installs the necessary equipment;

- drainage - to control the drainage system;

- observation room - to monitor the condition of the sewer;

- telephone - for laying communication networks;

- for gas pipeline networks. Install the structure in cases corresponding to GOST;

- for a cesspool - a way to organize sewage;

- for a septic tank - a place for a sump;

- storm - to remove excess water from the site.

What can you make a mold out of?

Reinforced concrete rings are poured, usually in formwork made of:

- steel sheet;

- boards.

In both of these cases, the finished form is a prefabricated structure consisting of several parts. Solid formwork for pouring reinforced concrete rings cannot be made. After all, it will be very difficult to get the finished product from the form of such a design after the cement mortar has hardened.

Formwork of this type is cut out from sheet steel by a grinder with a preliminary cutting. Next, the metal is given the appropriate shape by bending and fixed in this position.

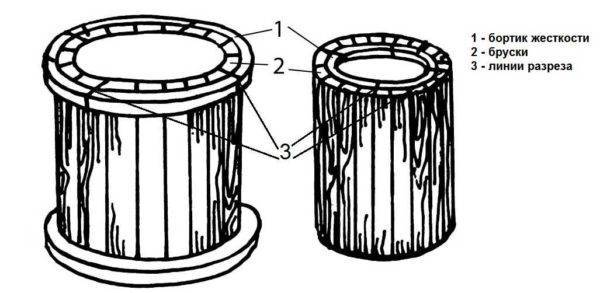

To make a wooden mold:

- Four narrow metal rings are welded. The diameter of these formwork elements is selected in accordance with the inner and outer diameters of the future reinforced concrete product.

- The rings made in this way are sheathed vertically with boards. Lumber for the assembly of such formwork should not be taken too wide.

- Divide the inner and outer parts of the resulting formwork into compartments.

- Locks are made to connect the arcuate parts of the form.

Construction stages

Installation is carried out in the following order:

- A place is selected, an installation scheme is built, and the parameters of the septic tank are calculated.

- A hole is being dug.

- Rings are installed, pipes are connected.

- Sealing and waterproofing works are underway.

- Covers are installed.

- Backfilling is underway.

Video description

The order of work and the installation of a septic tank from concrete rings on the video:

How to choose the best place for a septic tank

The structure is mounted above the groundwater level. The best location is at the maximum distance from the house (at least 7 meters, but not more than 20, so as not to increase the cost of pipeline construction).It is logical to have a septic tank on the border of the site, next to the road. This will reduce operating costs, since the cost of leaving the tanker-vacuum truck is affected by access to the system and the length of the hose. In addition, with the correct location, the sewage truck does not need to drive into the yard, and the hoses will not roll on the beds or paths (otherwise, when the hose is rolled up, the waste can get into the garden).

Pit preparation

Ground work using an excavator takes 2-3 hours. The size of the pit should be slightly larger than the dimensions of the wells. This is necessary for the smooth installation of rings and their waterproofing. The bottom is covered with rubble and concreted.

Preparing a pit for a septic tank from concrete rings

Installation of rings and sewer pipes

Rings for a septic tank are installed using lifting equipment, which saves a lot of time (when compared with manual installation). Fixation of the seams is provided with cement mortar, metal ties (brackets, plates) are additionally placed.

The crucial moment is the process of installing rings

Sealing and waterproofing

Sealing the seams of the septic tank from concrete rings is carried out on both sides of the structure. For this, cement and coating protective solutions are used. Inside the well, you can install ready-made plastic cylinders. Such additional costs will make the system 100% hermetic.

In the process of waterproofing concrete rings for a septic tank, the joints are treated with liquid glass, mastic based on bitumen or polymer, concrete mix. To prevent freezing (and destruction) of the structure in winter, it is recommended to insulate it with a layer of polystyrene foam.

Sealing joints and waterproofing a septic tank from concrete rings

Manhole installation and backfill

The wells are covered with concrete slabs, with holes for manholes. In the first two wells, ventilation is necessary to remove methane (gas appears as a result of the vital activity of anaerobic bacteria). To backfill the installed floors, use the soil taken out of the pit (backfill).

