- Drum bearing: the weak point of the washing machine

- Disassembly process

- Dismantling or sawing the tank

- Step by step replacement of worn bearings

- Replacement and repair

- Replacing the bearing on the drum of a front-loading washing machine

- Contacting a specialist

- How much does it cost to replace a bearing?

- Removing the tank from a Samsung car

- Removing covers

- We disassemble the tank, change the bearings

- Required Tools

- pliers

- Open end wrenches in various sizes

- A hammer

- A metal rod with a pencil diameter or a blunt chisel

- Phillips and slotted screwdrivers

- Replacing a bearing in a Bosch washing machine. Replacing bearings in a Bosch Max Classic 5 washing machine at home

- How to replace

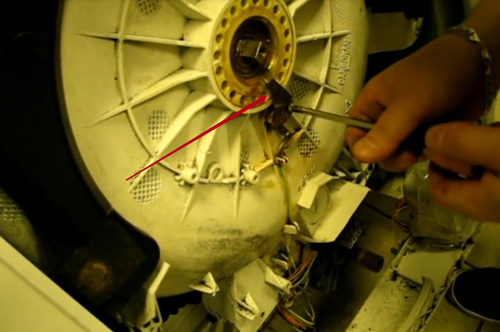

- Dismantling the pulley and motor

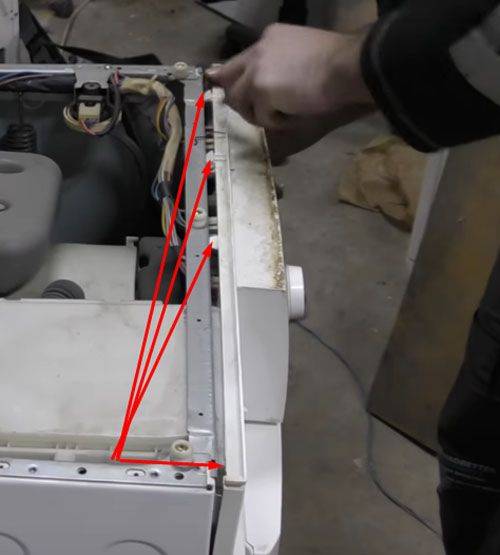

- Removing the top cover

- Removing the drum

- Removing and replacing bearings

Drum bearing: the weak point of the washing machine

A washing machine is a rather complex household appliance and it works in high load mode. The most vulnerable point of this domestic worker is the drum bearing - a part due to which, in fact, the washing process in the machine takes place.It is very easy to understand that the time has come to change it: if there is a faulty bearing, the unit begins to make extraneous sounds during operation, which, if nothing is done, increase over time.

But that's not the most annoying thing. If the bearing fails, the drum stops working normally. And this means that very soon the washing machine will finally break down, and you will have to pay quite a lot of money for its overhaul.

The average service life of a quality drum bearing is 6-8 years. However, due to improper use of the machine, destruction of the oil seal, corrosion due to leakage, etc. it breaks much faster. That is why the unit should not be overloaded: in most cases, the causes of bearing failure are increased friction intensity and, as a result, excessive heating of the structural elements of the part.

Disassembly process

Having prepared for the repair, you can begin disassembly. The disassembly scheme is as follows:

- Remove the top cover. It is attached with two bolts on the back of the case. Slide the lid back, lift up and set aside.

- Remove two more panels: top and bottom. The instrument panel can only be removed after removing the plastic powder flask.

To remove the intake, pull it all the way out and hold down the button in the center, pulling the cuvette towards you. The dashboard is fastened with screws (their number and location depends on the model of the machine). Unscrew the fasteners and remove the tidy.

Under it you will find the control board - from it comes a whole bunch of wires. You can disconnect them all by first taking a picture of the contacts, or you can carefully hang the panel on the service hook.

The bottom panel is removed with a thin screwdriver or other object that can be used to release its latches. - Remove the hatch cover. Without this action, you will not remove the front of the case, which is essential for disassembling the machine. The rubber band is attached with a clamp, find it and pry it with a slotted screwdriver to remove it. Direct the free part of the cuff inside the body.

