- Jets for a gas stove: bottled gas and natural gas - the difference, how to replace

- How to convert a gas stove to bottled or natural gas

- Choosing household chemicals

- Safety Precautions When Replacing the Injector

- How to clean nozzles?

- Required Tools

- How to change nozzles on a gas stove

- How to determine the correct operation of the gas stove

- Choice of nozzles

- Safety Precautions When Replacing the Injector

- Product cost

- Instructions for replacing hob and oven jets

- Instruction # 1 - replacing the nozzles of the hob

- What is a jet?

- Types of jets and their main characteristics

- Nozzle cleaning technology

- What is a gas jet

- Conclusions and useful video on the topic

Jets for a gas stove: bottled gas and natural gas - the difference, how to replace

Most gas stoves are capable of running on both natural and liquefied gas. To do this, the manufacturer supplies the device with two types of jets. Typically, household appliances are initially configured to be connected to the gas main. To convert it to bottled gas, you should change the nozzles. If this is not done, the stove will not work correctly, which is dangerous for users.

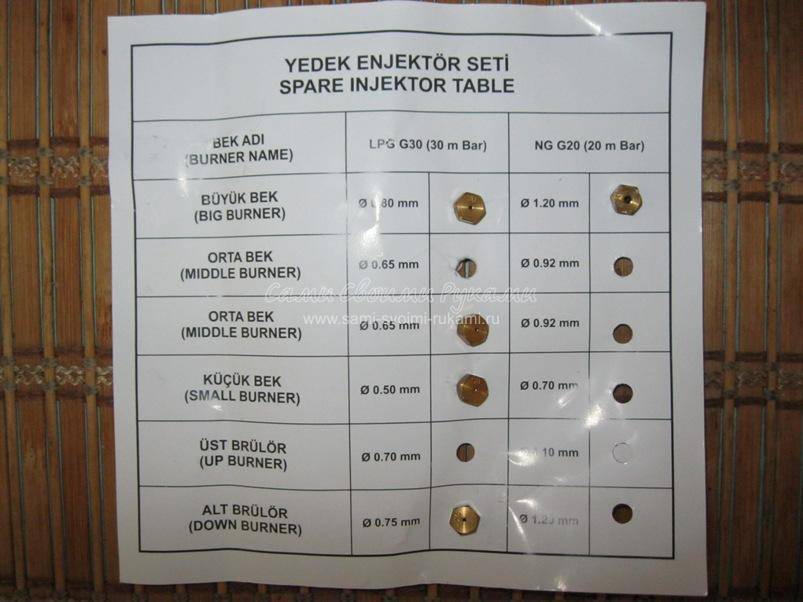

How to convert a gas stove to bottled or natural gas

From the central gas supply system, natural gas is supplied to the kitchen, usually NG G20, which is supplied to the device at a pressure of 20 mbar. Liquefied gas is used for cylinders, LPG G30 is the most common. It enters the device at a pressure of 50 mbar. The combustion of gas-air mixtures is not the same due to differences in composition and pressure. To equalize the flame and prevent the appearance of soot, jets of certain sizes are installed in the burners.