Backfilling of finished wells

How does the septic tank start up

In order for the system to begin to function effectively, the erected septic tank must be saturated with anaerobic microflora. The natural accumulation process takes several months, so it is accelerated by saturating the septic tank with imported microflora. You can do this in two ways:

- A new septic tank is filled with wastewater and defended for 10-14 days. Then it is loaded with sludge from an operating anaerobic septic tank (2 buckets per cubic meter).

- You can buy ready-made bioactivators (bacterial strains) in the store (the main thing here is not to confuse them with aerobes that are intended for other treatment systems).

Ready to run septic tank from the rings

What rules must be observed when maintaining a septic tank

There are simple rules that support the quality of the system.

- Cleaning. Twice a year, in addition to cleaning the drains, the septic tank must be inspected and the pipelines cleaned. Once every 5 years (and preferably in 2-3 years), bottom heavy fats are cleaned. The volume of sludge must not exceed 25% of the volume of the tank. During cleaning, part of the sludge is left to restore the microflora.

- Quality of work. Effluent at the outlet of the system must be cleaned by 70%.Analysis of wastewater in the laboratory will determine the acidity index, which will allow you to know the quality of the drainage system.

- Security measures:

- Work inside the septic tank is allowed only after enhanced ventilation and using a safety belt (gases formed inside can be dangerous to human life).

- Increased safety measures are required when working with power tools (wet environment).

A septic tank made of concrete rings makes private housing more autonomous and, despite its shortcomings, it is one of the most reliable and durable options for treatment facilities for suburban real estate.

Buy ready-made or make your own?

First, let's analyze the cost. On average, a finished ring costs from 1,500 rubles. up to 4500 rubles, depending on the brand of concrete, weight and dimensions.

For the manufacture of one ring with a diameter of 1.5 m, 0.3 cubic meters of concrete are needed. The price of a cube of cement is from 2500 rubles. up to 4500 rubles, depending on the brand. The cost of the ring on average is 750 rubles. Savings are evident.

Secondly, we will analyze labor costs. When buying ready-made concrete products, all efforts will be directed to finding a conscientious manufacturer from whom you can purchase a quality product. You will also need to organize the delivery of finished products to the site.

If a decision is made to make reinforced concrete rings with one's own hands, then it becomes necessary to search and purchase high-quality material, tools and make special molds for pouring reinforced concrete products. According to the efforts made, the option of buying ready-made rings comes first.

Useful video on the topic

In the video clip, the master independently assembles a metal mold, coats its walls with used oil, prepares a concrete solution and fills the formwork.With the help of special equipment, the mixture in the form is carefully compacted so that there are no defects in the walls of the well.

The video shows how easy it is to remove the formwork starting from the inner ring. By the way, the well ring is made without a reinforcing frame, so the thickness of the product is at least 15 cm.

In this video, the mold is designed for casting a thinner reinforced concrete ring. The master uses steel wire as reinforcement. The plot shows in more detail the process of putting ingredients into a concrete mixer.

As you can see, any healthy man can make reinforced concrete rings for a well. Special skills in making molds and mixing concrete mortar are not required.

Little tricks can be seen in the video stories on this topic. In a month, a person on his own can cast up to ten reinforced concrete rings using one mold. This is quite enough to equip the well shaft. Its depth depends on the level of the aquifer in your area.

Do you have experience in making concrete rings? Please share information with our readers, tell us about the features of your method. You can leave and ask questions on the topic of the article in the form below.

