- Advantages of water heaters "Vector"

- Disadvantages of water heaters "Vector"

- Speaker problems

- The general structure of a household column

- Rules for dismantling and disassembling the gearbox

- Removing the reducer from the column

- Dismantling the frog of the water heater "Neva 3208"

- The procedure for removing the gearbox "Neva-transit"

- Water Regulator Disassembly

- Frog reassembly

- Testing the repaired node

- Subtleties of settings

- Water leaks

- Purpose and structure of the water node

- Water reducer device

- The principle of operation and the meaning of the regulator

- Types of water heaters

Advantages of water heaters "Vector"

The technique has several advantages, which made it very popular among Russian buyers.

Price

Not everyone can spend more than 10 thousand rudders on such a device, and it is quite difficult to do without it in a country house or in a private house. The brand "Vector" does not have models more expensive than 4 thousand rubles - despite this, the equipment is quite high-quality and versatile.

Design

The equipment looks stylish and discreet. The column will not attract attention, and sometimes even emphasize the interior. The manufacturer also took care of the compact dimensions of the equipment. In the event of a breakdown, the owner can always find the necessary spare parts that will be inexpensive and extend the life of the device.

Control

All models are equipped with a simple and convenient control system. It consists of two switches. The first regulates the gas supply, and the second is responsible for the amount of water entering the heat exchanger. There is also a technique with a third switch for the Winter/Summer function. The first program activates all sections of the burner. The “Summer” program, on the contrary, turns off some of the sections - a plus for savings.

Disadvantages of water heaters "Vector"

Do not think that for modest money you will purchase newfangled equipment that will last for decades - this is not so. You need to understand that budget options are not designed for long-term use and cannot offer innovative technologies that are present in expensive counterparts. It happens that after a season of use, equipment needs repair and replacement of parts.

Another disadvantage is the burnout of the heat exchanger. Although it is made of copper, its layer is quite thin. Therefore, over time, the heat exchanger can no longer withstand high temperatures and the equipment breaks down.

Even these shortcomings do not stop buyers and heaters are actively sold. Someone believes that they are much better and better than models from a more expensive segment. In any case, it is impossible to say for sure about the quality without testing the water heater yourself.

Speaker problems

We will immediately make a reservation that we will consider the problems of flow heaters with an open combustion chamber, of which there are a great many installed in apartments and houses. We will bypass the repair of fully automated turbocharged columns with mains power and ignition from a hydrogenerator. These devices are quite complex and intervention in their design to an ignorant person is contraindicated.Troubleshooting of supercharged units should be carried out by service or gas services.

The list of malfunctions inherent in gas water heaters after several years of operation is as follows:

- the smell of gas;

- problems with ignition and start-up of the main burner;

- turning off the heater during operation;

- various leaks.

If you smell gas, whether it is permanent or intermittent, you must immediately turn off the corresponding tap, open the windows and call the emergency service. Explain to the dispatcher the nature of the problem, and he will make a decision - to urgently send a team to your home or simply send the master in the order of the queue. There are no other options, it is strictly forbidden to fix methane leaks on your own

There are no other options, it is strictly forbidden to fix methane leaks on your own.

