- PPE caps - 8 types

- Errors when connecting branch lines to the trunk

- Connection sleeves for high current conductors

- Requirements

- Sleeves

- Purpose and advantage of connectors

- Application example

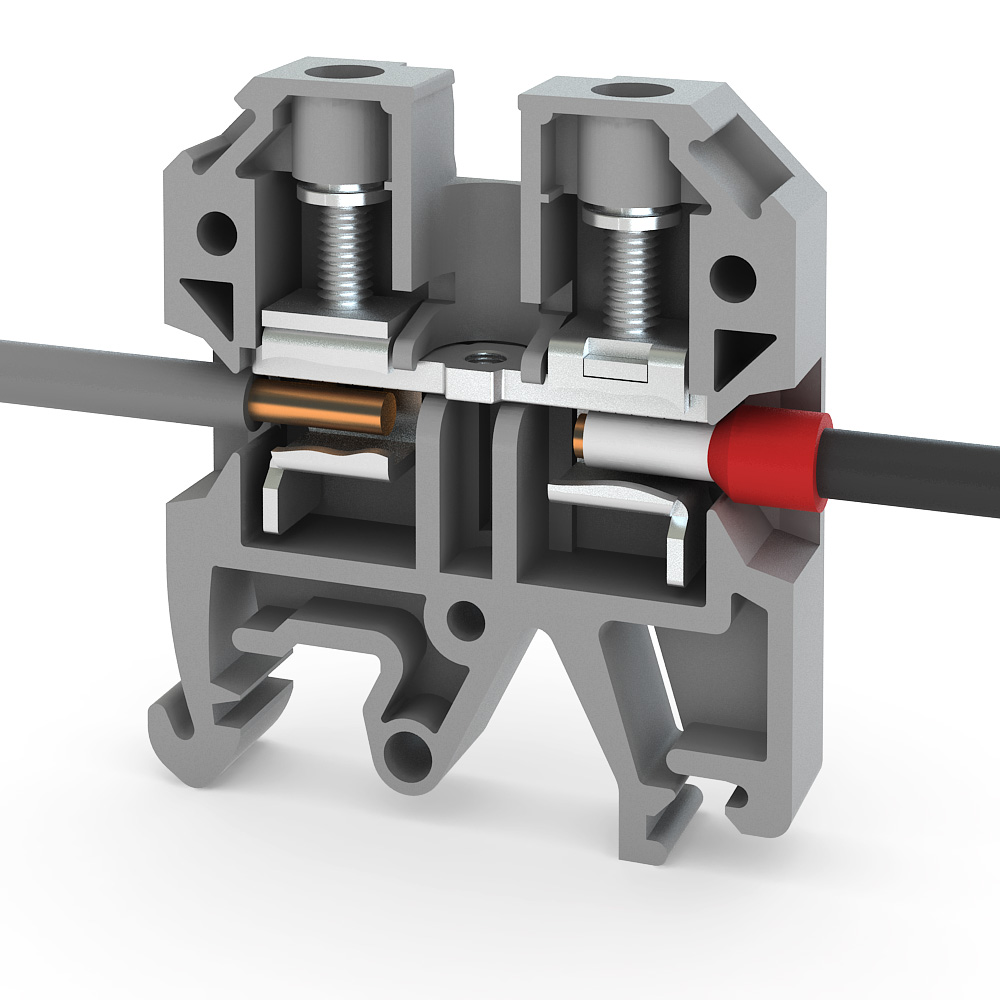

- Terminal clamps

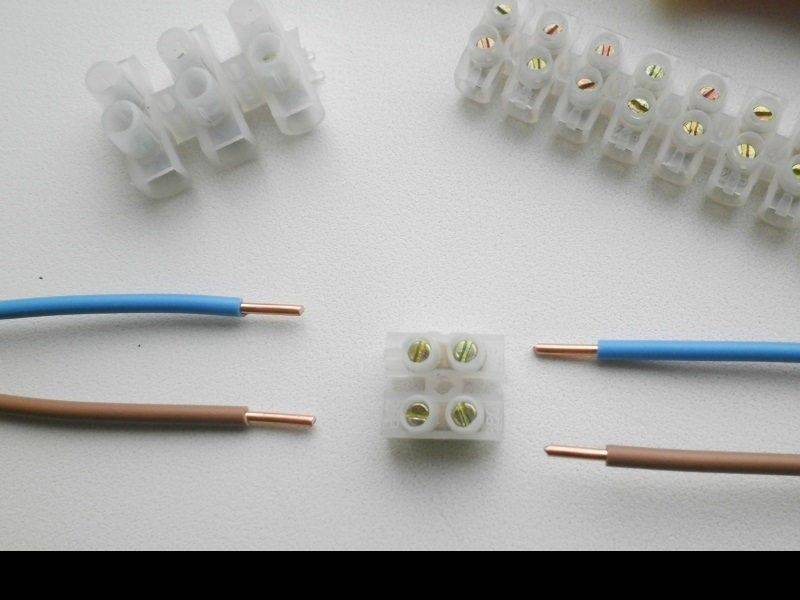

- Terminal block

- Terminals on plastic blocks

- Self-clamping terminals

- Methods for connecting wires or cables to each other

- Crimping

- Bolted connection

- Terminal blocks

- Types of terminal blocks for multi-core and single-core cables

- Terminals in junction box (copper or metal)