How and from what to make molds for concrete rings

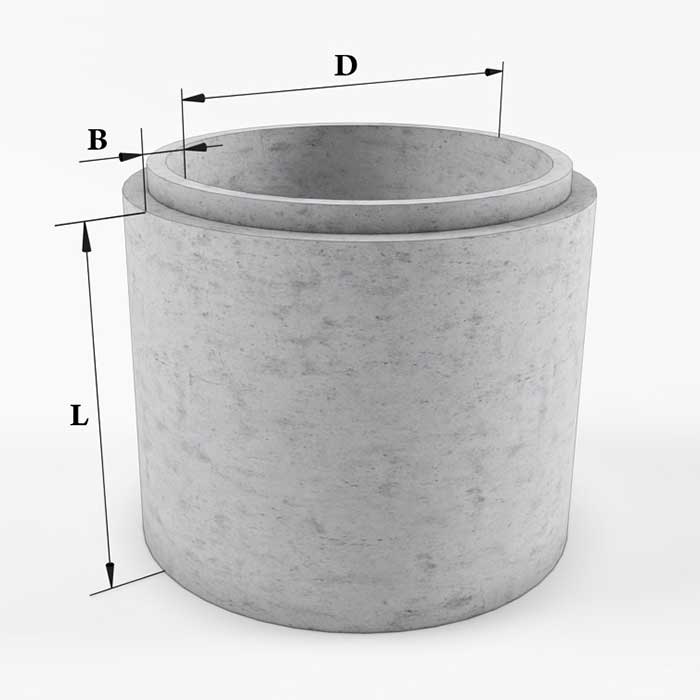

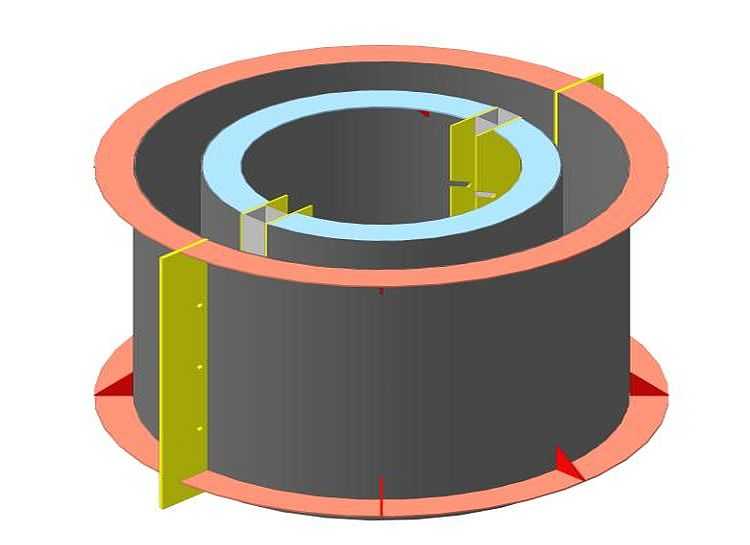

Factory forms are made of sheet metal, reinforced with stiffeners. Metal thickness - 3-8 mm depending on dimensions rings.

Forms for well rings are most often made of metal

From barrels with thick walls

At home, bending sheet metal with the required radius of curvature is not at all easy. It is much easier to find two thick-walled barrels with different diameters. The diameters should differ by 14-16 mm.In this case, the wall thickness will be 7-8 mm. For a well ring with reinforcement - what is required.

To make it easier to work with the form for reinforced concrete rings, you can fasten the two halves with door hinges

The bottom of the barrels is cut off, the inside is made about 10 cm higher - it’s more convenient. In order to be able to remove the formwork from the finished ring, the barrels are sawn lengthwise into two parts. The halves must be securely connected. You can do this in different ways:

- having welded corners with drilled holes, tighten with bolts;

- make "ears" into which to drive wedges.

To prevent the inner part from leading, several spacers must be welded to each half, which will keep the walls from curvature.

Having inserted one part of the formwork into another, they are set at the same distance one relative to the other (measuring the gap in a circle). Holes are drilled in several places - under the studs with which they will be fixed. Studs are pieces of bar on both sides of which a thread is cut. The holes are positioned one opposite the other so that the formwork parts can be securely fixed.

Studs are inserted into the drilled holes, tightened with nuts. With a not very large wall thickness of the mold for concrete rings, most likely, you will have to put large washers or plates cut out of metal with a hole under the nuts so that the mold does not bend when pouring concrete.

sheet metal

If desired, you can make forms for concrete rings and from strips of sheet metal and wooden blocks, which will give rigidity to the formwork. Cut off a strip of the desired length - along the circumference + 10 cm per connection. The width of the strip is equal to the height of the ring + 10 cm. Bend the sides 5 cm at the bottom and top, make the same side along the edge of the strip.Drill holes in the side rail for the tie bolts. Cut the upper side every 20-25 cm (less if the diameter of the ring is small). Now the strip can be bent - get a ring. But it is very unstable - "plays". Rigidity can be given with a wooden frame.

