- Connection and setup

- Connecting to bottled gas

- Causes of soot

- Connection and setup

- Connection to the cylinder

- Purpose and design of jets

- The principle of operation and the device of the nozzle

- Nozzle diameter and thread

- Nozzle replacement

- In burners

- In the oven

- Alternate nozzle operation

- Where to buy a kit

- Buying and replacing jets

- Oven door won't close

- jet service

- jet replacement

- Ignition type

- What gas is in household stoves. Gas stove jet: replacement features

- Important points when choosing a nozzle

- to

- Possible malfunctions

- Popular injector malfunctions

Connection and setup

It is not difficult to change the jets on your own, but if the equipment is under warranty, then such manipulations can cancel it. If possible, it is better to contact a specialist. A professional will correctly change the jets and will be responsible for the safety of further operation of the gas stove.

Connecting to bottled gas

Decided to buy a new gas stove, but the old one is still functional? The best option would be to take it to the country and connect it to the cylinder.To do this, you just need to change the standard jets to nozzles for the stove for liquefied gas, and also connect the cylinder itself to the stove.

The process of connecting bottled gas to the stove is technically simple, but you need to carefully approach all manipulations:

- Screw the reducer onto the cylinder, while installing the gasket.

- Screw the fitting onto the inlet pipe of the stove. And here you need a gasket.

- Connect the gas hose to the stove with a fitting.

- Secure the hose with clamps.

- If the gas cylinder is installed outside the room, on the street, then a piece of pipe must be installed in the hole in the wall so that the hose does not fray.

Hose requirements:

- the length must be at least 1.5 m;

- the hose must be fixed and motionless;

- it should not bend or break;

- it is necessary to use only a special hose for gas equipment;

- at the end of the service life, replace;

- regularly check the hose for damage.

After completing the connection, check the stove for leaks. Open the gas, and coat all joints with soapy water. If a leak is detected, tighten the nuts, harnesses, replace the gaskets. When replacing the cylinder, such a check is also necessary.

Watch this video on YouTube

Causes of soot

Currently, most gas stoves are connected to a main gas pipeline that transports methane to consumption points. The jets of such devices are often equipped with a wide through hole.

Remember, the specific gravity of a propane-butane mixture is four times that of natural gas.That is why, after connecting standard units to bottled fuel, there is a sharp increase in pressure in the network, as a result, the color of the flame changes (from blue to yellow-red) and the stove begins to smoke.

Consider the main factors that contribute to the appearance of soot

Clogged jets (nozzles). To eliminate the problem, the stove should be cleaned of dirt, while it is necessary to first disassemble the burner.

In order to avoid the ingress of foreign elements into the gas passages of the device, which inevitably lead to clogging of the nozzles and the formation of soot, the dismantling of parts and cleaning of the jet holes must be carried out with the utmost care.

Poor-quality burner material. Budget models of gas stoves are often equipped with a silumin flame divider. Intensive operation of the device for a long time contributes to the gradual deformation of the alloy. This process is often accompanied by the formation of a significant amount of toxic smoke.

Remember, most often a malfunction occurs in the design of the most powerful burner. To eliminate soot, it is enough to replace the divider.

Mismatch gas stove nozzles type of fuel used. In urban networks, in contrast to the balloon capacity, the pressure of the energy carrier in the system is much less. That is why in standard furnaces, the holes of the jets are adapted directly to the pressure of the main gas. However, when the device is “powered” from a liquefied mixture, the diameter of the nozzles should be much smaller. Otherwise, when connecting a standard stove to bottled gas, strong soot formation often occurs.To fix the problem, you should convert the kitchen unit by installing jets designed for propane.

Remember, drilling or caulking nozzle holes is strictly prohibited.

As a rule, at home it is almost impossible to obtain the required diameter of the jets.

An incorrect inclination of the burner passage can lead to an uneven distribution of the gas flame, fuel getting under the hob of the unit, while it is important to take into account the fact that the accumulation of an air-gas mixture represents a potential explosion hazard, which absolutely cannot be allowed.

Remember, smoking of the device may occur as a result of a change in the chemical composition of the main gas. However, in this case, it is often quite problematic to solve the problem that has arisen at gas distribution stations.

