- How to connect a solid fuel boiler

- How the scheme works

- Way to reduce the cost of strapping

- Types of liquid pumps

- vibrating

- drainage

- Self-priming centrifugal

- Manual piston

- The procedure for filling the heating system with water

- Features of filling a closed-type heating system

- How to pour water into a closed heating system with and without plumbing

- Preparatory operations

- Filling water from the tap

- Pouring water without plumbing

- Classification of heating systems

- Types and properties of heat-carrying liquids

- Filling methods

- Launch of the apartment building system

- Launching a gravity open heating system

- Starting a closed heating system

- Water or coolant choose the optimal system filling

How to connect a solid fuel boiler

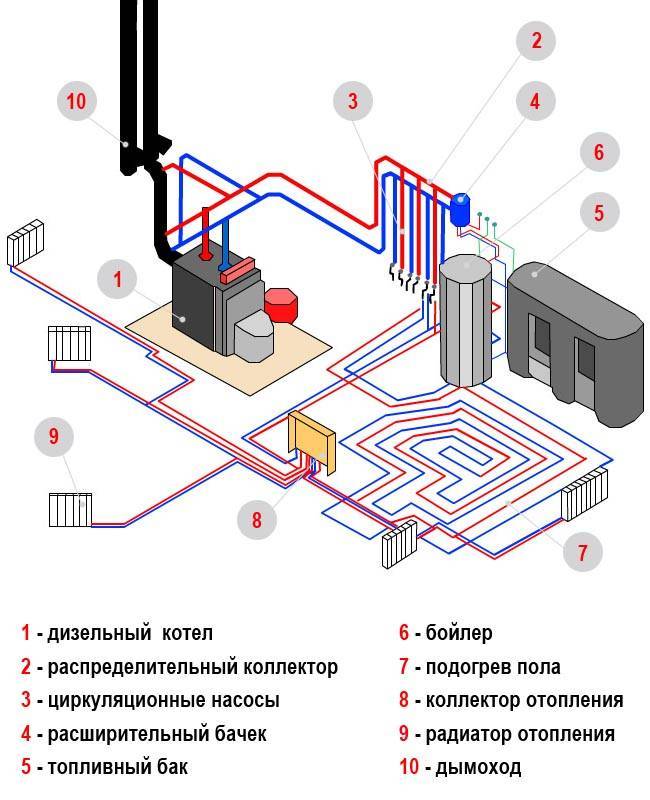

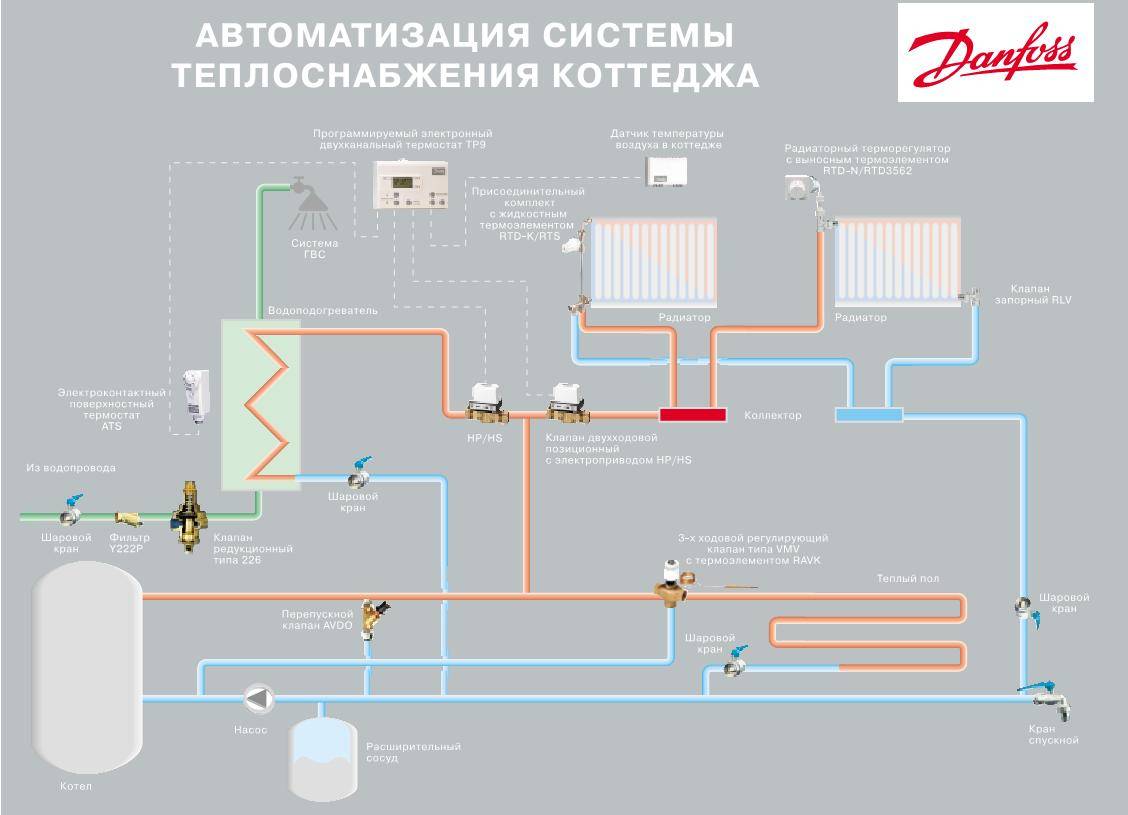

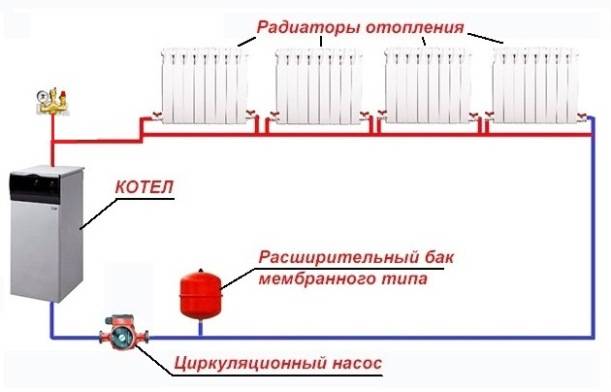

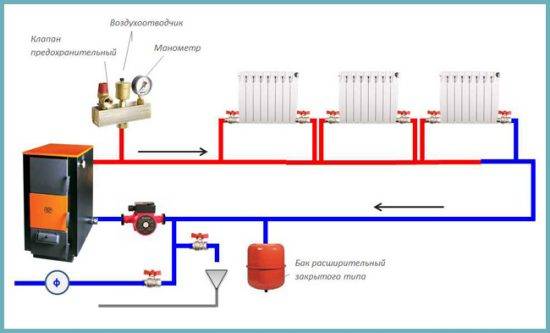

The canonical scheme for connecting a solid fuel boiler contains two main elements that allow it to function reliably in the heating system of a private house. This is a safety group and a mixing unit based on a three-way valve with a thermal head and a temperature sensor, shown in the figure:

Note. The expansion tank is conventionally not shown here, since it can be located in different places in different heating systems.