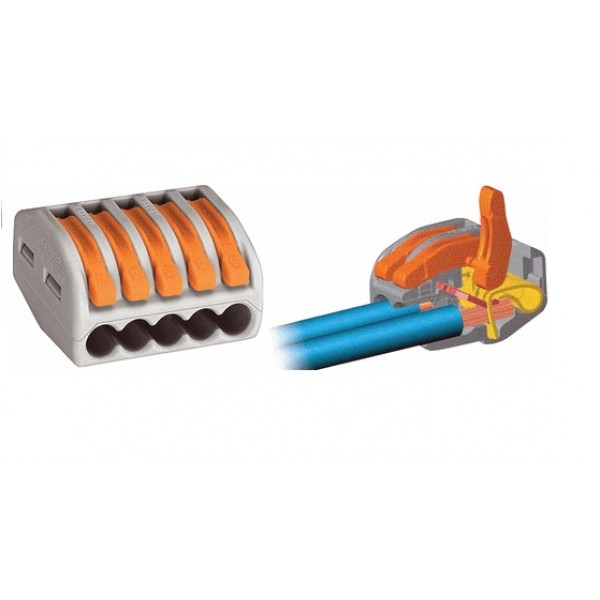

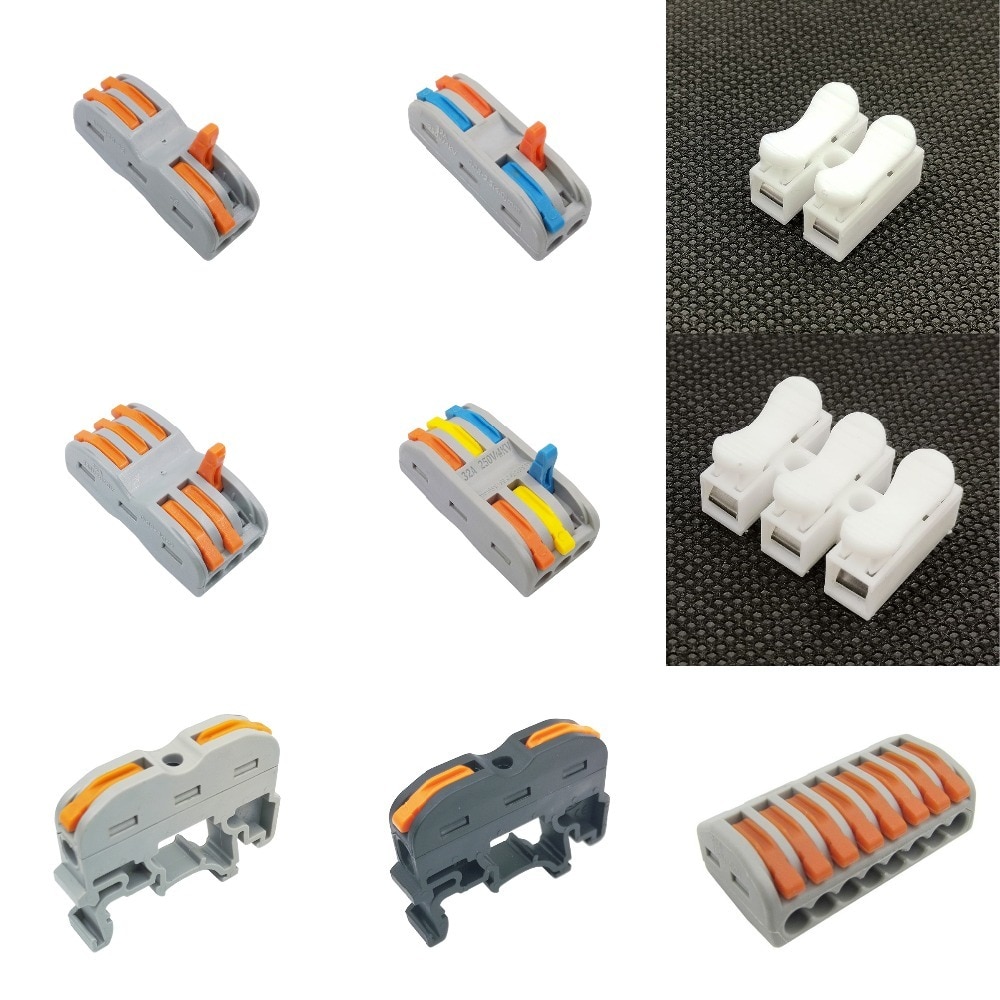

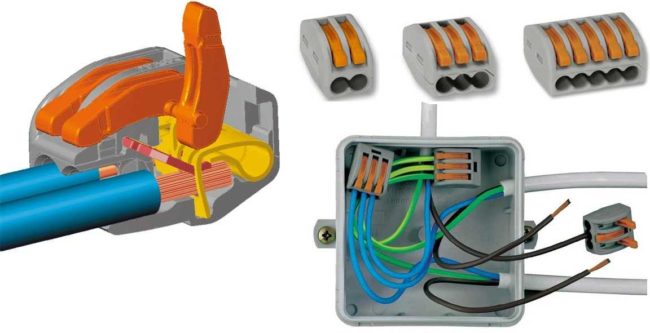

- Self-clamping terminal blocks WAGO

- Use of tips

- Soldering wire lugs

- Main types of terminals

- Screw (construction, barrier)

