- How does a water heater work?

- Ignition type

- Piezo ignition

- Electric ignition

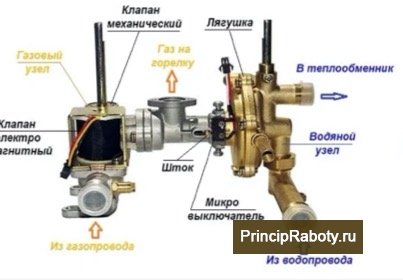

- Scheme and structure of the gas column.

- Model overview

- Do-it-yourself column water reducer malfunctions

- Classification

- Internal details of the column, their purpose

- Peculiarities

- Security systems

- Principle of operation

- Popular speaker models

- Varieties of combustion chambers

- The principle of operation of a flowing gas device for heating water

- Purpose and structure of the water node

- Water reducer device

- The principle of operation and the meaning of the regulator

- Geyser Vector JSD 11-N

- The most common breakdowns

How does a water heater work?

The task of water heaters of this type is to respond by turning on the burner to open a hot water tap anywhere in the house and ensure that it is heated to the desired temperature. To describe in detail the principle of operation of a gas column, we list the sequence of processes occurring in atmospheric models:

- At the first stage, the user ignites the igniter located in the viewing window and directed towards the main burner.

- After opening the tap in the DHW system, a flow of water appears, and the pressure increases. The device of the water unit (colloquially - frogs) provides that in this case the membrane is activated and moves the stem connected to the gas valve.

- From the impact of the membrane of the water unit, the valve opens the fuel supply to the main burner, which is immediately ignited from the igniter or directly from the spark electrode. The power of the flame can be adjusted manually by the user using a tap located on the front panel.

- The water entering the gas column heat exchanger begins to heat up even in a coil made around the copper casing. This principle of operation avoids the formation of condensate on the pipes due to the temperature difference between cold water and the burner flame.

- The heated water is supplied to consumers. After the valve is closed, the “frog” membrane pulls the stem, the valve shuts off the gas supply and the burner device fades, and the heating stops.

If, for various reasons, the burner flame breaks off and it goes out, the thermocouple will work and the valve will stop the gas supply. The same will happen when the draft in the chimney disappears at the signal of the corresponding sensor.

Scheme of operation of a water heater not equipped with a wick

Scheme of operation of a water heater not equipped with a wick

The operation of forced draft water heaters is based on the automatic maintenance of the water temperature set by the user. Ignition is carried out from the mains or from a hydro generator built into the water supply system and generating electricity when a flow occurs. Further heating is controlled by the controller, guided by the readings of the temperature sensor. It changes the fan performance and combustion intensity depending on the outlet water temperature.

Ignition type

In order for the column to start its work, it is necessary to ignite the gas. Old models were lit by hand, bringing a burning match to the igniter. Today, such units are no longer on sale, they are a thing of the past.They were replaced by others that work in automatic or semi-automatic mode.

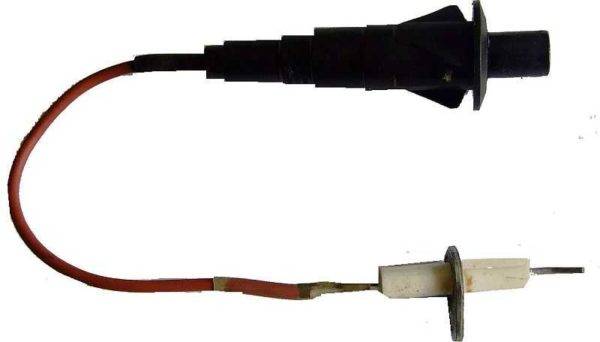

Piezo ignition

In geysers with a piezoelectric element, ignition occurs in a semi-automatic mode. There are two burners - main and pilot. The pilot burner is a small wick that burns constantly, whether there is hot water flow or not. The main burner turns on only when the valve is opened. The rest of the time it is off.

The procedure for starting a gas column with piezo ignition is simple: press the button displayed on the front panel, a spark appears on the candles, which ignites the pilot burner. When a hot water tap is opened, gas is supplied to the main burner, ignition takes place from the pilot burner. While water is flowing, both burners are lit. The valve was closed, the gas supply to the main one stopped, only the pilot one is on fire again.

Piezo ignition device for gas water heaters - a simple and inexpensive device

What are the advantages of geysers with piezoelectric elements? These are the cheapest models, they usually have a mechanical control - a regulator that allows you to change the height of the flame, thereby regulating the temperature of hot water. These models are non-volatile, which can be important for giving.