Forms for concrete rings can be made from sheet steel

From the bar cut into pieces of 20-25 cm long. Fasten them under the side, drill a hole in the metal, screw pieces of bars onto the screws. With a length of bars of 20-25 cm, the shape will not be round, but multifaceted. If this is critical for you, you can make cuts more often, cut the bars shorter. You also need to strengthen the height. For this, bars are also used. They need to be fastened more often - so that the walls do not sag.

If you know how to use welding, you can go the other way. In addition to sheet metal, you will need a profiled square pipe. Fits 15*15mm or 20*20mm. First you need to bend four identical half-arcs from a profile pipe. Four large ones are for the outer formwork and four smaller ones are for the inner formwork. Weld cut strips of metal to the arcs.

How to use arcs from a profile pipe as a basis

From wooden boards or bars

If it is easier for you to work with wood, you can assemble molds for reinforced concrete rings made of wood. They are assembled from narrow planks, fixed at the bottom and top with a ring. The ring can be made of metal, for example, from a bent profiled pipe. It can be bent on a pipe bender with the required radius of curvature.

Ring molds can be made from wood

If cooperage is your forte, you can also make arcs from wood. The material is not so important. The strength and rigidity of the resulting shape is important

Please note that the ledge is attached outside the larger formwork and inside the smaller one.

Important! In order for the formwork to be removed easily, it is necessary to lubricate the molds before pouring. If you plan to use concrete rings for a well with drinking water, you can use sunflower oil. If some kind of technical structure is planned, it is possible to use mining mixed with engine oil or diesel fuel (or pure engine oil) as a lubricant.

If some kind of technical structure is supposed, it is possible to use mining mixed with engine oil or diesel fuel (or pure engine oil) as a lubricant.

Basic Information

Postulate 1. Position correctly

Choose a place for a septic tank on the most elevated platform of the site. This is necessary so that storm drains do not flow into it.

For the placement of the septic tank, see SP 32.13330.2012, the distances to it should be as follows:

- from home - 5 m;

- from the reservoir - 30 m;

- from the river - 10 m;

- from the well - 50 m;

- from the road - 5 m;

- from the fence - 3 m;

- from the well - 25 m;

- from trees - 3 m

Postulate 2. Look at the GWL

If the groundwater level (GWL) is high, i.e. water accumulates in the pit already at a depth of 1-1.5 m, then this is a reason to think about choosing a different septic tank design, possibly a plastic sump or biological treatment plant. We discussed in detail about ready-made VOC options in this article.

If you firmly settled on the wells, then you should wait until the GWL is lower. For example, summer or winter.This will simplify the development of the pit and the construction of wells: you will not stand knee-deep in water and will be able to concrete the bottom normally and make the seams between the rings airtight.

Postulate 3. Calculate the volume of the septic tank with a margin

Carefully calculate the volume of the septic tank. Please note that the rule according to SP 32.13330.2012, in which the volume must be more than 3 times the volume of wastewater discharged into the sewer per day, is valid only on sandy soils and at low GWL. The rules assume that 1 person per day will discharge 200 liters of wastewater. And this means that in this case you need a septic tank with a volume of 600 liters.

In other cases, the worse the soil drains, the larger the volume of the septic tank. There is a working rule: for a family of 4-5 people with permanent residence, depending on the soil, the septic tank will be 30 m³ - on clay, 25 m³ - on loam, 20 m³ - on sandy loam, 15 m³ - on sand.