- Clamp (spring, self-clamping): wire clamps

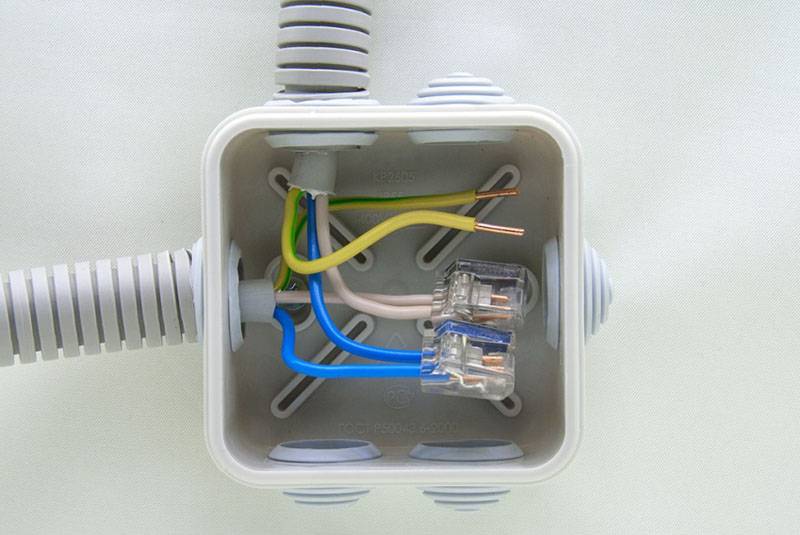

- Junction box terminals

- Fused terminals

- Terminal blocks

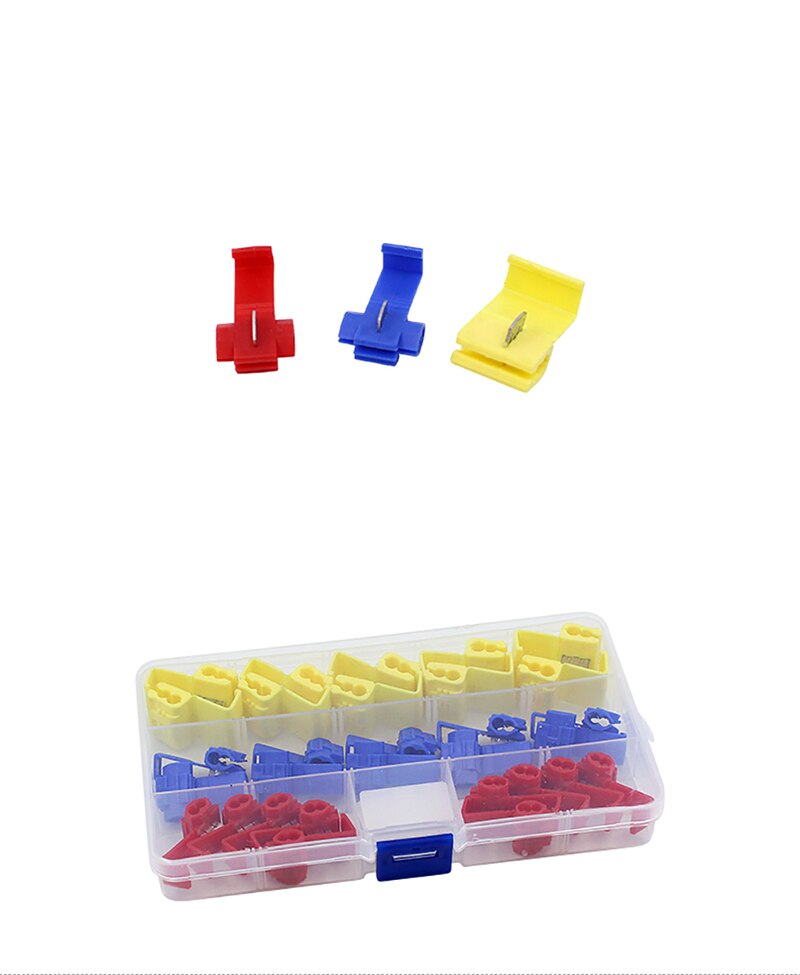

- Knife terminal blocks

- The most common types of electrical clamps

- Simple screw terminals

- Self-pulling and lever clamping designs

- Connecting insulating clips

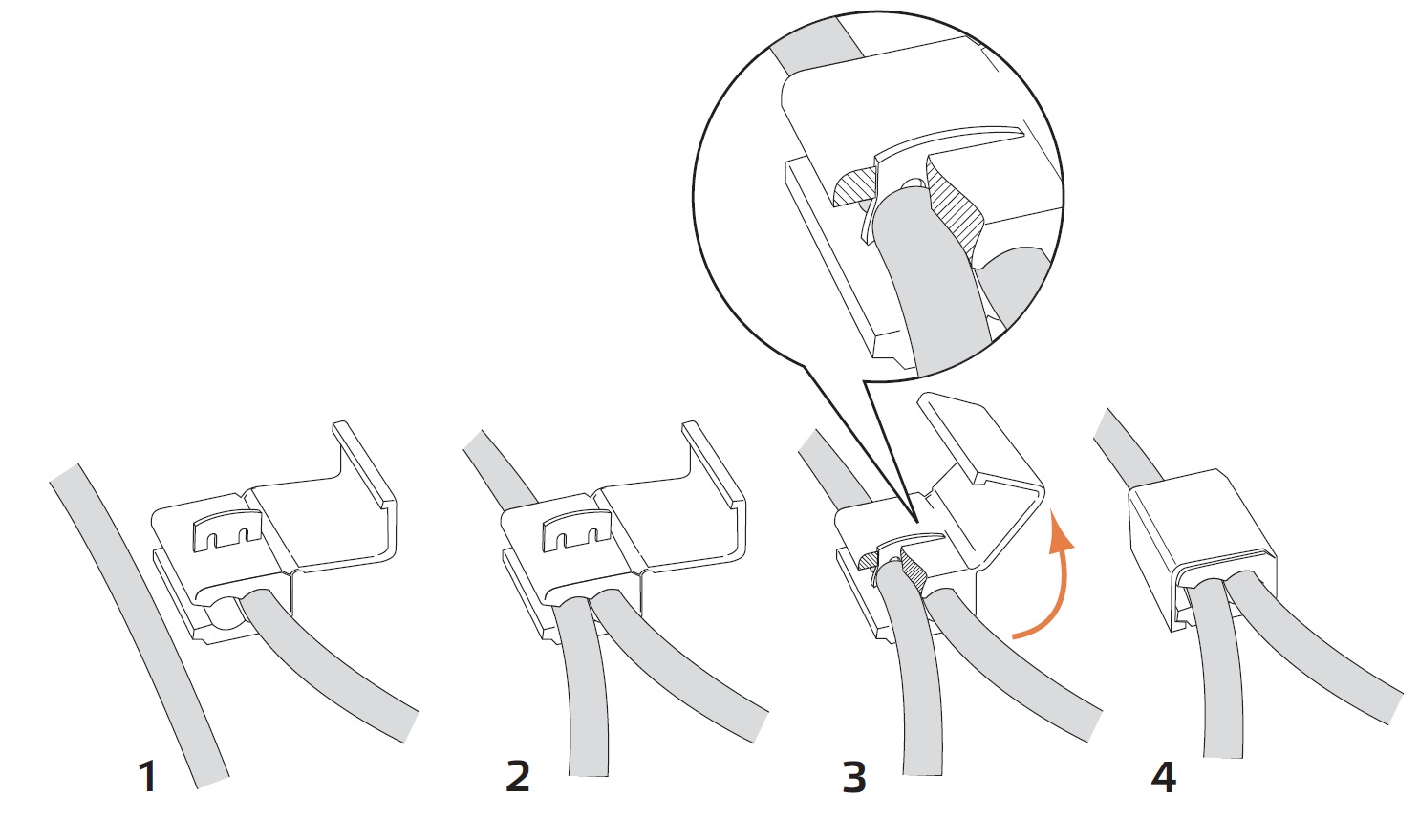

- Piercing clamping mechanism

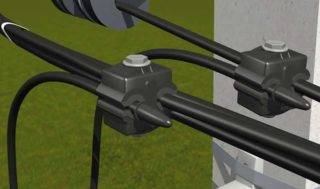

- Piercing mechanisms for SIP

- Clamp between nut and bolt

- What it is

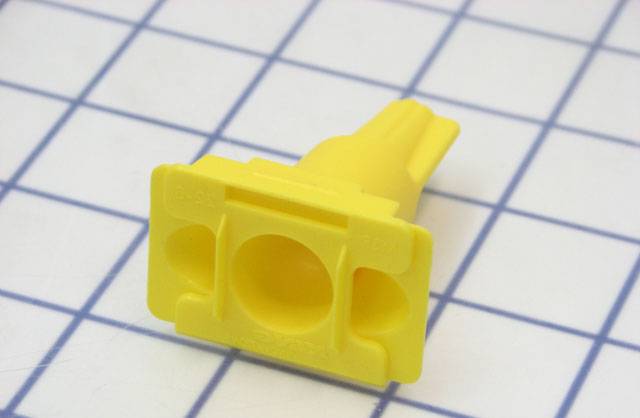

PPE caps - 8 types

PPE - stands for connecting insulating clamp. This type of caps came to us from the West.In America, it is this connection and the method of insulating wires that is considered the most common.

Moreover, the choice of foreign consumers is much richer than ours.

Our manufacturers actually produce only two types of PPE:

- regular smooth PPE

- PPE caps with wings

In the West, as they say, you can pick up for all occasions. It is not clear why the Chinese have not yet made a fuss and have not begun to produce the same thing for our market.

Here are the main 8 types of PPE caps that you can find there (taken from here).

This is the classic and reinforced (with wings) PPE that we are all familiar with:

PPE with an improved cap shape that provides more comfortable work when twisting:

PPE cap with low profile design for working in confined spaces or small junction boxes:

Low profile design with winglets for increased torque:

The next cap is a very controversial decision in my opinion, but it is also produced. PPE for connecting aluminum conductors with copper. The cap is filled with a special antioxidant that prevents oxidation:

Moisture-proof clamps that can be installed on wires in electrical cabinets on the facade of the house, or wet rooms, and even directly in the ground in the garden:

They contain 100% silicone sealant that protects against moisture and corrosion.

There is no need for heat shrinkage or hermetic insulation of the joints.

PPE with a hole in the top of the cap.

This is not a defect at all, as it might seem at first glance, but a clamp specially designed for twisting grounding conductors.One of them is just brought out through the hole and connected to the body of the shield or equipment.

There are also similar clamps, where the wire is pressed not with a spring, but with a screw connection.

There is also a device - a connector filled with silicone.  Any PPE cap with wires is placed inside it.

Any PPE cap with wires is placed inside it.

After that, this twist can be safely considered waterproof and placed underground - in the garden, near the waterers, when entering the house, etc.