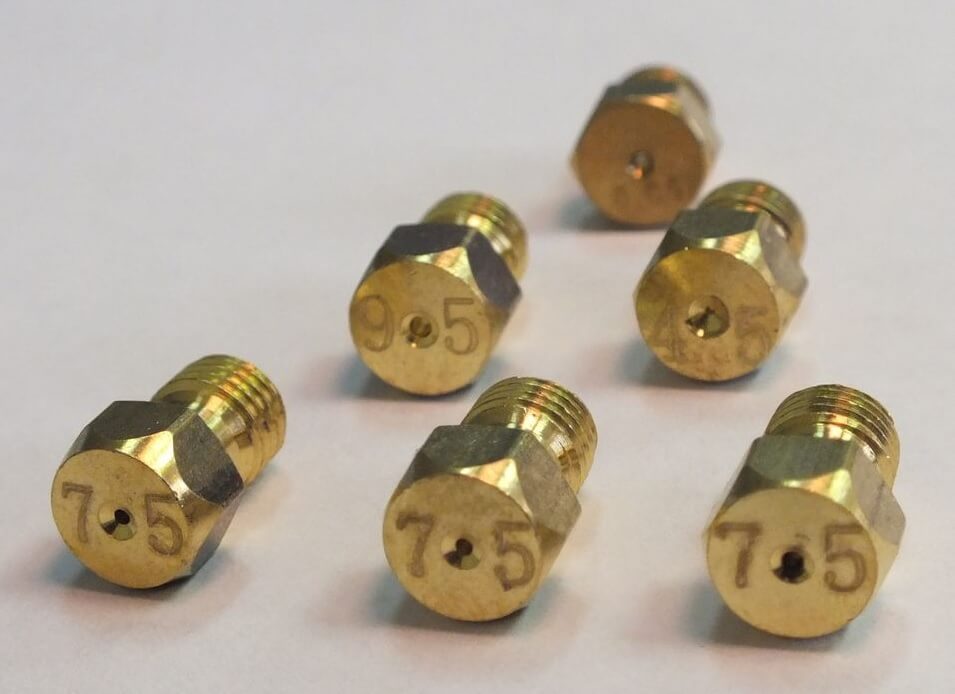

The nozzle (nozzle or nozzle) is usually made of bronze or brass. It looks like a threaded bolt, but only with an internal hole through which fuel is supplied. The larger it is, the more gas flows through it. At the end of the nozzle, numbers are knocked out that indicate the diameter of the hole in hundredths of a millimeter. For example, the number 75 means that the diameter of the hole is 0.75 mm, and the number 115 corresponds to the diameter of 1.15 mm.

Choosing household chemicals

No matter how trite it may sound, a gel-like dishwashing detergent is a good helper in the fight for the cleanliness of a gas stove. It is well washed off, does not scratch glass-ceramics, enamel, steel, excellently breaks down fats.

However, dishwashing gel only helps with simple stains. If the situation is running, take a walk through the department of household chemicals. Manufacturers offer a number of special formulations for washing gas stoves. These are thermonuclear chemicals, which are presented in several forms: pastes, sprays, aerosols. After their application, the decomposition of proteins and fat deposits begins, and the surface remains to be wiped with a clean cloth.

The standard restriction applies to metal washcloths, brushes, abrasive powders.All of these handy tools lead to the formation of scratches and chips, which exacerbates the accumulation of dirt and subsequently causes corrosion.

I note that among all household chemicals there are those that contain silicone. This is a very useful supplement. It forms a thin layer on the surface that protects it from pollution.

Safety Precautions When Replacing the Injector

Therefore, do not neglect a number of rules:

- Before replacing jets, disconnect the stove from gas and electricity.

- Make sure the burners are cool.

- Before starting work, open windows, turn off devices that run on electricity that can give a spark.

- Do not engage in self-modification of plate parts or replace them with non-native, unsuitable sizes or made by yourself.

- After mounting the parts, be sure to check all gas connections for possible leaks. To do this, the compounds are washed from all sides (with a brush or sponge) and, by turning on the gas supply, observe whether bubbles form. If a leak is detected, the connection is either tightened or disassembled and reassembled.

Do not use nozzles designed for gas burners of stoves of a completely different design or other gas devices.

You should not replace the nozzles in the gas stove yourself if you are unsure of your capabilities.

How to clean nozzles?

It is recommended to periodically clean or change the nozzles - this is an integral part of maintenance procedures that must be carried out at least 1 time per year. The delay in cleaning leads to a deterioration in the burning of the flame: the appearance of yellow tints, smoking, a decrease in the thermal coefficient and other undesirable consequences.In order to clean the nozzles, you will need the following:

- cleaning products: vinegar, soda or detergent;

- old toothbrush;

- thin needle.

