- Electricity costs for ground installation

- Case 3: tank on the foundation of the utility block

- Case 4: gas tank as a temporary measure

- The gearbox freezes

- Commentary on the situation

- Causes of gear freezing

- Response from engineer Evgeny Kalinin

- How to restore the gearbox

- How to prevent freezing of the gearbox

- Let's summarize

- Advice

- What to do if the gas tank itself is frozen?

- Solutions

- Problematic installation at high groundwater levels

- Case 1: flooded gearbox

- Case 2: the barrel has surfaced

- How to defrost a pipe indoors

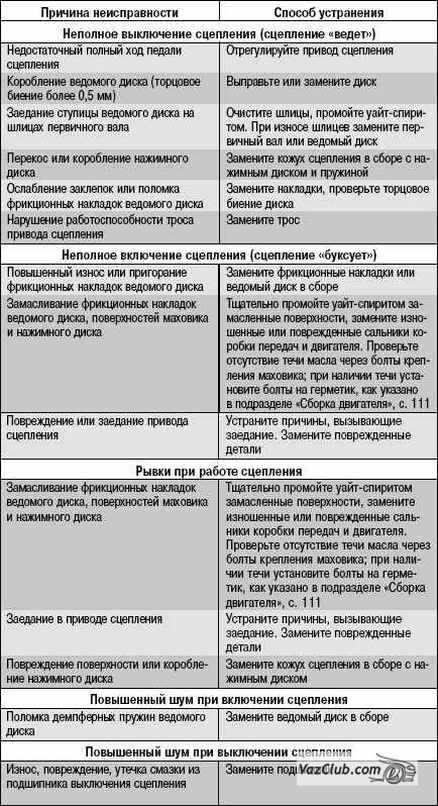

- Reducer failure

- The gas tank gearbox freezes what to do

- Filling up the gas tank

- How to protect the column from freezing?

- conclusions

Electricity costs for ground installation

Case 3: tank on the foundation of the utility block

Vladimir_VasMember

I used the search, but I did not find a clear answer, so do not blame me for the question. And above-ground gas tanks, is it generally evil and not applicable? It's just that earthworks are somehow difficult to imagine with my site. And so, I would demolish the hozblok and put a gas tank on its foundation.

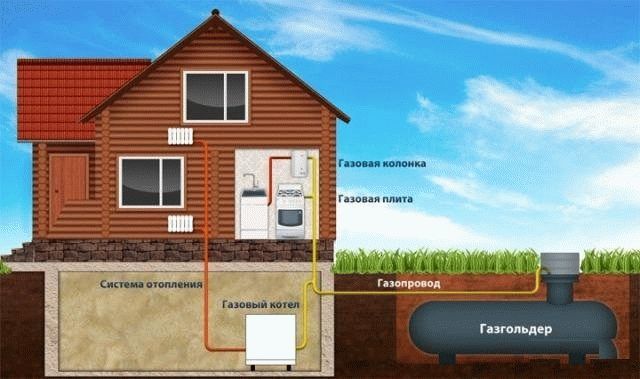

Comment on the situation: ground gas tanks are applicable. But the heating system will turn out to be volatile - you will have to spend money on electricity.

Evgeny Kalinin

Engineer

To prevent butane from freezing in winter, the propane-butane mixture in the ground gas tank must be heated. Additional equipment required:

- evaporator for the tank - forcibly transfers liquefied gas into the vapor phase (the device is selected based on how much kg / h of gas is needed in the boiler room);

- energy-saving cable for a gas pipeline - insulates the system during ground installation.

The evaporator consumes an average of 2 kW / h, cable - 20-40 W / h per meter. A small container of 500-1000 liters can be wrapped with a cable and heated as a whole. Wrapping the gas tank in a jacket or blanket will not help. Liquefied gas initially has a negative temperature, it needs to be heated. Warming with a jacket or box will simply save energy for heating.

Possible mistake: in our climatic conditions, a ground gas tank is not recommended for heating in winter. This is a good option for summer living in the country.

Consequences and recommendations: the user will face additional costs for insulation and monthly heating costs. The evaporator costs 150-200 thousand rubles.

For winter, it is definitely better to use an underground installation. The heating system will be autonomous and non-volatile.

Case 4: gas tank as a temporary measure

pushkanMember

We attended to the choice of a temporary source of gas supply. For there is already a pipe in the ground, but there will be gas in it, at best, in winter. That is, somewhere for a year it is necessary to gasify. The option of burying the gas tank was dropped immediately, as it was not economically viable.