There are more disadvantages and they are more serious. The wick burns (should burn) constantly while you use the column, and this is gas consumption. Let it be small, but constant, as a result, quite a decent amount accumulates in a month. So this is far from the most economical way to heat water. The second minus is also associated with the burning of the wick. If it goes out, you will not be able to light the column.The wick goes out because it does not have enough oxygen to burn, or because a reverse draft periodically occurs in the chimney, which blows out the flame. Since there is a flame controller, this is not a problem - the gas is automatically shut off, but the need to re-ignite the pilot burner is unpleasant.

Electric ignition

Automatic geysers have electric ignition. This is an electric spark generator that is activated when the tap is opened. The rest of the time the gas does not burn, which significantly saves fuel. There is an electric ignition, powered by batteries, there is - from a 220 V network. Which gas water heater is better for this parameter, you have to choose according to the circumstances.

If you often turn off the light, it makes sense to choose a model that runs on batteries. As you understand, in this case, you have to make sure that they "do not sit down." If there are no problems with electricity or there is a backup power source, it is better to choose a geyser powered by 220 V. Plug the cord into the outlet once and forget about it. Electricity consumption is negligible, so they have almost no effect on the bills.

The electric burner is controlled by a microprocessor

Geysers automatic machines have electronic control. A board with a microprocessor is installed in the case, the desired temperature is set from a small control panel (button or touch). A small LCD screen is often placed here, which displays the current state of the equipment, the temperature of the water, if it is being heated. This type of geyser is the best if you value ease of handling.

Disadvantages - higher price and power requirements. Electronics needs a stable voltage of 220 V with small deviations of the order of 2 * 3 V.We do not maintain such parameters, so in order for the automatic gas water heater to work for a long time, a stabilizer is required, and it is better not a relay one, but an electronic one

It not only stabilizes the voltage, but also evens out the shape of the pulses, which is also very important for imported water heaters.

Scheme and structure of the gas column.

The copper radiator serves to receive heat from the hot gas and transfer it to the water. The copper radiator of the column is also called the heat exchanger. The heat exchanger consists of two parts: a box - forming a fire chamber; heater - curved tubes with copper plates for receiving heat. The heat exchanger has two pipes: cold water inlet and hot water outlet to the taps. To heat up to the desired temperature, one circle of water around the heater is enough. The water receives all the heat through the tubes of the heat exchanger walls and carries it away to the consumer. The tubes are heated by the high temperature of the exhaust gases.

Model overview

Each manufacturer of equipment has the most successful models. If we talk about the Vektor brand, there are several options:

vectorJSD 20

A few years ago, this gas heater won the appreciation of users. It is not surprising, because the price of the equipment barely reached 4,000 rubles. Also, it is impossible not to notice the compact dimensions of the device. From the equipment, we highlight automatic ignition and a digital display, which greatly simplify the use of equipment. Another plus for connoisseurs of beauty is that the model is available in three stylish colors: white, gold and silver.

Characteristics:

- Type - flow.

- Dimensions - 34x60x18cm.

- Heating - gas.

- Power - 20kW.

- Productivity - 10l / min.

- Protection - gas control.

- Features: thermometer, auto ignition, power indicator, digital display.

vectorLuxEcoJSD 20-1

The company took a step forward and released a new model - luxury eco. The column is equipped with the same features as the others, but already has enhanced security. Also, the control has been improved, which allows you to select and adjust temperature modes. As for the design, the heater has an original mirror finish and one of the patterns to choose from. The kit includes the heater itself, a faucet, a shower, fasteners and instructions.

Characteristics:

- Type - flow.

- Dimensions - 64x35x20cm.

- Heating - gas.

- Power - 20kW.

- Productivity - 10l / min.

- Protection - gas control.

- Features: "Winter / Summer" mode, auto ignition, digital display.

vectorJSD 11-N

The water heater is distinguished by a high-quality copper heat exchanger - this will extend the "life" of the device. The chimneyless column has a stainless steel burner. All technical details are of high quality. In combination with high performance and low price, the heater is rightfully considered one of the most popular among the model range. Also, the equipment is equipped with multi-level protection to prevent malfunctions and gas leakage. Unlike previous "brothers", JSD 11-N runs on liquefied gas.

Characteristics:

- Type - flow.

- Dimensions - 37x27x14cm.

- Heating - gas.

- Power - 11kW.

- Productivity - 5l / min.

- Protection - gas control.

- Features: auto ignition.

Do-it-yourself column water reducer malfunctions

1) At operating water pressure, the column does not turn on.

Possible reasons:

- the elastic membrane is torn;

- stem stuck.

Troubleshooting:

- a torn membrane changes to a whole part;

- the locked stem is lubricated, developed by hand.

2) Weak pressure of hot water.