Cleaning is done as follows:

- the area where the jet is located is cleaned of soot, fat, plaque and other foreign substances;

- the nozzle is removed - it can be unscrewed using a socket head of the appropriate diameter, equipped with an extension cord (the jet may be located deep in the body, which makes it difficult to unscrew it with a conventional wrench);

- the cleaning object is soaked in a solution of soda, vinegar or cleaning agent for a while (depending on the degree of contamination);

- the outer surface is cleaned with a toothbrush with a cleansing kitchen powder;

- the inner hole is cleaned with a thin needle; in some cases, purging with a compressor or pump is effective (a car one is enough).

After cleaning is completed, the jet needs to dry well. At the end of drying, its hole should be visible through the light, and there should be no foreign rubbish in it. The reverse installation of the nozzle is carried out in the opposite order to the disassembly. If there was a sealing gasket under the jet, you need to replace it with a new one.

Required Tools

The replacement of jets should be entrusted to gas service specialists who have the necessary knowledge and qualifications and will be able to correctly adjust the gas supply when switching to another fuel. It is not recommended to redo the gas stove on your own.

If the user decides to change the nozzles with his own hands, he will need the following tools:

- crosshead screwdriver;

- a set of open-end and box wrenches.

How to change nozzles on a gas stove

First, the stove is disconnected from the gas, if it was connected. After that, they act according to the following algorithm:

- Remove the top cover of the gas stove by unscrewing the screws to get to the burner.

- Then they find the retainer, squeeze its ends and carefully pull it out. After that, tips with nozzles are removed from the traverse with burners.

- The tip is released from the socket and removed from the gas pipeline tube. The sealing ring is removed from it and put on the tube.

- The jets are unscrewed with a socket wrench counterclockwise. New ones are installed in their place.

- Perform reverse assembly. The accuracy of the reassembly depends on how evenly the burner will burn.

It is easier to change modern models of gas stoves for other fuels. To gain access to the burner, only grates with burners are removed in them. Then the tips are removed and new nozzles are installed.

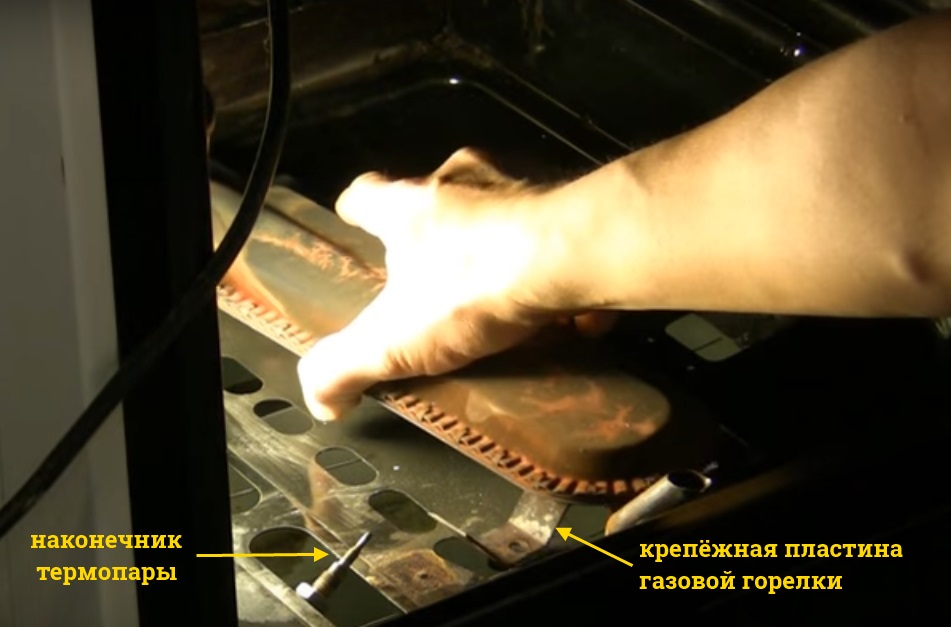

The replacement of jets in the oven is carried out as follows:

- open the oven door and the lower compartment of the device;

- pull out the floor of the oven compartment;

- unscrew the burner fasteners;

- carefully, so as not to strip the thread, unscrew the jet (it is located on the left in a special case);

- install a new nozzle and reassemble.

