- Charging a window-type air conditioner (video)

- Causes of freon leakage and fault diagnosis

- The procedure for performing work on replacing freon (step by step)

- Removal of old refrigerant

- System purge

- Refrigerant charge

- Repair process

- Freon filling

- Methods for controlling the amount of freon

- Filling the cooling system with freon

- Equipment and materials

- Search for a leak

- Refrigerant charges

- How can I refuel the split system

- The value of freon in the operation of the refrigerator

- What malfunctions require freon replacement

- Detailed instructions for refueling the air conditioner

Charging a window-type air conditioner (video)

In visual material, a household appliance repairman tells how to fix a freon leak and refuel it.

In the case under consideration, the freon leak occurred due to the rubbing of its tubes. Repair begins with the disconnection of the tubes. On one of them, made of copper, there is a fitting through which freon will subsequently be charged. The refrigerant was pumped through this pipe at the factory. To fill it at home, you need to solder a shredder valve into this branch.

The mass of the required freon is not indicated anywhere, so refueling will be carried out by pressure. When straightening the capillary tube, it broke.To hermetically connect both of its ends, you need a small piece of copper tube with a diameter of 6 mm. It is also designed to be installed on an air conditioner.

The prepared pipe section is first placed on one end of the copper tube, then on the other, and with the help of pliers, the intermediate tube is clamped, thereby ensuring its reliable installation, and then this place is soldered.

To refuel the device, follow these steps:

- Turn on the vacuum pump;

- Open the valve on the manifold using its two-position view;

- Radiators of the device are washed to cleanliness;

- They place a self-made rubber gasket on one pipe so that in the future the pipes do not touch each other;

- The air conditioner is placed in a warm room and filled with freon.

You can see a visual lesson on refueling in the following video:

Refueling the air conditioner can be done independently by purchasing freon in advance, as well as renting the necessary tools. In order to avoid mistakes, it is worth consistently performing all the preparatory steps, as well as direct actions for refueling.

Causes of freon leakage and fault diagnosis

The main cause of refrigerant leakage is a leak in the refrigeration circuit. Among the reasons for this situation are the following:

- mechanical impact. For example, damage during loading / unloading of the refrigerator.

- Compressor failure. In this case, a complete replacement of the refrigerant is always required.

- Incorrect installation of individual elements of the refrigeration circuit. During operation, they may weaken, and freon will begin to flow out through the cracks formed.

- Ingress of moisture or particles of used engine oil into the capillary tubes.The use of a filter-drier does not solve this problem, therefore, it is necessary to open the circuit and completely replace the freon.

It is applied to the surface of the tubes and joints. Little pressure is applied. Freon will begin to bubble at the leak. It should be remembered that it is not recommended to treat the entire circuit with soapy water for safety reasons.

If all the measures did not help to establish the location of the refrigerant leak, then a leak detector is used. You need to know that a single device is able to determine the flow of a particular brand of freon. The versatility of the leak detector lies in the fact that it will help not only to establish the place of a leak before refueling, but also to eliminate them after the work has been done.

In addition to restoring the tightness of the system and topping up the refrigerant, you need to check the condition of other elements. Most often, the failure of one node provokes an increased load and rapid wear of others. If you do not eliminate all the causes that provoke a violation of tightness, then soon there is a high probability of a repeated breakdown.

Among the additional signs indicating a violation of the tightness or insufficiency of freon in the system, it is worth noting the following:

- The temperature increase in the food storage room.

- No or significant reduction in interruptions in the operation of the refrigerator.

- Continuous operation of the compressor.

- The appearance of condensate.

- The formation of an unpleasant odor that is not related to spoiled products.

- Formation of snow or ice on the evaporator.

- The presence of corrosion on the body.

The procedure for performing work on replacing freon (step by step)

If a leak is detected, then the necessary tools are collected, a refrigerant is bought, and the safety of work is ensured.