Possible reasons:

- weak pressure of cold water;

- the strainer is clogged.

Troubleshooting:

- weak pressure of cold water is checked in water pipes or information is specified in the relevant authorities;

- the clogged filter is changed or cleaned, installed in place.

3) Delay in turning on the column when opening a hot water tap.

Possible reasons:

- clogging of the retarder ball channel;

- Incorrect adjustment of the retarder stop.

Troubleshooting:

- clogged channel - cleaned;

- incorrect adjustment of the stop is corrected by screwing in the adjusting screw 2-3 turns.

4) The geyser does not work at full capacity or goes out.

Possible reasons:

membrane integrity is compromised.

Troubleshooting:

the damaged part is changed.

More serious malfunctions are repaired by the masters of the gas service or the gearbox for the geyser is changed.

When using a geyser, pay attention to the stability of the gearbox installed on the geyser. If necessary, do a preventive inspection of the unit, lubricate rubbing parts, change worn parts

Classification

Gas instantaneous water heaters are included in the hot water supply system of a residential building. The device heats the water in the stream with the released heat from the burnt gas.

Depending on the operating conditions, flowing gas heaters are divided into types.

According to the ignition method, the device is automatic and with manual piezo ignition.The first option assumes that when the tap is opened, the burner turns on automatically (it also turns off). The fire is switched on by electronic ignition. You do not need to supervise the operation of the device. Manual piezo ignition is a connection with a button. Such a device must be mounted in an accessible place.

The subsequent division is done taking into account the power of the device. A low power device includes 17-19 kW speakers; with an average power indicator there will be a device of 22-24 kW; a high-power column is 28-30 kW. The more water consumption points and the number of family members, the greater the power indicator should be at the gas column.

The constancy of the temperature regime of the water in the tap depends on the type of burner of the device. Separate the burner with constant power, when the burner operates at the same power with different water supply. Then, depending on the pressure, the temperature of the liquid in the tap will also change. The modulating type burner adjusts to the water pressure in the water supply. Therefore, the temperature will be the same regardless of the pressure of the liquid.

The device is divided into a design with smoke removal in a natural way. When the removal of gases occurs with traction. The second type of column is turbocharged structures (chimneyless model). Combustion products are forcibly drawn out by means of a fan built into the column design. It starts working from the first seconds of ignition of the burner.