If during the operation the jet managed to boil, unscrew the three fastening screws and remove the left side wall. With a 17 key, unscrew the nut and take the pipeline to the side. Then unscrew the two screws that secure the nozzle body to the wall. The stuck thread is treated with WD-40 or kerosene and the jet is unscrewed.A new one is installed in its place and the oven is mounted in the reverse order.

After replacing the jets, the plate is connected to a cylinder or central gas supply using a flexible connection. If the equipment is connected to a gas main, one end of the hose is connected to the gas pipe through a plumbing fixture or fitting. The winding is preliminarily washed on the thread of the drive in a clockwise direction. An o-ring is inserted into the hose nut. The parts are connected and tightened with a gas wrench. The other end of the flexible hose is connected to the exit thread of the plate, using linen or fum tape when fastening.

If the device needs to be connected to a cylinder, one end of the flexible hose is connected to the stove nozzle through a fitting and secured with a worm clamp. The other end is attached to the gearbox and also tightened with a clamp. The reducer is connected to the cylinder using paronite gaskets; while it should be horizontal. Fasteners are tightened with an open end wrench.

Then check the tightness of the connection. All joints are smeared with soapy water and gas is released. If the soap does not foam, then there are no leaks. After that, the gas is lit in turn in the burners. A blue flame without yellow or red hues indicates that the work has been done correctly.

How to determine the correct operation of the gas stove

When igniting the burner, there should be no extraneous sounds in the form of pops. The flame should burn evenly, its tongues should be bluish-white in color, it is not for nothing that the gas is otherwise called "blue fuel".

If, during the combustion of the air-gas mixture, yellowish impurities are observed, and the flames acquire a red tint, then this clearly indicates a malfunction of the jets.

Yellow and red flames are evidence of incorrect operation of the nozzles.

Yellow and red flames are evidence of incorrect operation of the nozzles.

When transferring the stove from main gas to bottled gas, all of the above disadvantages are very characteristically manifested. And plus, due to improper pressure, soot will be observed. So it is difficult to notice it immediately with the naked eye, but it will manifest itself in the form of black spots on the dishes after 1-2 days of operation.

Avoiding all these troubles is quite easy. It is necessary to choose the right nozzles for a gas stove when operating conditions change and conversion to bottled gas. In this case, it should be borne in mind that due to the difference in pressure of the incoming fuel, the diameter of the holes in the nozzles (jets) will also be different.

Choice of nozzles

Each gas equipment has its own characteristics, so it is important to select nozzles individually for each generation of LPG. Many motorists raise the question "Which nozzles for HBO are better?". In the case of gas-balloon equipment, this wording is initially incorrect, because the well-known proverb applies to it: what is good for a Russian is death for a German

Naturally, the saying should be rephrased for gas equipment and understand that for one generation, specific nozzles can be simply ideal, but not able to work with another.

In the case of gas-balloon equipment, this wording is initially incorrect, because the proverb known to many applies to it: what is good for a Russian is death for a German. Naturally, the saying should be rephrased for gas equipment and understand that for one generation, specific nozzles can be simply ideal, but not able to work with another.

