- Rules for dismantling and disassembling the gearbox

- Removing the reducer from the column

- Dismantling the frog of the water heater "Neva 3208"

- The procedure for removing the gearbox "Neva-transit"

- Water Regulator Disassembly

- Frog reassembly

- Testing the repaired node

- Features of batteries for the speaker and the nuances of choice

- Methods and means of cleaning

- Descaling

- Elimination of soot and soot

- Nozzle cleaning

- Cleaning the water intake

- Device assembly

- What are membranes for geysers

- Signs of broken membrane

- Purpose and structure of the water node

- Water reducer device

- The principle of operation and the meaning of the regulator

- Switching on the device

- Starting the appliance and adjusting the temperature

- How to set the water temperature

- pressure problems

- What are membranes for geysers

- Recommendations for maintenance and repair

- Dismantling and adjustment of the gearbox

- Cleaning the water unit

- Repair of heat exchangers of geysers

- How to get rid of limescale?

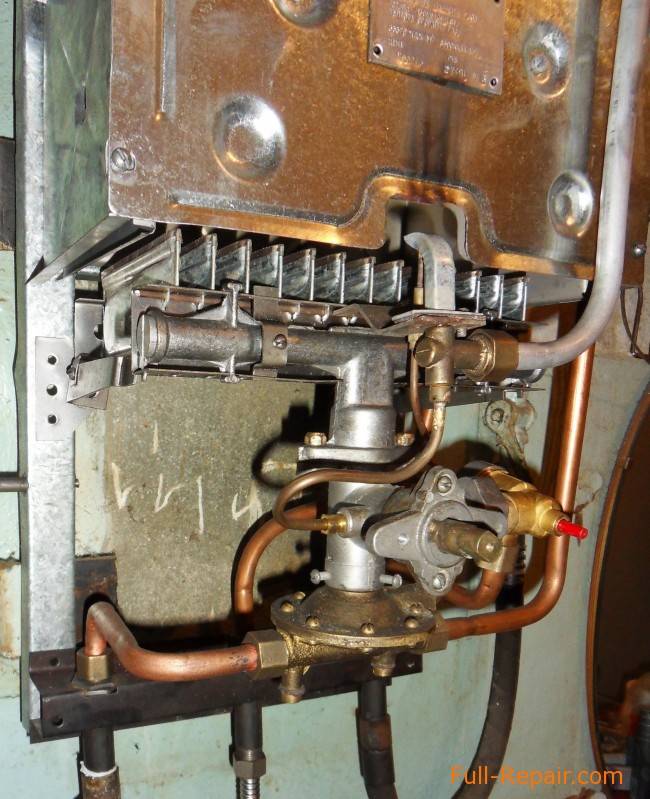

- Water-gas group device

- Disassembly of the water-gas group

- Selection Tips

Rules for dismantling and disassembling the gearbox

Regardless of the modification of the geyser, before starting repairs or preventive maintenance, turn off the gas and cold water supply to the unit.

To drain the water from the system, open the hot water tap located below all water-folding devices powered from the column. We place a wide container (basin or bucket) under the dismantled water unit, where the remaining water from the gearbox will drain.

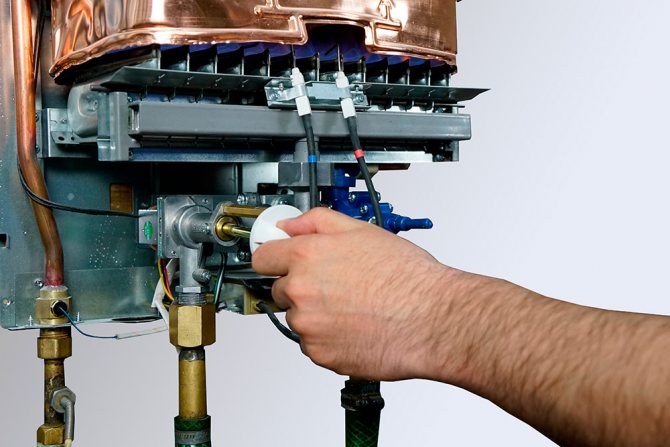

Removing the reducer from the column

Often the frog can be removed separately. But in some columns it is impossible to do this, so you have to dismantle both blocks together. There are models of instantaneous water heaters in which, in order to gain access to the insides of a frog, it is not at all necessary to dismantle it - just remove the cover.