Connection and setup

Connection to the cylinder

To connect and configure the stove, we need the following materials and tools:

- Metal box for a balloon.

- Reducer with gasket for liquefied gas cylinder.

- Rubber gas hose (select the diameter for the reducer).

- Fitting with a gasket for a hose for a stove.

- A set of nozzles.

- Screwdriver.

- Socket or open-end wrench 7 or 8 mm.

- Gas wrench for installing the gearbox and fitting (better if there is an open-end wrench).

Place the metal box outdoors. Better if it has a lock

Screw the reducer to the cylinder, placing it horizontally (this is important). Screw the fitting to the plate

In both cases, a special sealing tape can be used. It is sold in stores. Route the hose through the pre-made hole in the wall from the box to the house.Put one end on the reducer, the other on the fitting and secure with worm-drive clamps.

Purpose and design of jets

Of the three systems existing in the gas stove, the gas system, consisting of shut-off valves, pipelines, burners and burners, is the basic one. We wrote in detail about the device of the stove in this material.

Regardless of the stove model, the composition of its components is the same, and in combination they serve to transport the gas supplied to the stove, mix it with air (to saturate it with oxygen), and dose it to the divider holes. On the gas path, the stopcock and the burner nozzle, otherwise called the nozzle or jet, are responsible for the dosage and pressure of the gas.

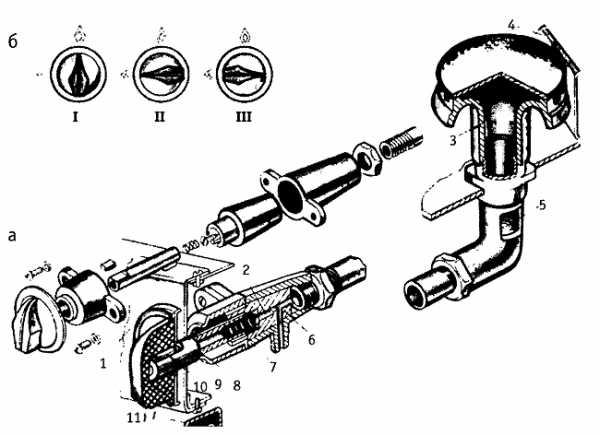

The principle of operation and the device of the nozzle

The gas supplied to the gas stove burner (the device where the gas-air mixture is formed) can be of various types - natural (methane) or liquefied (balloon - propane).

For efficient, stable operation of the gas stove, the mixing of gas and the supply to the burner divider must be carried out evenly, at a certain speed. To do this, in the design of the gas burner there is an important detail - the jet.

Let us consider in more detail what jets are in a household gas stove. This is a part in the composition of the burner, designed to ensure that gas enters the burner with the appropriate pressure in the required volume. To do this, a calibrated passage hole is made in the nozzle, which determines the parameters of the gas jet that meet the conditions specified by the manufacturer.

These conditions are correlated with the optimal power of the gas stove, determined by the maximum complete combustion of the consumed gas, indicated by the manufacturer among the technical characteristics of the equipment.

Nozzle diameter and thread

The nozzles are bolt-shaped, equipped with an external thread and a head with a hexagonal slot. The through hole (nozzle), located in the center of the part, has a diameter calculated according to the type of gas, its pressure, as well as the method of supplying the gas-air mixture and the power of the burner.

For bottled gas, the nozzle diameter (with the same design and burner power) is needed a little less, for natural gas - a little more.

If jets for natural gas are installed on the stove connected to bottled gas, the pressure of the gas entering the burner will be greater, less air (and oxygen) will be captured, the flames will be noisy and long, have an orange color and smoke. In this case, the situation can only be changed by replacing the jets with parts with a smaller nozzle diameter.

In most models, the hex slot of different jets has the same standard size, so a 7 mm wrench is needed to unscrew the replacement part of different plates.

Hole diameters, thread pitch and part length are different in jets (for natural fuel, the length is shorter, for liquefied fuel, it is longer). The dimensions of the channel diameter are knocked out on the head of the part (in hundredths of mm, much less often the marking is in mm).