The presented diagram shows how to connect the unit correctly and should always accompany any solid fuel boiler, preferably even a pellet one. You can find various general heating schemes anywhere - with a heat accumulator, an indirect heating boiler or a hydraulic arrow, on which this unit is not shown, but it must be there. More about this in the video:

The task of the safety group, installed directly at the outlet of the solid fuel boiler inlet pipe, is to automatically relieve the pressure in the network when it rises above the set value (usually 3 bar). This is done by a safety valve, and in addition to it, the element is equipped with an automatic air vent and a pressure gauge. The first releases the air that appears in the coolant, the second serves to control pressure.

Attention! On the section of the pipeline between the safety group and the boiler, it is not allowed to install any shut-off valves

How the scheme works

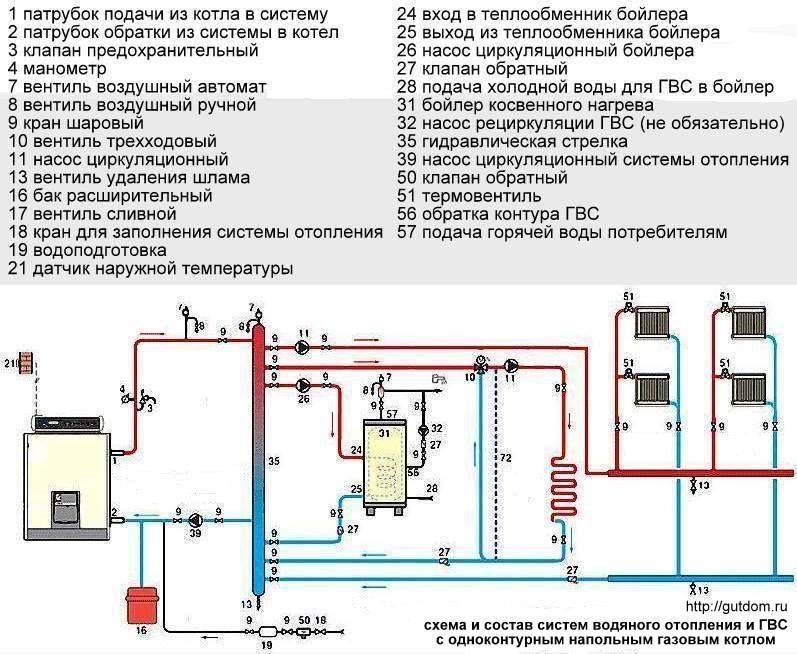

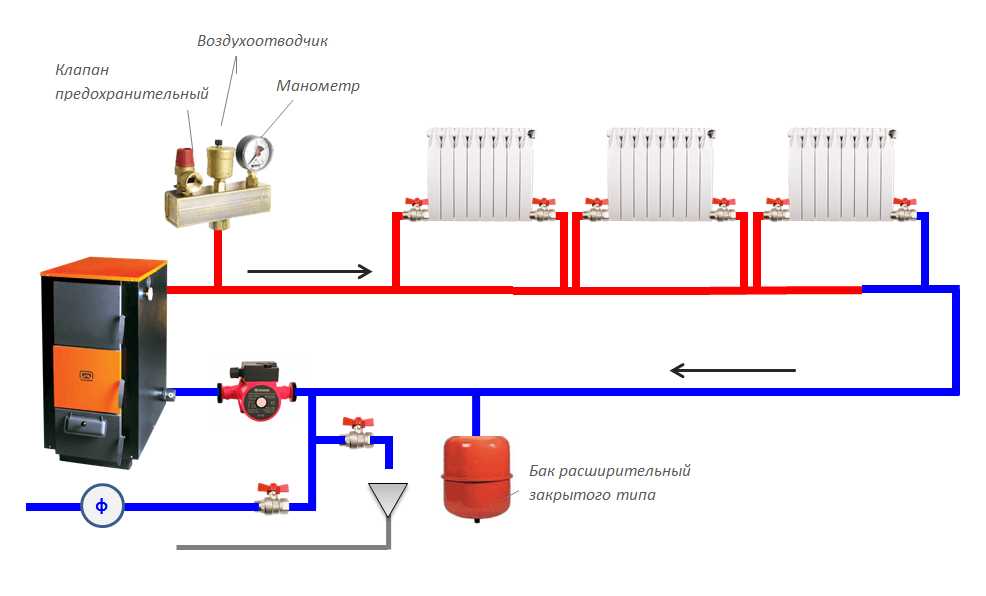

The mixing unit, which protects the heat generator from condensate and temperature extremes, operates according to the following algorithm, starting from kindling:

- Firewood is just flaring up, the pump is on, the valve on the side of the heating system is closed. The coolant circulates in a small circle through the bypass.