Dismantling the frog of the water heater "Neva 3208"

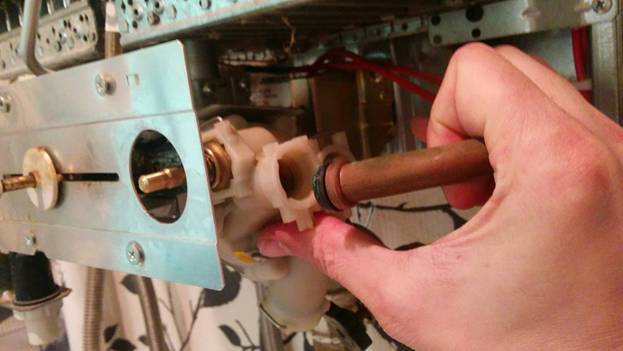

In the column "Neva 3208" it is easy to dismantle the gearbox, as in other similar devices. To do this, unscrew the union nuts on the inlet and outlet pipes of the housing, and also unscrew the three screws that secure the frog to the gas unit. When unscrewing the nuts and screws that fix the water regulator, hold the dismantled block with your hand so as not to accidentally deform the parts of the gas unit.

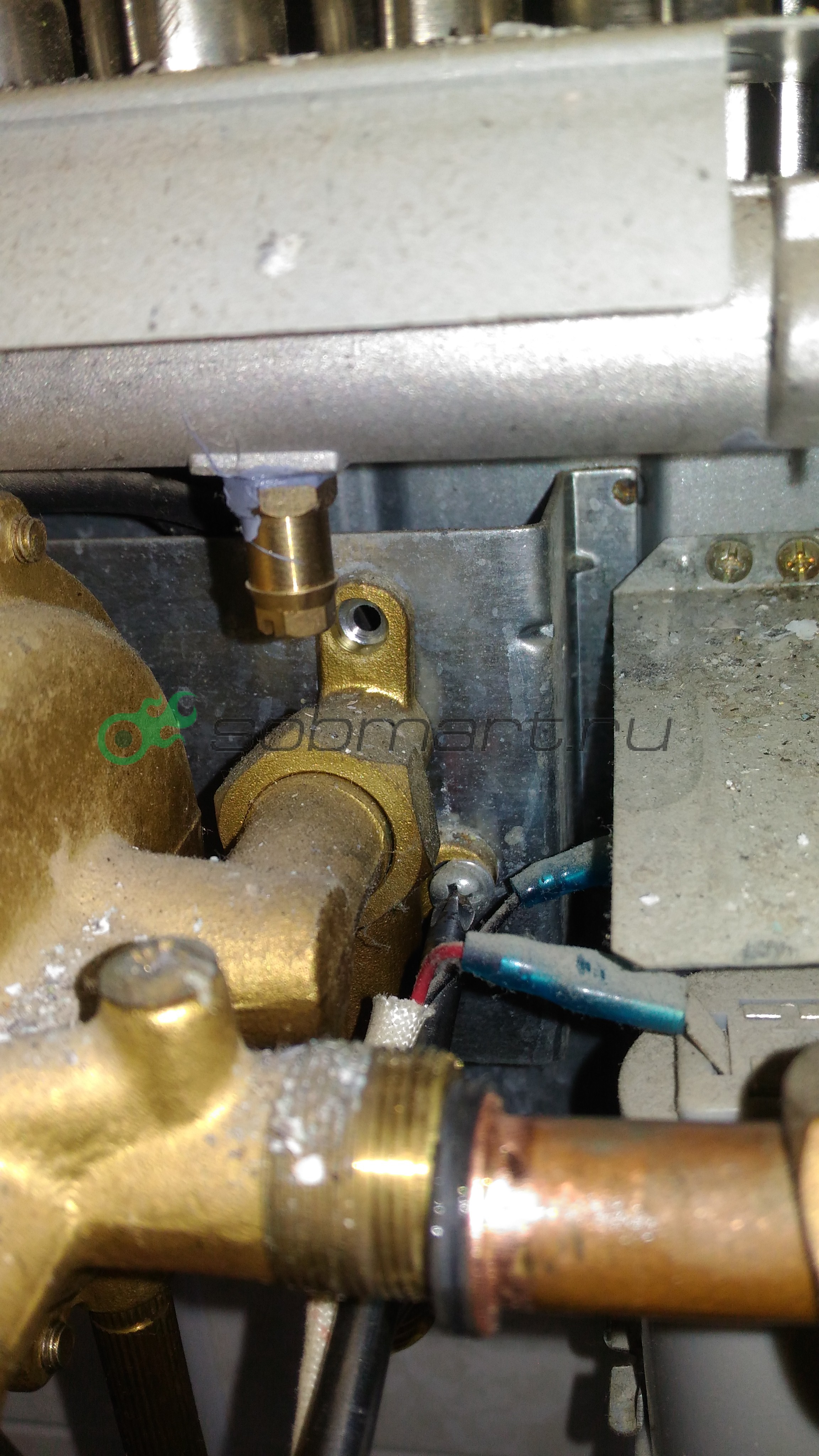

When dismantling the water regulator with a wrench, unscrew 2 union nuts of the pipes in the indicated order, then unscrew 3 screws with a screwdriver

The procedure for removing the gearbox "Neva-transit"

To repair the water reducer, it must be removed from the column housing. We will analyze how to do this using the example of dismantling the Neva-Transit column, since the fastening of gas-water units in many modern models is very similar. First, remove the adjusting knobs on the front panel. They are just dressed in stocks.