Jets are interchangeable parts. When selling stoves, they are usually equipped with nozzles designed for natural gas. The components of many modern models of gas stoves also include nozzles designed to switch them to bottled gas. If this is not the case, then a set of jets can be purchased separately in the same place, in specialized stores, or via the Internet.

The nozzles are made of brass.It is thermally stable, durable and corrosion resistant. During operation, they heat up slightly. In the plates of the old model, the vertical nozzles were made of brass, and the base into which they were screwed was made of aluminum alloy. Therefore, when replacing or cleaning the nozzle, care must be taken not to damage the threads.

If the documents for the unit are lost, determining the thread of the gas stove jet when buying replacement parts can cause some difficulty. However, determining the thread pitch of the nozzles of most stoves is not difficult, since there are only two values \u200b\u200b- 0.75 and 1.0 mm.

Until 2009, plate jets were produced with a thread pitch of 1 mm. Most new stoves manufactured since 2009 have nozzles with a thread of 0.75 mm. To determine the size, it is enough to attach a ruler with clearly visible millimeter divisions to the thread.

When transferring the stove to gas from a cylinder, not only nozzles are replaced. The gas reducer is also replaced.

Nozzle replacement

A specialist from the gas service will be able to qualitatively and professionally change the jets. He has the necessary knowledge and qualifications to properly adjust the gas supply when switching to another fuel. Especially considering that in order to use bottled gas, it is necessary to additionally connect a reducer. But if you rely on the data that the correspondence table contains, then the home master will confidently cope with such work.

In the table below, you can find the required diameter of the gas jet, depending on the fuel used.

In burners

For those who decide to change the jets with their own hands, the following is an algorithm of actions that must be followed:

- to gain access to the burner, you need to remove the top cover of the gas stove, which is fixed with screws;

- then, from the traverse with burners, you should get the tips with nozzles, for which you first need to find a latch (outwardly resembling a clothespin), squeeze its ends effortlessly and carefully remove it;

- then the tip should be released from the socket and removed from the gas pipeline tube;

- an o-ring will remain in the tip, which must be removed from there and put back on the tube;

- the next step is to carefully unscrew the jets with a socket wrench counterclockwise (if the nozzle is stuck and does not lend itself, it is recommended to use a vise);

- and finally, new nozzles must be screwed into each tip, and then reassembled.

Advice! In order not to confuse old jets with new ones, you should check them according to the marks applied. The dimensions of the nozzles are indicated there.

Due to the low pressure in the network, it is not necessary to seal the threaded connection. How to lubricate the o-ring. It depends on how carefully and correctly the reassembly of the structure is carried out, how evenly the burner will burn.

Important! It must be remembered that gas fuel is a source of increased danger

Therefore, it is imperative to follow all the rules and precautions when working with gas equipment.

In modern gas stoves, the process of converting to another fuel is even easier. To get to the burners, it is enough to remove only the grates with burners. After that, you can easily get the tips and replace the jets with new ones.

In the oven

To change jets in a gas oven, follow these steps:

- fully open the oven door and the lower compartment of the stove;

- pull towards you and pull out the floor of the oven compartment;

- unscrew the fasteners of the gas burner and put it aside;

on the left, a nozzle is hidden in a special case (if the stove has not been used for a long time, then the jet will easily unscrew from this position, and if the nozzle has already boiled, then you need to continue disassembling so as not to strip the thread);

remove the left side wall by unscrewing the three fastening screws;

using a 17 wrench, unscrew the nut and take the pipeline to the side;

unscrew the last two screws that secure the nozzle body to the wall;

- treat the stuck thread with kerosene or WD-40 and use a vice for convenience when unscrewing the jet (if necessary);

- install a new nozzle.

Then you need to carefully mount the oven in reverse order.

Alternate nozzle operation

The classic solution for stoves is considered to be a gas state supply device. It includes a burner, transport channels, stopcocks and, indeed, the burner itself. Regardless of the type of model and price segment, these elements remain unchanged.

The volume of gas supplied and its pressure fall on the shoulders of the shut-off valve and burner. This tandem is most often called a jet and nozzle, where the first is part of the second. As a fuel, liquefied gas - propane (in cylinders) and natural gas - methane (pipeline) can be used equally.