- Remove the front part of the housing by unscrewing the screws. When removing the panel, do not make sudden movements so as not to break the wire.

- Remove the UBL wire, set the panel aside.

- Disconnect other parts: detergent box by twisting the bolts. Together with the powder intake, you will also remove the filling valve. But first, remove the wiring from the valve and disconnect the pipes by opening the clamps.

- Carefully pull off the drain pipe by loosening the clamp. On some machine models, the nozzle is accessed through the bottom, so you may need to lay the CM on its side.

- Disconnect the heating element from the wiring (the location of the heater in different models is different - it can be in front, behind and even on top).

- Remove the wiring from the electric motor.

- If you see that the drain pump is interfering with you, disconnect the wires and remove the pump.

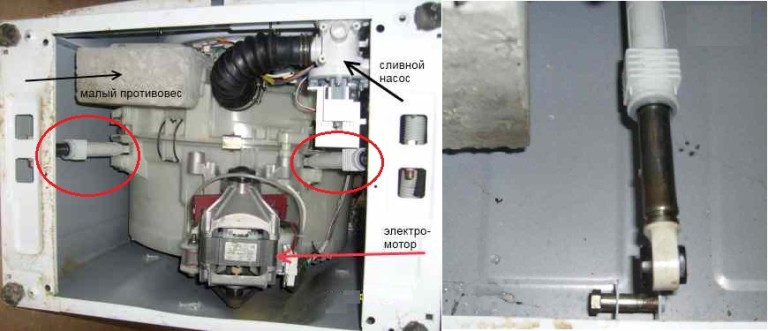

- Unscrew counterweights (large and small "stone" at the top and bottom of the tank). These elements can also have a different location - be installed both in front and behind.

- Disconnect the pressure switch connector.

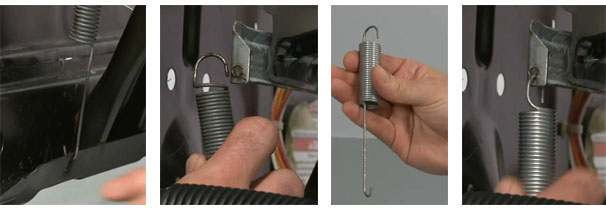

- Remove the shock absorbers by unscrewing the fasteners (you will need a wrench, but it is most convenient to work with a head with an extension).

- Remove the tank from the springs. The tank is not too heavy, but it is inconvenient to remove it, so it is better to ask for help. One person holds the tank, the second disconnects the springs.The tank is removed together with the electric motor, which can be removed after removing the tank.

- Unscrew the shock absorbers remaining on the tank.

The next step is to replace the tank bearing. We will consider in detail the scheme and sequence of actions.

Dismantling or sawing the tank

The bearings can only be accessed by dismantling the tank. If the halves of the tank are fastened with bolts or latches, then there will be no difficulties. But if the bearings are in a non-separable tank, you will have to saw it.

In this case, pre-drill holes through which you will then fasten the tank, you will also need a good waterproof glue. Washing in a glued bin is risky, but cutting the bin is easier and more profitable than buying new parts or a new car.

Sawing can be done with a regular hacksaw.

Then follow this instruction:

- Disconnect the drum. To prevent the pulley from interfering with this, you need to remove it. Remove the bolt holding the drum pulley, remove it from the axle and set it aside. Screw the unscrewed bolt into the shaft again so that, knocking out the drum, do not break the shaft and complicate the repair.

- Using a normal hammer, use a little force to strike the shaft to knock it out. If the shaft goes easily, then calmly continue to apply light blows. If you see that your efforts are in vain - unscrew the factory bolt and take any unnecessary one, because after deformation it will need to be thrown away. When the shaft reaches the bolt head, remove the mount and remove the drum.

