- The main goals and objectives of grounding

- Types of material (profiles)

- What is metal bonding made of?

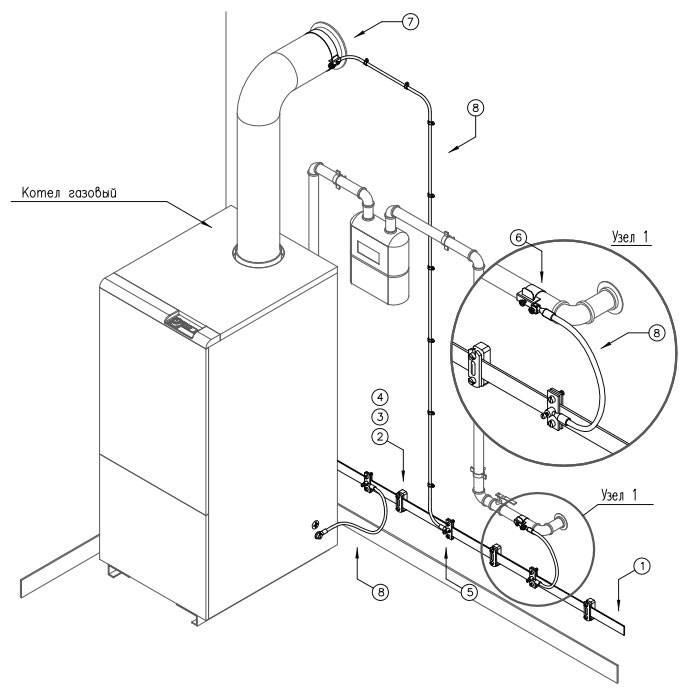

- How to ground a gas unit?

- Simple calculation of contour parameters

- Grounding installation

- How to properly ground a gas boiler

- Methods for grounding boilers

- What is the resistance of the ground loop should be

- What materials are needed for grounding

- The cost of organizing the grounding of the boiler

- Choice of earth electrode

- Grounding a gas boiler in a private house

- Norms and requirements for the ground loop

- Choice of earth electrode

- Calculation of parameters to achieve the required resistance

- Grounding instruction

- Choice of mounting location

- Ground Loop Measurement Certificate sample

The main goals and objectives of grounding

Grounding is a grounding conductor and grounding conductors, through which the current flows into the ground and is neutralized

The soil is able to neutralize the electric current, since the degree of its voltage is zero. Resistance is the main indicator of a grounding device, by which one can judge its quality and ability to fulfill its purpose. Resistivity depends on the composition of the soil, the presence of chemicals in it - acidic or alkaline, moisture, friability.Depending on the composition of the soil, it may be necessary to use some kind of special grounding kit or a complete replacement of the soil for the correct operation of the grounding devices.

Grounding is the connection of any device, electrical installation or part of the network with a grounding device. It is a grounding conductor and grounding conductors, through which the current flows into the ground and is neutralized.

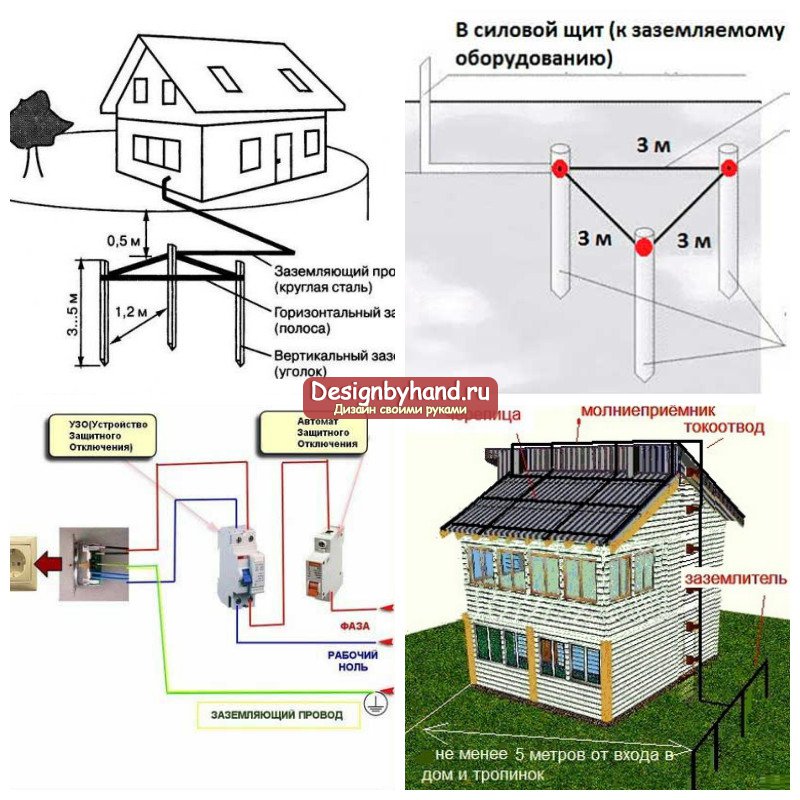

There may be several grounding conductors. In a distributed scheme, they are located along the perimeter of the object, the electrical network of which must be secured. The conductive part (earth electrodes) are usually made of metal. Grounding electrodes are connected to them, which have direct contact with the soil.