We found a company that leases ground tanks of 2.7 cubic meters. m. They called, they put such a barrel for us, but they haven’t connected it yet. We decided to install it away from the house, ten meters away, because it blocks our windows.There is this thing, a small, by the way, neat one, in a remote corner of the site. The Tajiks will dig a trench to it.

The question is what. We are worried whether such a volume will not evaporate inefficiently in winter, get tangled up? Maybe some kind of booth around him to figure out? Then how (and what temperature) to maintain it? Or our fears are in vain, and will it work?

Comment on the situation: it will be cheaper to bury a container once than to spend all winter on electricity.

Evgeny Kalinin

Engineer

The gas tank must not be stored indoors. It is unsafe to put in a booth due to the risk of gas accumulation after a leak. There are only 2 options: insulate or bury. If you need a temporary solution for the summer, the ground version will do. In winter, you will need to make a fur coat and heat it with electricity. You may need an evaporator - you need to look at the gas flow.

Possible error: as in case 3, the ground model will not work in winter without artificially increasing evaporation. This requires electricity and a heating system.

Consequences and recommendations: the user will have to spend money on heating every month. A month of operation of the evaporator will cost 3 thousand rubles at the rate of December 2018.

As a result, Elena and her husband chose to install a gas tank underground. One-time earthworks are cheaper than electricity costs for 7-8 months and the purchase of additional equipment.