- Perform a thorough inspection of the bushing and shaft. If you put off repairs for a long time, then the elements could wear out, and the crosspiece will need to be replaced. The integrity of the shaft is checked by the presence of wear on it - to see it, wipe the part thoroughly.Put new bearings on the shaft, if there is play, then the cross and the shaft must be replaced.

The bushing needs to be checked for wear or grooves that shouldn't be there. If there is too much wear, it is better to change the bushing with a new one.

Step by step replacement of worn bearings

The case is gradually moving towards completion, and soon it will be possible to get rid of the faulty bearings, but there are still a few preliminary steps ahead.

Now you need to carefully disconnect the drum from the back of the tank - a responsible operation that needs increased attention. First you need to get rid of the fasteners holding the pulley. The tank is turned over with the pulley up, the bolt fixing it to the shaft is disconnected.

When the pulley is removed from the axle, the unscrewed bolt is returned to its place in order to avoid damage to the shaft when the drum is knocked out.

The tank is turned over with the pulley up, the bolt fixing it to the shaft is disconnected. When the pulley is removed from the axle, the unscrewed bolt is returned to its place in order to avoid damage to the shaft when the drum is knocked out.

First you need to get rid of the fasteners holding the pulley. The tank is turned over with the pulley up, the bolt fixing it to the shaft is disconnected. When the pulley is removed from the axle, the unscrewed bolt is returned to its place in order to avoid damage to the shaft when the drum is knocked out.

The shaft is removed gradually, by gentle tapping of the hammer.

Some experts advise inexperienced craftsmen to use a rubber mallet in this case, so as not to inadvertently flare the bearing seat

If the shaft is fed little by little, the work is continued patiently. If the result is negative, before increasing the effort, the standard bolt should be replaced with one that is not a pity to throw it away in case of deformation.

When the position of the shaft is equal to the head of the bolt, the latter is unscrewed, the drum is pulled out.

Such a drum shaft must certainly be cleaned to a shine and only then returned to its original place. You can additionally treat the surface with anti-corrosion paint

The bushing located on the shaft must also be free of defects from wear and mechanical damage.

Pronounced transverse grooves eloquently say that the stuffing box on such a bushing will not be able to protect the bearing from moisture, and, therefore, repeated repairs are inevitable.

Before removing the bearings, the seal must be removed. The operation is elementary: pick up with a flat screwdriver and remove. If it doesn’t work out right away, you will have to soak it with a penetrating lubricant.

There will be no trouble if the oil seal breaks, it still needs to be replaced.

The tank is placed on wooden blocks, and the turn of work comes with a metal rod or a blunt chisel. Having attached the pin to the worn bearing, they hit the part with a hammer.

Subsequent blows are applied in a circle until the part is knocked out. During operation, it is necessary to ensure that the bearing does not warp. Remove the outer bearing first.

Tank - the part is quite fragile, so many craftsmen, in order to avoid breakage, knock out the bearing by placing the container on their knees or a soft base

In the same way, get rid of the second bearing. Strikes should be accurate and not strong. And yet, this procedure is quite noisy, so the neighbors will be grateful to the home craftsman if he finds an opportunity to do it outside the walls of the house.

Now nothing prevents you to install serviceable bearings. Initially, this is done with what is smaller.

A metal rod will help here too: it is alternately applied to the bearing from opposite sides and guided with careful hammer blows to the right place.

The fact that the part is placed correctly will be reported by the sound: it will become much louder. The larger bearing changes in the same way.

When installing new bearings, craftsmen use the same tools: a hammer and a metal rod. you can use other convenient mounting devices

It remains to install a new seal. First of all, it must be treated with a lubricant created specifically for washing machines. Only then can it be placed in its proper place.

The lubricated tank shaft is installed at the same address - in the back cover. Before connecting the halves of the tank, it is recommended to replace the sealing gum with a new one. In extreme cases, fill the groove along with the gasket with a layer of sealant in a circle.

It is not superfluous to first make sure that the tank is tight by pouring water there above the gasket. If it does not flow out, then everything is done correctly, the work on replacing faulty bearings has been successfully completed

It remains to collect the car. Do this by following the reverse order of disassembly. And here the photographs that he took when disassembling the unit will provide an invaluable service to the home master.