- When the temperature in the return pipeline rises to 50-55 °C, where the remote-type overhead sensor is located, the thermal head, at its command, begins to press the three-way valve stem.

- The valve slowly opens and cold water gradually enters the boiler, mixing with hot water from the bypass.

- As all the radiators warm up, the overall temperature rises and then the valve closes the bypass completely, passing all the coolant through the unit heat exchanger.

This piping scheme is the simplest and most reliable, you can safely install it yourself and thus ensure the safe operation of the solid fuel boiler. Regarding this, there are a couple of recommendations, especially when tying a wood-burning heater in a private house with polypropylene or other polymer pipes:

- Make a section of the pipe from the boiler to the safety group from metal, and then lay plastic.

- Thick-walled polypropylene does not conduct heat well, which is why the overhead sensor will frankly lie, and the three-way valve will be late. For the unit to work correctly, the area between the pump and the heat generator, where the copper bulb stands, must also be metal.

Another point is the installation location of the circulation pump. It is best for him to stand where he is shown in the diagram - on the return line in front of the wood-burning boiler. In general, you can put the pump on the supply, but remember what was said above: in an emergency, steam may appear in the supply pipe. The pump cannot pump gases, therefore, if steam enters it, the circulation of the coolant will stop. This will accelerate the possible explosion of the boiler, because it will not be cooled by the water flowing from the return.

Way to reduce the cost of strapping

The condensate protection scheme can be reduced in cost by installing a three-way mixing valve of a simplified design that does not require the connection of an attached temperature sensor and a thermal head. A thermostatic element is already installed in it, set to a fixed mixture temperature of 55 or 60 ° C, as shown in the figure:

Special 3-way valve for solid fuel heating units HERZ-Teplomix

Note. Similar valves that maintain a fixed temperature of mixed water at the outlet and are designed for installation in the primary circuit of a solid fuel boiler are produced by many well-known brands - Herz Armaturen, Danfoss, Regulus and others.

The installation of such an element definitely allows you to save on piping a TT boiler. But at the same time, the possibility of changing the temperature of the coolant with the help of a thermal head is lost, and its deviation at the outlet can reach 1–2 °C. In most cases, these shortcomings are not significant.

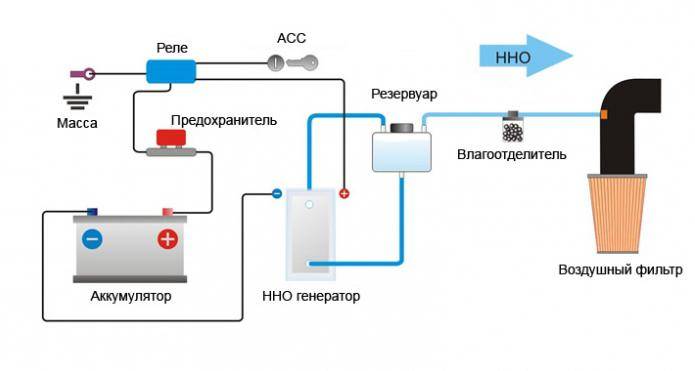

Types of liquid pumps

Filling an open system is not a problem from a hardware point of view - a regular bucket is sufficient. To speed up the process and make it more convenient, a hand pump or a device powered by electricity is used.

A closed system, on the contrary, is filled only with a pump, the coolant is supplied under pressure.

Any pumps are suitable for these purposes; there are no specialized pumps for pumping antifreeze into the heating system.

vibrating

Vibratory submersible pumps are completely immersed in the liquid. This is how the popular "Baby" works, which is used in wells and wells. This device is quite suitable for pressurizing up to 4 atm. It is also useful for the system that this pump is equipped with filters.

drainage

This is also a submersible device, but there is a difference from the previous type of device: the unit skips switching on, the maximum size is indicated in the data sheet.

Using such a device, measures are taken to prevent foreign particles from entering the system.

When choosing a container for the pumped liquid, one more feature of this type of device is taken into account: a float mechanism that turns off the unit if there is little liquid left.

Self-priming centrifugal

These pumps work by remaining on the surface - the hose is immersed in the liquid. Due to their high power, they are used for filling the system and for crimping.

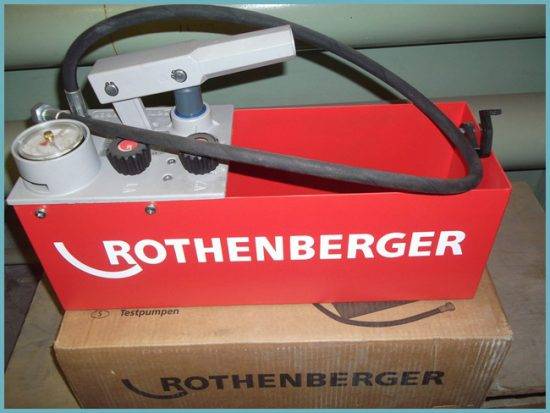

Manual piston

Convenient economical unit with a tank, equipped with a pressure gauge, which allows you to control the pressure. Requires significant physical effort.

The procedure for filling the heating system with water

Since water is the most popular coolant, the process of filling the heating system with this substance should be considered in more detail and all the nuances of its characteristics should be taken into account.

Water has a lot of impurities and minerals, which, when boiled, settle in the form of scale on the walls of the heating equipment, which leads to system clogging and breakdown. Therefore, before filling the heating system, the water must be boiled. If funds allow, then instead of boiling, you can buy distillate.