In order to make a competent choice of nozzles, it is enough to adhere to the following points:

- First, find out what generation your gas equipment is. In the selection process, this plays an important role, because each type of HBO has its own nozzle standards. So, for the first generation, the EURO safety standard is applied, for the second - EURO-2, for the third, fourth, fifth and sixth - EURO-3 and higher;

- Second, determine the number of nozzles needed. It should be noted that for HBO generations 1-3, it is permissible to purchase nozzles separately. In the case of older versions of equipment, it is recommended to buy ready-made kits. This approach will help to avoid problems in the further configuration of the equipment;

- Thirdly, check the connection method and other technical features of your HBO regarding injectors;

- And fourthly, when choosing new dispensers, give preference to trusted manufacturers. At the moment, they are deservedly considered Valtek, BRC, Digitronic, Rampa, Barracuda and Lomato. Moreover, the same BRC and Lomato produce their own LPG, so it is quite possible for their owners to avoid difficulties in selecting new nozzles by telling the seller only the model of their equipment.

Safety Precautions When Replacing the Injector

Ensuring that the replacement can be carried out safely is of the utmost importance when performing gas-related activities.

Therefore, do not neglect a number of rules:

- Before replacing jets, disconnect the stove from gas and electricity.

- Make sure the burners are cool.

- Before starting work, open windows, turn off devices that run on electricity that can give a spark.

- Do not engage in self-modification of plate parts or replace them with non-native, unsuitable sizes or made by yourself.

- After mounting the parts, be sure to check all gas connections for possible leaks. To do this, the compounds are washed from all sides (with a brush or sponge) and, by turning on the gas supply, observe whether bubbles form. If a leak is detected, the connection is either tightened or disassembled and reassembled.

Do not use nozzles designed for gas burners of stoves of a completely different design or other gas devices.

You should not replace the nozzles in the gas stove yourself if you are unsure of your capabilities.

Product cost

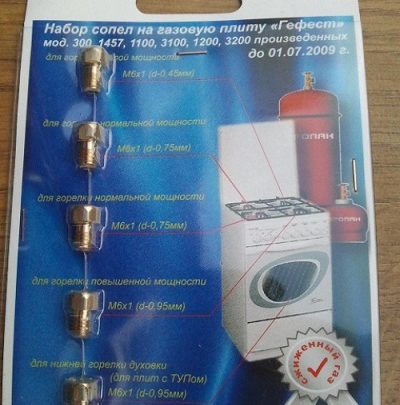

Basically, all manufacturers complete new furnaces with a set of jets for transferring to another fuel. But if for some reason you need to purchase a separate set of nozzles, you can do this in specialized gas equipment stores. Also, nozzles are available for free sale on Internet resources. For reference, below is a list of average prices for jets for gas stoves from some popular manufacturers:

| Gefest | 400 r |

| Moravia 1436 | 650 r |

| Indesit | 650 r |

| Hansa | 650 r |

| Flama | 550 r |

| Darina | 700 r |

| Ricci | 590 r |

From the above, it follows that the operation to change the jets is not complicated and is quite within the power of any person without special education. And installing the right nozzles will not only save gas fuel consumption, but also save the room from soot and unpleasant odors.

Instructions for replacing hob and oven jets

Next, consider the detailed replacement instructions nozzles on the stove, as well as the oven.

Instruction # 1 - replacing the nozzles of the hob

Further on what to do and how to replace the injectors on the gas stove. Since the designs of gas stoves vary, consider some of the most typical options. In the designs of new modifications, access to the nozzles is facilitated (it is enough to remove the burners). Other common models are of interest.

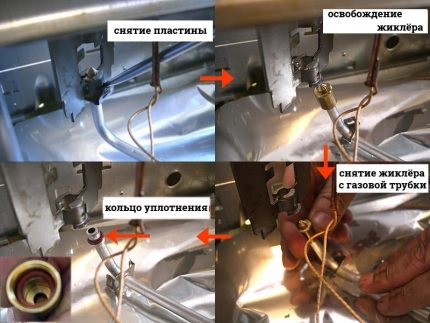

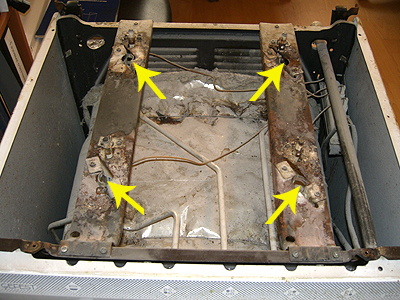

According to the device of the burners, some models of the stoves "Hephaestus" and "Darina" are similar. To replace the nozzles of the cooking part of the Hephaestus stove, a series of steps are performed in sequence.