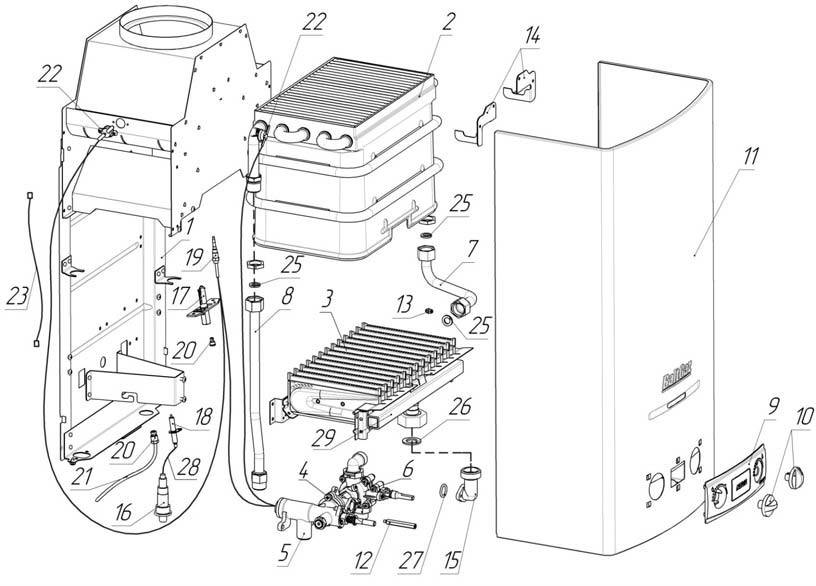

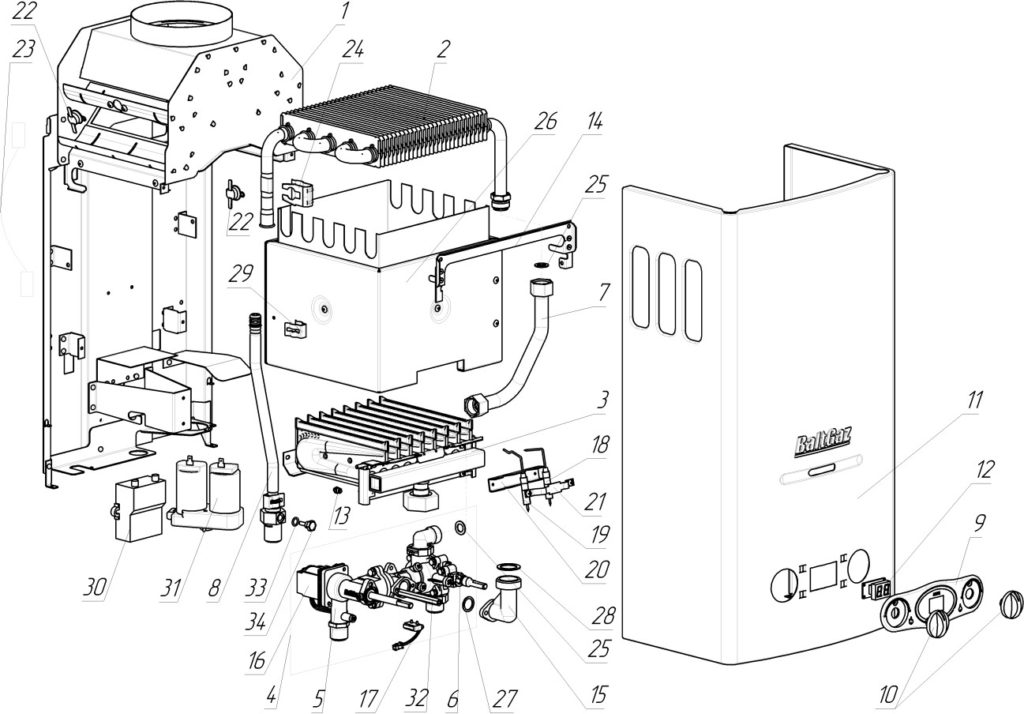

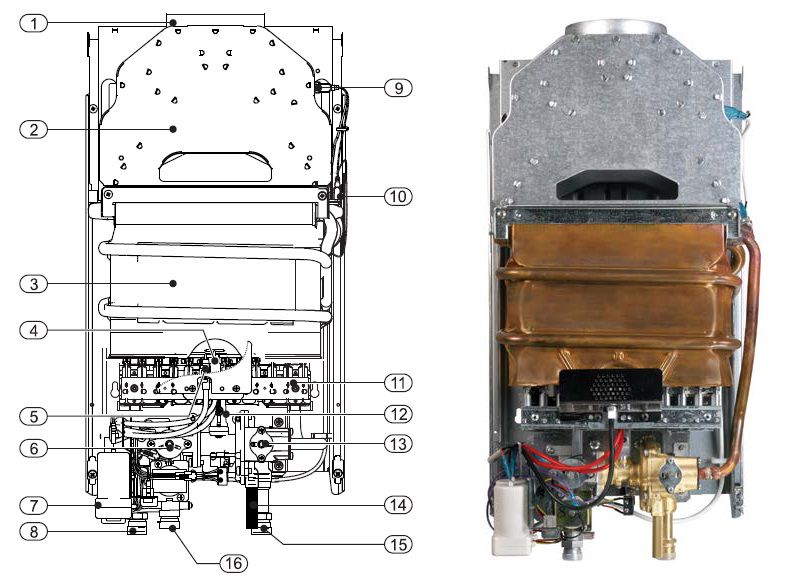

Internal details of the column, their purpose

Before looking inside the column, it should be clarified that there are 2 types of modern gas flow models:

- With an open combustion chamber.The air necessary for burning the gas will flow through the viewing window or from the bottom of the structure without compulsion, naturally from the room.

- With a closed type of combustion chamber. They are called: turbocharged. The necessary air enters the combustion zone by force, with the help of a fan.

This division is important to know, because the columns are structurally different from each other. Installation of the device is carried out on the wall

It is connected to water and gas pipes.

The device is installed on the wall. Water and gas pipes are connected to it.

A simple atmospheric water heater consists of components and parts:

- light metal body;

- gas burner with igniter;

- finned type heat exchanger with a casing and a copper coil;

- automatic sensor for adjusting the intensity of combustion;

- the safety valve is installed on the mechanical water unit;

- ignition system;

- the chimney is connected through a branch pipe, which is located on the diffuser.

- combustion products accumulate in the diffuser. Inside it has a thrust sensor. Wires to the gas valve depart from it;

- a flame sensor is also connected to the gas valve. It is located in the combustion zone;

- water and gas supply is carried out through the lower pipes. They end with fittings for accession.

In the photo, an atmospheric gas water heater is painted on the details.

Modern columns are set on fire with electrodes that can ignite the gas with an electric discharge.

A geyser without a chimney (calibrated) differs from atmospheric, although they are similar in design to each other:

- The turbocharged column has a modulating burner model. The intensity of burning changes automatically.On the atmospheric - burner with manual control.