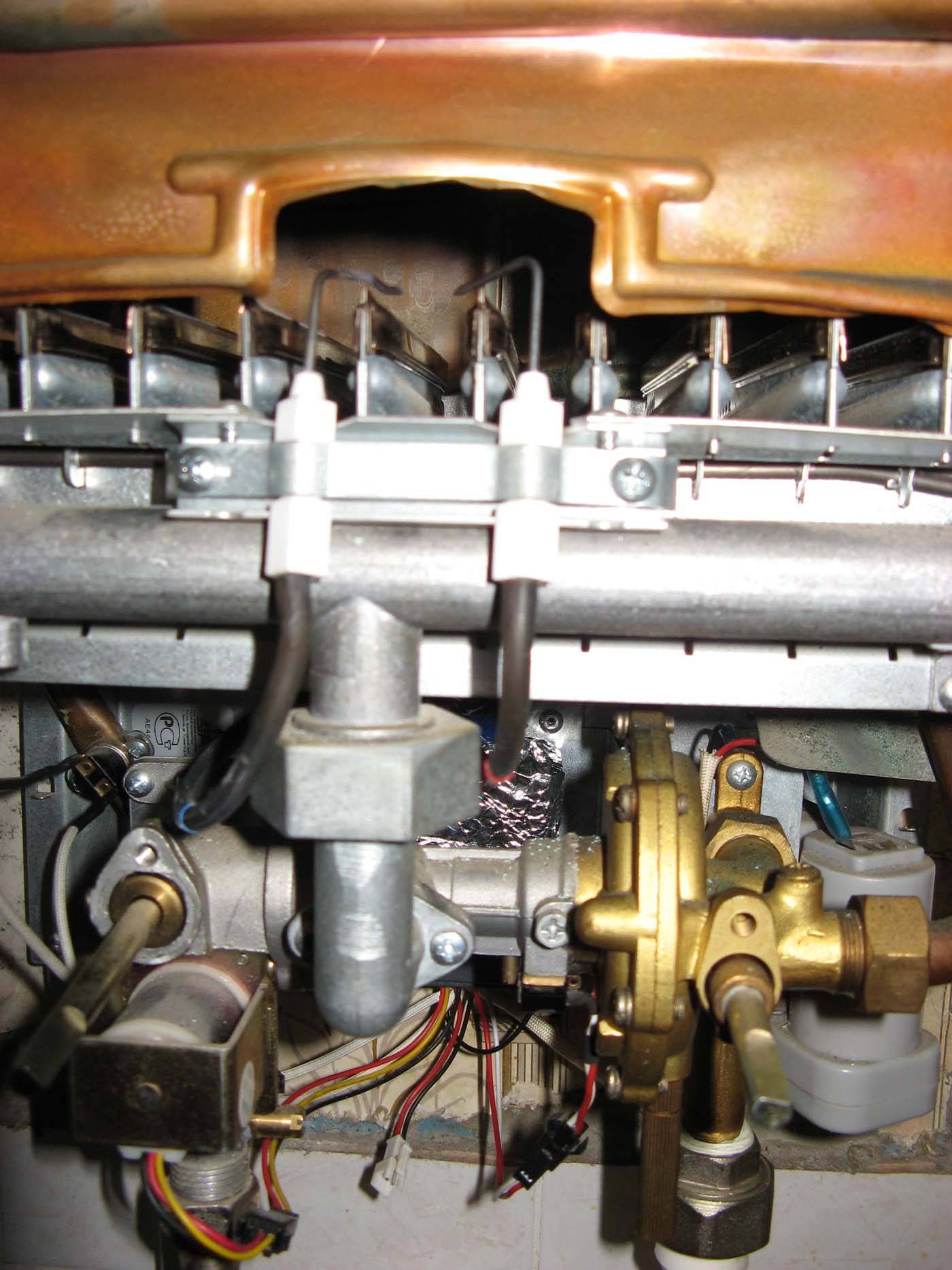

The general structure of a household column

A geyser is a flowing water heater. This means that water passes through it and heats up as it goes. But, before proceeding to an analysis of how a household geyser for heating water is arranged, we recall that its installation and replacement are associated with a centralized gas supply system.

Therefore, it is imperative to submit documents to the gas service of your region along with the corresponding application. You can read about the norms and necessary documents in our other articles, and now let's move on to the device.

Different models of geysers differ from each other, but the general structure of a household geyser looks something like this:

- Gas-burner.

- Igniter / ignition system.

- Exhaust and connection to the chimney.

- Chimney pipe.

- The combustion chamber.

- Fan (on some models).

- Heat exchanger.

- Pipe for gas supply.

- Water node.

- Pipes for water supply.

- A branch pipe for an output of hot water.

- Front panel with controller.

The central element of the column is a gas burner in which gas combustion is maintained, which contributes to heating the water. The burner is installed in the housing, it collects hot combustion products, the purpose of which is to heat water.

The body is made of metal and completely covers the front and sides of the speaker.

It is important that the body material conducts heat well, because the quality of heating depends on the transmission of heat.