Step 1. Remove the grate from the stove, dismantle all burners.

Step 2. Having unscrewed the fastening screws, remove (raise) the top panel. Darina has latches that are released with special stops from the plate kit.

Step 3. To release the burner, use a Phillips screwdriver to unscrew the two screws that secure its structure.

Step 4. Using a flat-blade screwdriver, remove the retainer (curved plate) from the side of the faucet handle, releasing the tube supplying gas to the burner. Take the phone aside.

Step 5. Unfasten the second end of the tube from the seat by removing the fixing plate with your fingers or with the help of pliers (in "Hephaestus") / screwdriver (in "Darina").

Step 6. In the Gefest plate, the end of the gas tube is connected to the nozzle through a transitional cone (a sealing ring is installed on the tube under the cone). Throw a key (on 14) onto the hexagonal pad of the cone, in order to hold and not damage the tube when unscrewing, with the second key (on

Step 7. Having unscrewed the old nozzle, replace it with a new one, lubricating the thread with graphite grease. The sealing ring is also replaced, which is convenient to do with a match. Use a 7 key to tighten.

Step 8 Assemble the entire assembly in reverse order.

A similar operation is performed for the remaining burners of the hob.

Taking advantage of the fact that the upper part of the unit is opened, it is cleaned of debris and dirt. In addition to replacing nozzles, screws can also be replaced in stoves to control low gas flow (or low flame). They regulate the reduced gas supply, sufficient so that, with a minimum gas supply, the flame on the burner does not die out.

What is a jet?

The jet is one of the main components of the gas stove. It ensures the supply of blue fuel to the burner in sufficient volume and the required pressure. Without a nozzle, the operation of a gas stove would generally be impossible.

Deviations in the work of the jets are immediately visible, they are noticeable by yellow and red flames and soot on the dishes

Deviations in the work of the jets are immediately visible, they are noticeable by yellow and red flames and soot on the dishes

In its shape, the jet resembles a bolt, in the head of which a through hole is arranged. The diameter of the hole must correspond to the pressure of the supplied fuel and the power of the burner.

It must be taken into account that the pressure of the main gas and bottled gas is significantly different, therefore the diameter of the nozzle for these types of fuel will be different. The jet regulates the pressure and ensures the flow of gas into the burner in the required volume, equivalent to the volume of air required for the normal combustion process

The jet regulates the pressure and ensures the flow of gas into the burner in the required volume, equivalent to the volume of air required for the normal combustion process

The jet regulates the pressure and ensures the flow of gas into the burner in the required volume, equivalent to the volume of air required for the normal combustion process

In order to ensure the most efficient operation of the stove, to exclude the release of harmful products, the smoking factor, to normalize fuel consumption, it is necessary to install nozzles, the dimensions and diameter of the outlet of which meet the requirements of the gas stove manufacturer.

Types of jets and their main characteristics

Jets or nozzles with a hexagonal head, external thread and a longitudinal internal hole. Most of them are made of bronze.

Jets for main and bottled gas differ in thread length and diameter of the gas supply channel, which is associated with different fuel supply pressures

Jets for main and bottled gas differ in thread length and diameter of the gas supply channel, which is associated with different fuel supply pressures

On the end part there is a marking that displays information about the throughput of the nozzle. Units of measurement - the volume of gas in cubic centimeters that the jet is able to skip in 1 minute.

Jets can be of two types - for natural gas (they have a large hole diameter and a shortened body), for liquefied gas (they have a smaller hole diameter and an elongated body, which is associated with higher pressure).