| Number of people | Septic tank volume, m³ (working values) | |||

|---|---|---|---|---|

| Sand | sandy loam | Loam | Clay | |

| 1 | 4 | 7 | 10 | 15 |

| 2 | 7 | 12 | 17 | 22 |

| 3 | 10 | 15 | 20 | 25 |

| 4 | 15 | 20 | 25 | 30 |

| 5 | 15 | 20 | 25 | 30 |

| 6 | 17 | 23 | 27 | 35 |

| 7 | 20 | 25 | 30 | 35 |

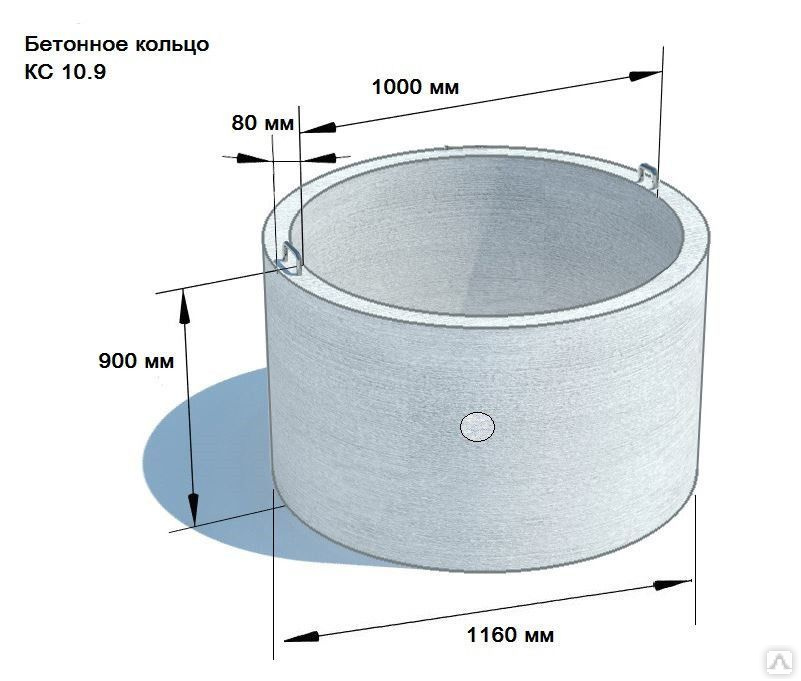

It is necessary to vary the volume of the septic tank not by the depth of the wells, but by the diameter of the rings. Those. if you have a choice of rings with a diameter of 1.5 m and a height of 0.9 m, or a diameter of 1 m and a height of 0.9 m, then it is better to take the first ones. They will need a smaller amount to obtain the desired volume. This means that a not so deep pit is required, there will be fewer seams in the wells.

Postulate 4. Hire people to develop the pit

If you are not a 20-year-old young man, and you do not have a couple of the same assistants who are ready to work for barbecue and beer, then entrust all earthworks to hired workers or hire an excavator.

The pit must be larger than the volume of the treatment plant, i.e. the distance from the wells to the walls of the pit is 30-50 cm.Subsequently, this volume must be covered with a sand-gravel mixture (SGM) or sand.

Postulate 5. Order rings with delivery and installation

Order rings only after the foundation pit is ready. Immediately with the installation, i.e. a truck with a crane-manipulator should arrive.

All lower rings must be bottomed. They are factory-made - convenient and reliable. The exception is filter wells, which are made on well-draining soils. But on clay by no means DO NOT DO IT like the picture below!

After 1-2 years, the bottom of the filtering well becomes silted and does not allow runoff to pass through, you have to call a sewage truck to clean the well, but this does not give a long-term effect.

Postulate 6. Use only red pipes

Pipes are only red, with a diameter of 110 mm, for external sewage. They need to be insulated only if they are in the open air in some area. Everything in the ground does not need to be insulated.

Red pipes are specially designed for outdoor sewage. They are multi-layered, withstand the pressure of the soil. Gray pipes are designed for work inside the house, they are single-layer and the soil will simply crush them.

The pipes are laid in trenches on a compacted sand cushion with a slope of 2 cm by 1 m. Avoid turns of 90 degrees, maximum - 45. A layer of ASG or crushed stone 30 cm thick is poured on top and sides. Next is the soil.

Postulate 7. The filtration field occupies a large area

The filtration field is needed at a high GWL, at a low one, you can get by with a filter well. On average, expect that for 1 person the area of the drainage field should be at least 10 m².

It is appropriate to make a filtration well on well-draining soils: sand and sandy loam.On clay and loam, significantly larger areas are needed from which drainage will be carried out. Underground filtration fields allow this to be done.

Pipes in the filtration field must be laid with a slope of 1 cm by 1 m, so that the treated drains have time to seep through the holes into the crushed stone layer.