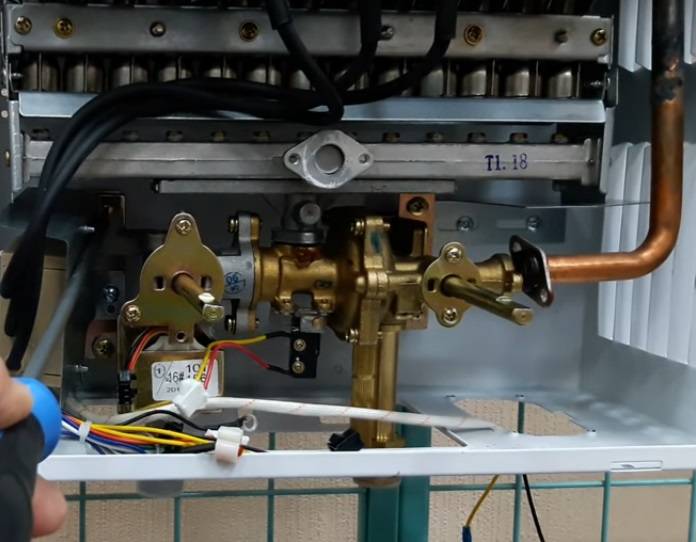

Structural components of the geyser located inside the housing. Closed gas equipment shown here

On top of the apparatus there is an exhaust hood and a chimney through which the products of combustion leave the column and the room. Their device depends on whether the column is open or closed, which will be shown below.

Pipes meander in a coil inside the body, water passes through them under natural pressure and is warmed by hot gases. This whole system of pipes is called a heat exchanger. Below are two pipes: on the right - for receiving cold water from the pipeline, on the left side hot water flows out.

A filter is often installed between the water supply network and the geyser, which regulates the hardness of the water. Without a filter, the column may be covered with scale at high water temperatures. When entering the column, water passes through the water node, which serves as a kind of "connection" between the water flow and the gas flow. We will talk about this connection a little further.

Burning gas burner with electric ignition and flame sensor. Sensors play an important role in the operation of equipment.Let's talk about their functions below.

With the help of another tube, which is also located below, the column is connected to the gas line.

There is also a front panel with a control unit. It is equipped with regulators to control the consumption of gas and water. Depending on the model, these can be simple knobs that need to be turned, or liquid crystal displays where you can see many characteristics of the speaker, or even the nature of its malfunction if the speaker does not work.

Rules for dismantling and disassembling the gearbox

Regardless of the modification of the geyser, before starting repairs or preventive maintenance, turn off the gas and cold water supply to the unit.

To drain the water from the system, open the hot water tap located below all water-folding devices powered from the column. We place a wide container (basin or bucket) under the dismantled water unit, where the remaining water from the gearbox will drain.