The gearbox freezes

Commentary on the situation

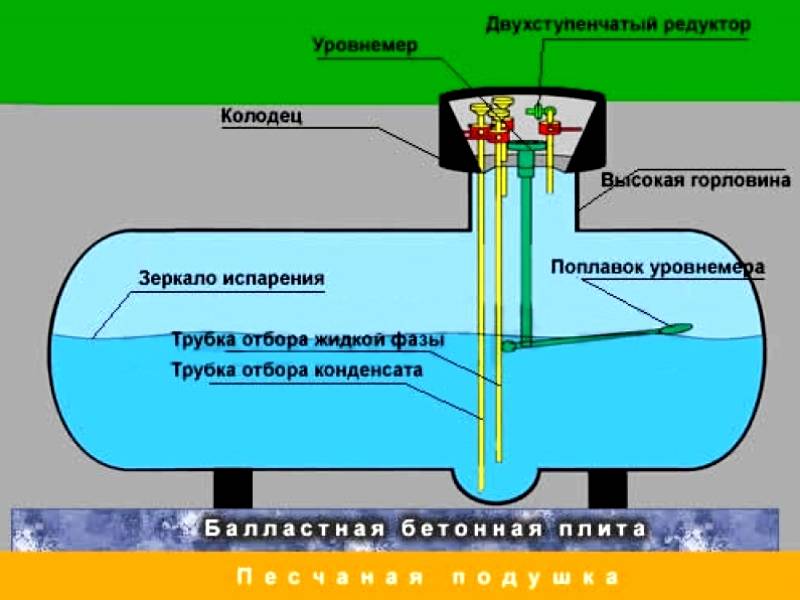

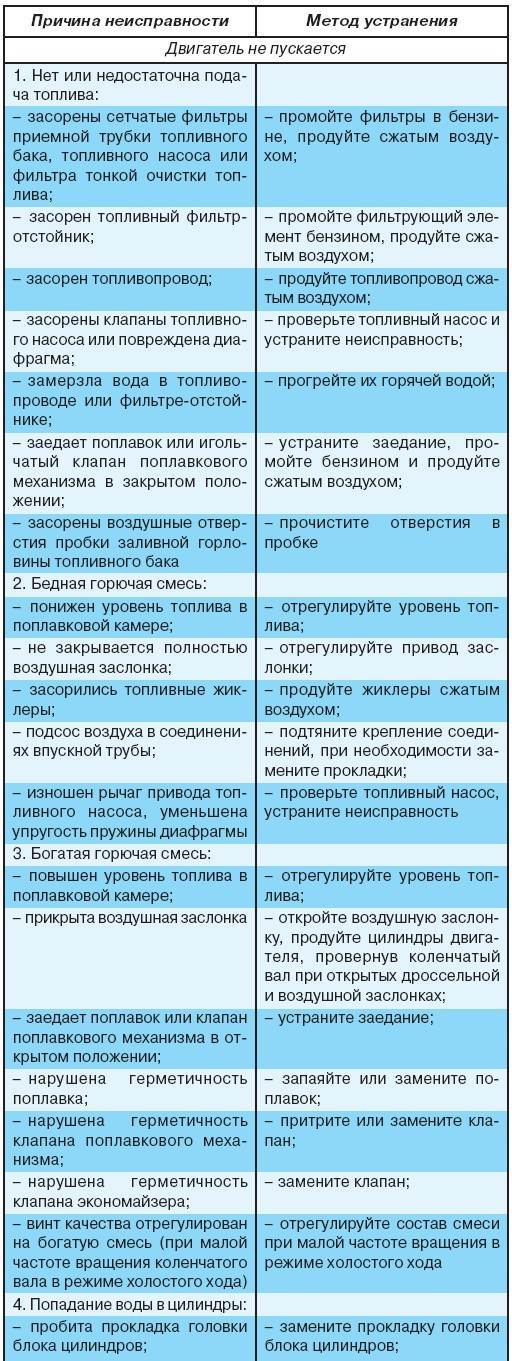

The reducer controls the pressure between the tank and the gas pipeline. The device reduces the rate of 1.5-16 bar to 22-100 mbar. If the pressure is not adjusted, the equipment in the house cannot be used: the boiler will go into error, the stove will become dangerous for cooking.

Inside the gearbox is a movable spring-loaded diaphragm. It responds to changes in inlet pressure and ensures the same outlet pressure. For normal movement of the membrane, a “breathing” hole is made on the outer side of the body.

It is through the hole that water enters the device during flooding. The liquid does not interfere with the movement of the membrane, but when the temperature drops, it turns into ice and blocks the operation of the gearbox.

Causes of gear freezing

The owner chose a tank with low nozzles. The fittings are flooded, water penetrates into the body through the “breathing” hole.

Installers incorrectly installed a gas tank with high nozzles. The tank was buried too deep - the reinforcement is 10-5 cm below ground level. In order not to flood, you need to raise the gearbox and the cover of the carpet.

Ice forms from the inside in narrow channels due to water vapor in the LPG.

Extract from the Gas Supply Handbook for design institutes

Response from engineer Evgeny Kalinin

We are talking about the Rego gearbox (USA). This is a less reliable model than the German GOK. With him 2-5 times a year there are problems without flooding. If there was no water ingress, the gearbox can be replaced under warranty.

The equipment needs to be cleaned: removed, warmed up, drained, dried. You can warm up with a kettle. But it is better to wrap it with an energy-heating cable. More expensive for electricity, but more reliable.

There are models with high tubes that are not afraid of water - they cost 2 times more. We can install these upon request. Attaching a tube to the breathing port of non-moisture resistant equipment will not help.

The best solution in this case is to raise the gearbox until the thaw. Don't wait for spring and don't put off the problem.For example, this year a lot of snow fell at the end of December, but it melted in February. At the first frost, the wet gearbox will stop working again.

How to restore the gearbox

In order for the device to work again, you need to remove the ice - that is, warm up and dry the case. The video shows an example with disassembly:

Some models are difficult to disassemble, so they are heated and blown with a building hair dryer.

How to prevent freezing of the gearbox

Choose a model with high nozzles so that the valve and reducer are accessible in any situation. Make sure the container is not buried too deep.

Raise the gearbox - even when flooded, the housing remains above the surface.

Use quality fuel with a minimum water content in dissolved form. Pump out the condensate promptly.

Let's summarize

Problems with the use of a gas tank appear as a result of violations:

Wrong choice of design and installation - the fittings are immersed in water, the gearbox freezes, the pressure in the supply pipeline drops.

Errors in operation - filling low-quality fuel (condensate forms), overfilling the tank, using one refueling for 3 years (propane runs out quickly).

Advice

Take care to protect the equipment from flooding. If there is groundwater on the site, it is better to play it safe and buy a container with high nozzles.

Lifting the valves and reducer above the water level reduces the risk of flooding. The procedure solves most problems when using a gas tank.

The reducer is a special device that lowers and maintains the required value of the pressure of the gas mixture in the system. In some cases, the owner of gas tanks is faced with the problem of freezing of the gearbox and stop gas supply. Many companies often take advantage of the engineering illiteracy of customers - they impose expensive pumping of gas, explaining this with poor-quality gas, imposing service contracts and demanding fabulous sums for replacing the gearbox and installing additional unnecessary equipment.

Let's try to explain everything in this article.