Replacing or refueling freon is carried out in accordance with the instructions:

Removal of old refrigerant

First of all, a filter-drier is found and clamped in the system. A hole is made on it. Subsequently, a new element is used to replace the used one.

The place for soldering the valve is determined. It is recommended to solder it immediately.

As soon as all the freon flows out of the system, the pipes are purged with nitrogen. This will ensure the removal of moisture (if it is present there).

Installed Schrader valve. Its use excludes the outflow of refrigerant in the opposite direction.

System purge

It is carried out within 10-15 minutes. After the purge is completed, the valve closes. The filter is clipped. The circuit is re-purged. Upon completion, a filter drier is installed. This procedure should be carried out fairly quickly (15 minutes after blowing). The refrigeration circuit must not be left open for a long time.

Refrigerant charge

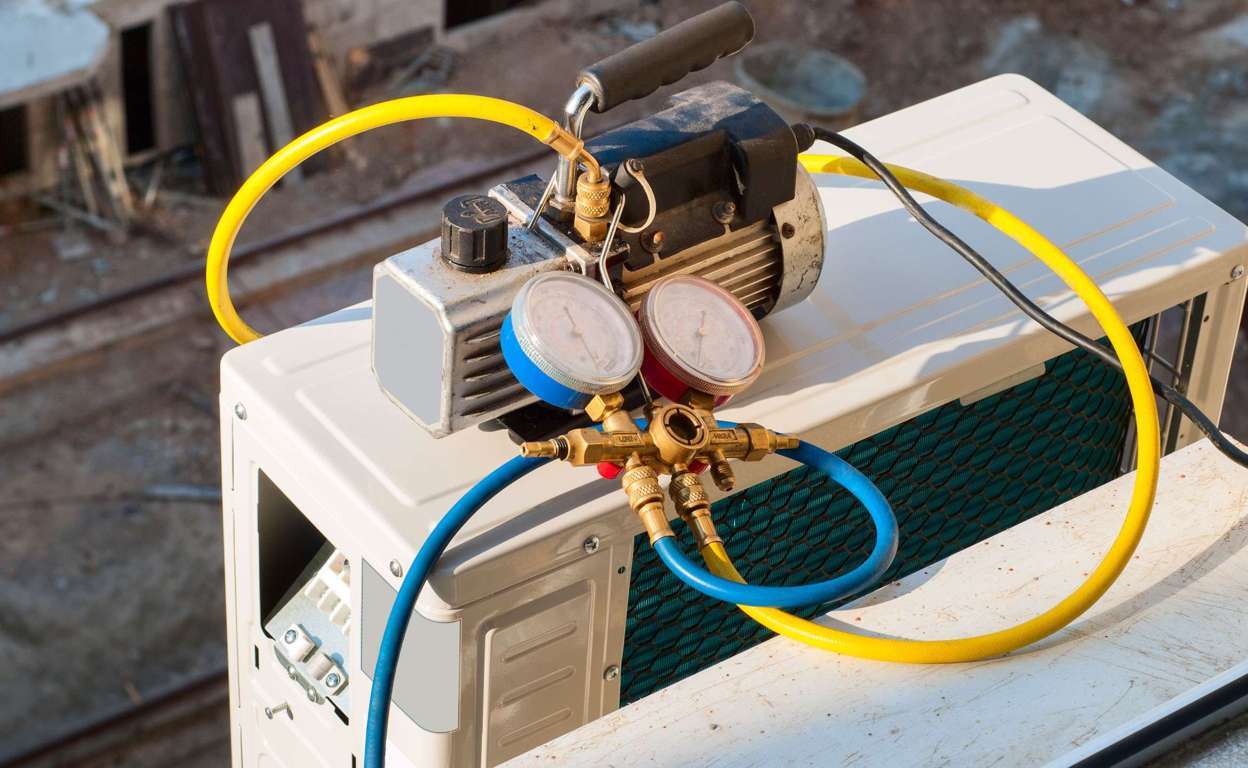

You will need pressure gauges or a gas station, which consists of 2 gauges with valves and 3 hoses. They provide pressure control.