- For burning the flame, air is supplied by a fan. Its operation is controlled by an electronic unit.

- Ignition is carried out automatically. The system is powered by electricity.

- An important role is played by the water temperature control sensor, which is connected to the controller. It keeps the water heating at a certain level, for example 60 degrees.

The photo shows a turbocharged gas water heater, in which all functions are automated. The set temperature is displayed on the LCD.

Peculiarities

The principle of operation of gas water heaters of various brands and models does not differ too significantly. Of course, the approach of each manufacturer allows you to influence the technical characteristics, but this is already from the field of private innovations. There is a big difference between atmospheric and turbocharged vehicles. Atmospheric design was used mainly in older systems. Now it is much less common.

The classic version involved the use of manually controlled burners. And in turbine systems, stepwise or even modulating gas combustion systems are used. The difference is also manifested in how exactly the air is exchanged: in atmospheric models, only the convection effect is used, while in turbine models, the fan takes on the main work.

The difference between specific models of geysers concerns:

- productivity;

- burner type;

- degree of security;

- ignition method;

- flue gas removal method.

Security systems

Modern geysers consist of many security systems. These include:

- Traction control systems - consists of a sensor located near the chimney. If there is no draft, the sensor will prohibit the start of the column;

- Gas control systems - this uses a thermocouple or ionization flame control. The essence of these systems is to turn off the gas supply when the column goes out. For ionization control systems, additional power is required, and the thermoelement performs a mechanical shutdown of the column;

- Overheating protection - if for some reason the heating temperature exceeds a critical value, the safety clan will work.

Even the cheapest devices are equipped with gas control systems, and more expensive models are characterized by the presence of multi-stage security systems.

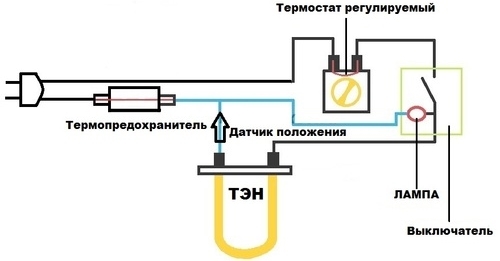

Principle of operation

The geyser is designed in such a way that its work on the supply of water occurs in automatic mode. When water enters the nozzle, its speed increases significantly. The liquid through the holes enters the upper cavity above the membrane.

Due to the spring, the membrane rises, simultaneously pushing the stem of the water part, which, resting against the gas actuator, opens the valve, and the gas begins to flow to the burner. If the water supply is shut off, then the action of the rods occurs in the reverse order and the fuel stops flowing into the combustion chamber. A safety valve is built into the gas system.

Its principle of operation in the device of the geyser is that when the combustion stops, the gas supply is automatically turned off. This action is performed thanks to the thermocouple installed in the valve, which is heated directly by an open fire.

The thermocouple in the electrical circuit of the geyser is connected to the valve, and when heated, it generates a short-term voltage that acts on the electromagnet of the locking device. When the flame stops, the thermocouple cools down and stops producing current, and the valve shuts off the gas supply due to the spring.

Popular speaker models

Currently, the choice of gas heaters, both domestic and foreign, is quite large. In the absence of centralized hot water supply, they are becoming increasingly popular. Among them it is worth noting the following models:

- Bosch WR 10-2P - this brand is an example of the latest developments in speaker production. Although it has large dimensions, it is possible to connect it to two water intake points at the same time. Thanks to the built-in piezoelectric element, starting the equipment is quick and easy. The heater is provided with a gas contamination sensor that immediately shuts off the fuel supply if the equipment starts to work with a large release of harmful impurities. The service life of this unit is 15 years.

- Ariston Fast Evo 11B - the operation of this device is fully automated, that is, it turns on and stops heating on its own. In a minute, this geyser is able to heat up to 14 liters of cold water, while the temperature is adjusted only once, and then everything happens automatically.

- Neva 4510-M is a heater with a compact design and small dimensions. The ignition of the gas burner is automatic, which makes it easier to start. The unit has built-in modulation of the flame depending on the amount of water supplied.All control is carried out by two handles, which are responsible for the amount of water and its temperature.

2 id="raznovidnosti-kamer-sgoraniya">Varieties of combustion chambers

Combustion chambers are of two types:

- Manufacturers most often install an open or atmospheric chamber on water heaters due to the simplicity and cheapness of the design. The circulation of air required to maintain combustion enters the interior of the chamber in a natural way.

- Air is forced into the closed chamber by a fan. Such gas columns are called turbine.

The creation of forced draft allows the water heater to work under any conditions. The unit with an open chamber will not ignite if there is no draft. A similar nuisance is observed in bad weather conditions, when the wind blows into the chimney.