Water contains oxygen, which contributes to the development of corrosion. The ability of water to mineralize and release oxygen when heated leads to equipment failure, therefore it is recommended to replace the water in the heating system no more than once a year.

Before carrying out work on filling the heating system, you should find out the required volume of coolant. To do this, sum up the volume of all the main elements of heating equipment:

- boiler;

- expansion tank;

- radiators;

- pipes.

Manufacturers usually indicate the volume in the technical documentation attached to the equipment. If this information could not be found, then there are special tables with average indicators that can be used in calculations.

If filling the system with coolant is associated with another replacement for preventive purposes, then the old water must first be drained into the prepared container. The order of work will be as follows:

- Unscrew the nipple to relieve excess pressure.

- Open the valve at the top point, and the drain cock opens smoothly at the bottom. To avoid the occurrence of water hammer, the opening of the valves must be slow and gradual.

- After removing the water, use the pump to clean the entire system with flushing liquid, and then with clean water.

- Check for leaks and repair if found. If necessary, replace obsolete gaskets in radiators.

- Fill the system with coolant. To do this, connect an electric pump to the lower point. Water is poured through the lower point, while the upper valve must be open. When water flows from the top point, the pouring process is over.

Next, you need to remove air from the system. To do this, valves open on all main heating units. A transparent hose is attached to the top point and lowered into the water tank. After connecting the pump, fill pipes and radiators until water flows out of the hose without bubbles.

Elimination of water leakage.

Removal of air from the system.

After the equipment is degassed, the circulation pump is connected without heating.If no problems are found, then you should connect the heat source and test the heating system, checking for uniform heating of all equipment. To do this, you can use a thermal imager or a special temperature meter.

In the event that the coolant is poured into only installed equipment, the filling procedure will be similar.

Features of filling a closed-type heating system

To perform the work, a pump and an expansion tank are required. It is recommended to do this together. The task of the first is to fill the circuit with water, while the second controls the air release.

If you have to do everything alone, it is enough to turn on a weak pressure. The gas relief valve must be in the upper part of the pipeline, away from the boiler.

Before starting, a container is placed under the place where the liquid flows out to collect it.

A faucet for removing water is placed at the bottom. Not far from it, near the boiler, a supply pipe is mounted. To fill, use a hose that is placed in the water supply or connected to a pump. A high pressure contributes to a successful process. The system will fill when liquid emerges from the bleed valve. Then comes the air release and pressure check. If necessary, repeat the procedure.

In a two-circuit system, the process is simpler. For the bay, use the recharge system, if any. It will automatically balance, remove gas and select the desired pressure. In its absence, you will need to connect the water pipe to the boiler with a hose and fill it through the latter. In this case, you will have to manually clean the circuit from air.

If the boiler is gas, you will have to remove the front cover from it. There is a boost pump. The device is turned on by heating the coolant.

The liquid is mixed with the gas to be removed: for this, the valve inside the device is slightly opened with a screwdriver. When water appears from it, the valve is closed.

The procedure is repeated 3-5 times with an interval of 2-3 minutes. If the boiler stops bubbling, check the pressure.

Having finished filling the closed system, they proceed to inspect the integrity of the pipes. After it, debugging and hydraulic tests are done.

How to pour water into a closed heating system with and without plumbing

Arkady How to pour water into a closed-type heating system?

No heating system will function without a coolant. because it directly provides the transfer of energy to the radiators and the subsequent heating of the air in the room. So after installation and repair work, you will inevitably need to pour new water into the equipment. To many, this procedure seems overwhelming. Especially if you need to fill a closed system. Indeed, the task is troublesome, but at the same time absolutely realizable, if you do everything according to the rules - they will be discussed further.

Preparatory operations

Before you start pouring coolant into a closed heating system, prepare it for work. In particular, the following procedures should be followed:

- Hydraulic test - before filling the system, it must be pressure tested. This is done using a special device that pressurizes and fills all pipes and batteries with compressed air. Pressurization is carried out at a pressure of 25% more than the base pressure for a particular heating system.

- Checking for malfunctions - after completing the pressure test, all joints of the heating equipment should be checked for depressurization and leaks.If there are any problems, they must be corrected.

- Closing valves - to avoid unplanned water consumption during filling, close the shut-off valves that remove fluid from the system.

When the preparatory work is completed, you can start pouring water. It can be run from a centralized water supply or, in the absence of the latter, from another source of water - consider both options.

Hand pump for pressure testing of the heating system

Filling water from the tap

If your house is connected to the water supply network, there will be no problems with filling the heating system. First you need to determine which fittings are closest to the heating boiler - it is through it that the coolant should be introduced.

Next, the heating boiler must be connected to a centralized water supply and a special shut-off valve must be installed between them. Filling is carried out precisely thanks to this valve: when it is opened, water begins to flow from the water supply into the boiler, which is then poured into the pipeline.

Important! Water should enter the heating system at a minimum speed - this will allow the air that remains in the pipeline to be removed without consequences through special Mayevsky taps on batteries. If the house has more than one floor, the system can be filled not at once, but in parts: starting from the lower radiators and ending with the upper heating points. If the house has more than one floor, the system can be filled not at once, but in parts: starting from the lower radiators and ending with the upper heating points

If the house has more than one floor, the system can be filled not at once, but in parts: starting from the lower radiators and ending with the upper heating points.