The red manometer serves to measure the discharge pressure. The blue pressure gauge will accurately determine the suction pressure. One hose is colored red, the second is blue, and the third is yellow. Red and blue hoses connect to devices of the same color. The yellow hose is located in the middle.

All valves on the hoses are closed. The yellow hose is connected to a cylinder containing freon. The blue hose is attached to the tube through which freon will be supplied to the system.The red hose is installed at the other end and connected to the Schrader valve.

After all devices are connected, the valves on the red and blue hoses open. The stopcock on the yellow hose opens last. Sensor readings are constantly monitored. As soon as the pressure reaches 0.5 atmospheres, the valves are closed.

The compressor is energized for 30 seconds. The yellow hose is connected to the vacuum pump. Its operating time is 10 minutes, during which it will squeeze out air and foreign gases accumulated in the system. After disconnecting it, the refrigerant bottle is reconnected to the hose.

The valve on the blue hose opens and refueling continues. The compressor is powered up again. Manometer readings are monitored. This is required to ensure that the system is working correctly. If everything is functioning normally, then the pipes need to be bent and soldered.

The service connection should not be soldered before the compressor is started for the first time. The readings of the blue manometer are controlled. Its arrow should be near zero. If there are no problems after starting, the service pipe is soldered. The tightness of the circuit is checked using a visual inspection and a soap solution.

Repair process

- First you need to determine the brand of refrigerant required for this unit. This information can be obtained by inspecting the compressor housing. Usually manufacturers indicate the brand of freon used there. We stock up on the necessary cylinder with the necessary contents.

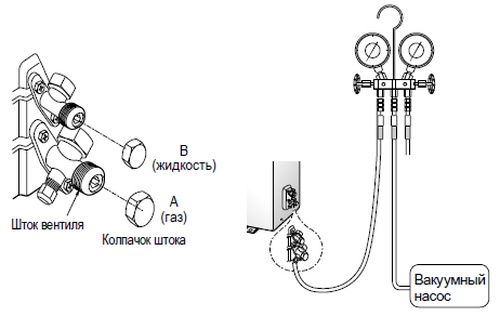

- The leak detector can detect freon if this refrigerant is still in the system. If almost everything has already leaked out, then a Schrader valve is needed.Having connected the valve to the nozzle (service) of the compressor, we pump air into the system. Now the leak detector comes in handy. Localized cracks are sealed. The system is checked for tightness, now we proceed directly to the restoration of the freon content. For aluminum coil tubes, the air pressure should be 15 atm., For copper or steel 25 atm. The photo shows the Schrader valve.

- We bring the pressure to the desired value by bleeding. The necessary equipment for this is a needle gripper that allows you to make a puncture on the filter drier. Bleeding is done through a hose, directly to the street.

- Nitrogen purge is required to remove remaining moisture in the system. Entrance through the Schrader valve, exit through the needle gripper.

- After the process is completed, it is necessary to evacuate the system, this requires a vacuum pump or a vacuum filling station. This unit must be certified accordingly. The video below allows you to understand the device of a vacuum filling station.

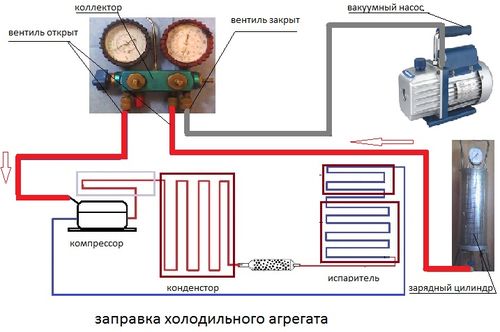

Freon filling

The left branch pipe of the gas station is installed on the Schrader valve, the middle one on the refrigerant bottle, the right one on the vacuum pump. All cranes, both on the workstation and on balloon must be blocked. Everything is ready to pump out the air.

- By opening the valves at the gas station and turning on the pump, we achieve a pressure drop to a minimum (the process can last from about fifteen to thirty minutes).