In order for the correct operation of the equipment, clearly adjusted proportions of the gas supply are necessary. So there is, the fuel must flow at a certain speed and in equal shares. Nothing else for this and you need a jet in the system.

In addition, it is impossible to choose nozzles without looking at the type of fuel.For example, an element designed to work with propane, stop smoking dishes and emit harmful substances if it is installed in a system that functions for methane.

To maintain the required volume of gas and pressure in the jet, an adjustable well is provided. On new slabs, the elements are calibrated to the optimal/universal measure. The latter are calculated based on the power of the equipment and the maximum rate of fuel combustion.

Where to buy a kit

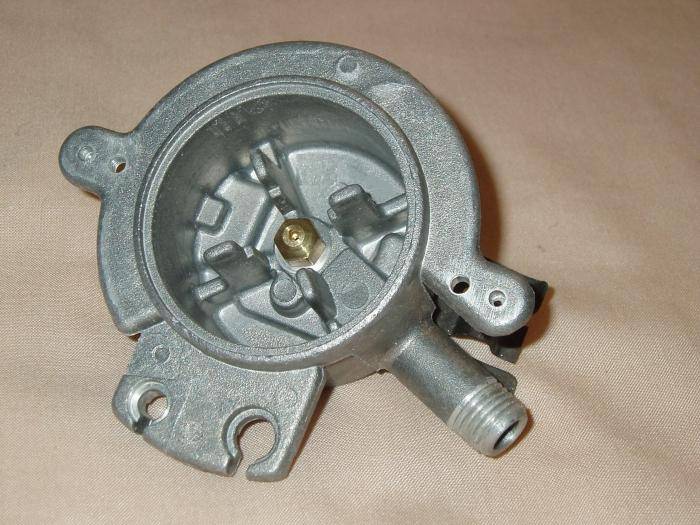

The internal manifold of the gas stove. Automatic devices of gas stoves. Maintenance of domestic gas stoves

Of course, each user is interested in the question - where can I buy such a set, and how much does this pleasure cost. It all depends on the brand of your cooking assistant. Jets for popular brands of gas stoves can be bought at any specialty store that sells spare parts for gas equipment. For rare ones, you can order it on the official website of the manufacturer or at a service center.

Approximate prices for injectors:

- Belarusian plate Hephaestus - 150 rubles;

- Ariston or Indesit (on liquefied gas) - 200 rubles;

- Zanussi - 230 rubles;

- for a Gorenje stove from Slovenia - 700 rubles.

All prices are for a set of nozzles or jets. Quite often, users are confused in the name of the parts of the gas stove: burners with flame dividers are installed at the top of the stove, they look like the one shown in the photo - you should not confuse them with burners.

Buying and replacing jets

When buying a gas stove, do not forget to check the availability of suitable jet kits. If you miss this important point, and direct the gas through the wrong nozzles, then you can get unstable work.The burner will smoke, periodically go out, or not be able to light up at all when ignited.

If, for some reason, the nozzles corresponding to the type of gas are not included with the stove, then they can be easily purchased separately. Information about the diameter of the jets must be indicated in the instructions for the gas appliance.

Table of average jet parameters for most models of gas stoves:

| Burner type | Gas type (pressure) | |||

| NG G20 (20mbar) | LPG G30 (50 mbar) | NG G25 (20mbar) | LPG G30 (30 mbar) | |

| small burner | 0.75 mm | 0.43 mm | 0.70 mm | 0.50 mm |

| Medium burner | 0.92 mm | 0.55 mm | 0.92 mm | 0.65 mm |

| Big burner | 1.15mm | 0.60 mm | 1.15mm | 0.75 mm |

| Oven burner | 1.20 mm | 0.65 mm | 1.15mm | 0.75 mm |

| Grill burner | 0.95 mm | 0.60 mm | 0.95 mm | 0.65 mm |

Replacing (installing) the jet will not be difficult - you just need to unscrew the old one with a wrench and screw a new one in its place. Only in some cases it may be necessary to additionally adjust the primary air supply and adjust the minimum steady flame level.

Oven door won't close

The most common oven failure is poor closing of the oven door. It occurs most often when there is a small child in the house who simply sits on an open door, as a result of which the brackets holding this part bend and do not fulfill their function of pressing the sash.