Pouring water without plumbing

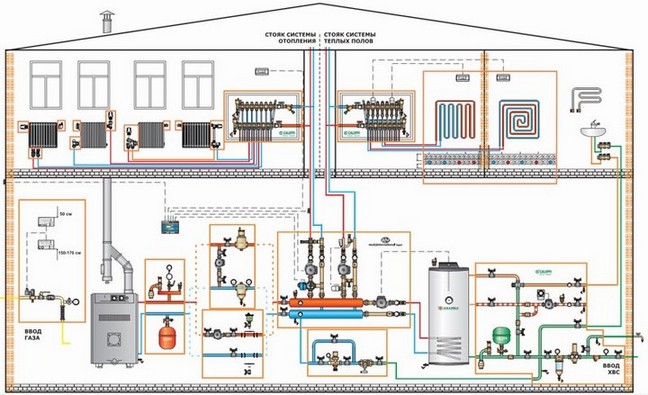

If the source of the coolant is not a centralized water supply, but a well, a well or a reservoir, auxiliary equipment will be required to fill the closed heating system. It can be a powerful pump or an expansion tank.

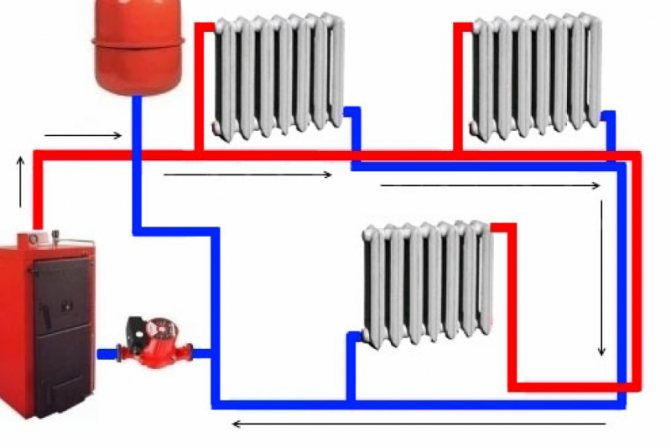

Scheme of the heating system device

In the first case, you will need a manual or electric pumping unit. With its help, the filling is performed according to the following scheme:

- Connect the pump hose to the drain pipe.

- Open the special valve on the nozzle.

- Open Mayevsky taps.

- Start the pump and start running water into the system.

In the second case, use a membrane tank with a baffle in two parts and a regular bicycle pump:

- Connect the tank to the heating system piping and fill it with water.

- Unscrew the nipple at the top of the expansion tank and bleed air from the tank.

- Connect the bicycle pump to the nipple and start pumping air into the tank, building up pressure to bring water into the system.

Advice. Pump up the tank until the pump pressure reaches 1.5 atm.

Now you know that you can fill water into a closed-type heating system both from a water pipe and without it. The main thing in both cases is to carefully prepare for the procedure and comply with all technical requirements. the subtleties of the work. So, if you follow the rules, filling the system will not be an overwhelming task for you.