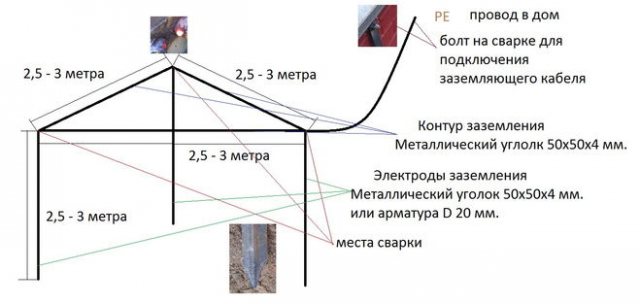

Ground loop device

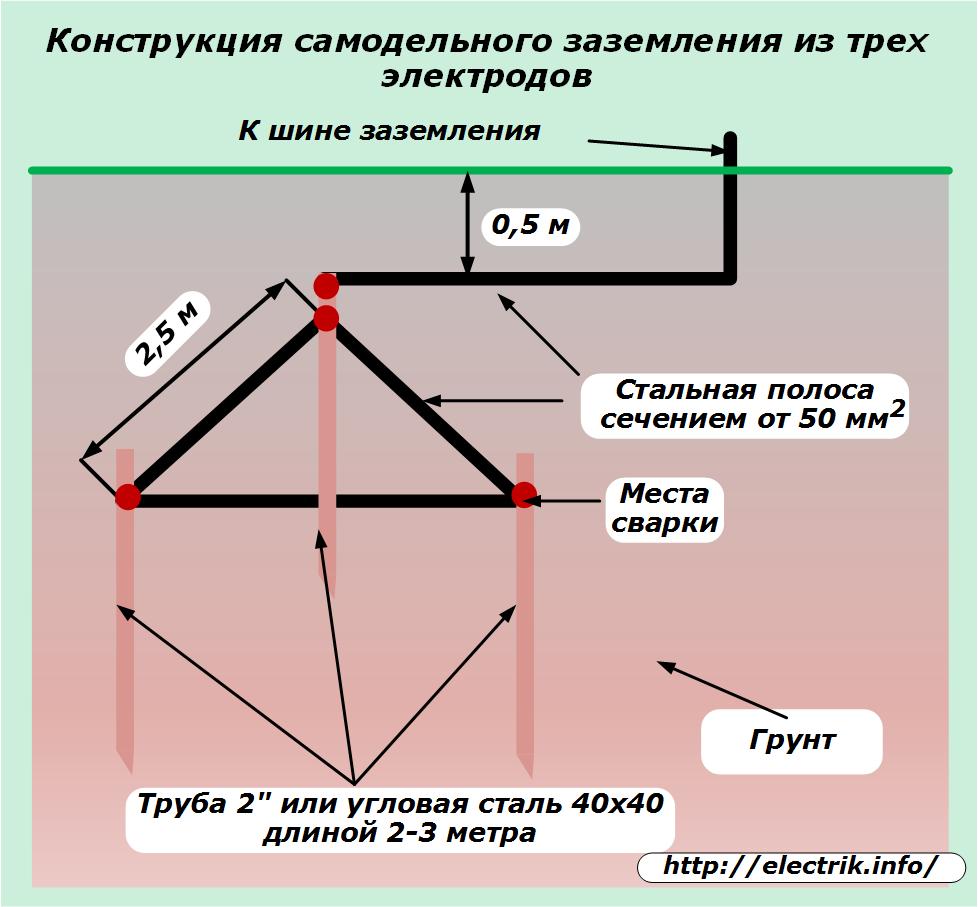

The grounding device is mounted along the contour. The ground loop is several conductors of electrodes that are driven into the ground. Their length is 3 meters, they are located at a small distance from each other. As a connection, a horizontal metal strip is used, which is laid in the soil to a shallow depth - up to 1 meter. The connection to the electrodes is carried out by conventional welding. In special grounding kits, parts of the equipment are connected by threads, which does not affect the working properties in any way.

Working grounding is necessary in the following cases:

- Protect equipment from the accumulation of static electricity. Processes occurring in nature, such as lightning, can affect the current flowing in a circuit, resulting in equipment damage. Electrodes installed in the ground drain excess current.

- Protection of the network from short circuits.

- Over voltage protection.

Types of material (profiles)

According to the requirements of the PUE, which contain indications of what the current spreading resistance in the soil should be, in most cases this indicator is set at a level of no more than 4 ohms. To achieve this value, it usually takes a lot of effort to adhere to the same technology requirements.

First of all, this concerns the materials used in the assembly of the ground loop, selected based on the following conditions:

- When choosing pins, preference should be given to ferrous metal blanks;

- The most commonly used bar with a size of 16-20 mm or a corner with parameters 50x50x5 mm and a metal thickness of about 5 mm;

- It is not allowed to use fittings as circuit elements, since it has a hardened surface that affects the normal flow of current;

- For these purposes, it is a clean bar that is suitable, and not its reinforcing substitute.

Note! For areas with dry summers, pipe thick-walled metal blanks are best suited, the lower end of which is flattened into a cone, and then several holes are drilled in this part of the pipe. According to the provisions of the PUE, holes of the required length are first drilled before they are placed in the ground, since it is rather problematic to hammer them manually

In the event of a particularly dry summer and a sharp deterioration in the parameters of the ground electrode, a concentrated brine solution is poured into the hollow parts of the pipes, which makes it possible to obtain such resistance, which should be in accordance with the requirements of the PUE. The length of pipe blanks is selected within 2.5-3 meters, which is quite enough for most Russian regions

According to the provisions of the PUE, holes of the required length are first drilled before they are placed in the ground, since it is rather problematic to hammer them manually. In the event of a particularly dry summer and a sharp deterioration in the parameters of the ground electrode, a concentrated brine solution is poured into the hollow parts of the pipes, which makes it possible to obtain such resistance, which should be in accordance with the requirements of the PUE. The length of pipe blanks is selected within 2.5-3 meters, which is quite enough for most Russian regions.

This type of profile blanks is subject to special requirements regarding the order of their placement in the soil and consisting of the following:

- Firstly, the pipe elements of the protective contour must be placed at a depth exceeding the level of soil freezing by at least 80-100 cm;

- Secondly, in especially arid areas, about a third of the length of the grounding conductor should reach the moist soil layers;

- Thirdly, if the second condition is met, one should focus on the peculiarities of the location of the so-called "groundwater" in a given region. If they are at a considerable depth, according to the rule formulated in the provisions of the PUE, it will be necessary to prepare longer pipe sections.