To repair the oven of the Indesit, Brest 1457 gas stove or Flama stove, you will need to disconnect the door from the unit. To do this, you need:

Since the door is held on hinges equipped with latches, they must be bent on both sides of the unit.

After that, carefully close the door until it stops against the latches.

Next, you need to pull the door slightly towards you and up, after which it will easily detach from the stove.

To get to the brackets when repairing the Gorenje gas stove or when repairing the Darin gas stove, as well as the Brest unit, it is necessary to remove the side walls of the oven. After removing the sidewalls, you will see the brackets that are responsible for the clamp.

The brackets must be removed from the gas stove oven and visually determine in which places they are deformed

Using a hammer and pliers, you can try to straighten the deformed places. But in the event that this part is broken, it must be replaced with a new one. The stores sell different types of spare parts for repairing the oven and stove. Select the brackets that match your gas stove model.

Summing up, we can say that only the above malfunctions can be eliminated by oneself. All types of troubleshooting of the gas stove associated with the disconnection of gas supply pipes and hoses must be carried out by a gas service employee, after which he draws up an act on the repair performed. The same rule applies to connections. gas stove to the main - it should be carried out by a specialist. To carry out self-repair, it will not be superfluous to familiarize yourself with how a gas stove is arranged.

jet service

For most popular models of well-known brands, it is not necessary to remove the nozzles for subsequent cleaning. It is enough to remove the burners to open access to contaminated parts.In some cases, it may be necessary to dismantle the hob if it is of a closed type.

An ordinary needle or copper wire is suitable for cleaning the nozzle. We pass the tool into the hole and rotate it around its axis. When the needle has reached the bottom, turn on the gas and only then take it out. Thus, the jet from the nozzle pushes dust with fine dirt out. Two or three seconds is more than enough to purge.

Nozzle cleaning

If there is a problem with field service, or the design of the plate does not allow for this, the nozzle must be completely removed, cleaned, rinsed and dried. In a good half of cases, the detailed procedure is described in the operating instructions for the equipment.

Required tool:

- jets - 8 mm key (for propane 7 mm);

- fixing burners - 14 mm;

- pipeline nuts - 17 mm.

On some specific plates, the fastening may differ from that indicated. As a universal option, you can use a wrench with a variable head diameter.

jet replacement

Remove the burners, identify new nozzles for each of them. In order not to make a mistake when replacing nozzles, make a sketch of the plate. Write down the nozzle markings for each burner and refer to them as you work. On some stoves, you need to remove the top panel to get to the jets. Usually they are mounted on screws for a Phillips or straight screwdriver.

Using a socket or open-end wrench, carefully unscrew the injector and insert the prepared replacement. Proceed in the same way with the rest of the injectors.

In the oven, you need to remove the bottom panel to gain access to the jets.

Please Note: Bronze is a soft material.Too much force on the wrench can strip the threads

When finished, screw the removed panels into place, install the burners, each in its place.

We have changed the nozzles for the gas stove. Do a test. Open the valve on the bottle. To comply with safety regulations, use a soapy solution to check the quality of the connections on the gearbox and fitting. Apply a soap solution with a brush to the junction of the rubber hose and reducer. ,

If bubbles appear, tighten the clamps and check again. Do the same procedure with the joint of the fitting. Do not neglect safety when working with gas appliances. The consequences can be severe. Ignite the gas on the burners in turn. If the flame is blue, without yellow and red tints, then the work is done well.

Ignition type

All burners can be divided according to the type of ignition:

- Electronic type. They do not have a constantly working igniter. Requires electricity to operate. Electric ignition is one of the most convenient inventions for modern heating units. Thanks to him, the operation of the furnaces has become as comfortable as possible. Electric ignition makes it possible to ignite the burner flame safely, without using improvised wicks or lighters.

- Burners with piezo ignition. Electricity is not needed.

Sometimes special working conditions are required, for example, burners are installed in the sauna stove, which must distribute the flame well. These are dividers or ordinary distribution tubes. This is how kitchen gas ovens work.

The flow rate of fuel passing through the burner can vary widely and depend on its design.