The principle of operation of a flowing gas device for heating water

Briefly describe the principle of operation of the gas column as follows: they opened the hot water tap - the burner ignited, the water flow stopped - the burner went out. In more detail, it goes like this:

When the faucet is opened, the flow of water begins. From the action of the flow, the water node is triggered. The mechanism acts on the gas unit. The valve opens, and gas is supplied to the burner, where ignition takes place from the igniter.

- Water is heated in a heat exchanger. The liquid circulating through the coil is heated, after which it flows through the pipeline to the mixer.

- During combustion, air enters the chamber in a natural way through the technological openings of the casing and the viewing window. Exhaust gases exit through the chimney. Natural air circulation creates traction. If not, the sensors give a signal to turn off the burner.

- When the water tap is closed, the water and gas units are activated. The gas supply will stop, after which the burner will go out.

Turbine-type geysers work in a similar way. The only difference is the method of supplying air inside the closed chamber. The blower is responsible for this function. A double-walled pipe serves as a chimney and discharge pipeline. They take her outside. Combustion products are discharged through the internal channel, and clean air enters from the street through the external passage.

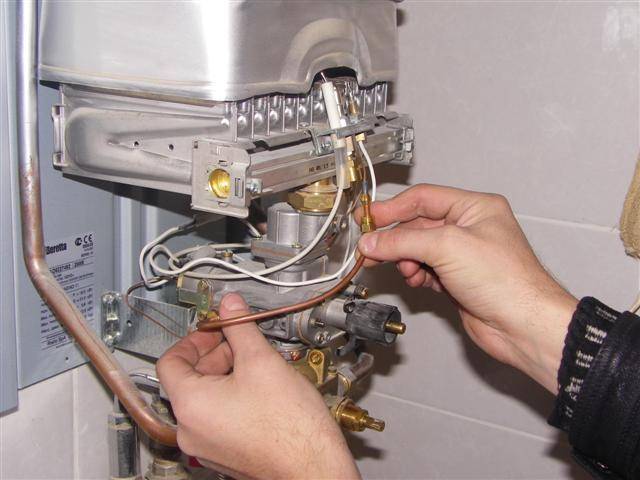

Purpose and structure of the water node

The membrane is an important detail in the regulation of gas supply. To understand its purpose and principle of operation, it is necessary to study in detail the device of the water block of the column, of which it is a structural element. This knowledge will help when replacing the membrane, because in order to get to it, you have to dismantle the entire assembly and disassemble it.

We also recommend that you get acquainted with the general arrangement of the geyser, so that it is easier to find a water block in its design. But first things first.