Replacement and repair

Self-pressing bearings is a technically simple operation. However, in reality, replacing a damaged bearing can be difficult due to deposits of rust and various kinds of contaminants that partially hide the cage.

Experts recommend that, before proceeding with the dismantling of old bearings, thoroughly clean the surface of any contamination, including using special rust removers, such as WD-40.

In order to independently dismantle the bearing block, the front of the tank is installed on a non-rigid surface upside down, it can also be placed on your knees. Some masters recommend the latter option as the safest.

With weak, but accurate blows, gradually moving in a circle, it is necessary to knock out the bearing with a chisel or a blunt steel pin. First, the outer large bearing is removed, and then the inner one is small.

It is important to hit the bearing hub without touching the edge of the seat in order to avoid rolling it. When the old bearings are removed, the seat must be treated with a rust remover and thoroughly wiped to remove any contamination.

Installing new parts is in reverse order. First you need to put the inner small bearing, and then the outer one - large. Further assembly of the washing machine occurs in the same way - according to the reverse scheme.

Changing the bearings of a top-loading washing machine is much easier. In such units, it is not necessary to remove the motor and other important parts. There is no need to prepare a large set of tools. New parts are purchased in duplicate, they are plastic blocks - calipers with a mounted bearing and oil seal

It is important to remember that the right and left calipers are not interchangeable, and you need to purchase the kit. Bearing blocks are removed from the drum shafts with a screwdriver

New calipers are installed in their place and fixed with screws. To do this, again, a simple screwdriver is enough.

Replacing the bearing on the drum of a front-loading washing machine

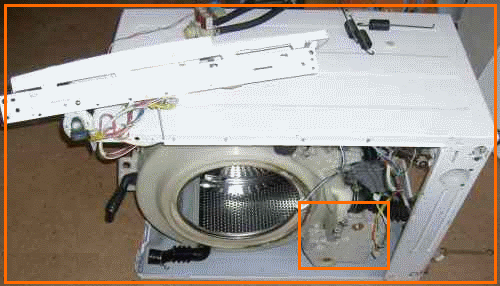

In this case, the process is complicated by the fact that you have to get the drum out of the device. We will consider the sequence of actions using the example of disassembling a Samsung washing machine. This is a standard model, therefore, according to the same principle, it will be possible to replace bearings in devices from another manufacturer.

Table number 1. Bearing Replacement Instructions

Step, illustration

Process description

Step 1. It is necessary to determine the model of the washing machine

There is usually a special sticker on the back wall of the structure, which indicates all the characteristics of the device. Using this information, you can purchase new bearings and seals without first dismantling the machine.

Step 2. Now you need to study the design of the device in order to proceed with the analysis

Since the back panel is not unscrewed here, all work will be done from the front. However, this is not difficult to do.

Step 3. Unscrew the top cover

Before starting work, you will need to disconnect all elements, including the powder tray.

Step 4. Next, you need to remove the dashboard

This should be done carefully, alternately unscrewing the screws

The upper part of the panel is fixed with latches, they are also dismantled carefully. Carefully disconnect each wire from the socket and note the location

If this causes difficulties, then it is better to draw a diagram or take a picture.

Step 5. Now you need to detach the bottom panel of the washing machine

In order to do this, you must first unscrew all the screw fasteners on the front panel.

Step 6Then you need to remove the tank from the body

In this case, you will need to remove the belt, motor and shock absorbers, as these elements will prevent further analysis of the tank.

Step 7. You need to unscrew the pulley to see the bearing and oil seal mounts

The pulley will be easy to unscrew using a 16 wrench.

Step 8. Now you need to evaluate the appearance of the gland

Here it is no longer usable, which requires replacement.

Step 9. Now you need to separate the oil seal and bearing

Both items will need to be replaced. As in the previous case, the oil seal should be carefully treated with grease, because the lubricating layer makes it possible to facilitate friction, which will significantly extend the life of the part. Don't skimp on lube.