Gas burners for ovens must be safe and energy efficient.This can be achieved if all technical requirements are met. Self-activity in this matter can only do harm. Therefore, the installation of gas burners must be carried out by specialists.

What gas is in household stoves. Gas stove jet: replacement features

The jet for a gas stove is a very important element that needs to be replaced from time to time. Most often, this procedure is performed if it is necessary to change the type of fuel. For example, if the old stove should be taken to the dacha and a balloon stove connected to it, although it has been working on natural all the time, then the jets should be replaced. If this is not done, then the device will begin to smoke heavily and fuel consumption will be much higher. The fact is that the presented element has a different cross section, which is intended for one or another type of combustible substance.

If the jet for the gas stove is not replaced and left in the apartment, then the burners will work very poorly. The first signs that a new nozzle is needed are the appearance of smoking or low fire. The element is a small bolt, which has holes of different diameters in the center. For example, a nozzle with a large hole is required for propane - with a small one.

Replacing the jet for a gas stove is quite simple, however, during operation, all safety rules must be observed: the supply of combustible substance must be turned off. Now you can remove all the burners and unscrew the nozzles with a special key (7 mm). This must be done in sequence. Each element has a corresponding number.

In order to replace the nozzles for gas stoves in older models, it is imperative to remove the top of the device. You won't be able to unscrew the bolts otherwise.The assembly process of the plate is carried out in the reverse order.

In addition to nozzles, the device is equipped with special nozzles that are installed in each burner. Thanks to them, the gas is sprayed. Nozzles for a gas stove have a different diameter, depending on the size of the burner. In addition, the size of the presented element depends on what kind of combustible substance is used. If the type of gas changes, then new nozzles should be installed.

Modern stove models can be sold with two sets of blowers. It should be noted that not all nozzles can be easily found on the market. Although if you have a stove from a well-known manufacturer and you contact a specialized store, then there should be no problems with the search. If the purchased elements do not fit, then you should not try to reduce or increase the diameter of the holes yourself. Qualitatively, this can only be done in the factory. In addition, you can make a mistake with the angle of inclination of the passage channel, which will lead to the wrong direction of the gas jet. In the worst case, an explosion may occur.

If there is no suitable equipment in stores, then you can contact the manufacturing plants or service centers. A socket wrench is required to replace injectors. The procedure itself is not difficult. After that, new elements can be adjusted.

So, both the nozzle and the jet for the gas stove are indispensable elements, without which the device will not be able to work. It is advisable to choose those spare parts that are intended specifically for your device.

A small part of any gas stove, without which it cannot work properly, is a jet.They have to be changed very rarely and only in the case when the incoming blue fuel is changed to the version of liquefied from cylinders instead of stationary gas. You can replace the jets in a gas stove with your own hands, only for this you need to know all the nuances of dismantling, and visually distinguish the nozzle from other parts.

All modern gas stoves can run on natural or main gas, as well as from a replaceable cylinder where liquefied gas is located. When propane is used, it is necessary to change not only the jets on the stove, but also the gearbox.

Jets are made in the form of a small bolt with a thread and a hole in the head - gas is supplied through it to the burner of the stove. Further, in the burner, it is mixed with air, this mixture is ignited, an open flame is formed, on which food is cooked.

Nozzles are available in two types: for natural gas the hole is slightly larger in diameter, and the part itself is shorter and visually different; under liquefied gas bolts are made with a longer thread.

This is what jets look like - a complete set for Hephaestus gas stove:

Important points when choosing a nozzle

Sales consultants can help in choosing a gas burner. But as you know, rely on others, but do not make a mistake yourself. Therefore, before purchasing, it is recommended to familiarize yourself with a number of points.

Room features. First and foremost is the area. If it is less than 12 sq. m., then it would be more reasonable to buy a supercharged type, if more - atmospheric

Ventilation also plays an important role. If the speed and volume of air circulation leaves much to be desired, it is worth purchasing a pressurized gas burner.

Furnace type

If the stove only runs on gas, you must purchase an atmospheric version. In other cases, the supercharged variety is perfect.