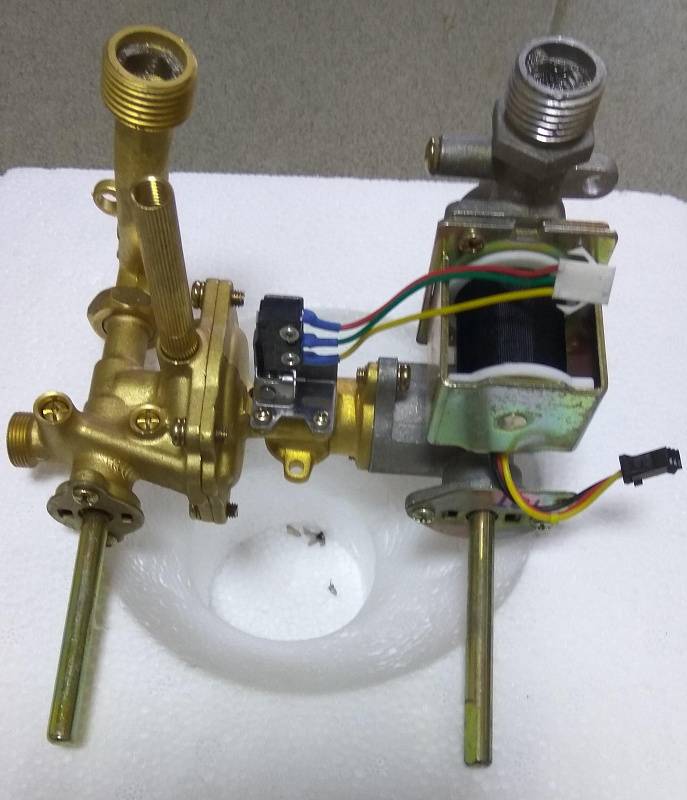

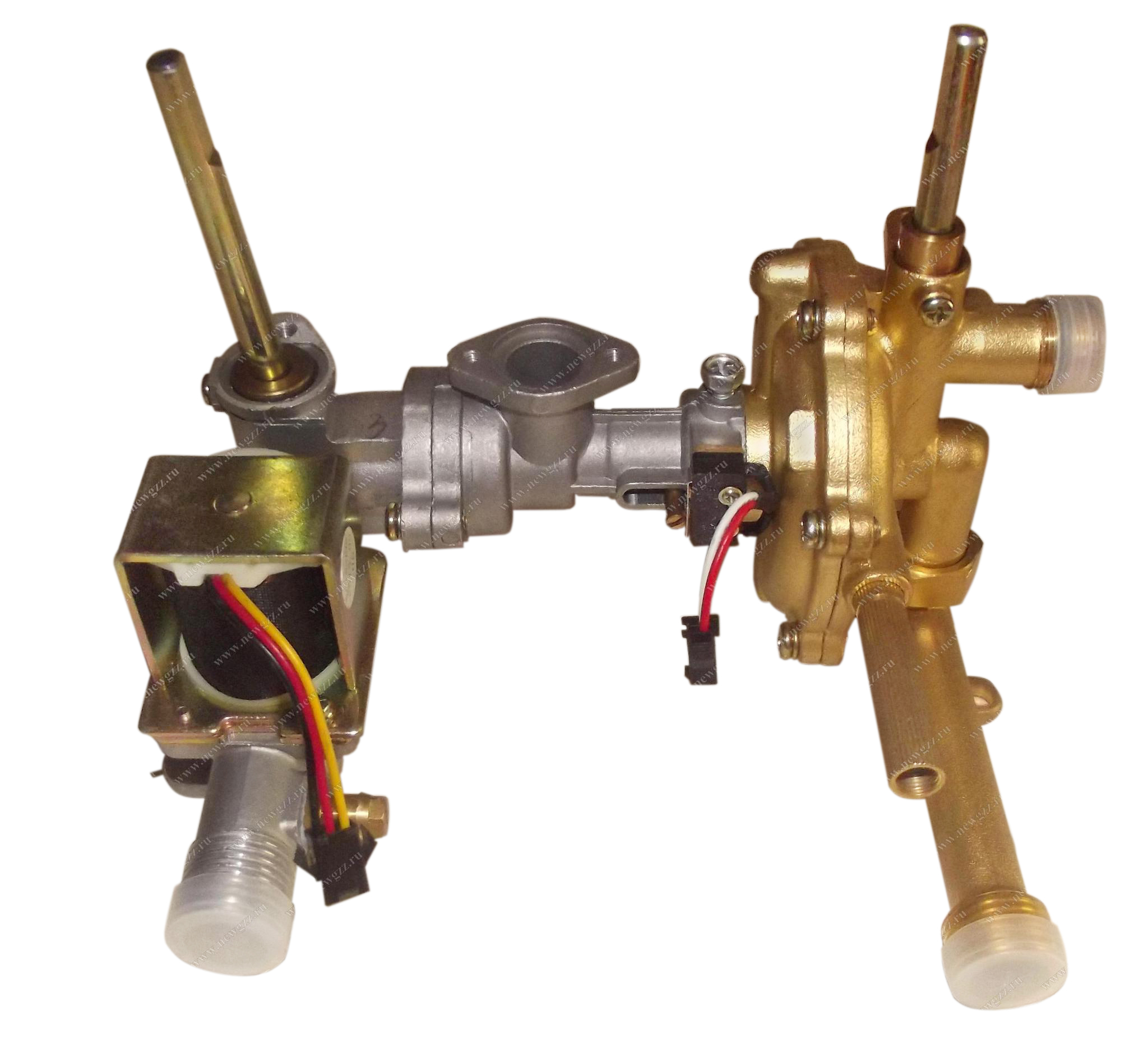

Water reducer device

One of the nodes of almost any gas heat exchanger is a water reducer (water node - WU, water regulator). It is designed to regulate the uniform supply of water and gas. The practically designed shape of the regulator (in common parlance - “frogs”) contributes to the compact placement of the unit in the column body. A technically simple device works automatically.

The functions of the reducer are as follows:

- starting and stopping the operation of the gas column when opening / closing the tap;

- regulation of water and gas supply;

- protection of the column from overheating in case of insufficient water pressure.

The design of the gearbox is well thought out and visually uncomplicated. The body is made of brass, polyamide (containing fiberglass), silumin or plastic.