At the same stage, it is necessary to replace the rubber seal if it has become unusable. At the same time, even if you are not going to change it, it is necessary to coat the junction with silicone sealant.

Step 10. Next, you need to collect all the elements one by one

It is necessary to return all elements and fasteners to their places.

Contacting a specialist

As we have already said, the design of not every washing machine will allow you to do the repair yourself, so it becomes necessary to contact the master. In this case, it is recommended to give preference to specialists who perform work at home, because the unit can be easily damaged during transportation to a service center.

If there is a complex internal device of the unit, it is better to call a professional master

If there is a complex internal device of the unit, it is better to call a professional master

The advantages of repairing by a master is that a professional, thanks to skills and special equipment, will quickly find the cause of the problem and spend only a few hours on repairs.At the same time, newcomers are trying to deal with the breakdown for several days in a row.

In addition, all major companies are required to issue a warranty card. This means that if there are malfunctions after repair, you can contact them again, but this time for free.

How much does it cost to replace a bearing?

If you decide to contact a specialist, then it must be borne in mind that replacing the bearing will cost from 1200 to 2500 thousand rubles. The cost is affected by the design feature (frontal or vertical), the complexity of the breakdown.

Before repair, it is advisable to carry out diagnostics in order to determine, based on its results, whether it is profitable to repair equipment

Before repair, it is advisable to carry out diagnostics in order to determine, based on its results, whether it is profitable to repair equipment

Removing the tank from a Samsung car

Having collected all the necessary tools, you can begin to figure out how to replace the bearing in a Samsung washing machine.

Prepare a convenient place in which you will disassemble the machine - it may not be enough in the bathroom, so if possible, move the equipment to a workshop or garage.

Next, you need to remove the "extra" parts that prevent you from dismantling the tank. You need to disassemble sequentially so as not to lose parts and fasteners, so carefully sort and lay out everything that you remove from the machine.

Disassemble the CM case according to the following scheme:

- Remove the top panel. To do this, unscrew the two fasteners located at the corners on the back wall. Then, with both hands, take the lid and pull it towards you, and then up. After removing the panel, set it aside so that it does not interfere.

- Remove the detergent dispenser. It's as simple as that:

- pull out the tray to the maximum;

- press the valve located in the middle;

- With the other hand, slightly lift the tray and pull towards you;

- if you did everything right, the receiver will pop off.

- After removing the powder receiver, unscrew the hoses that supply water to it, as well as the pipe through which the dissolved powder is poured into the tank. Loosen the clamps using pliers.

- At the top of the washer you will see a counterweight. It looks like a big brick or stone. Choose a suitable head to unscrew the fasteners.

- Next, you will need to dismantle the rubber seal.

Removing the rubber cuff on a Samsung washing machine is easy:

- Remove the two bolts that hold the sunroof lock.

- Remove the sensor - this is necessary in order not to break the wiring when removing the cuff.

- Use a thin screwdriver to pry off the wire tie.

- Guide the screwdriver under the collar until you hit the fasteners. Your task is to weaken it.

- Loosen the bolt and remove the clamp.

- Place your fingers under the cuff and pull it towards you.

You can not get the seal completely. The point is that it does not interfere with the removal of the front panel.

Next, lay the machine on its side to gain access to the bottom of the CMA. Remove the bottom by unscrewing the 4 screws holding the cover. Set it aside.

Get started with electronics:

Find the engine and drain pump. Remove all wiring connected to these parts. If possible, record the disassembly process on video so that you do not mix up all the wires later. If this is inconvenient, then mark everything using a marker.

Now you need to remove the racks - replacing the bearing of the Samsung washing machine is not possible with them. The ends of the racks are attached to the tank with four bolts, on the other side of the rack are screwed to the body of the machine.

At the bottom of nothing but the motor, no longer shoot.The pump will also not hurt you - it will only be enough to remove the pipes going to it.

Leave the washer in a horizontal position - so it will be more convenient for you to remove the water inlet valve along with the tubes and sensors going to it.