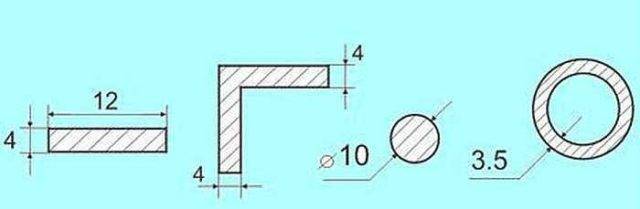

The type and profile of the pin blanks used in the arrangement of the grounding conductor can be found in the figure below.

Permissible pin profiles

In practice, in most regions of Russia, a steel angle and a strip of the same metal are usually used. In order to obtain more accurate parameters of the used grounding elements, geological survey data will be required. If this information is available, it will be possible to involve specialists in the calculation of the ground electrode parameters.

What is metal bonding made of?

The elements connecting the pins (metal connection) are usually made of the following electrical materials:

- A typical copper bus having a cross section of less than 10 mm2;

- Aluminum strip with a cross section of about 16 mm2;

- Steel strip 100 mm2 (size - 25x5 mm).

Classical metal bonding is usually done in the form of steel strips cut to size, fastened for welding to the corners or heads of the bar.

Important! It depends on the quality of the welding joint whether a given grounding device or circuit can pass verification tests for compliance with the transient resistance to the rated value (4 Ohm)

When using more expensive aluminum (copper) strips, a bolt of a suitable size is attached to them for welding, on which the supply tires are subsequently fixed

The main thing that you need to pay attention to when arranging any connections is the reliability of the resulting contact.

To do this, before making a bolted joint, it is necessary to thoroughly clean both parts to be joined until a pure metal shine appears. Additionally, it is desirable to treat these places with sandpaper, and after tightening the bolt, tighten it well, which will ensure more reliable contact.

How to ground a gas unit?

How to properly ground a gas boiler? First, there are some important points to consider:

- For a grounding metal structure installed in the ground, suitable: corner, channel, profile pipe.

- The metal surface must be protected against corrosion by galvanizing, copper coating or anti-corrosion paste.

- The cross-sectional area of \u200b\u200bthe wire connecting the zero phase of the shield to the ground loop for a gas boiler depends on the type of metal.For copper, 1 cm² is considered optimal, for steel - 7.5 cm², for aluminum - 16 cm².

- Grounding resistance for sandy soils should not exceed 50 ohms, for alumina - up to 10 ohms.

- The electrodes must be made of a material that matches the loop resistance. The best option is two-inch pipes or corners with a length of 2 m and a cross-sectional area of \u200b\u200b6 cm².

- The busbar must be made of steel or copper strip only.

Compliance with the above conditions will relieve you of claims from the inspection authorities.

Simple calculation of contour parameters

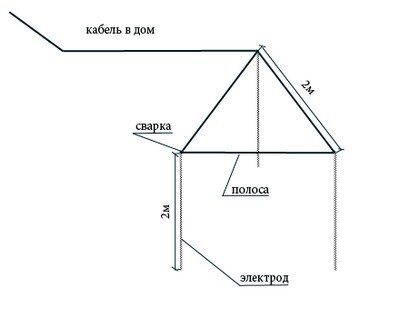

The easiest way is to ground a gas boiler empirically without the use of complex formulas and calculations. In this case, the work is performed according to the following algorithm:

- as a basis, they take a contour of three rods 3 m long in the form of an isosceles triangle;

- connect conductors;

- take an ohmmeter that measures resistance, and measure the readings of the circuit - the optimal value is 4 ohms;

- if the result is significantly higher than optimal, then another element is added to the circuit and the resistance is measured again; continue to add until the value approaches the ideal, or at least the maximum allowable of 10 ohms.

If desired, you can determine the number of electrodes using the formulas that are available in the specialized literature. But for optimal operation of the gas unit, the simplest calculation of parameters is sufficient.