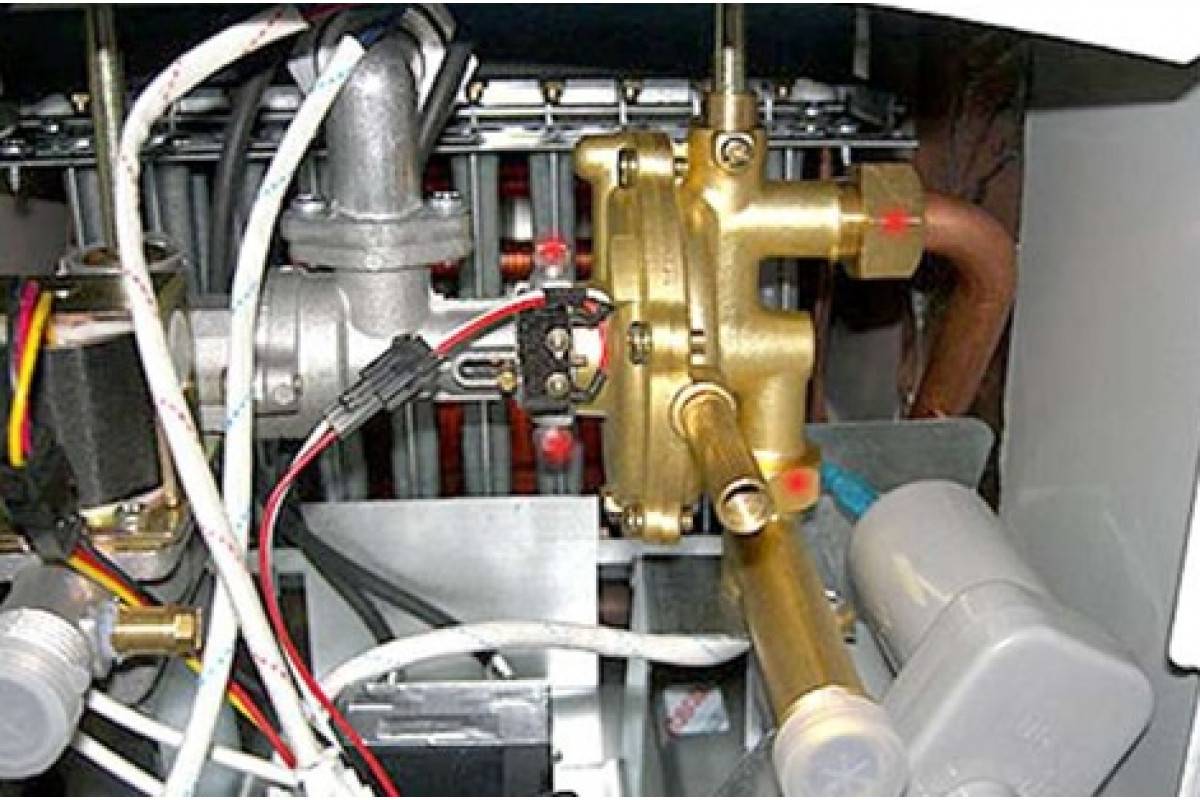

Removing the reducer from the column

Often the frog can be removed separately. But in some columns it is impossible to do this, so you have to dismantle both blocks together. There are models of instantaneous water heaters in which, in order to gain access to the insides of a frog, it is not at all necessary to dismantle it - just remove the cover.

Dismantling the frog of the water heater "Neva 3208"

In the column "Neva 3208" it is easy to dismantle the gearbox, as in other similar devices. To do this, unscrew the union nuts on the inlet and outlet pipes of the housing, and also unscrew the three screws that secure the frog to the gas unit.When unscrewing the nuts and screws that fix the water regulator, hold the dismantled block with your hand so as not to accidentally deform the parts of the gas unit.

When dismantling the water regulator with a wrench, unscrew 2 union nuts of the pipes in the indicated order, then unscrew 3 screws with a screwdriver

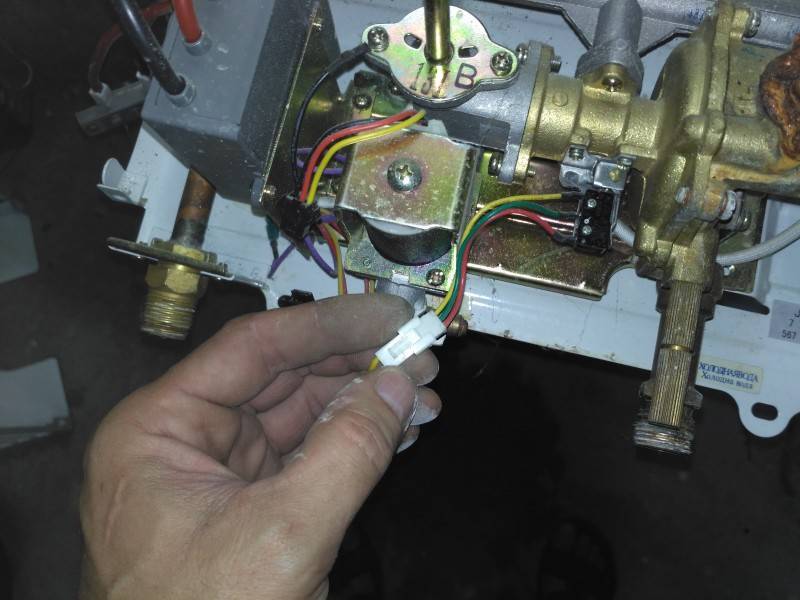

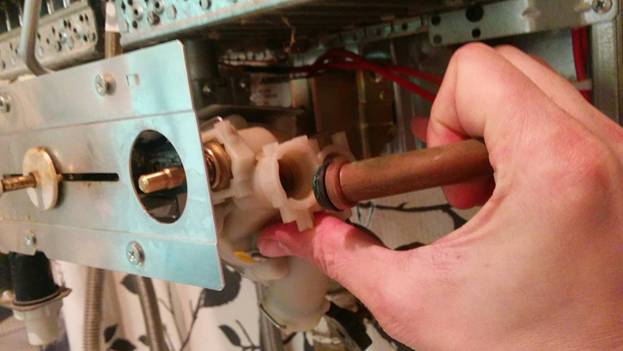

The procedure for removing the gearbox "Neva-transit"

To repair the water reducer, it must be removed from the column housing. We will analyze how to do this using the example of dismantling the Neva-Transit column, since the fastening of gas-water units in many modern models is very similar. First, remove the adjusting knobs on the front panel. They are just dressed in stocks.