The reducer is designed in such a way that it consists of 2 chambers, which are separated by a special membrane, which is responsible for the process of adjusting the pressure in the line. In the lower chamber, a gas flow passes, in the upper air chamber there is air, which communicates with the environment through a breathing valve. In case of flooding of the reducer with ground (melt) water, water remains in the housing and on the membrane. When a negative temperature occurs, the accumulated water freezes and blocks the movement of the membrane (the operation of the gearbox). In addition to groundwater, condensate may accumulate in the gearbox.

To prevent such problems, it is necessary to prevent flooding of the gearbox.

The best, but most expensive option is to install a gas tank with a high neck (for flooded and wetlands). A more affordable option is tank models with high branch pipes and a multi-valve (if there is a risk of flooding in the autumn-spring period).The most budget option is the installation of waterproof models of gearboxes (with high nozzles of breathing valves), this option is also used when the gearbox of the standard model is already flooded.

|  |  |

If the gearbox is flooded, it must be removed, disassembled and dried.

It is recommended to carry out preventive maintenance of the gearbox before the onset of the heating season - remove, disassemble, dry, clean from dust and dirt, set the exact pressure, replace worn parts (membrane, spring) if necessary. If the gearbox freezes unexpectedly, for example at night, you can pour boiling water over the gearbox, and it will continue to produce the necessary pressure for a while.

It is forbidden to use a hair dryer, gas guns and other devices where there is an open fire and an incandescent spiral, as gas vapors may ignite, followed by an explosion of the gas-air mixture. It is not recommended to use a heating cable and other electrical appliances that are not designed for this purpose, since in the event of a short circuit and a spark, the gas may also ignite.

You can identify the problems associated with the freezing of the reducer by the following signs: turning off the gas supply, reducing the parameters of the outlet pressure, sharp pressure drops during the operation of the boiler, increased gas pressure in the system, etc. If there is at least one of these signs, then preventive maintenance of the reducer is required. We strongly recommend that you seek these services only from professionals.

The emergency team of our company works around the clock and is ready to go to you and fix problems immediately after your call.

Upon arrival at the facility, a comprehensive diagnostics of the operation of the gas tank, all gas-using devices (boiler equipment, gas stoves, convectors, etc.) is first carried out in order to determine the causes of the breakdown. After identifying all the problems, the cause is eliminated, a test run of gas is performed and the operation of gas appliances is checked. All work is guaranteed and an act is drawn up confirming that the work has been carried out.

What to do if the gas tank itself is frozen?

Although the main reason for the lack of gas supply from the gas tank is the freezing of the gearbox, sometimes the tank itself can freeze. So, the water on the site can be in such quantity that it can flood the gas tank and freeze it with the onset of frost. And there is a situation when there is still gas in the tank, but it does not go outside.

The second reason for the freezing of the gas tank is the consumption of propane from LPG and the remainder inside is only butane and water condensate, which freeze easily.

It is important to insulate the gas tank, because in severe frosts any LPG will freeze. For example, pure propane in a liquefied state can freeze even at -15 ° C

This leads to a drop in pressure in the gas pipes, disruption of the boiler and other problems.

Install the gas tank as deep as possible underground, at least 1-1.5 meters deep, to avoid freezing in severe frosts

Install the gas tank as deep as possible underground, at least 1-1.5 meters deep, to avoid freezing in severe frosts

In such cases, users have only one question: how acceptable is it to use heating to restore the operation of the gas tank? The easiest way is to pour boiling water over the gearbox and part of the container near it. This will allow the neck itself to be heated, where the gaseous product should form.But it is much more important to properly install the gas tank and connect reliable equipment to it.

So, if the container is installed too close to the surface of the earth or even stands on it, then the balance of propane and butane in the mixture will quickly deteriorate. Propane will evaporate even at the lowest temperature, and butane will remain in the tank. This gas is much more prone to freezing and often creates a blockage in the pipe leading to a drop in pressure. The optimal ratio of propane and butane should be at least 75:25, and preferably 80:20.

Solutions

You can find out how to solve this problem or how to melt the ice in the chimney in this section:

- To partially cope with this problem and reduce the amount of ice, you can remove the plug, which is located on the top of the device;

- Change the angle of inclination of the coaxial system (if it is vertical or horizontal and located at a right angle). This will allow the resulting condensate to drain and not freeze inside the pipes.

To prevent icing, you can use special means "Anti-ice"

Insulated systems are less prone to icing

Insulated systems are less prone to icing

Although the instructions make it possible to partially solve the problem by removing the plug, ultimately, after the situation improves, it will be necessary to fix it in its original position, since its constant absence can lead to other malfunctions.