Remove the wire connected to the valve sensor, then unscrew the fasteners that hold it. Remove valve, set aside. At the end, remove the 4 springs on which the tank hangs.

Removing covers

Now there is nothing left to get to the tank - you only need to remove the wall and the front cover. The control panel is held on by 5 bolts. By unscrewing them, you can easily remove it.

The front wall holds about a dozen fasteners. Find them all and open them. Remove the lid and set aside. By the way, under the front cover there is another smaller counterweight than the main one. Take the socket wrench and unscrew it.

Now everything that previously prevented you from getting the tank has been eliminated. You can get the engine and tank

It is important not to damage the wiring and other vulnerable components, so as not to add work to yourself.

- Turn the tank over.

- Remove the belt from the pulley.

- Unscrew the pulley with a hex. If the pulley fasteners are tight, add a little WD-40 to keep the bolt from stripping.

You coped with the routine work and dismantled almost the entire machine. Now, you can disassemble the tank to see for yourself which bearings are in your Samsung washing machine and make sure that they need to be changed.

We disassemble the tank, change the bearings

To change the bearings, a screwdriver or screwdriver, a small hammer and a drift will come in handy (it can be replaced with an ordinary metal rod). The tank of the Vyatka-automatic machines is made of stainless steel and is collapsible.You just need to unscrew the bolts around the circumference of the tank, and get access to the drum. To remove the drum from the tank, you will have to unscrew the cross and carefully knock out the shaft. Let's analyze the algorithm for replacing bearings and stuffing box step by step:

- use a thin screwdriver to pry the gland and remove the sealing gum;

- set the drift to the center of the outer bearing;

- tap the “ring” by moving the drift in a circle and hitting it with a hammer;

- knock out the inner bearing in the same way.

This is how old bearings are dismantled. Before installing new components, you need to clean the seat from dirt and metal chips. It is also necessary to treat the recess, the “rings” themselves and the oil seal with a special lubricant - it will protect the assembly from moisture and temperature changes.

The shaft should also be cleaned. This can be done first with sandpaper-zero, and then with GOI paste. To install the bearings, it is worth putting them one by one into the corresponding recesses and carefully press them in with a drift and a hammer. Knocking is allowed only on the inner race of the ring, otherwise the part may be damaged.

Next, you need to put the cross in place, connect the halves of the tank and proceed with the assembly of the Vyatka machine. It is carried out in reverse order. The main container is fixed in the body with dampers and springs, a pressure switch hose, a drain pipe are connected to it, and lower counterweights are placed. The cuff, heating element, engine, drive belt and other elements are fixed. After completing the assembly, it remains to connect the "home assistant" to utilities and run a test wash. If the machine does not buzz, rotating the drum normally, then the replacement is done correctly.

Share your opinion - leave a comment

Required Tools

In most bearing failures, it becomes necessary to replace it along with the seal. To carry out a complex replacement, you need to prepare a set of tools, without which it is impossible to perform the procedure correctly.

pliers

With the help of pliers it is convenient to unscrew the internal fasteners. To gain access to the bearing, you will have to remove several mechanisms, so you will not be able to do without pliers.

Open end wrenches in various sizes

Open-end wrenches have a U-shaped working base and are suitable for unscrewing hex locks. Wrenches cover 2 or 3 sides of the fastener. To replace a bearing, several types of open end wrenches need to be prepared, including the following:

- Double-sided keys that have 2 working areas that differ in diameter. Using these wrenches, you can install and remove fasteners of various sizes.

- One-sided impact wrenches that help remove old fasteners with corroded threads. For dismantling, you need to apply the impact force of a hammer to the key.

- Convex wrenches used for fasteners with crumpled edges.

- Open-end wrenches with different angles between the axis and the head. The standard figure is 15 degrees, but keys with an angle of 30-70 degrees are also available. The larger the angle, the easier it is to use the tool in a limited space, since you have to throw it less often.