After that, unscrewing the screws, remove the front panel

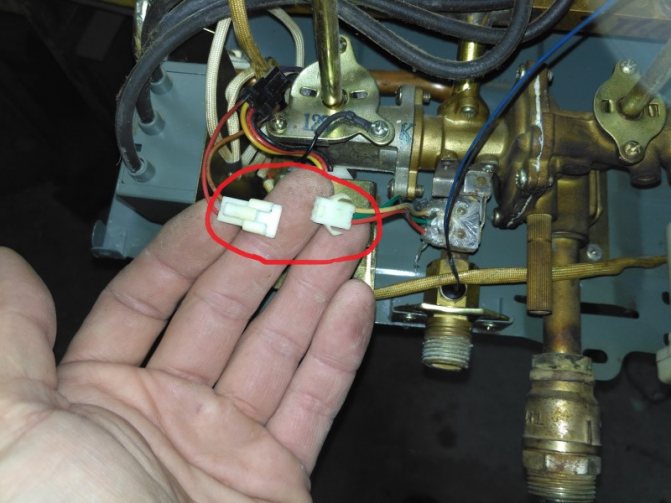

Please note that the digital display on the front panel is connected with detachable terminals to the electronic devices of the speaker. Therefore, by pulling the panel towards ourselves, we disconnect the terminals and only after that we remove the panel completely

Do you have a Neva gas water heater? We recommend that you read more about typical malfunctions and how to fix them.