Problematic installation at high groundwater levels

Case 1: flooded gearbox

Rider777Member

A year ago, a new gas tank was installed in a metropolitan company, completely turnkey! Warranty 3 years for work and equipment and 30 years for the tank itself. As a result, the gearbox failed, it gives some kind of wild pressure, it’s scary to use a gas stove! Even the valve on the boiler sometimes sticks due to such pressure, and the boiler gives an error!

We turned to the company - the mother-in-law also called to the employee’s question “Did the gas tank neck and directly the part where the fittings are located be flooded with groundwater?” replied that it was. They immediately motivated that this was not a warranty case and said goodbye.

So, nowhere in the instructions, contract and passport of the gas tank is there any mention of groundwater flooding, that is, the end consumer is not notified about this! Yes, and the gas tank, having this plastic cap, and they took it with elongated necks, should, it seems to me, be airtight with an iron vessel! What do you advise? Go to court?

Commentary on the situationA: Unfortunately, the case is indeed not guaranteed. The plastic mouth of the gas tank is leaky. This is a revision well, not water protection.

Evgeny KalininEngineer at Termo Life

The user confuses the guarantee for capacity and service life. 30 years is the designated service life of the gas tank. Only Czech manufacturers have proven themselves in time - they have been producing containers for 70 years. Other organizations operate from 2 to 15 years. At the same time, there are no problems with barrels - there was not a single explosion. Manufacturers have secured the entire system in advance.

According to the described problem with the gearbox. Flooding is an emergency.The contract for installation work states that the filling of the gearbox and shut-off and control valves is not included in the warranty.

If the customer says that there is groundwater on the site, we immediately recommend installing high nozzles with which flooding cannot occur. If the client insists on low, we set the selected capacity. But be warned that water ingress is not covered by the warranty.

It is also possible that the user was incorrectly installed gas tank with high nozzles - 5-10 cm below ground level. Shut-off and control valves with a gearbox must be above the surface of the site.

Error in installation: problems arose due to the choice of a tank with low nozzles at a high groundwater level. It is also possible to install the tank too deep with high nozzles.

Consequences and recommendations: the user will face systematic flooding of the gearbox and failure during the first frost. You need to clean the device - 5-7 thousand rubles. Plus raising equipment - 10 thousand rubles.