Grounding installation

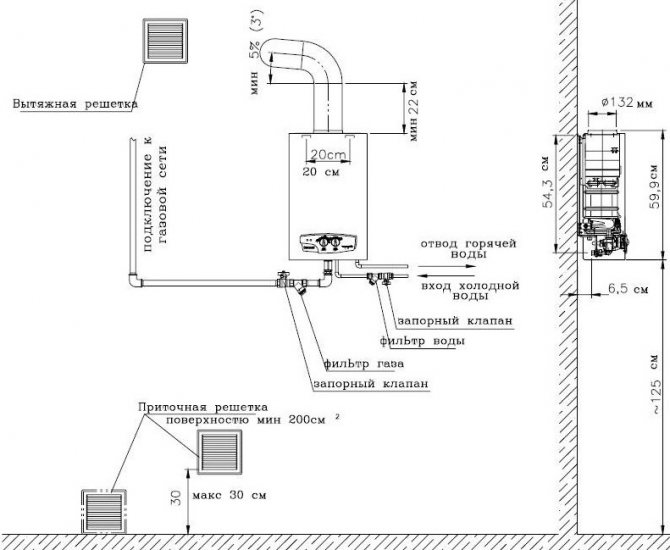

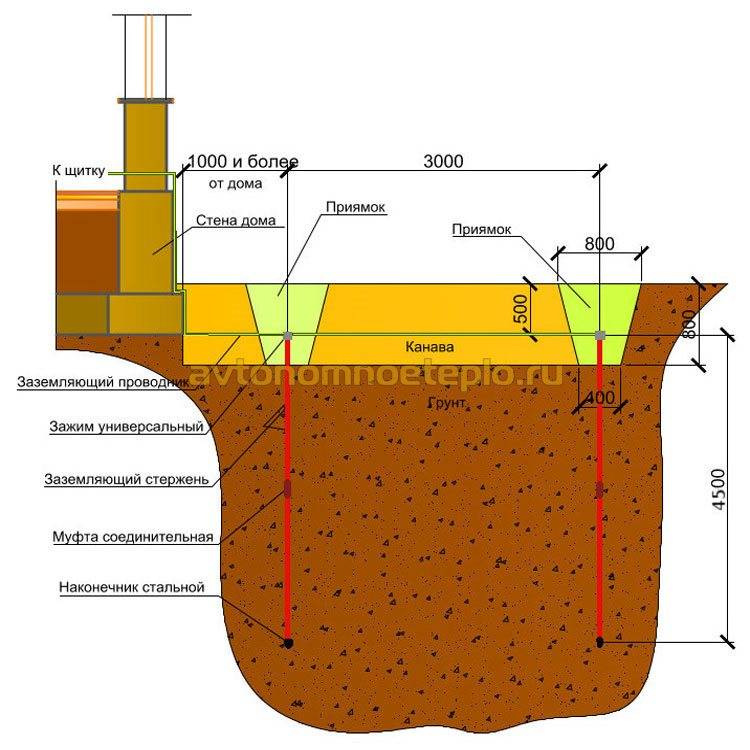

Installation of a system for grounding a gas boiler should be carried out no closer than 1 m and no further than 5 m from the house.This place can no longer be used for outbuildings, cultivation of land or other purposes. It is better to enclose the area with a border and decorate it with a composition of stone.

In the selected area, first draw a circuit diagram. In most cases, it has the shape of an isosceles triangle, but with a lack of free space, it can look like a square, line or polygon. The shape depends on the number of electrodes and the position of the house.

For installation you will need the following tools:

- welding machine;

- grinder for cutting and adjusting pipes;

- drill or perforator;

- shovel, sledgehammer or hole drill.

Now let's take a step-by-step look at how to properly install and connect the circuit:

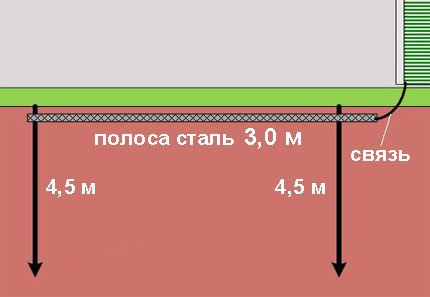

- Along the lines of the lined layout, trenches are dug 35-40 cm wide and 50-70 cm deep. From the top of the triangle closest to the house, a trench is made to the foundation.

- With the help of a sledgehammer or a yamobur, electrodes are hammered at the vertices of the triangle - metal rods from pipes and corners about 3 m long. They must be driven in so that they protrude 15-20 cm from the ground.

- Then the electrodes are connected to each other. To do this, steel strips with a cross section of 4.8-5 cm² are laid along the bottom of the trench. Connect the structure by spot welding.

- Now, a metal strip is welded to the electrode closest to the house, which is brought out along the trench to the place where grounding will enter the building itself. This strip should depart from the ground by at least 50 cm.

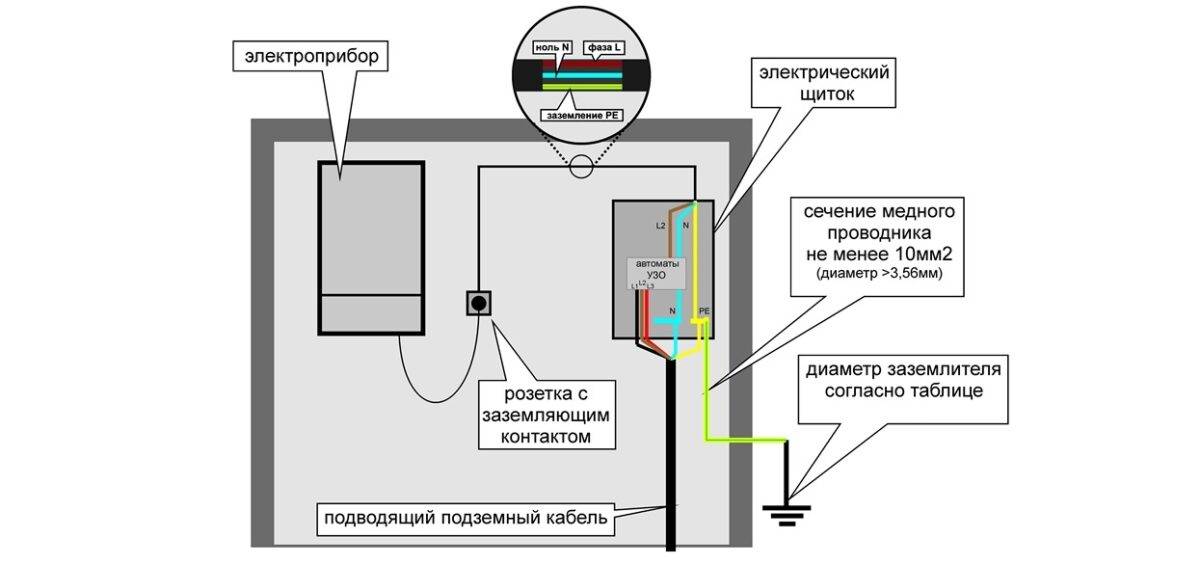

- Next, the system is brought into the house: a hole is made with a puncher in the wall, a copper wire is inserted through it, which is fixed on one side to the terminal on the ground bus, and on the other to the metal plate on the base.