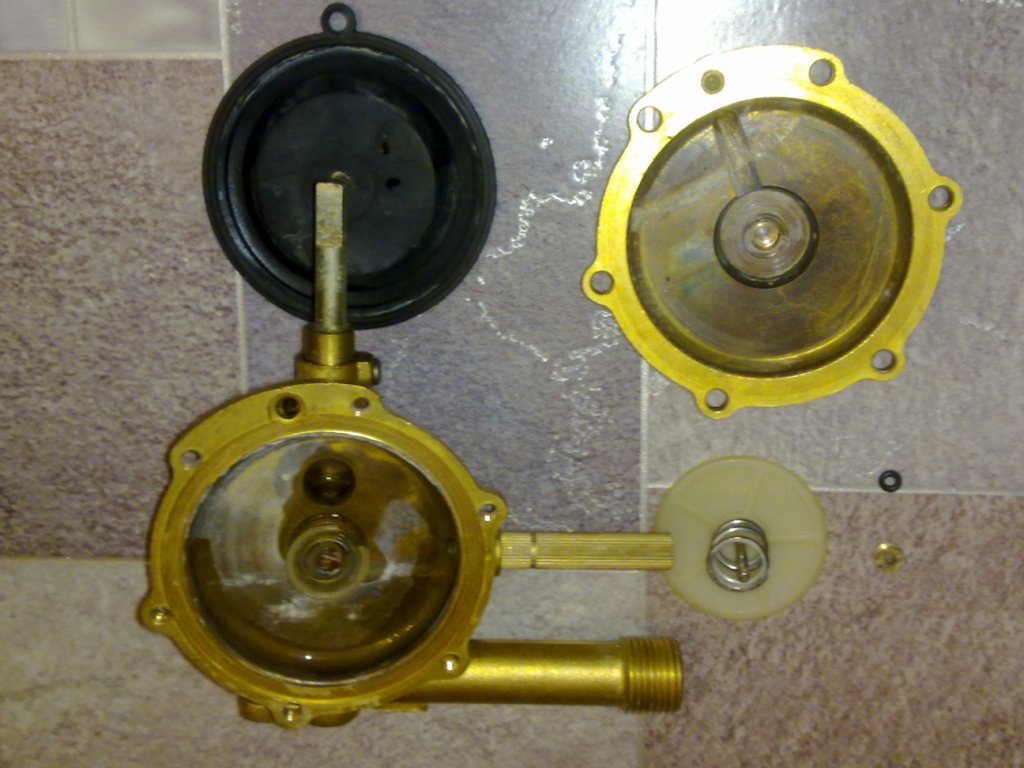

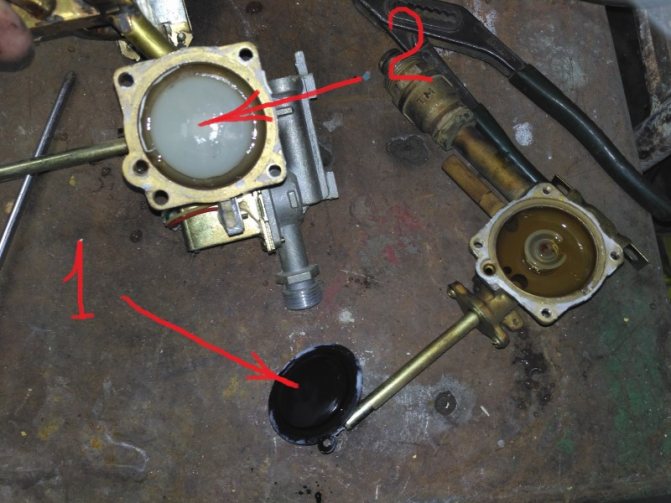

Water Regulator Disassembly

Having freed the frog and drained the last water from it, unscrew the lid. Often the screws are soured. To facilitate the work and in order not to disrupt the slots, we use the special tool WD-40. After unscrewing the screws, remove the cover, remove the membrane and inspect the condition inside.

We replace the parts that have become unusable, clean and wash the insides (surfaces, channels, if necessary, clean the body from the outside), install the parts in place and assemble the frog in the reverse order.

Frog reassembly

It is especially important to set the aperture correctly.The bypass hole must exactly match the holes of the same name in the cover and base.

If the channel connecting the cavities of the base and the cover is blocked, the column will not work.

After installing the cover on the base, tighten the screws. We install the assembled gearbox in place (also in the reverse order), not forgetting about the sealing gaskets on the pipes and on the connection of the water-gas unit with the platform of the gas burner leg.

Screws should be baited and finally tightened without misalignment. To do this, they are installed and baited in pairs-crosswise and similarly screwed up to the stop.

A gasket is installed in this place (between the burner and the gas unit). Be careful - the safety of the geyser is ensured by the tightness of this unit

Testing the repaired node

After installing the repaired frog, we check the operation of the water part without connecting the gas by opening the hot water tap.

Watching:

- whether drops have appeared on the connections;

- whether the flow rate is the same when hot and cold water are turned on separately;

- whether the burner igniter clicks;

- whether the stem moves normally when opening and closing the valve.

If not everything goes as it should, it is worth double-checking your work. However, sometimes the reason may lie not only in the water node.

Only after the mounted frog has passed the test can gas be supplied to the column. But do not forget about the safety rules when using the column. And if you smell gas, you should immediately shut off its supply, arrange ventilation and call the gas workers.

Subtleties of settings

These devices have only one geyser temperature controller. Thanks to it, the heating temperature and power are adjusted. The self-diagnosis system evaluates the operation of the nodes when turned on. If there are problems, the red light comes on and the device is blocked from starting. Then you need to adjust the water pressure.

Then you need:

- Remove batteries from the compartment;

- Turn off the microswitch;

- Supply a source of electricity;

- Turn on the hot faucet and run the microswitch;

- The pressure on the burner must be maximum;

- After saving the settings, the orange lamp will turn on.

In other columns, the water temperature is adjusted by turning the toggle switch and controlling the strength of the water flow.

Alas, it is impossible to easily set the settings according to the instructions. Each system has different meanings. If there are difficulties with your own hands adjust the temperature controller of the geyser, you should contact the professionals.