Power. The expression “the higher the power, the better” does not fit here. This value should be calculated based on the area of \u200b\u200bthe room. So, for 10 sq. m. requires 1 kW of energy.

Producing country. When choosing gas equipment, it should be remembered that foreign products are of better quality and more durable than domestic ones.

Therefore, first of all, it is recommended to pay attention to American, German and Italian nozzles.

The purchase of a gas nozzle will first of all help to strengthen the financial situation, and only then free you from the constant running around with firewood or coal. A gas stove is a very convenient and practical invention, but you must remember about the explosiveness of this fuel. Therefore, you should not buy the cheapest and low-quality products.

to

Installation of an air duct for a kitchen hood. An air duct is an element that connects a kitchen hood with a ventilation shaft. Its purpose is to remove the exhaust air generated during the cooking process outside the premises.

Installing an air conditioner: recommendations for choosing the location of the unit and the sequence of work. The key to reliable operation of the air conditioner for a long time is the correct installation, as well as the quality of the components from which the structure is made.

The design and principle of operation of water heaters. Home improvement with an autonomous hot water supply system involves the installation of a device for heating water.As a rule, the design features of the water heater directly affect the way the equipment is operated.

Microwave oven design. A microwave oven is a universal device for quick preparation of a hot sandwich, dietary food without oil or warming up ready-made meals. Thanks to many advantages, the device has gained wide popularity all over the world and, according to

Possible malfunctions

Summarizing the story about the device of HBO injectors, it would not be out of place to pay attention to their possible malfunctions. In fact, there are few of the latter, or rather, only three:

- The first option is the nozzles or some of them are out of order. The problem is solved by disassembling, cleaning and, if possible, repairing faulty elements. If this approach did not give an effect, then you will have to install new nozzles;

- The second option - there was a malfunction in the system "injectors - control unit". The malfunction can be eliminated by “ringing” the network and setting up the equipment “on a new one”. Often a problem of this nature is solved through an appeal to the HBO master;

- The third option - the nozzles are simply clogged. The easiest way to get rid of this “breakage” is to remove the dispensers, disassemble them and clean them thoroughly.

Note that on older generations of LPG (up to 3) there may be problems with the confrontation of the car’s mono power systems with gas equipment. It seems possible to solve them by introducing an injector emulator into the HBO system (the most preferable choice is an instance from BRC).On most of the third and all subsequent HBOs, the conflict between mono-power systems and equipment is resolved automatically in the control unit, so such a omission of equipment cannot happen with them.

Any malfunction of the injectors is indirectly manifested by the following symptoms:

- instability of the motor;

- loss in power and dynamics;

- inability to switch to gasoline;

- increased fuel consumption;

- failures in the operation of the engine while driving.

In general, on the issue under consideration today, the most important provisions have been successfully considered. We hope that the above material was useful to you. Good luck on the roads!

Popular injector malfunctions

Usually the jets last a long time. Their replacement is required when switching to a different type of gas or in the event of a manufacturing defect. More often there is a need to clean them from soot and clogging.

The following manifestations are associated with clogged nozzles:

- the stove smokes, instead of an even blue flame, red-yellow tongues appear above the divider;

- one of the burners does not light up;

- the burner does not burn well, sometimes it goes out;

- when the button (knob) is released, which turns on the ignition device, the oven flame goes out or does not ignite at all - this happens when, due to insufficient gas supply, the generated heat is not enough to heat the temperature sensor, and the fuel supply is automatically shut off by the gas control system.

Replacement of a separate nozzle is required if the gas burns so intensely on the burner that the flames come off the divider. This happens in the case of a factory marriage. If a similar picture is observed on all burners, it is worth checking the gearbox.

You will need a few tools for work related to nozzles: a set of open-end and box wrenches, a Phillips screwdriver, a thin needle (it is better to attach it to the end of a pencil), wire or fishing line. A soapy solution or other liquid dishwashing detergent is also useful for cleaning. Abrasives must not be used!

The most commonly needed keys are:

- for old jets - 8 mm (for liquefied gas - 7 mm);

- for burner nuts - 14 mm;

- for the tip of the pipeline of the oven - 17 mm.

However, since the plate designs are different, other wrenches may be needed. Therefore, it is more rational to stock up on their full set.