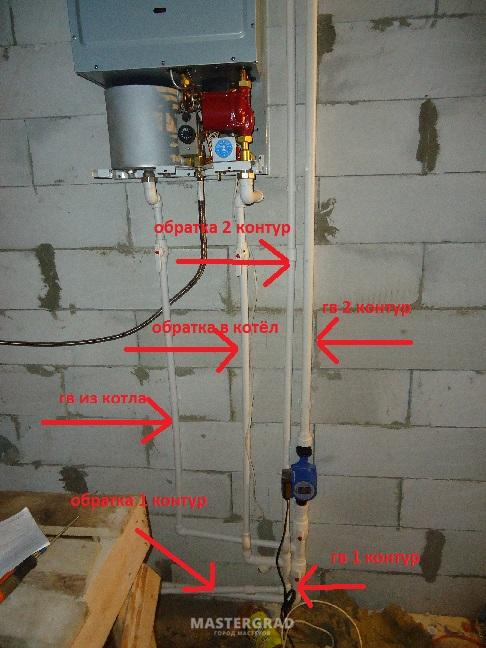

- Now the gas boiler is connected to the shield through the machine using a three-wire wire. It is also recommended to connect a voltage stabilizer.

Before burying the structure, you need to check the resistance of the current divergence along the circuit. If the result is less than the allowable indicator of 10 ohms, then you can dig in. If the resistance is greater than the control value, more electrodes should be added until the indicator reaches the norm.

Common reasons why a gas boiler is noisy

All about possible malfunctions of the gas boiler and how to fix them here

There is another sure way to check the received grounding for operability. This will require a 100 W light bulb inserted into a carrying cartridge. One of its ends is connected to the 220 V phase, and the other is connected to a metal strip on one side of the system. If the paw is lit, as if inserted into a socket, then grounding is working. If the light is dim or flashing, you should check the joints of the system. If the light does not light up, you need to check the entire structure.

How to properly ground a gas boiler

The PUE stipulates the need for grounding, but does not stipulate that it is required to purchase a ready-made grounding kit (although this is recommended by representatives of the gas service). The contour is quite possible to do with your own hands.

In order to independently and correctly perform the work, take into account the following nuances:

- Possible type of grounding system.

- Resistance options.

- Recommended materials for the manufacture of a ground loop.

- Cost of work.

The ground loop for connecting a gas boiler must strictly comply with the standards and parameters specified in the PUE.If the check shows a deviation from the norms specified in the documentation, the representative of the Gas Service has the right to refuse to put the equipment into operation.

Methods for grounding boilers

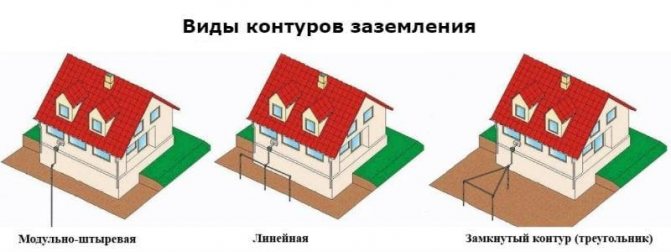

There are several ways to install a ground loop:

- By type of device - there is a need for a separate grounding of the gas boiler. Household appliances: washing machines, refrigerators, kettles, etc., have differences in parameters and technical characteristics from heating equipment. PUE impose higher requirements for connecting a gas boiler. Therefore, if it is planned to install grounding through a socket, it must be connected not to the switchboard, but directly to the circuit.

- According to the manufacturing features - the connection is made with a ready-made kit, specially made for connecting to a gas boiler, or with the help of improvised materials.

The PUE relating to grounding describes the rules prohibiting the use of a water, sewer or gas pipe as grounding when connecting the boiler.

What is the resistance of the ground loop should be

The required resistance for grounding when connecting a gas boiler depends not only on the characteristics of the heating equipment, but also on the soil. PUE 1.7.103 specifies the following standards:

- Clay soil - the permissible resistance should not exceed 10 ohms. The norm is valid for single-phase current and line voltage (380 V).

- Sandy soil - the maximum resistance of the grounding device should be no more than 50 ohms.

Representatives of the gas industry often rely on clause 1.7.59 of the PUE, according to which the minimum requirements are higher than in 1.7.103. In normal soil, the resistance should not be higher than 10 ohms.

What materials are needed for grounding

Grounding requirements when connecting a gas boiler also affect the types of materials used in the installation work. There are the following recommendations:

- The ground wire from the shield to the circuit laid in the ground must have a cross section: copper - at least 10 mm², aluminum - 16 mm², steel - 75 mm².

- As vertical pins driven into the ground, steel pipes or corners are used, connected by a bus to each other using spot welding. Ready-made kits include galvanized or copper-plated electrodes.

- Automation and RCD - the boiler is connected to a panel with installed electrical fittings. The PUE prohibits the installation of an RCD with a gas boiler without grounding. But duplication of the security system is allowed when the ground loop is simultaneously installed together with the residual current device.

The cost of organizing the grounding of the boiler

To calculate how much it will cost to connect the boiler, you will need to calculate the ground loop. Several factors affect the cost:

- Soil type.

- Selected electrode material and wire thickness.

- The type of grounding used.

Another factor that is often not taken into account is which organization will carry out the audit and issue a protocol for testing the resistance of grounding conductors and grounding devices.

In a modular gas boiler room, a special metal tape or bus is provided, on which the “ground” is brought out from all metal structures and electrical units. To connect, you need to install metal electrodes in the ground and connect the circuit and the output terminal with a wire.