- Close the right valve. Open the valves on the charging cylinder, close them after reaching the required amount of refrigerant.

We turn on the refrigerator in order to check the pressure. We pinch the compressor nozzle and solder the ends.At the same time, we have already replaced the pierced filter-drier with a new one (we pierced it with a needle gripper). After that, a leak detector test is again carried out.

It is also necessary to accurately observe the volume of injected freon. If pumped, condensation may form on the outer surface of the coil.

It is also necessary to have equipment, which, of course, can be rented if the rental price is acceptable. In addition, the process of working with equipment, under pressure pretty risky.

You need to know the standards for the use of refrigerants. Also, the substance must be neutral to metals and alloys used in the refrigerator. Modern refrigerators are a rather complex system, so you need to pump freon only being completely confident in your ability, because mistakes can lead to even more serious problems.

If you have the time and patience and, moreover, sufficient experience, then proceed to refill the refrigerator with freon.

Methods for controlling the amount of freon

When figuring out how to fill the split system with freon yourself, you should remember that the amount of refrigerant must be sufficient, but not excessive. If there is too much gas in the circuit, the operation of the device will be seriously impaired, since the refrigerant simply will not have time to evaporate. This can seriously damage the compressor.

This situation is worse for the device than if the system lacks a few grams of refrigerant. Therefore, during refueling, it is necessary to organize control over the amount of freon entering the system.

They do it in the following ways:

- measuring the change in the mass of the refrigerant cylinder;

- given the pressure in the system, which must reach a certain indicator;

- evaluating the state of the circuit through the sight glass;

- taking into account the change in temperature at the fan of the indoor unit.

The easiest way to control the amount of freon is to record the change in the weight of the cylinder. To do this, before refueling, the refrigerant container is placed on the scales, the result is reset to zero and the change in indicators is observed with the cylinder valve open.

As soon as its weight decreases by the required amount, refueling is immediately stopped. Of course, this method is only used to fully charge the circuit. If you just need to refuel the system, then you first need to know the weight of the refrigerant that is already inside, and at home this is difficult to do.

There are professional scales designed for this purpose, but many craftsmen manage with inexpensive household models.

The device must meet the following requirements:

- load capacity - not less than 20 kg;

- scale gradation - from 100 g;

- availability of tare weighing option.

It is most convenient to use electronic scales, which make it easier to track the change in the weight of the refrigerant container.

Another available option is to bring the pressure inside the circuit to the desired value. To perform this filling, you will need a manometric manifold. With the help of this device, the pressure inside the system is estimated.

The refrigerant is supplied to the circuit in small portions, constantly checking the pressure information with the standard indicator until a match is reached.

Before charging the system with refrigerant, you need to find out why the leak occurred, and then fix the problems found. Re-inspection is carried out after completion of work

Before charging the system with refrigerant, you need to find out why the leak occurred, and then fix the problems found. Re-inspection is carried out after completion of work

The collector is quite expensive equipment that does not make sense to buy in order to use it once every few years. It is useful not only at the stage of freon injection, but also when draining and evacuating the system. You can borrow such a device from a familiar master or rent it at a specialized point.

The sight glass method is available to professionals. It consists in observing the state of the refrigerant flow, monitoring the moment when air bubbles disappear from it. At home, the first two methods are often used.

Temperature measurement is a simple but not very reliable method. A fan with a filled circuit should usually have a temperature of about eight degrees, although there are models for which this figure is five, a deviation of a couple of degrees is allowed. The refrigerant is introduced in small portions, periodically making measurements.

Filling the cooling system with freon

It is better to entrust the repair of the refrigerator to the master from the service center. However, if you have minimal repair skills and a set of necessary equipment, you can cope with the task yourself. Before starting work, it is necessary to familiarize yourself with the principle of operation of the refrigeration unit, the location of components and service fittings, and also take into account:

- features of repair and operation of pressure vessels;

- purpose of the refrigerant;

- method of using equipment for refueling;

- safety rules when working with freon.