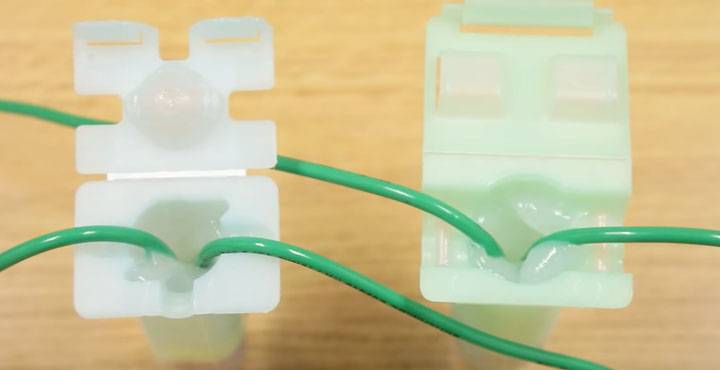

Errors when connecting branch lines to the trunk

The situations described below are by no means acceptable.

- When mounting the clamps, do not fully press the head. There may be bad contact.

- Use branch clamps a second time. Even if it looks like a working new one, during the first installation, the cutting teeth could be damaged (bent, broken), and contact in this case may not work.

- Connect wires that do not branch off from the main, but are equivalent to each other.

- Try to use the clamp to connect not one, but two lines. Since the cutting contacts are centered on one core, they must accurately cut through the central part and fall into the conductor. Otherwise, they will miss or bend.

Connection sleeves for high current conductors

Connecting sleeves for high current wires - Photo

Connection sleeves are used for high currents. Suitable for aluminum and copper wires or a combination. The usage is quite simple.

High current crimped wires — Photo

One or more wires are placed inside the sleeve and it is clamped with special pliers. The use of the tool provides a high-quality connection that does not require additional maintenance.There are several types of products:

- To connect the wire to the housing when performing grounding, sleeves with a flat end and a hole in it are used;

- For single-core wires, screw terminal sleeves are used;

- Tinned copper universal sleeves are used for any combination of wires.

Tip for crimping stranded wires - Photo

The tip is designed for safe connection of stranded copper wires. On the one hand, it has an extension. Before connecting the copper wires, their ends must be twisted and inserted into the extension. Then the tip is pressed with clamping tongs. In the future, the end of the wire treated in this way can be used in any type of connection.

The main goal pursued when using various means for connecting wires is to ensure their reliable and long-term contact. Knowledge of the purpose and design features of products will help to use them in practice as efficiently as possible.

Requirements

For reliable and durable, it is necessary that the connecting clamps meet certain requirements. Their body should be made of fiberglass reinforced plastic - for better insulation of parts.

The plastic used for the manufacture of fittings must be durable, resistant to mechanical stress. In addition, the branch terminal must be immune to sunlight, ultraviolet rays and heat radiation.

The body of the armature after connecting the wires must be perfectly sealed in order to prevent the penetration of moisture to the jumper. Oxidation of contacts can lead to a blackout of the network or, even worse, to a short circuit.

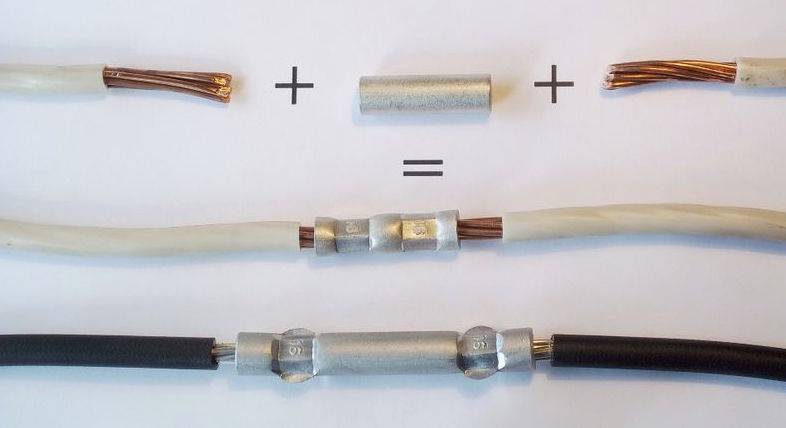

Sleeves

When powerful clamps are needed for several wires, sleeves are used. They are a tinned copper tube, or a flat tip with a hole made for fastening.

It is necessary to insert all the wires to be connected into the sleeve and crimp using a special crimper tool (crimping pliers). This wire clamp has a number of positive aspects:

- It is very convenient to use lugs with holes when there is a need to fix the wire knots on the housings with screws.

- Crimping at the junction does not contribute to increased resistance.

As you can see, there are a lot of wire clamps, each with its own advantages and disadvantages. Choose based on which wires you need to connect, where the junction will be located. But do not forget that the most important thing in electricity is reliability and safety.

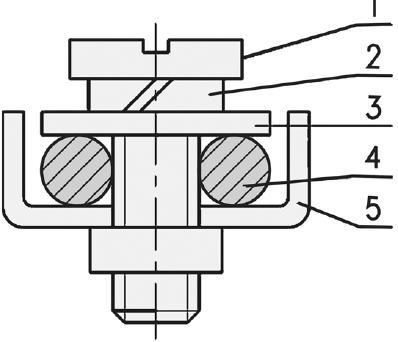

Purpose and advantage of connectors

The main purpose of this clamp is to perform the necessary branches from the main electrical wire without breaking the main line. The nut-type connector is installed at the junction of the main cable with branch wires without cutting it. To do this, simply remove part of the outer insulation and fix the clamp with the wire.

The advantage is that the "nuts" allow you to connect copper and aluminum electrical wires

It is important to take into account that the connection of copper with aluminum without the use of an intermediate plate, mainly brass, is unacceptable, since after a while the oxidation process may begin.