Details of the water unit: cover (1) and base (2) connected with screws; plate (4); stem opening/closing gas valve (5); membrane (6); venturi fitting (7); gland nut (8); water outlets (9); adjusting screw (10); fixing screws (3); mesh filter (11); retarder ball (12)

The principle of operation and the meaning of the regulator

The hollow cavity of the gearbox divided in two by a membrane is filled with water. Water enters the cavity from the plumbing. From the lower part, passing through the Venturi fitting, it enters the upper compartment through the bypass. However, the water coming from the water supply to the lower part always presses on the membrane with the pressure force of the water in the pipeline, and in the upper part the pressure force changes, depending on whether the water flows through the heat exchanger.

The fact is that in pipelines with narrowed sections, the pressure of the flowing fluid in the bottleneck decreases. When the tap is opened and water passes through the Venturi fitting, the pressure in front of the local constriction (nozzle) of the fitting increases.

Due to the increase in the flow velocity in a narrow place, the pressure decreases both in the fitting and in the upper cavity of the frog. It's like flattening the end of a garden hose. With a difference in the diameters of the choke nozzle (0.3 cm) and the main chamber (2 cm), the pressure difference reaches 1 atmosphere. This is enough for the membrane to bend upward and press on the plastic plate, which is rigidly fixed on the stem axis.The rod with force presses on the gas valve, causing the valve to open and gas flows to the gas burner.

When the membrane is raised, water from the upper compartment begins to exit through the bypass channel, where the steel retarder ball is located. The ball, moving to the right, partially blocks the channel, so the gas is switched on and supplied to the burner smoothly. Smoothness is regulated by means of an adjusting screw.

The Venturi nozzle is located in the outlet pipe (on the right side of the frog). This is a local constriction that provides a pressure drop when the valve is opened. Clogged fitting must be cleaned

When the hot water (DHW) tap is closed, the flow of water stops and the pressure in the Venturi nozzle equalizes with the pressure in the cavity under the membrane. Due to the action of the springs, the rod together with the plate are shifted down, and the membrane returns to the middle position.

The gas valve closes automatically. The gas valve is turned off quickly, since the ball is displaced to the upper cavity (to the left) by the reverse flow of water in the culvert and ceases to impede the flow of liquid. We recommend that you look at information on what to do if the gas valve does not work.

If the hot water flow is less than 2-3 l / min, the required pressure drop does not occur, and the springs do not allow the stem to open the gas valve at all or it is enough to fully heat the water. Also, there is no necessary pressure difference in violation of the integrity of the membrane.

The water regulator, based on the principle of the Venturi nozzle, is a safety device, as it allows the water heater to be turned on only when sufficient water flows through the heat exchanger.Thus, the reducer automatically protects the geyser from overheating.

The overflow hole connects the Venturi nozzle and the upper cavity of the frog. This hole must be left open when installing the diaphragm in order for the gearbox to work correctly.

Geyser Vector JSD 11-N

Gregory

An excellent column for giving, as this model simply does not need a chimney. Due to the low productivity of combustion products, so little is released that they can be released directly into the atmosphere. Just in case, then we ventilate the room. The small size of the column and the possibility of connecting bottled gas are also pleasing, which our neighbors in their summer cottage rejoiced at - they don’t have gas in the house, but they live in the country all summer. Now they, too, rejoice in the presence of hot water and the opportunity to bathe or wash dishes under warm water. If the column did not go out when the water pressure changed (at the dacha, the pressure constantly jumps), then it would be doubly wonderful. But in general we are satisfied.

Advantages:

- A chimney is not needed, which is important for a small country cottage;

- Large range of temperature adjustment;

- Possibility of working from bottled gas, and the parts for connecting the cylinder do not need to be purchased separately - everything is included in the kit.

Flaws:

- Sometimes it goes out, but this is due to pressure drops - there's nothing you can do about it;

- There is no temperature indicator, you have to adjust the heating by touch.

The most common breakdowns

Finally, I will give some of the most common breakdowns of geysers. The most common problems that can be observed in the operation of heaters:

Coil clogged with scale

. If the pressure in the hot water tap is low, while cleaning the gearbox did not solve the problem, then the coil is clogged. In this case, it must be washed with a remover, such as Antinakipin;

- Doesn't ignite.There are several reasons why the column may not light up:

- low water pressure;

- there is no draft in the chimney - perhaps a foreign object got into the chimney;

- the batteries are exhausted (applies to speakers with automatic ignition);

- Poor water heating. There may be several reasons:

- blockage of gas equipment;

- the need to adjust the burner - in modern columns there is a valve that allows you to adjust the gas supply to the burner.

That's all the most common malfunctions of gas water heaters that you can fix yourself. The service manual, which usually comes with the passport, will help with this.

If you are not sure that you can fix the breakdown yourself, it is better to seek help from specialists. The repair price starts from 300 rubles, excluding the cost of parts.

Performing serious operations, such as soldering a radiator, costs 1000-1200 rubles. Prices are current in spring 2017.