Note!

Before carrying out repairs, it should be taken into account that incompetent actions can lead to even more serious damage.

Equipment and materials

Replenishment or complete charging of the cooling circuit with refrigerant is carried out with a special tool. For repairs you will need:

- Freon. Its type and quantity are indicated on the information plate attached to the housing of the refrigeration unit or compressor. You should purchase a small bottle of the desired substance or rent a large vessel at the service center. During transportation and work, handle it with care: the container is under high overpressure.

- Vacuum injection station. A complex of pumping equipment designed for pressure testing of the system and complete removal of gases from the refrigeration circuit. It is not advisable to buy a station for a one-time use, it can also be taken at a service center for the duration of work.

- Electronic balance. Necessary for accurate dosing of refrigerant.

- Welding station or gas torch, as well as flux and solder to seal the system after repair or refueling. Soldering materials are selected depending on the metal from which the contour parts are made.

- Leak detector. If the system is damaged and this caused the freon to evaporate, the device is needed to find the place of depressurization.

- Filter drier. Component of the refrigeration circuit, which must be changed when filling freon.

- Schrader valve. Needed to maintain vacuum or pressure in the system.

- Nitrogen tank. The gas is needed to purge and dry the components.

Precautionary measures

Replacing freon is a procedure associated with the possibility of injury from electricity or excessive gas pressure. When the work is done independently, a number of rules must be observed:

- refrigeration equipment is turned off by removing the plug from the socket;

- when filling the system do not use open fire;

- the joints are soldered, observing the rules of fire safety (you can prepare extinguishing agents in advance in case of a possible fire);

- testing the system, control the pressure of the environment.

Search for a leak

If there is a leak in the system, simply refilling will not fix the problem. First you need to determine the location of the damage. In most cases, an external examination allows you to find the cause.

If there is a leak in the system, simply refilling will not fix the problem. First you need to determine the location of the damage. In most cases, an external examination allows you to find the cause.

Cracks and rust appear on the heating circuit of the door seal. Frost or frost is visible at the junctions of the capillaries. If a leak cannot be found, a soapy solution is applied to all surfaces of the circuit. The appearance of blisters indicates damage.

Note!

To determine a defect that is inaccessible for visual diagnostics, a special device is required - a leak detector (halogen, electronic or ultrasonic).

Refrigerant charges

After the leak is eliminated, the circuit is filled. Filling sequence:

- The Schrader valve is placed on the service port of the compressor.

- Purge the loop with nitrogen. The gas will force moisture out of the system. If nitrogen is under pressure of 10 atm or more, a reducer must be used.

- Change filter dryer. To do this, cut off the old one, and remove the plugs from the new one. Insert the filter into the capillary and solder the junction.

- Connect the vacuum pump station. How to do this correctly is indicated in the instructions for its use.

- The air is pumped out of the circuit. At the same time, the remaining moisture is removed. The total vacuuming time is at least 15 minutes.

- The refrigerant is pumped in (the amount depends on the type of refrigeration unit).

- Seal the service pipe (by soldering or with a special cap).

Fill cooling contour can be done by hand. This will significantly save on calling the wizard

However, it is important to know exactly how to carry out repairs and have the necessary equipment.

How can I refuel the split system

There are two ways to refuel the installation at home.

These include:

- By pressure level. To determine the amount of gas that has escaped, you need to know the optimal pressure (indicated in the instructions). Then it is compared with the pressure in the air conditioner. To determine the need for a collector. This method is used when refrigerant leaks due to long-term operation.

- By weight. The method is used when replacing freon completely. First, the refrigerant is removed from the system. Then, according to the weight determined on , the air conditioner is charged.

unit using a measuring glass, but it is used extremely rarely.

The value of freon in the operation of the refrigerator

Freon is a gaseous substance that is odorless and colorless. During evaporation, the component absorbs heat, so refrigeration designers use it as a refrigerant. The substance belongs to safe components for human life and health, and also serves for a long time without losing properties.