The connection of conductors using a branch clamp is most often used when it is necessary to install electrical networks for domestic or industrial purposes, or to connect lighting electrical equipment. The use of nuts for connecting wires is possible in all power supply networks up to 660 volts.

Application example

Consider a multi-storey building consisting of seven floors. As you know, it is customary to have switchboards at the entrance on each floor. Starting from the lower floor to the upper one, a four-core or five-core cable is laid (in new houses with modern wiring, where a grounding conductor goes separately). It passes through all shields on the floors. From each shield, the apartments are already powered. In this situation, the use of a "nut" connector is simply extremely necessary in order to ensure the connection of electrical wires on each floor with a common trunk cable without breaking it on each individual floor.

If in this situation to break the "backbone" on all floors, connecting it to the terminal blocks. this will significantly reduce the level of reliability of power supply to consumers. That is, if there is no contact on one of the phases of the consumers of the lower floors, the consumers of all the upper floors, which, in turn, are connected to this phase, in this case, risk being left without voltage.

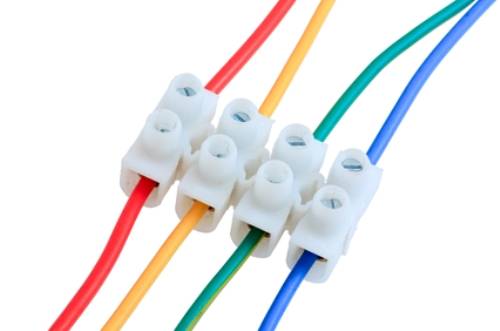

Terminal clamps

Terminal blocks for connecting wires give one indisputable advantage, they can connect wires of different metals. Both here and in other articles, we have repeatedly reminded that it is forbidden to twist aluminum and copper wires together.The resulting galvanic couple will result in the occurrence of corrosive processes and the destruction of the connection.

And it doesn't matter how much current flows at the junction. Sooner or later, the twist will still start to heat up.

The way out of this situation is precisely the terminals.

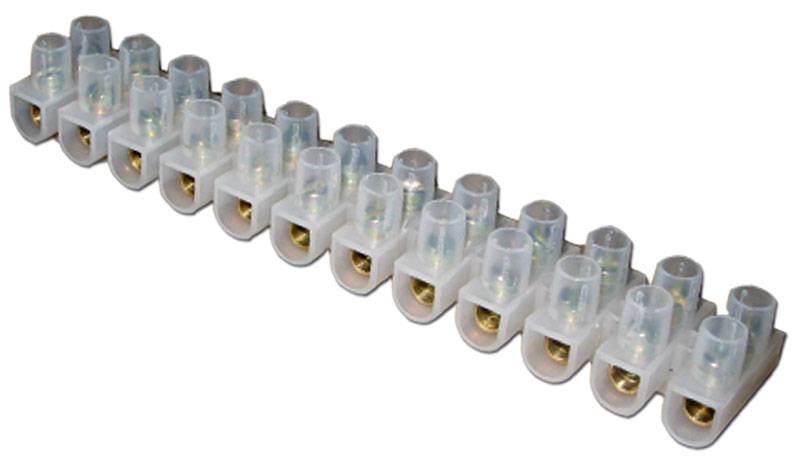

Terminal block

The simplest and cheapest solution is polyethylene terminal blocks. They are not expensive and are sold in every electrical store.

The polyethylene frame is designed for several cells, inside each there is a brass tube (sleeve). The ends of the cores to be connected must be inserted into this sleeve and clamped with two screws. It is very convenient that as many cells are cut off from the block as it is necessary to connect pairs of wires, for example, in one junction box.

But not everything is so smooth, there are also disadvantages. Under room conditions, aluminum begins to flow under screw pressure. You will have to periodically revise the terminal blocks and tighten the contacts where the aluminum conductors are fixed. If this is not done in a timely manner, the aluminum conductor in the terminal block will loosen, lose reliable contact, as a result, spark, heat up, which can result in a fire. With copper conductors, such problems do not arise, but it will not be superfluous to make a periodic revision of their contacts.

Terminal blocks are not intended for connecting stranded wires. If stranded wires are clamped into such connecting terminals, then during tightening under pressure of the screw, the thin veins may partially break, which will lead to overheating.

In the case when it becomes necessary to clamp stranded wires into the terminal block, it is imperative to use auxiliary pin lugs

It is very important to choose its diameter correctly so that the wire does not pop out later. The stranded wire must be inserted into the lug, crimped with pliers and fixed in the terminal block

As a result of all of the above, the terminal block is ideal for solid copper wires. With aluminum and stranded, a number of additional measures and requirements will have to be observed.

How to use terminal blocks is shown in this video:

Terminals on plastic blocks

Another very convenient wire connector is a terminal on plastic pads. This option differs from terminal blocks by a smooth metal clamp. In the clamping surface there is a recess for the wire, so there is no pressure on the core from the twisting screw. Therefore, such terminals are suitable for connecting any wires in them.

In these clamps, everything is extremely simple. The ends of the wires are stripped and placed between the plates - contact and pressure.

Such terminals are additionally equipped with a transparent plastic cover, which can be removed if necessary.

Self-clamping terminals

Wiring using these terminals is simple and quick.

The wire must be pushed into the hole to the very end. There it is automatically fixed with the help of a pressure plate, which presses the wire to the tinned bar. Thanks to the material of which the pressure plate is made, the pressing force does not weaken and is maintained all the time.

The internal tinned bar is made in the form of a copper plate. Both copper and aluminum wires can be fixed in self-clamping terminals. These clamps are disposable.