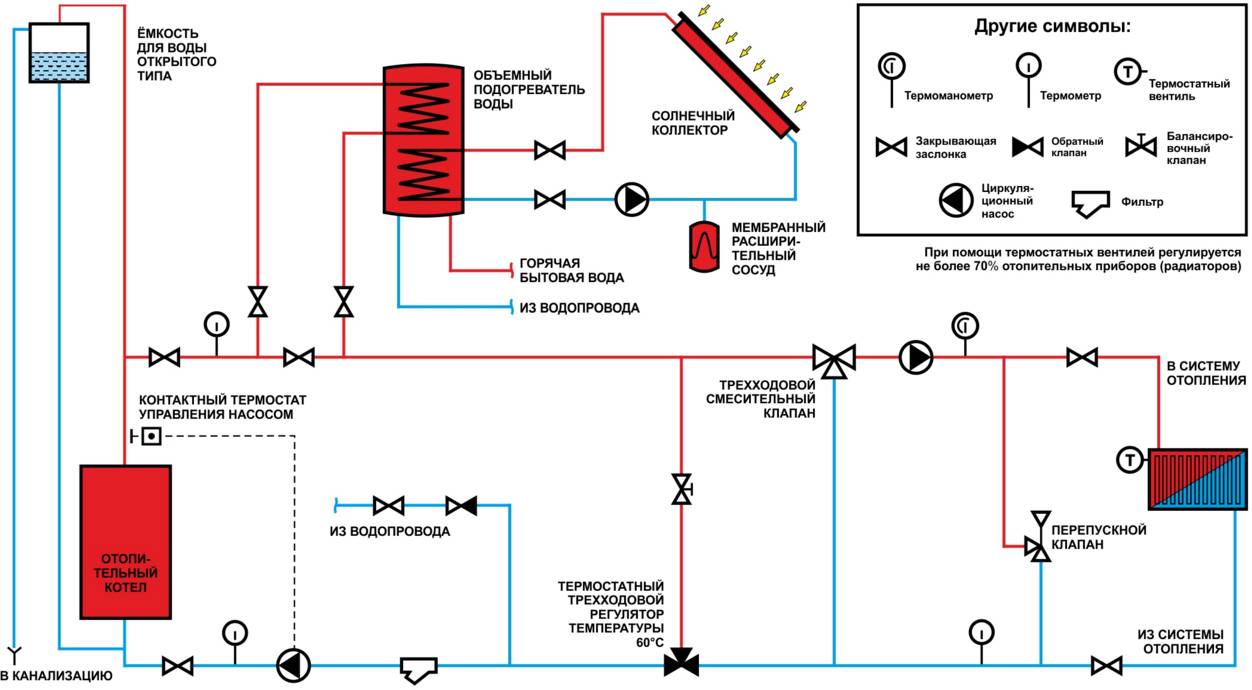

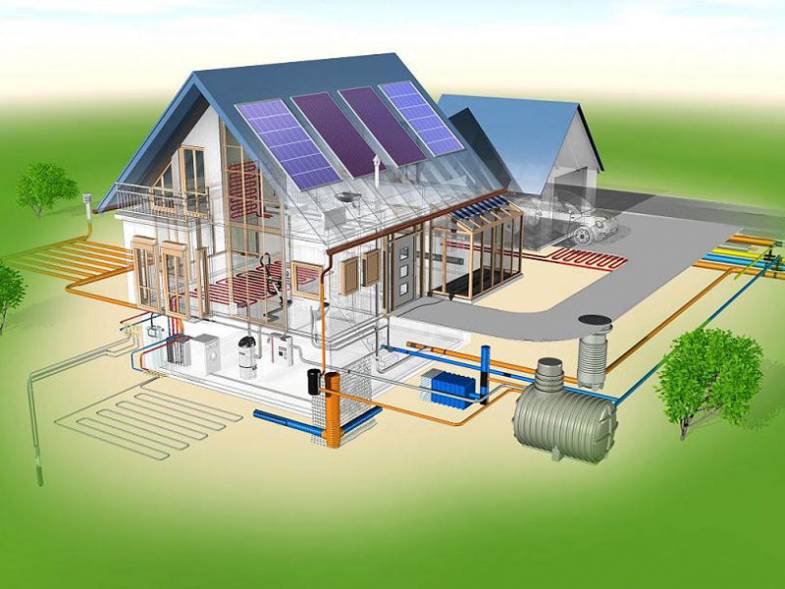

Classification of heating systems

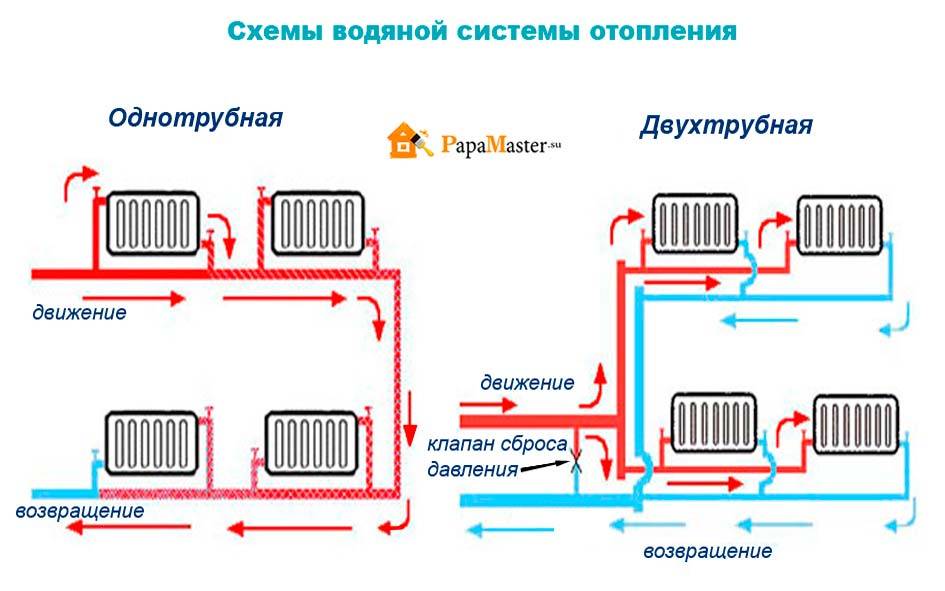

To properly fill the water heating system. you need to know what type it is.There is a classification of systems according to the method of piping: from the top, from the bottom, horizontal, vertical or combined. According to the method of connecting devices with the help of pipes, the systems are: single-pipe and two-pipe.

Also in the system, water can circulate naturally or forcibly (if a pump is used). According to the scale of action, local and central heating systems are distinguished. In the direction of water movement in the pipes - dead-end and associated. All these types in everyday life are used in a mixed manner.

Types and properties of heat-carrying liquids

The working fluid of any water system - the heat carrier - is a liquid that takes a certain amount of boiler energy and transfers it through pipes to heating devices - batteries or underfloor heating circuits. Conclusion: the efficiency of heating depends on the physical properties of the liquid medium - heat capacity, density, fluidity, and so on.

In 95% of private houses, ordinary or prepared water with a heat capacity of 4.18 kJ/kg•°C (in other units - 1.16 W/kg•°C, 1 kcal/kg•°C) is used, freezing at a temperature of about zero degrees. The advantages of a traditional heat carrier for heating are availability and low price, the main disadvantage is an increase in volume during freezing.

Crystallization of water is accompanied by expansion; cast-iron radiators and metal-plastic pipelines are equally destroyed by ice pressure

The ice that forms in the cold literally splits pipes, boiler heat exchangers and radiators. To prevent the destruction of expensive equipment due to defrosting, 3 types of antifreezes made on the basis of polyhydric alcohols are poured into the system:

- Glycerin solution is the oldest type of non-freezing coolant. Pure glycerin is a transparent liquid of increased viscosity, the density of the substance is 1261 kg / m³.

- An aqueous solution of ethylene glycol - dihydric alcohol with a density of 1113 kg / m³. The initial liquid is colorless, inferior in viscosity to glycerin. The substance is toxic, the lethal dose of dissolved glycol when taken orally is about 100 ml.

- The same, based on propylene glycol - a transparent liquid with a density of 1036 kg / m³.

- Compositions based on a natural mineral - bischofite. We will analyze the characteristics and features of this chemical separately (below in the text).

Antifreezes are sold in two forms: ready-made solutions designed for a certain sub-zero temperature (usually -30 ° C), or concentrates that the user dilutes with water himself. We list the properties of glycol antifreezes that affect the operation of heating networks:

- Low crystallization temperature. Depending on the concentration of polyhydric alcohol in an aqueous solution, the liquid begins to freeze at a temperature of minus 10 ... 40 degrees. The concentrate crystallizes at 65°C below zero.