Water leaks

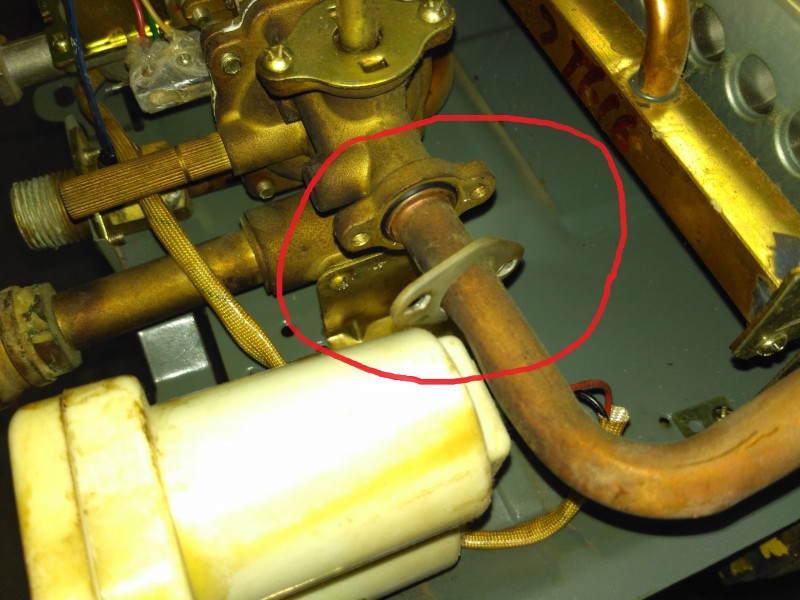

Inside the flow heater, the water tubes are connected to the various assemblies with union nuts and O-rings. Homeowners who have not maintained their units for years may find dripping water under the appliance. If this is found, then geyser repair consists in checking all interfaces and replacing seals.

There are other places where water can leak, such as through the operating stem of a water assembly. This suggests that at least the seal on the frog rod needs to be replaced, which will require its removal and disassembly.In models equipped with a safety valve, the latter can also leak, especially if it has had to relieve pressure several times. Finally, the most unpleasant situation is a damaged heat exchanger in which a fistula has formed. Buying a new one is very expensive, it is easier to repair the old one, which is discussed in the next section.

Purpose and structure of the water node

The membrane is an important detail in the regulation of gas supply. To understand its purpose and principle of operation, it is necessary to study in detail the device of the water block of the column, of which it is a structural element. This knowledge will help when replacing the membrane, because in order to get to it, you have to dismantle the entire assembly and disassemble it.

We also recommend that you get acquainted with the general arrangement of the geyser, so that it is easier to find a water block in its design. But first things first.

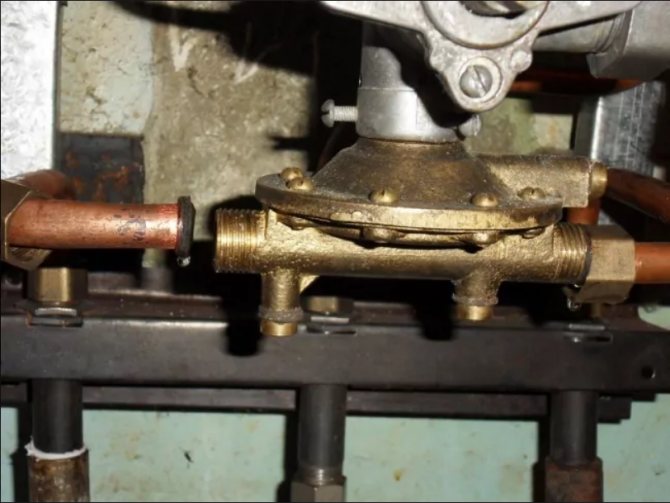

Water reducer device

One of the nodes of almost any gas heat exchanger is a water reducer (water node - WU, water regulator). It is designed to regulate the uniform supply of water and gas. The practically designed shape of the regulator (in common parlance - “frogs”) contributes to the compact placement of the unit in the column body. A technically simple device works automatically.

The functions of the reducer are as follows:

- starting and stopping the operation of the gas column when opening / closing the tap;

- regulation of water and gas supply;

- protection of the column from overheating in case of insufficient water pressure.

The design of the gearbox is well thought out and visually uncomplicated. The body is made of brass, polyamide (containing fiberglass), silumin or plastic.

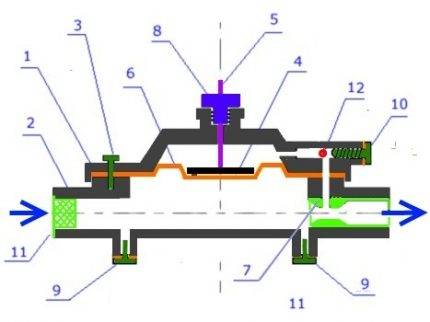

Details of the water unit: cover (1) and base (2) connected with screws; plate (4); stem opening/closing gas valve (5); membrane (6); venturi fitting (7); gland nut (8); water outlets (9); adjusting screw (10); fixing screws (3); mesh filter (11); retarder ball (12)

Details of the water unit: cover (1) and base (2) connected with screws; plate (4); stem opening/closing gas valve (5); membrane (6); venturi fitting (7); gland nut (8); water outlets (9); adjusting screw (10); fixing screws (3); mesh filter (11); retarder ball (12)

The principle of operation and the meaning of the regulator

The hollow cavity of the gearbox divided in two by a membrane is filled with water. Water enters the cavity from the plumbing. From the lower part, passing through the Venturi fitting, it enters the upper compartment through the bypass. However, the water coming from the water supply to the lower part always presses on the membrane with the pressure force of the water in the pipeline, and in the upper part the pressure force changes, depending on whether the water flows through the heat exchanger.