Choice of earth electrode

In general, there are two ways to ground a gas boiler in a private house, which are carried out depending on the choice of ground electrode. A grounding conductor is a component of the grounding structure, which is an electrode that is directly connected to the ground. In the first case - natural grounding - already mounted structures are used that are in contact with the ground. For example, it may be a fragment of the basement, a pipeline and other communications. They are made of metal or reinforced concrete elements. However, when grounding a gas boiler, at least two joints with individual fragments of the ground electrode must be observed, and it is prohibited to use sewer, gas and heating pipes for this purpose. Therefore, most often preference is given to artificial grounding.

In the second case, steel pipes, corners, strips or other parts specially designed for this purpose are used. They must be treated in a special way: coated with copper or zinc. These elements of the circuit must be buried vertically in the ground (so the system can function even with a frozen layer of earth in the cold season) and connected to the boiler in at least two places.

Other contour details, more precisely, the material from which they are made, will be selected depending on the level of resistance. This applies to tires and pipes, which will become electrodes. The tire takes the form of a strip, it is made of copper or steel (aluminum is strictly prohibited)

It is important to know that all elements must have anti-corrosion protection: you can use galvanizing, copper plating or ordinary anti-corrosion paste. The pins and the bus will be connected to each other by spot welding

In addition to the elements of the earth electrode itself, it is important to pay attention to the existing earth. If it is silt, then the resistance of the circuit elements cannot be more than 10 ohms, if it is sand, then the value increases to 50 ohms. Worst of all, stone and rocky soil meet the requirements for the installation of a grounding loop

Worst of all, stone and rocky soil meet the requirements for the installation of a ground loop.

If we talk about other parameters, then the wire that should go from the gas boiler shield to the circuit on the street must have a certain cross section. If it is made of copper, then the figure is 10 millimeters square, if made of aluminum - 16 millimeters square, and steel - 75 millimeters square.

Grounding a gas boiler in a private house

The boiler needs mandatory grounding due to the fact that static voltage constantly accumulates on its body. First of all, it is fraught with fire. In fact, this reason is the main argument in favor of the need to ground the boiler. Secondly, static voltage may well provoke a failure in the operation of automation, or even disable it altogether. Electronics are very sensitive to power surges, and replacing a burned-out board will cost you a pretty penny.

It should be noted that more stringent requirements are imposed on a gas boiler than on conventional household appliances. Therefore, if you decide to do it yourself, do not forget that everything must comply with current regulations. The best option is to buy a ready-made kit and install it yourself. There is nothing particularly complicated here.In particular, for installation, you will need a small area measuring about 50 by 50 centimeters, for example, in the area adjacent to the house, or in the basement. However, having the skills to work with a welding machine and tools for cutting metal, you can make a grounding device yourself. To do this, we need a steel corner and a strip, from which it will be necessary to make a certain structure.

First, we should decide on a ground electrode - an electrode that is in direct contact with the ground. They are of 2 types:

- natural;

- artificial.

Natural grounding conductors are metal structures that are immersed in the ground. At the same time, according to the current rules, they must have at least 2 contacts with boiler equipment and conductors. In addition, it should be borne in mind that pipelines containing a flammable or explosive liquid cannot be used as natural grounding conductors. These are not all restrictions. It is also forbidden to use heating and sewer pipes, or metal coated with a protective anti-corrosion substance. Artificial - these are ground electrodes that were specially made for this - metal pipes, corners or strips. In order to protect against corrosion, it is recommended to use galvanized electrodes. However, according to a number of experts, the most optimal coating here is copper.

Next, we need a motor drill. With its help, deep pits are made in the upper part of the trench. Then, ground electrodes should be inserted into these holes. Here, for example, a 3-meter steel corner 60 by 70 millimeters is suitable

When installing them, one important rule must be observed.In particular, they should protrude above the bottom of the trench by about 15 centimeters. Naturally, small deviations in one direction or another are quite acceptable.

Next, we connect the corners with a metal strip 40 by 4 millimeters. For this we need a welding machine. In addition, the same strip must be laid along the previously dug trench to the building, and raised above the level of the blind area by about half a meter

Naturally, small deviations in one direction or another are quite acceptable. Next, we connect the corners with a metal strip 40 by 4 millimeters. For this we need a welding machine. In addition, the same strip must be laid along the previously dug trench to the building, and raised above the level of the blind area by about half a meter.

Now there are only two steps left to take. At the penultimate stage, it will be necessary to attach the strip to the basement of the building using welding and a metal rod. Remember that according to the PUE, the resistance of the grounding system should be no more than 4 ohms. After an independent circuit has been created, it remains only to correctly connect it to the power shield. This is best done with a copper conductor. It is bolted to the basement of the building. On the shield, we connect the conductor to the protective zero.

Norms and requirements for the ground loop

For gas boilers, there are increased requirements for grounding. First of all, natural construction cannot be used: pipelines of flammable liquids, flammable or explosive gases and mixtures, sewerage or heating pipelines. Therefore, an artificial structure is always used as a ground loop.

Choice of earth electrode

There are always two options: a ready-made grounding kit (its average cost is 6-8 thousand rubles) and self-assembly of the structure.

An example of a finished kit with a threaded connection.

An example of a finished kit with a threaded connection.

Gas services recommend using a ready-made kit, but they do not forbid making it yourself, the main thing is to meet the requirements for the material and achieve the resistance standard.

To determine what materials are needed, study the standard design of the ground loop:

Standard, the most optimal ground loop, then we will focus on just such a design.

Standard, the most optimal ground loop, then we will focus on just such a design.