- High kinematic viscosity. Example: for water, this parameter is 0.01012 cm² / s, for propylene glycol - 0.054 cm² / s, the difference is 5 times.

- Increased fluidity and penetrating power.

- The heat capacity of non-freezing solutions lies in the range of 0.8 ... 0.9 kcal / kg ° C (depending on concentration). On average, this parameter is 15% lower than that of water.

- Aggressiveness to some metals, for example, zinc.

- From heating, the substance foams, when boiled, it quickly decomposes.

Propylene glycol antifreezes are usually dyed green, and the prefix "ECO" is added to the marking.

In order for antifreezes to meet operational requirements, manufacturers add additive packages to glycol solutions - corrosion inhibitors and other elements that maintain antifreeze stability and reduce foaming.

Filling methods

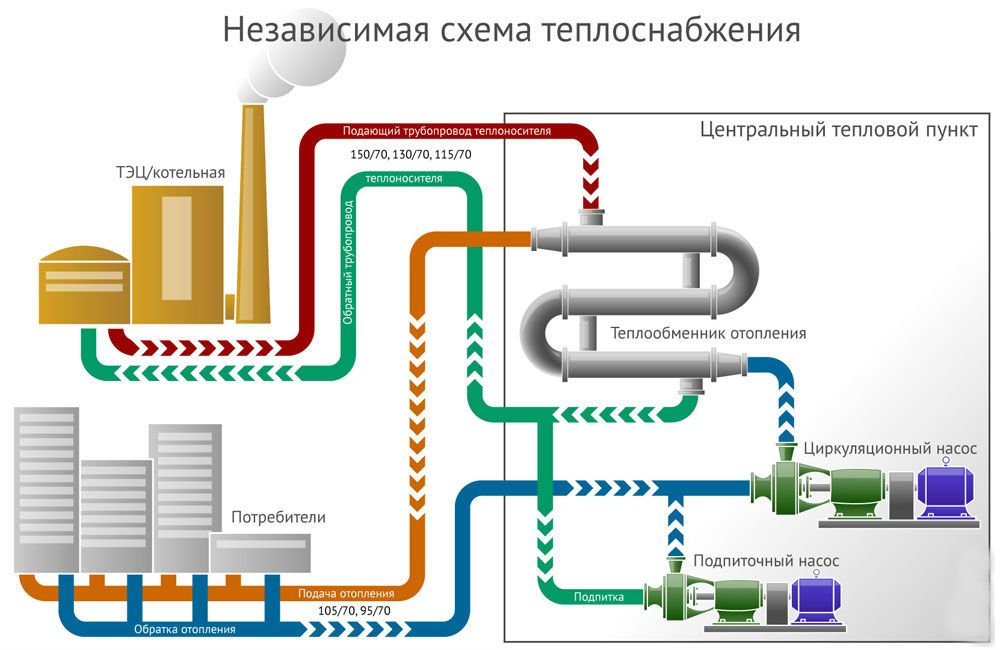

Launch of the apartment building system

The procedure for the bottom filling house will be as follows:

- With the house valve closed at the supply, we open the discharge on the supply pipeline. The return outlet is closed.

- SLOWLY open the valve on the return pipeline. If you do this quickly, there is a possibility of a water hammer with the most unpleasant consequences, up to the separation of the radiators.

- We wait until water without air comes out of the discharge.

- We block the discharge and open the valve at the feed.

- We bleed air from the access heating circuits, service premises and so on - in a word, wherever there is access.

Top filling greatly simplifies the start of heating.