A hammer

The impact of a hammer is required to dismantle the fasteners, which, due to prolonged use of the machine and contact with moisture, have become rusty. The hammer allows you to create enough impact force to unscrew the latches.

A metal rod with a pencil diameter or a blunt chisel

Using a chisel, you can punch a hole in metal parts or separate stuck components from the surface. Externally, the chisel is a metal rod, at the end of which there is a working part in the form of a sharpened point.

Phillips and slotted screwdrivers

Several types of screwdrivers are used to loosen bolts holding internal components. Depending on the design features of the washing machine, screwdrivers of different sizes may be required.

Replacing a bearing in a Bosch washing machine. Replacing bearings in a Bosch Max Classic 5 washing machine at home

Replacement of bearings in CMA Bosch. Despite the fact that this unit in Bosch washing machines is designed for a long period of operation, sooner or later it wears out. This happens for several reasons:

- tank overload;

- resource has been developed.

Due to the excess amount of laundry, the seal is damaged, and water begins to get on the bearings, as a result of which they are destroyed. And also, over time, a protective lubricant is produced, and passes moisture. Replacement can be done at home. It is absolutely possible to do the work with your own hands, without the involvement of a master. Consider the CMA Bosch Maxx Classixx 5 as an example.

The destruction of the bearing leads to increased noise during washing, and especially during the spin cycle. There is a characteristic roar of rolling balls. With severe wear, a small amount of rusty liquid flows out from under the machine. You can also find it if you remove the back cover. Brown traces of water will be visible in the pulley area.

Bearing failure can be determined as follows. Grasp the edge of the drum and pull it inward and towards you, as well as in different directions. If there is a noticeable play, then it is necessary to carry out repair work. The sooner the replacement is made, the better.

The fact is that with each wash cycle, loosening increases. This leads to the fact that the drum begins to touch the tank and destroy it. The same thing can happen with the pulley - it will make furrows on the outside. The delay will lead to the fact that you have to change the entire tank assembly.

Enough space is needed. For repair, attachments are removed and the tank is pulled out, which is then halved. Without tools, repairing the washing machine will not work.

List:

- a hammer;

- Phillips and slotted screwdrivers;

- metal punch;

- ratchet;

- pliers;

- a set of Torx screwdrivers;

- penetrating lubricant WD-40, or equivalent;

- blue thread lock;

- high temperature sanitary sealant.

repair kit:

- bearing 6204 and 6205;

- gland 30*52*10/12;

- lubricant.

It must be understood that in other models, for example: WOL, WAA, WFT, WFR, WFD, other bearings and an oil seal may be used. A reasonable decision - after dismantling, go to the supplier and buy similar ones.

Important! We disconnect the washing machine from electricity, water supply and sewerage. Consider all the actions in steps:. Consider all the actions in steps:

Consider all the actions in steps:

- Remove the top panel. We unscrew the two screws at the back and lightly tap the front with the palm of our hand.

- We take out the tray for washing powder by pressing the tab with your finger.

- Unscrew three screws in the tray area, and one on the right side. After that, remove the panel.It is held on with plastic clips. We use a screwdriver to pry them out. It is not necessary to disconnect the wires. You can bring the panel to the side and attach it to the body with tape. One chip leading to the bay valves must be pulled out. Otherwise, she will interfere. Mark the landing site, or better yet, take a picture.

- Remove the counterweight from the top of the tank by first unscrewing the screws. Take it aside.

- Open the hatch and remove the sleeve that holds the cuff on the front panel. Use a slotted screwdriver. Unfasten the rubber.

- Unscrew the self-tapping screws securing the hatch blocking device (UBL).

- Remove the cap that covers the pump filter.

- Loosen the fixing screw and remove the bottom plate.

- Remove the self-tapping screws that hold the front panel - bottom and top, and pull it out.

- Using pliers, unfasten the clamp on the pipe between the dispenser and the tank. Unhook the hose coming from the cuff.

- Unscrew the screws that secure the fill valve. Remove the entire block with the dispenser, wires and can.