The fact is that in pipelines with narrowed sections, the pressure of the flowing fluid in the bottleneck decreases. When the tap is opened and water passes through the Venturi fitting, the pressure in front of the local constriction (nozzle) of the fitting increases.

Due to the increase in the flow velocity in a narrow place, the pressure decreases both in the fitting and in the upper cavity of the frog. It's like flattening the end of a garden hose. With a difference in the diameters of the choke nozzle (0.3 cm) and the main chamber (2 cm), the pressure difference reaches 1 atmosphere. This is enough for the membrane to bend upward and press on the plastic plate, which is rigidly fixed on the stem axis. The rod with force presses on the gas valve, causing the valve to open and gas flows to the gas burner.

When the membrane is raised, water from the upper compartment begins to exit through the bypass channel, where the steel retarder ball is located. The ball, moving to the right, partially blocks the channel, so the gas is switched on and supplied to the burner smoothly. Smoothness is regulated by means of an adjusting screw.

The Venturi nozzle is located in the outlet pipe (on the right side of the frog). This is a local constriction that provides a pressure drop when the valve is opened. Clogged fitting must be cleaned

The Venturi nozzle is located in the outlet pipe (on the right side of the frog). This is a local constriction that provides a pressure drop when the valve is opened. Clogged fitting must be cleaned

When the hot water (DHW) tap is closed, the flow of water stops and the pressure in the Venturi nozzle equalizes with the pressure in the cavity under the membrane. Due to the action of the springs, the rod together with the plate are shifted down, and the membrane returns to the middle position.

The gas valve closes automatically. The gas valve is turned off quickly, since the ball is displaced to the upper cavity (to the left) by the reverse flow of water in the culvert and ceases to impede the flow of liquid. We recommend that you look at information on what to do if the gas valve does not work.

If the hot water flow is less than 2-3 l / min, the required pressure drop does not occur, and the springs do not allow the stem to open the gas valve at all or it is enough to fully heat the water. Also, there is no necessary pressure difference in violation of the integrity of the membrane.

The water regulator, based on the principle of the Venturi nozzle, is a safety device, as it allows the water heater to be turned on only when sufficient water flows through the heat exchanger. Thus, the reducer automatically protects the geyser from overheating.

The overflow hole connects the Venturi nozzle and the upper cavity of the frog.This hole must be left open when installing the diaphragm in order for the gearbox to work correctly.

The overflow hole connects the Venturi nozzle and the upper cavity of the frog.This hole must be left open when installing the diaphragm in order for the gearbox to work correctly.

Types of water heaters

Water heaters share on two grounds:

- principle of action;

- the type of energy that heats water.

According to the principle of action, they distinguish:

- accumulative;

- flowing;

- flow-accumulative.

A storage water heater is similar to a kettle. It has a water tank and tubular heating elements - heating elements. Such devices are called boilers.

In an instantaneous heater, water is heated while it runs through pipes in the body of the appliance. It does not accumulate hot water - there is no tank.

The flow-accumulative heater combines a boiler and a flow-through water heating unit.

According to the type of energy due to which water is heated, heaters are divided into:

- electrical;

- gas;

- indirect heating and combined.

Electric heaters are powered by the mains, in gas water the burning gas heats the water, in indirect heating boilers the water receives heat from the heating system. In combined heaters, the heating system heats the water in winter, and electricity in summer.

There are pressure (closed) and non-pressure (open) heaters. In pressurized water moves due to the pressure in the water supply. They are convenient because they can simultaneously supply hot water to the bathroom, kitchen and other rooms where pipes are connected.

In non-pressure units, water flows down from the tank into the faucet by gravity. They work no matter what the pressure in the water supply. But they are mounted only on one crane.

Which water heater is suitable for an apartment or a country house is decided based on the specific conditions and characteristics of the devices.