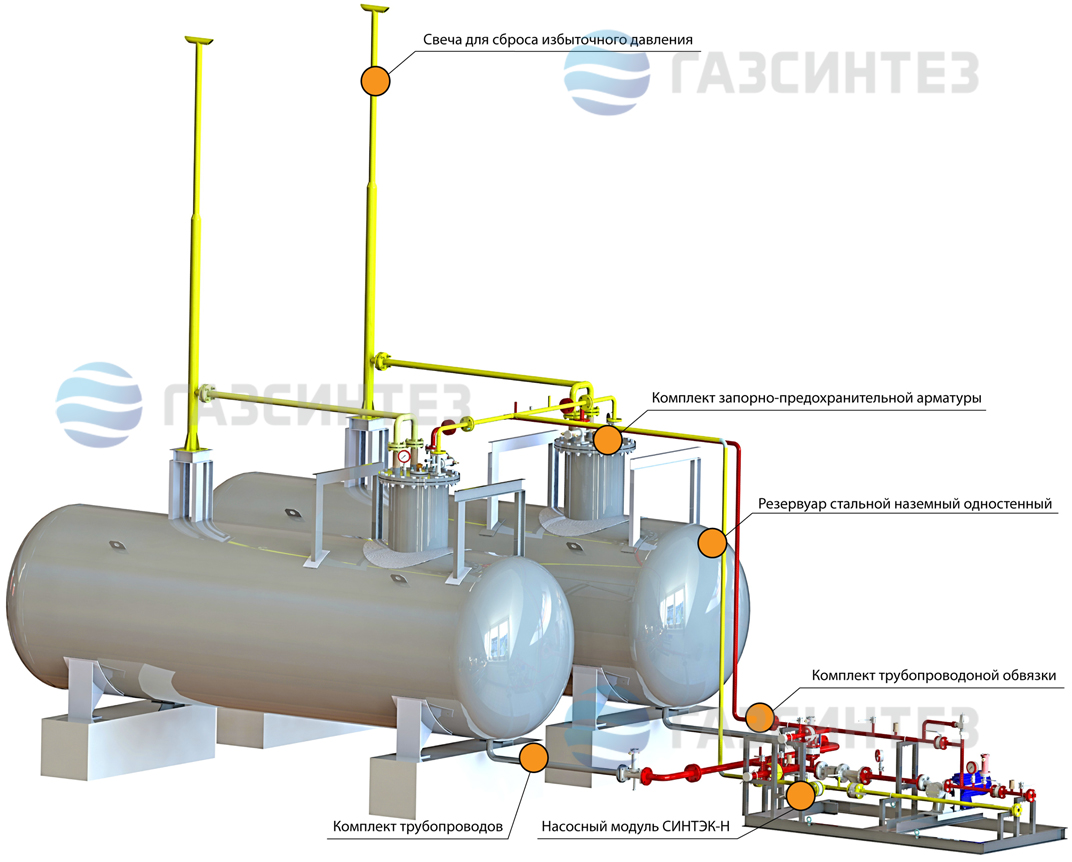

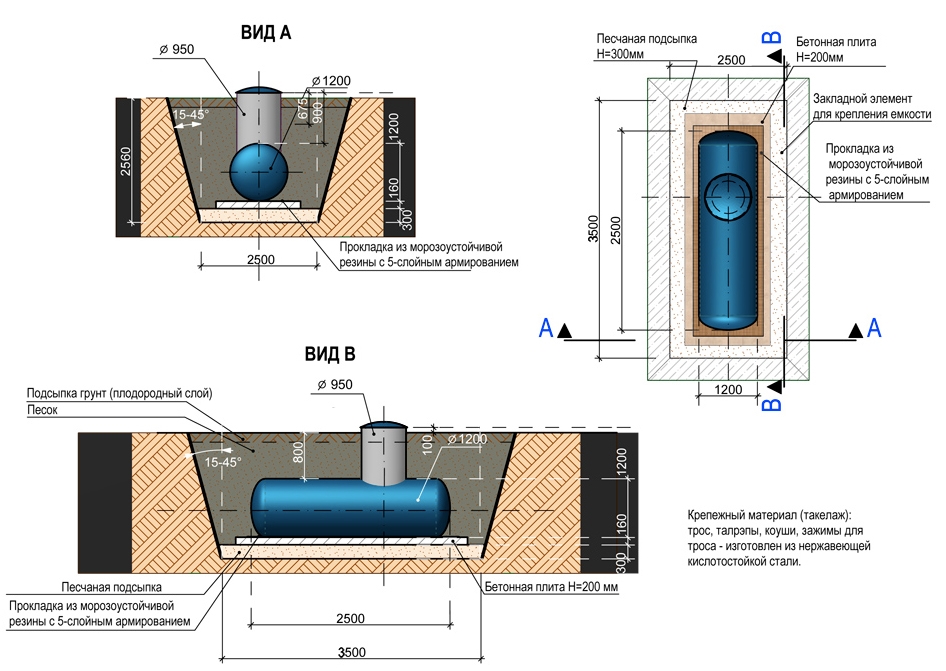

Case 2: the barrel has surfaced

Max_221Member

I ordered the installation of a turnkey gas tank. Groundwater in the area is high. When the gas holder was installed, fixed with cables to the slab and started to be covered with sand, all four cables burst and the barrel surfaced. The installers shrug their shoulders and say that they have never seen anything like this. It looks like they don't know how to install. What to do in this situation? How to fix the barrel? The pit quickly fills with water, how to deal with it?

Commentary on the situation: the professionalism of the installers raises many questions. There is a gross error with the assessment of the risk of surfacing of the container.

Evgeny Kalinin

Engineer

The cable should definitely not be torn, the barrel will rather rise with the plate. If the cables broke, the installers chose the wrong plate by weight. The anchor is calculated according to the level of groundwater - so that the gas tank does not float. In most cases, a hollow slab is sufficient.

In difficult areas, we can install a full-bodied slab, but this is not an ordinary case. Almost 90% of our installations are carried out by a manipulator through the customer's fence. A solid slab is heavier, so you have to call a crane - the minimum price is 15 thousand. Plus, the equipment must come to the site. Sometimes it's just not possible.

Installation can also be carried out in a pit with water, if the container is properly anchored. When a quicksand appears, when the walls of the pit do not hold due to sand and water, we put a box to strengthen the pit.

Error in installation: problems arose due to poor-quality installation. The team incorrectly picked up the weight of the plate.