- Disconnect the pressure switch and the tube leading to it.

- We dismantle the two metal strips on top.

- We remove the front counterweight, freeing ourselves from the screws.

- From below we take out all the contacts from the tubular electric heater (hereinafter referred to as the heating element). We bite off, but rather unfasten the plastic clamps holding the wiring.

- Disconnect the pump from electricity.

- We loosen the bandage pressing the rubber drain pipe with a socket screwdriver. It is located at the bottom between the tank and the pump. Let's unhook him.

- Then remove the screws securing the shock absorbers to the body.

How to replace

Before starting repair work, it is necessary to disconnect the machine from the electrical network in order to avoid the possibility of electric shock. After that, unscrew the water supply and drain hoses by pulling them slightly forward.

Dismantling the pulley and motor

To solve the problem of wear of oil seals and bearings, the motor and pulley of the washing machine should be removed. To do this, you must first remove the drive belt by screwing the pulley and pulling the belt forward.

After that, fix the pulley by inserting a strong pin into it. You can tighten the pulley if you unscrew the bolt that secures it. The pulley is removed from the shaft by swinging it a little and pulling it towards you. In this case, it is not necessary to dismantle the heating element. Although, this is the time to consider what condition the heating element is in. If there is a thick layer of scale on it, it is better to remove it.

The engine can be removed by unscrewing the bolts with which it is attached. In this case, you need to remove the pipe. It is easier and easier to do this through the bottom of the machine, turning it on its side.

Removing the top cover

On the back of the machine there are 2 self-tapping screws, through which the cover is attached to the body. Unscrewing them, the cover will move back a little. After that, it can be lifted and removed.

Some models of the Indesit washing machine are equipped with special plastic latches that secure the lid. In this case, it is enough to unfasten them, which will allow you to remove the top cover.

Removing the drum

The next step in replacing the seal and bearings is to dismantle the drum. To do this, you need to get and pull out the tank by pulling it forward. All Indesit models are equipped with a one-piece tank. In order to be able to access the drum, you will have to divide the tank into 2 parts. This can be done by sawing it with a grinder or a saw for metal work.

Before you start cutting the tank, you need to make a final decision on how its subsequent assembly will be carried out.To do this, on its surface, you need to make several holes for the bolts, with which the tank can be assembled into a one-piece structure.

Having disconnected the drum from the tank, experts recommend inspecting it for damage. In addition, you should check the condition of the gasket located under the drum. If it is stretched and has cracks on the surface, it is better to replace it.

Removing and replacing bearings

Now it's time to change the oil seal, which performs a protective function for the bearings. To do this, you can use a screwdriver, prying the gland with it. It is possible that this will be difficult to do. You will have to use hammers and a chisel, gently knocking out the bearings, tapping them in a circle.

If it is impossible to do this on your own, you will have to contact the service, where, using special equipment, the cuff will be pressed out of the bearings.

After successfully removing the cuffs and bearings, you need to clean and lubricate the place where the new parts will be installed. For lubrication, it is recommended to use a special sealant.

Purchased new bearings and a cuff can be installed in their original place by using a hammer and a wooden block. As a result of this, it will be possible to significantly soften the force of the hammer blow, preventing cracking of the bearings and damage to the stuffing box. The main direction of impact is recommended to be directed to the edges of the parts. The seal must be on bearings. After that, it remains to assemble the Indesit washing machine in the reverse order.

In order for the replacement not to be too expensive, it is recommended to adhere to the following work rules:

- pulley operations must be performed carefully, without sharp jerks.It must first be easily swung to the sides, and then pulled forward. Otherwise, the pulley can be broken;

- during prolonged use of the machine, its bolts can boil, which complicates their unscrewing. If you apply force when unscrewing the bolts, you can rip off their heads. To avoid this, spray them with WD-40;

- when dismantling the tank cover, you can break the wires of the temperature sensor;

- you should carefully assemble the washing machine, not forgetting to connect all the sensors.

Compliance with these simple rules will help to avoid additional costs for repairs.