And if you want clamps for connecting reusable wires, then use terminal blocks with levers. They lifted the lever and put the wire into the hole, then fixed it there by pressing it back. If necessary, the lever is raised again and the wire protrudes.

Try to choose clamps from a manufacturer that has proven itself well. WAGO clamps have especially positive characteristics and reviews.

The advantages and disadvantages are discussed in this video:

Methods for connecting wires or cables to each other

The connection points of two conductors must meet the following requirements:

- reliability;

- mechanical strength.

These conditions can also be met when connecting conductors without soldering.

Crimping

This method requires special equipment. Crimping of wires with sleeves is carried out for both copper and aluminum wires of different diameters. The sleeve is selected depending on the section and material.

Pressing algorithm:

- stripping insulation;

- stripping wires to bare metal;

- the wires must be twisted and inserted into the sleeve;

- conductors are crimped using special pliers.

The selection of the sleeve causes the main difficulties. An incorrectly selected diameter will not be able to provide reliable contact.

Bolted connection

Bolts, nuts and several washers are used for contact. The junction is reliable, but the design itself takes up a lot of space and is inconvenient when laying.

The connection order is:

- stripping insulation;

- the cleaned part is laid in the form of a loop with a diameter equal to the cross section of the bolt;

- a washer is put on the bolt, then one of the conductors, another washer, the second conductor and the third washer;

- the structure is tightened with a nut.

A bolt can be used to connect several wires. Tightening the nut is done not only by hand, but also by a wrench.

Terminal blocks

The terminal block is a contact plate in a polymer or carbolite housing. With their help, any user can connect the wires. The connection takes place in several stages:

- stripping insulation by 5-7 mm;

- removal of the oxide film;

- installation of conductors in sockets opposite each other;

- bolt fixing.

Pros - you can connect cables of different diameters. Flaws - can only be connected 2 wiring.

Types of terminal blocks for multi-core and single-core cables

In total there are 5 main types of terminal blocks:

- knife and pin;

- screw;

- clamping and self-clamping;

- cap;

- walnut grips.

The first type is rarely used, they are not designed for high currents and have an open design. Screw terminals create a reliable contact, but are not suitable for connecting multi-core cables. Clamp terminal blocks are the most convenient devices to use, no special equipment is needed for their installation. Caps are also used frequently, but unlike clamping devices, caps can be used repeatedly. "Nut" is practically not used.

Terminals in junction box (copper or metal)

Terminals are the most common connection method in a junction box. They are cheap, easy to install, provide a secure contact, and can be used to connect copper and aluminum. Flaws:

- cheap devices are of poor quality;

- only 2 wires can be connected;

- not suitable for stranded wires.

Self-clamping terminal blocks WAGO

2 types of Vago terminal blocks are used:

- With a flat-spring mechanism - they are also called disposable, since reuse is impossible. Inside is a plate with spring petals. When installing the conductor, the tab is pressed out, and the wire is clamped.

- With lever mechanism. This is the best connector. The stripped conductor is inserted into the terminal, the lever is clamped. Re-installation is possible.

With proper operation, Vago terminal blocks work for 25-30 years.

Use of tips

For connection, 2 types of tips and sleeves are used:

- in the first, the connection is made inside the product;

- in the second, the termination of two electrical wires occurs with different tips.

The connection inside the sleeve or tip is strong and reliable. There are also special sleeves for connecting copper and aluminum wires.

Soldering wire lugs

The tips are connected to the wiring using a press. If not, contact can be made by soldering.

The electrical wire and the tip are tinned inside, the stripped cable is brought inside.

The entire structure on the contact must be wrapped with fiberglass tape, heated with a burner until the tin melts.

Main types of terminals

Screw (construction, barrier)

Screw terminals are the most popular option, which are characterized by simplicity and excellent reliability. Such terminal blocks are suitable for connecting sockets and for laying electrical wiring.

In this case, the connection of wires using screw-type clamps is used. This allows for a firm hold.Do not use screw terminals for aluminum wires.

Screw connectors

Screw connectors

Clamp (spring, self-clamping): wire clamps

Such products are also called crimp terminals for wires. The cables in them are clamped with a spring. This does not require a special tool. The stripped wire is installed all the way into the block and fastened with a spring. In modern models, a self-clamping function is provided.

Spring terminals are popular because of the reliable connection. To remove the core, you need to pull the lever back. When choosing this option, the terminal block must be selected taking into account the number of connections. Spring products are made from different polymeric materials. The contact element is made of two brass plates.

Clamping products

Clamping products

Junction box terminals

To carry out the connection of wires in the junction box, a terminal made of a plastic case with holes for conductors, a spring element and a current-carrying busbar is used. For connection, the conductor must be inserted into the terminal as far as it will go. In this case, the spring element firmly presses the conductor.

Terminals inside the box

Terminals inside the box

Fused terminals

Fused terminals are used for selective protection of secondary circuits. Both flexible and rigid conductors are used.

Terminal blocks

The terminal block is a device for switching all kinds of circuits with pairwise connected clamps. Products contain nests of large diameter. The pads have threadless and threaded outlets. Metal screws are used to tighten the wires. The types of pads are different, but the principle of their device is the same.

Vago pads are often used to quickly connect wires. They are of two types:

- with a flat-spring mechanism;

- universal with lever mechanism.

Compact terminal blocks

Compact terminal blocks

Knife terminal blocks

Such options are used for grounding and for grounding circuits. They are also used for cutting branches into the conductor. Knife connections are often used for audio equipment. Their feature is that the installation does not require stripping the conductor. The wire is simply installed in the terminal block and crimped.