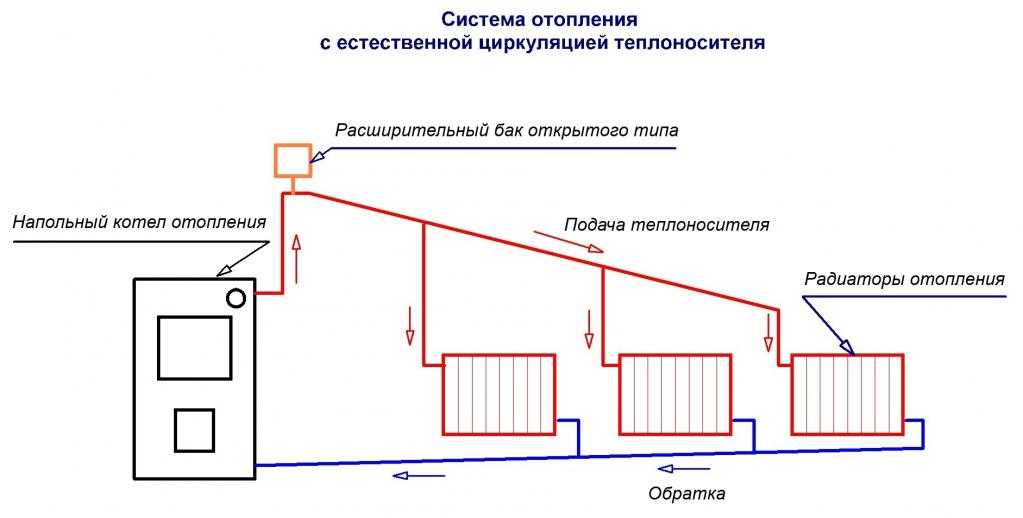

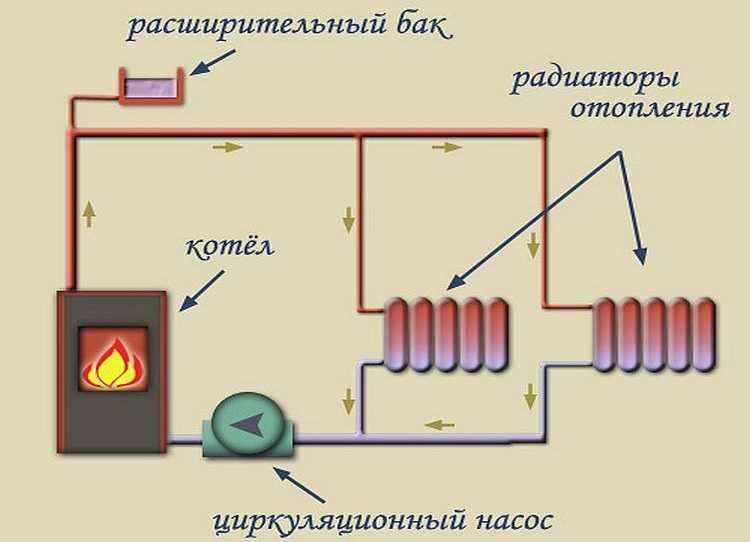

Launching a gravity open heating system

Are you expecting difficulties? They are not expected: just pour a few buckets of water into an open expansion tank. Water should appear at its bottom. Do not try to fill it with a margin in order to add coolant less often: when heated, the water will increase in volume and pour onto the attic floor.

Of course, if the heating circuit is assembled by hand and filled for the first time, it is worth going through and inspecting all threaded and welded joints for leaks.

Starting a closed heating system

What is the difference between a closed system with forced circulation in terms of its filling with a coolant?

- The boiler and the circulation pump require excess pressure to operate. Usually its recommended value is 1.5 kgf / cm2.

- Before starting in normal mode, it is recommended to pressurize the heating system by one and a half times with high pressure. This operation is especially important for systems with water-heated floor: it will be buried in the screed, where repair work is ... shall we say, difficult.

How to create the necessary pressure in the circuit?

If there is a central water supply in the house, the problem is solved extremely simply: for pressure testing, the system is filled through a jumper with a water supply system with continuous monitoring of pressure by a pressure gauge. After pressure testing and checking for leaks, excess water is discharged through any valve or air vent.

In the water supply system, the pressure is usually not less than 3 kgf / cm. This is clearly more pressure than the pressure of the heating system, not to mention the operating pressure.

How to fill the heating system with water if the water source is a well or a river? Or in the case when the system is filled with ethylene glycol or other non-freezing coolant?

Normally, in such cases, a special pump is used to fill the heating system and pressure testing - manual or electric. It is connected to the circuit through a valve; after the necessary overpressure is created, the valve is closed.

In the photo - a manual pressure test pump.

Is it possible to do without a pump?

Recall: 1.5 atmospheres of excess pressure correspond to 15 meters of water column. The obvious and simplest solution is to connect to a relief valve conventional reinforced garden hose, raise its other end by a dozen meters and fill it with water through a funnel.This option is easy to implement if the house is on a slope or there are tall trees nearby.

Finally, an expansion tank can solve the problem. Its main function is to contain excess coolant during its expansion. After all, water is practically incompressible, and reinforced plastic or metal pipes are not very elastic.

The membrane expansion tank is a container, which is divided into two parts by a rubber elastic partition. One of them is designed for coolant, the second contains air. All tanks are equipped with a nipple that allows you to adjust the pressure in it by bleeding off excess air or pumping it up with an ordinary bicycle pump.

The solution will be easy:

- Bleed air from the tank by unscrewing the nipple. Expansion tanks are supplied with excess pressure of just 1.5 atmospheres.

- We fill the system with water. The tank is mounted with a thread for connection upwards, therefore, its own weight will help the coolant to overcome the elasticity of the membrane.

To create the right pressure in the expansion tank, you need a conventional bicycle pump.

The price of a large volume expansion tank is relatively high, but we do not lose anything: in any case, it is necessary for the normal operation of a closed heating system.

Water or coolant choose the optimal system filling

Antifreeze for heating system

The optimal composition of the liquid should be determined by the parameters of the heating system. Often the heating system is filled with water, as it has a number of significant advantages. The determinant is the affordable cost - they often take plain tap water. However, this is fundamentally wrong.A large number of metal elements and alkali will contribute to the formation of build-up on the inner walls of pipes and radiators. This leads to a decrease in the passage diameter, an increase in hydraulic losses in certain sections of the pipeline.

But how to properly fill a closed heating system with water in order to avoid such troubles? Experts recommend using distilled water. It is maximally purified from impurities, which affects for the better its physical and operational properties.

Energy intensity. Water accumulates heat well in order to subsequently transfer it to the room;

Minimum viscosity index

This is important for closed heating systems with forced circulation and affects the power of the centrifugal pump;

When the pressure in the pipes increases, the boiling point shifts upwards. Those. in fact, the process of transition from liquid to gaseous state occurs at a temperature of 110 ° C

This makes it possible to use high-temperature heating modes.

in fact, the process of transition from liquid to gaseous state occurs at a temperature of 110°C. This makes it possible to use high-temperature heating modes.

But if there is a possibility of exposure to negative temperatures, then water, as a liquid for filling heating systems, is unacceptable. In this case, antifreezes should be used, in which the crystallization threshold is much lower than 0 ° C. The best option is solutions of propylene glycol or glycerin with special additives. They belong to the class of harmless substances and are used in the food industry. Solutions based on ethylene glycol have the best technical qualities.Until recently, they filled closed heating systems. However, they are extremely harmful to humans. Therefore, despite all their positive qualities, it is not recommended to use ethylene glycol-based antifreezes.

But what can fill the heating system - water or antifreeze? If there is no possibility of exposure to low temperatures, water is the best choice. Otherwise, it is recommended to use solutions of a special coolant.

Automotive antifreeze must not be poured into the heating system. This will not only lead to a breakdown of the boiler and failure of the radiators, but it will also be dangerous to health.