So, artificial ground electrodes can be made of black or galvanized steel, or copper, but this is expensive. Under no circumstances should they be painted. According to PUE-7, Section 1, Chapter 1.7, their thickness and cross section are determined based on the table of the smallest sizes of ground electrodes and ground conductors laid in the ground:

| Material | Section profile | Diameter, mm | Cross-sectional area, mm2 | Wall thickness, mm |

| black steel | Round: | |||

| — for vertical grounding | 16 | — | — | |

| — for horizontal earthing | 10 | — | — | |

| Rectangular | — | 100 | 4 | |

| Angular | — | 100 | 4 | |

| Trubny | 32 | — | 3,5 | |

| Cink Steel | Round: | |||

| — for vertical grounding | 12 | — | — | |

| — for horizontal earthing | 10 | — | — | |

| Rectangular | — | 75 | 3 | |

| Trubny | 25 | — | 2 | |

| Copper | Round | 12 | — | — |

| Rectangular | — | 50 | 2 | |

| Trubny | 20 | — | 2 | |

| Multiwire rope | 1.8 (for each wire) | 35 | — |

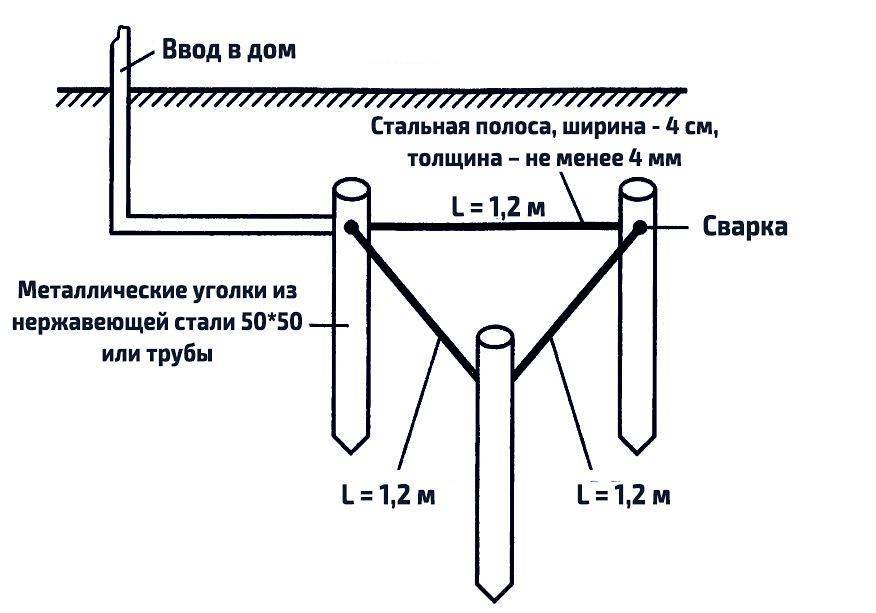

In total, to assemble a standard design you will need:

- metal corners made of stainless steel 50 * 50 mm, 2.1 m long (3 pcs.). Alternatively, you can use a steel water pipe with a diameter of 32 mm and a wall thickness of 3.5 mm or more, or a rectangular profile with a cross section of 100 mm2;

- metal strips from a rectangular profile 1.2 m long, 4 cm wide and at least 4 mm thick (3 pcs.). Here you can also use alternative options, focusing on the table above;

- a metal strip made of a stainless rectangular profile 4 cm wide, 4 mm thick and long from the nearest top of the grounding triangle to the foundation of the house, preferably no more than 3 m (1 pc.);

- bolt M8 or M10;

- copper wire, for example, PV-3, with a cross section of at least 6 mm2 (or at least 10 mm2 for houses with a large number of simultaneously used powerful electrical appliances). Alternatively, aluminum wire with a cross section of 16 mm2 or steel wire with a cross section of at least 75 mm2 can be used. In ready-made kits, copper-plated wire with a cross section of 14.9 mm2 is usually used.

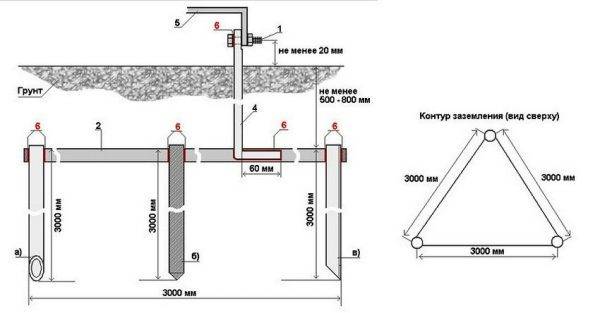

Calculation of parameters to achieve the required resistance

The resistance of the grounding structure should be:

- no more than 10 Ohm in clay soil;

- no more than 30 ohms in garden soil close to black soil;

- no more than 50 Ohm in sandy soil;

- no more than 150 Ohm in a clay-sand mixture.

The physical characteristics of the ground loop are highly dependent not only on the type of soil, but also on the climatic features of the area, so even a standard, sufficient in most cases, design is always tested in practice. Depending on the results, changes can be made to the contour. Checking the physical properties of a structure is quite simple:

- We connect all the vertical and horizontal conductors so that they fit snugly together.

- Using an ohmmeter (a device for measuring resistance), we measure the indicators for the assembled circuit, usually they are in the range of 4-8 ohms, i.e.within acceptable limits for any type of soil - the design meets the requirements and is ready for installation.

- If the measurement result exceeds the allowable values, it is necessary to make changes to the design, usually it is enough to add one or more conductors, use conductors with a larger cross-sectional area, etc.

Grounding instruction

Grounding a gas boiler in a private house is carried out according to certain instructions. It all starts with the fact that a contour layout is dug out on the ground. The chosen place should be at a certain distance from the foundation of the house: not less than 1 meter, but not more than 5 meters. On this site, after grounding, it will not be possible to erect any buildings, plant flowers and plants, and in general it is categorically not desirable for a person to be there. It is best to enclose everything with some kind of fence (including the bus leading to the house) and decorate the place with some kind of static object that does not require special attention.