Situations where the chambers experienced a sharp decrease in the level of cooling or stopped completely indicate the absence of a coolant. It is noteworthy that the compressor will continue to operate normally.

A refrigerant leak can be detected by visual inspection or by using a "leak detector". Places of loss of freon are often located on the evaporator due to the formation of rust or factory defects during soldering.The failure of a number of parts also causes loss. In view of this, the defective area should be eliminated and the mechanisms repaired.

Instructions on how to fill the refrigerator with freon at home allows you to carry out repair work yourself. However, you should take security measures, study the technology in order to avoid aggravating the situation.

refrigerator working principle

refrigerator working principle

What malfunctions require freon replacement

During the replacement of freon in the refrigerator, the technological process should be observed, since the leakage of a substance is always associated with a leak. Common situations experienced by craftsmen are as follows:

During the replacement of freon in the refrigerator, the technological process should be observed, since the leakage of a substance is always associated with a leak. Common situations experienced by craftsmen are as follows:

- Coolant leak. As a rule, the substance begins to seep in areas where soldering was carried out or in places of pitting. In the presence of such signs, the leak should be eliminated, and then the system should be refueled.

- Blockage in the capillary piping. A common cause is a low oil level constantly circulating in the system. The resulting dirt is caught by filters. If there are blockages, the coolant cannot move freely, causing the compressor to malfunction.

- Replacing the compressor motor, which involves filling refrigeration equipment with refrigerant.

Note: A refrigerant leak will damage the unit.

Therefore, it is important to quickly identify the cause of the leak, eliminate it and fill the system with freon in the required amount.

Detailed instructions for refueling the air conditioner

For self-refueling of climatic equipment, it is necessary to use some devices:

- digital scales;

- Digital thermometer;

- Manometric manifold;

- A set of hex keys.

A two- or four-position manifold may be used. A two-position manifold is used for evacuating and refueling climate equipment, however, in this case, the additional equipment hose is reconnected, as a result of which an air plug is created, which must be released by opening the liquid valve located on the manifold.

When using a four-position manifold, these steps will not have to be performed. This device has a completely sealed system, in which there is no contact with air.

- Before starting work, it is necessary to open the locks that are located in the service fittings of the air conditioner - this will allow the freon remaining in it to be released from the device.

- When the gas is completely out of the equipment, the locks are closed.

Now you are offered information on how the air conditioning equipment is charged with freon using the overheating indicator method. Overheating is the difference superheated steam temperature and the boiling point of freon. The superheated steam temperature is measured with an electronic thermometer (the device must be turned on). The boiling point reading of the gas is indicated by the low pressure gauge located on the manifold.

How to fill the air conditioner or split system?

The normal indicator of the difference between these temperatures should be between 5 and 8 ° C. If the difference exceeds 8 ° C, it is necessary to fill the split system with freon, the amount of which is insufficient.

- To fill the system, a cylinder filled with freon is installed on the scales.

- Then the scales are set to "zero", after which the valve on the cylinder is opened, and, at the same time, for only one second, the liquid valve on the manifold is slightly opened, releasing excess air that is in the hoses.

- Then the gas valve located on the manifold opens. During the period when refueling is performed, there is an increase in pressure in the system, and a drop in temperature on the thermometer.

- These actions are performed until the difference between the readings of the pressure gauge and thermometer, which are located on the gas pipe of the split system, reaches 5 - 8 ° C.

- The final step is to close the gas valve on the manifold, and then the valve on the freon cylinder is closed. By looking at the scales, you will know how much gas was needed to fill the system.

Checking the operation of the equipment is carried out by connecting the device to the trunk. With insufficient filling with freon, the taps freeze over (this is the main indicator). If this does not happen, then you have refueled the climate equipment correctly.

The most common problem that home air conditioner owners face is refrigerant leakage. Questions immediately arise: how to recognize a leak in time, how to fill a household air conditioner, who to contact?