The pressure in the cylinder exceeds the pressure in the gas line, which explains the smaller diameter in the head of the corresponding jet. The power of the burner is determined by its size, therefore, the diameters of the holes in the corresponding jets will be different.

The diameter of the hole in the nozzle must correspond to the gas pressure:

- Large burner - 1.15 mm (20 bar); 0.6 mm (50 bar); 1.15 mm (20 bar); 0.75 mm (30 bar).

- Medium burner - 0.92 mm (20 bar); 0.55 mm (50 bar); 0.92 mm (20 bar); 0.65 mm (30 bar).

- Small burner - 0.75 mm (20 bar); 0.43 mm (50 bar); 0.7 mm (20 bar); 0.5 mm (30 bar).

- Burner in the oven - 1.2 mm (20 Bar); 0.65 mm (50 bar); 1.15 mm (20 bar); 0.75 mm (30 bar).

It must be taken into account that the incorrect operation of the jets can be caused not by a change in the type of fuel, but by a banal clogging of the outlet. In this case, you can clean the nozzles without resorting to replacing them.

Nozzle cleaning technology

From time to time you have to change the nozzles or clean them. The recommended frequency of the procedure is once a year.

Clogged nozzles impair the quality of the flame, leading to a decrease in the amount of heat generated. In addition, fuel consumption increases, which is undesirable for owners of liquefied gas equipment. This fact will not suit homeowners with installed gas meters.

To clean the jets you will need:

- Universal means - soda or vinegar, dishwashing detergent;

- dish cleaner;

- Toothbrush;

- Thin wire or needle.

Work begins with the removal of soot, soot and fat from the area of \u200b\u200bthe jet. The nozzle must be unscrewed and soaked in detergent, in a solution of soda or vinegar.

To clean the nozzles, no special tools are required, it is enough to have a thin wire, a toothbrush and detergent on hand.

To clean the nozzles, no special tools are required, it is enough to have a thin wire, a toothbrush and detergent on hand.

The outer surface can be cleaned with a toothbrush using regular household scouring powder. The nozzle opening should be cleaned with a needle, blowing with a pump or compressor is sometimes justified.

The cleaned and dried jet must be reinstalled

In this case, it should be noted that if there is a sealing gasket under the jet, it is necessary to replace it

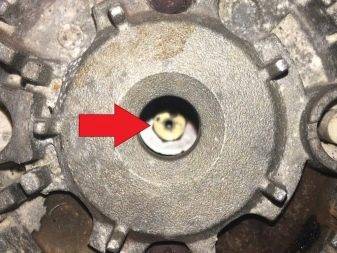

What is a gas jet

Jet (nozzle) - a part through which a gas-air mixture for a flame is supplied to the burner of a gas stove.

The jet for a gas stove in the center has a hole of a certain diameter. The value of the diameter (in hundredths of a millimeter) is necessarily stamped on the end (face) of the jet. For example, the number 135 on the edge of the nozzle means that the hole for the passage of the gas-air mixture has a diameter of 1.35 mm.

Jet (nozzle) for a gas stove

The diameter of the jets depends on the power of the particular burner and the type of gas that the stove is set to. So, we approached the questions of what nozzles are for, and what features the stoves have, depending on the type of gas supplied.

Conclusions and useful video on the topic

Replacement of jets in the Gefest gas stove:

The jets are the main element of the gas stove, they are responsible for the pressure and volume of the incoming fuel, providing an optimal combustion mode.

In Gefest stoves, it is not as easy to replace jets as in modern models from more popular manufacturers. However, with strict observance of the instructions, the work will not cause any particular difficulties. Yes, and replacement is within the power of any person, there is no need for special knowledge or special tools - just care, accuracy and observance of elementary rules.

Tell us about how you changed the nozzles in the stove with the Hephaestus logo with your own hands. Share the nuances of the process that you know. Please leave comments in the block below, ask questions, post thematic photos.