The advantage of such terminal blocks is considered to be time saving for installation, reliability and safe connection due to a special lever. In addition, no special tools are required for installation.

Knife models

Knife models

The most common types of electrical clamps

Wire terminals

Wire terminals

You can find a wide range of different clamps in electrical supply stores. They differ in material (metal, plastic, plastic), purpose, method of fixation, installation location (street, room). It is impossible to describe all types, but there are a number of models that are used most often. The use of a specific type of clamping mechanisms depends on the characteristics of the power supply, connection parameters, operating conditions and other important criteria.

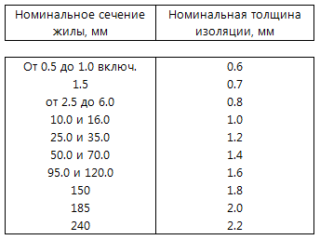

Simple screw terminals

Screw terminals for wires allow connection without disturbing the cable structure. The terminal reliably fixes wires even from different alloys, such as copper and aluminum.

Wire insulation thickness standards

Wire insulation thickness standards

The design of the device is a channel made of metal (bronze, brass) of small length with a small diameter. The channel has two threaded holes for fixing screws.Usually in everyday life one-way screws are used on a polyethylene basis or made of plastic. The connection of two segments is made by installing the end parts into the channel from both sides, after which the screws are fixed.

You can find different clamp configurations depending on the installation parameters. These include:

- wire diameter;

- isolation class;

- number of contact points;

- current characteristics.

Self-pulling and lever clamping designs

Clamping terminal mechanisms self-pulling

Clamping terminal mechanisms self-pulling

Such mechanisms are distinguished by increased ease of use. To work with self-tensioning disposable clamps, it is enough to insert the stripped end of the wire into the hole until it stops.

The plate clamps for connecting the conductor have a spring inside that prevents the conductor from slipping out. When laying inside the cable, the plate is pressed against the core and blocks the wire. To pull out the wire if necessary, you will need to squeeze the plate through the hole in the second row with a screwdriver. This type of clamping device is capable of withstanding 3-4 repeated connections.

A more convenient configuration is considered where levers are used instead of screws. The wire rises with the help of a plate, which is fixed by a lever. To operate such a device, it is enough to raise the lever, insert the cable into the channel and lower the mechanism until it clicks. To pull out the wire, the reverse procedure is performed.

Connecting insulating clips

Clamping caps

Clamping caps

Spiral wire clamps are used to connect small diameter conductors. Several wires are stripped, formed into a group and covered with an insulating mechanism until they stop. For reliable fixation, the cap should be turned several times.The contraction of several cores is carried out by means of a conical spiral. When screwing on the cap, the group of cables is pulled into a single knot.

Cap connectors made of plastic are used for electrical wiring of low power. Also, such clamps are used when installing electrical networks inside the house.

Types of caps:

- without persistent protrusions;

- with stubborn protrusions.

The second type is used for wires with a large diameter.

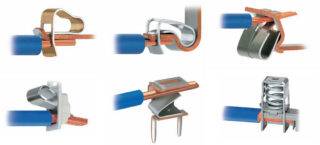

Piercing clamping mechanism

Cable piercing clamp

Cable piercing clamp

Power lines up to 1 kW use piercing clamps. They allow you to connect segments with a cross section of 1.5-10 sq. mm on branch lines and with an area of 16-95 sq. mm. on the highways.

Structurally, they are a metal girth, which is covered with insulation. It is compressed with a thrust bolt. On the wrapping plate, metal teeth are applied, which pierce the insulation and dig into the conductor itself, fixing it securely.

Piercing mechanisms for SIP

Connection using a moisture-proof CIP wire clamp

Connection using a moisture-proof CIP wire clamp

With the help of such mechanisms, it is possible to connect the SIP to a bare wire without wasting time stripping the insulation. They are made of reinforced fiberglass and polymers.

There are two options for SIP clamps:

- with one bolt;

- with two bolts.

The first method is also called naked SIP. Suitable for connecting bare wires to SIP.

The second method with two bolts is used in connection on the main lines. The body is made of glass-reinforced polymer.

Clamp between nut and bolt

Bolted wire connection

Bolted wire connection

A simple and reliable method of fixing using bolted clamping devices is actively used in power networks.

The following parts are required for connection:

- bolt of the appropriate diameter;

- screw;

- washers;

- lock-nut.

This method can even connect conductors of different materials.

What it is

Such products are distinguished by a variety of designs and shapes, but in many situations they involve “nuts” connectors. The device includes 2 clamping plates made of high quality anodized steel. Each has special notches for the wire. When it is between the plates, they are tightly compressed by tightening 4 screws.

branch clamp

branch clamp

Terminal blocks are located inside a durable housing, which is made of special plastic. Like the clamp, the case includes 2 separate parts. The plates are placed in the middle: both are attached to the body halves with a spring. Every connection is hidden inside. "Nut" for connecting the cable acts as a connecting and protective device.

Important! The main advantage of the technical component will be the possibility of a reliable and safe connection of copper wires and cable. To carry out such switching, there is no need to cut the main line

It is necessary to clean a small section of the cable placed in the die. The branch is fixed to a perpendicular gutter.

"Nuts" produce various parameters with similar technical indicators. The dimensions of a particular model are selected according to the cross section of the conductor core. According to GOST, clamps 4-150 are selected for main highways, and 1.5-120 square meters for branches. mm.

What does a branch clamp look like

What does a branch clamp look like