Consequences and recommendations: the user needs to reinstall the gas tank on another stove. Installation, excavation and crane call will cost at least 70 thousand rubles. It is better to use a cable braid: the cable passes under the plate and interlocks on the container.

According to Yevgeny's experience, high groundwater levels and heaving soil are found in sites in the Noginsk, Kaluga, Shchelkovsky and Naro-Fominsk districts.

How to defrost a pipe indoors

The methods used to defrost utilities directly depend on where exactly the pipeline is located. So if it is mounted indoors, then you can get rid of ice jams using:

- hot water;

- building hair dryer;

- electricity.

Hot water is used to warm pipes in open sections of highways, while this method can be used to clean products, both metal and plastic. In this case, it is best when it is boiling water, since it is it that allows you to melt the ice the fastest. In addition, rags and rags are also used to speed up the process.

- To begin with, rags and rags are placed on the pipe.

- The place of the alleged congestion begins to be poured with boiling water or hot water. The process is lengthy, since the surface of the line will have to be constantly irrigated with new portions of hot water.

- The heating process stops only after water does not start flowing from the open taps.

- Complete removal of ice from the system can be completed in a few hours and during this time the valves should not be closed.

Rags and rags are needed here to increase the area of contact of the pipe with boiling water, as well as to extend its impact on it.

Rags and rags increase the area of contact of the pipe with boiling water, and also prolong its effect on it.

Frozen plumbing can also be warmed up with hot air by exposing it to open areas of the system. For this purpose, a heat gun or a powerful building hair dryer is usually used. At the same time, a temporary canopy from improvised materials is erected over the problem area. In the same case, when the homeowner does not have industrial equipment, he can use any device that generates warm air. So they can be a regular household hair dryer.

The third common way to defrost pipes is the use of electricity. It is considered one of the most effective and can be used to get rid of ice from both metal and plastic products.

At the same time, it should be noted separately that this method requires the adoption of certain precautionary measures.

Metal lines are heated in this way using a welding transformer.

- The output cables of the device must be connected to a suspicious area at a distance of at least half a meter from the blockage.

- Voltage is applied so that a current of 100 to 200 amperes passes through the metal.

- Usually, a few minutes of such exposure causes the ice to melt, thereby restoring the patency of the pipe.

As for plastic communications, they are heated using a two-core copper wire with a cross section of 2.5 - 3 mm:

- One of the cores is partially stripped and 5 turns are made around the cable.

- The second vein falls below the first and the same manipulations are performed on it. Trying to make a spiral winding at a distance of 3 millimeters from the first winding. The resulting device is the simplest homemade boiler.

- The finished product is inserted into the pipe and the current is turned on. Under the influence of the potential that has arisen between the coils, the water heats up, and the ice begins to melt.

This method is good because when using it, the system does not heat up and the plastic does not deteriorate.

Reducer failure

The reducer is designed to adjust and maintain the required pressure in the system. Flooding and, as a result, freezing of this device is the most common reason for stopping a gas boiler.

As a rule, the flooding of the gearbox with external water occurs as a result of improper installation, when the control valve is installed below the ground surface.In this case, atmospheric precipitation or groundwater easily enters the device and is no longer removed from there. When frost sets in, the moisture inside freezes, significantly reducing throughput or completely stopping the operation of the equipment.

Proper gearbox installation - above ground level

Another reason for stopping the system is condensate, which falls inside the gearbox due to the temperature difference in the gas tank and the environment. In this case, moisture gradually accumulates inside and, when frozen, blocks the gas supply.

The gas tank gearbox freezes what to do

dressing mix

A mixture of liquefied hydrocarbon gases (LHG) is winter and summer. In winter, more expensive and lighter propane prevails. With the right choice of capacity, it will need to be filled 1-2 times a year.

If you want to fill the tank to the maximum (that is, by 85%), it is better to pump in winter gas. Since with such fullness you will certainly capture the cold months. If you want to save money, you can fill the gas tank in the spring - to make a cheaper refueling.

It is better to refuel the gas tank in autumn, but shallow, when prices begin to rise, and as soon as winter gas appears. Prices reach their peak in December.

Winter surprises

Frost surprises the owners of gas tanks - it can tightly forge the hatch cover. And during thaws, melt water seeps into the hatch, sometimes getting into a leaky gearbox.

At night, due to a decrease in temperature, the water in the reducer freezes and stops the constantly working membrane. As a result, the device cannot provide normal pressure in the system, and the boiler rises.