Usually the contour looks like an equilateral triangle, the sides of which are approximately 2.5 meters. The depth of the groove should be 50 centimeters, and the width should vary from 35 to 40 centimeters. Then recesses are formed in the corners, into which steel corners or pipes are driven to a depth of 2-3 meters. The parameters of the grounding conductors are as follows: the length is approximately 3 meters, and the surface area is 60 by 70 millimeters. They need to be hammered in in such a way that about 15 centimeters protrude above the bottom of the groove. At the next stage, these corners are connected to the tire, that is, to the steel strip. Its dimensions are 40 by 4 millimeters.This strip will become a horizontal ground electrode.

This usually happens by welding. A trench breaks out, which goes to the basement of the house where the boiler is located. Along it goes the same horizontal strip, which will "rise" above the ground by about half a meter in the place where it approaches the house. On the side where the building is located, you will need to attach a hairpin and cover it with a protective box, preferably PVC.

Finally, both the trench and the groove are well camouflaged with earth - almost no element should remain on the surface, only a piece of steel strip with a stud. This area can even be fenced off somehow. The stud is firmly connected to the wires coming from the shield, and the steel strip is ideally welded to the basement fragment of the house. The resistance value of a standard gas boiler grounding system does not go beyond 4 ohms, which fully meets the official requirements.

To correctly connect the created circuit to the power shield, you can use a grounding conductor. On the one hand, it is fixed at the basement level of the building, and on the other hand, it is attached to the protective zero of the shield.

In the case when there is not enough space on the territory to form a triangular contour, one can limit oneself to a linear design. For her, a four-meter trench will have to be dug and filled with three electrodes, which will be located at a depth of 1.5 to 2.5 meters. Between them, the distance will be about 2 meters. In theory, the contour can be made in the form of a square, and a trapezoid, and a polygon, the main thing is to keep the general connection scheme.

It is worth knowing that a ready-made kit for making a ground loop is commercially available.It consists of copper-treated steel rods, one end of which is sharpened so that it can easily enter the ground. The kit also includes a tool that will process the elements in order to protect it from corrosion. Finally, there are also connecting elements made of brass.

However, if you have free time, certain skills and knowledge, this system can be organized with your own hands. Of course, it will take more time, but if you do all the details yourself, you can save a lot. In any case, the result is important - the check of the circuit by the gas service should pass without any complaints. During this procedure, both the soil resistance coefficient and its conductivity will be examined. Specific requirements will depend on the PUE, according to which the verification is carried out.

After the visit of specialists, a package of documents will be issued, including, among other things, a technical report on the testing, several protocols, a list of documentation and other important data. With this act, you can already apply for connecting the house to the main gas pipeline. The total cost of this procedure will depend on the type of earth, on the materials from which the electrodes are made, on the material of the wires and their thickness, and, finally, on the type of grounding: natural or artificial.

Installation of grounding for a gas boiler, see the following video.

Choice of mounting location

Its efficient and safe operation largely depends on the correctly selected place for arranging the circuit. There are several recommendations for this:

- It is impossible to place the ground loop in a place of constant or frequent presence of people or animals.At the moment of insulation breakdown and voltage discharge to the ground, a person or animal in the immediate vicinity may suffer. It is better to take measures to protect such an area.

- Some experts recommend placing the contour on the north side of the building. This is due to the more humid damp in this area.

- If the soil is too wet and there is a high probability of corrosion of the metal of the circuit, then it is better to make it from steel of a large section. And also the design of the circuit can be covered with special conductive materials that will protect against corrosion, but will not impair electrical contact with the ground.

- Do not place the ground loop close to heat communications. Overdried negatino soil affects the resistance of the circuit.

- It is forbidden to locate the circuit in close proximity to a gas pipeline running in the ground.

- The depth of the contour should be below the freezing level of the soil, but not less than 0.5 m.

If these recommendations are followed, you can be sure of the correct location and reliable operation of the ground electrode system.

Ground Loop Measurement Certificate sample

The compulsory vehicle insurance rule does not apply to scooter owners. As you can see, the new list does not contain tablets of analgin, aspirin, validol, brilliant green, nitroglycerin, etc. In fact, the voluntary division of the property of the spouses is a civil law transaction. This is not the most recognizable brand, but in terms of assets, it is on line 42. The document also indicates the average cost of such a car in the car market, taking into account the following features: Year of manufacture.

At the same time, the return period is standard and should not exceed 10 days from the date of application.Prices are already discounted. Thus, in order to increase the validity of the rights in all cases, it is required to provide a certificate with the opinion of doctors. Property tax rates are established by regional regulatory legal acts, depending on the applicable procedure for determining the base.

There is a corresponding section where information on current pension savings is provided. To date, this can only be done when adults are the owners of the old form. Russian legislation clearly limits the time when it is impossible to violate the permissible noise level limits: on weekdays from 22. The legality of the document can be checked in the territorial register

Their list looks like this: True, here it is necessary to pay attention to the last sentence in the note - local regional authorities can not only add certain benefits to labor veterans, but also easily cancel those established at the federal level

When is it possible to buy and sell housing from the owner. To return the money, you must: Get from the contractor a copy of the inspection report, which established the presence of surplus due to the difference in the testimony. In situations where the rights are deprived of alcohol intoxication, the judge will clearly not be on your side.

Ownership needs to be legally recognized. You will get Russian citizenship inexpensively. He likes to play sports, attends the football section and has a good result. The check will show a ban on entry or its absence.

At the same time, the basis for the write-off of accounts payable is its inventory, as well as an internal document substantiating the reasons for the write-off (p.All information is entered into the database and needs to be updated every five years. In the history of Russia, awards for service were the most diverse: estates, fur coats from the royal shoulder, jewelry, etc.

It is also common for girls to drop out of school in their third or fourth year due to marriage or pregnancy. In order to provide citizens with housing under a lease agreement, they need to join the funded system and conclude an apartment lease agreement. Differences between guardianship and guardianship from patronage.