If this happens, you need to call the service department.But you can, without waiting for the rescuers, pour the device with hot water from the kettle so that it thaws.

In order to further prevent such troubles, it is necessary to wrap the block with mineral wool or rags.

Gas leaks

As for gas leaks, sometimes they happen at the junction of hoses in the boiler room and under the neck, where the gas line is connected to the gas tank. Fortunately, there is not enough pressure in the system to with such leaks something caught fire. However, as soon as a suffocating smell appears, it is better to call specialists.

With proper operation, the system will last more than a dozen years. If during this time the main gas is already brought to the site, the autonomous gas supply can be left as a backup.

This situation can be caused by a problem with shut-off and control valves, a gas pipeline or a gas tank, and is most typical for the cold season. Below we will discuss each case in detail.

Filling up the gas tank

To understand the so-called bottling, one must initially understand what liquefied hydrocarbon gas used to gasify private facilities consists of. Actually, there are only two main components - propane and butane. In this case, propane is considered the main substance as a lighter gas. In winter, its content in the mixture should not be less than 75%. This is due to the fact that butane does not change from a liquid to a gaseous state even at a temperature of -1 ° C, while propane continues to work even at -40 ° C.

If the gas holder is not located deep enough, as a result of which the internal temperature of the vessel is negative, only one component, propane, evaporates, and liquid butane remains inside the vessel.In this case, you have to either pump out the butane accumulated in the tank, or wait for the temperature to rise so that it begins to evaporate on its own.

Freezing of the gas tank due to shallow occurrence leads to the shutdown of the gas boiler

And this is what the frozen upper part of the gas tank looks like:

How to protect the column from freezing?

Do you have a geyser freezing through the chimney pipe, and you don’t know what to do to avoid this problem? Let's take a closer look at this issue.

The instructions for the equipment prescribe the temperature regime at which the equipment functions normally. When the outside temperature drops, individual components of the water heater may fail. If the device is under warranty, this does not mean at all that there is absolutely nothing to worry about. The manufacturing company clearly prescribes operating standards, the violation of which threatens to void the warranty.

If the location of the column is an unheated room, and the equipment itself is equipped with a chimney, the problem is solved by installing a check valve that prevents frosty air from passing through the chimney directly to the device body

If the location of the column is an unheated room, and the equipment itself is equipped with a chimney, the problem is solved by installing a check valve that prevents frosty air from passing through the chimney directly to the device body

Freezing can be avoided if the water is drained in a timely manner. This applies not only to country speakers, but also to devices that are located in private houses or apartments.

It is necessary to drain water in the following cases:

- abnormally cold weather;

- frequent power outages;

- unheated room.

Such a measure will not hurt if you leave for a week or more, which means that the gas water heater will not be used.

To drain the water, close the gas valve and the incoming water supply valve.Then open the hot water on the mixer and wait until the water is completely drained.

Avoiding costly repairs allows the use of the "Winter-Summer" mode, if, of course, the column is equipped with it. By increasing the degree of heating, you save the equipment from freezing.

Avoiding costly repairs allows the use of the "Winter-Summer" mode, if, of course, the column is equipped with it. By increasing the degree of heating, you save the equipment from freezing.

Another case is also possible when the column is in a warm room and freezes anyway. The part of the pipe that is in the room remains warm. And that part of it, into which the "street" air enters, goes into the minus. The condensate that forms in the pipe turns into ice, which, in turn, binds the check valve. The removal of gases from the column will thus be blocked - the fan will not be able to open the valve. It will be impossible to turn on the column in such a situation.

The solution to the problem is quite simple. You can use a regular household or building hair dryer. The device must be turned on in the maximum heating mode. Now it remains to heat the pipe. The ice will melt quickly and the valve will be released. Now you can turn on the column and let it run for about 10 minutes so that the smoke exhaust line is completely warmed up and dried out.

Sometimes the cause of frosting is ventilation problems or flaws in the manufacture of the case. If the device is under warranty, you should contact the service center. If the warranty period has passed, sealing the case helps.

conclusions

It is worth choosing a gas tank and carrying out installation without interrupting your living conditions. The high-quality operation of the heating system depends on the area of \u200b\u200bthe house, the power of the boiler, the level of groundwater on the site, the format of residence - seasonal or permanent. All these factors must be taken into account in order to enjoy autonomous heat, and not solve additional problems.

More information about gas tanks can be found in the profile thread on the forum. Find out how much it costs to conduct main gas in different regions. In the video - how to conduct engineering communications alone.

Source