After that, unscrewing the screws, remove the front panel

Please note that the digital display on the front panel is connected with detachable terminals to the electronic devices of the speaker. Therefore, by pulling the panel towards ourselves, we disconnect the terminals and only after that we remove the panel completely

Do you have a Neva gas water heater? We recommend that you read more about typical malfunctions and how to fix them.

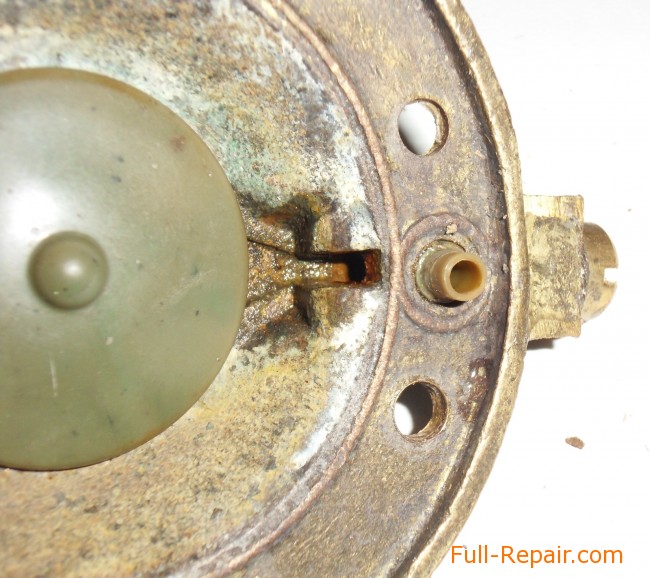

Water Regulator Disassembly

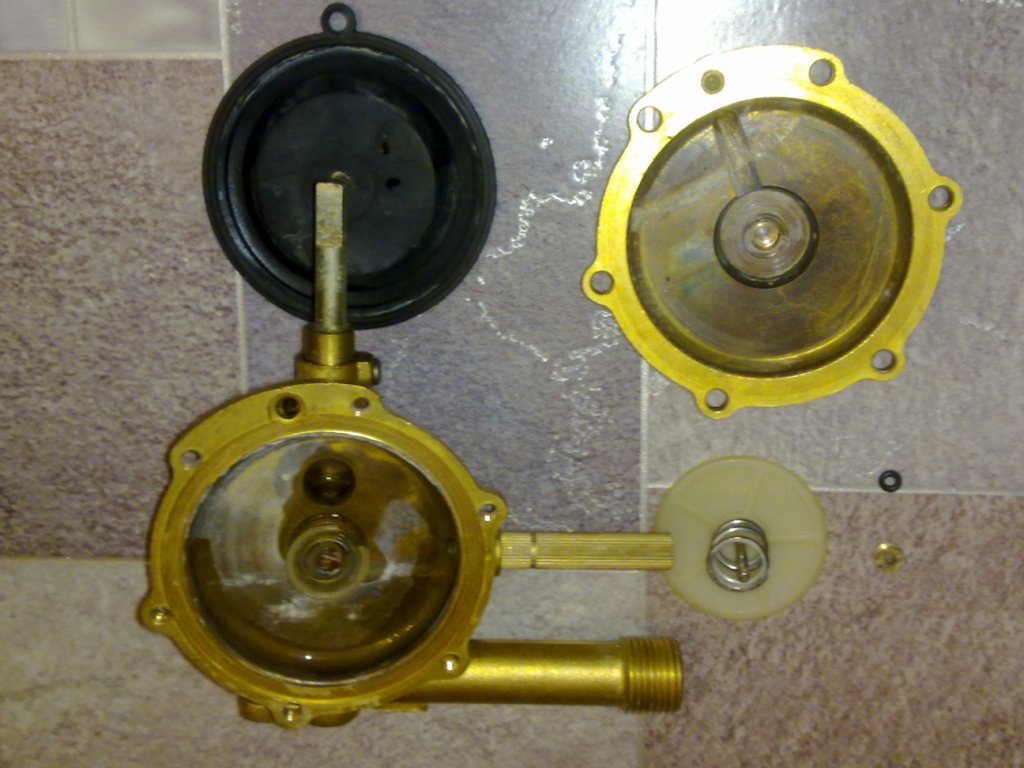

Having freed the frog and drained the last water from it, unscrew the lid. Often the screws are soured. To facilitate the work and in order not to disrupt the slots, we use the special tool WD-40. After unscrewing the screws, remove the cover, remove the membrane and inspect the condition inside.

We replace the parts that have become unusable, clean and wash the insides (surfaces, channels, if necessary, clean the body from the outside), install the parts in place and assemble the frog in the reverse order.

Frog reassembly

It is especially important to set the aperture correctly. The bypass hole must exactly match the holes of the same name in the cover and base.

If the channel connecting the cavities of the base and the cover is blocked, the column will not work.

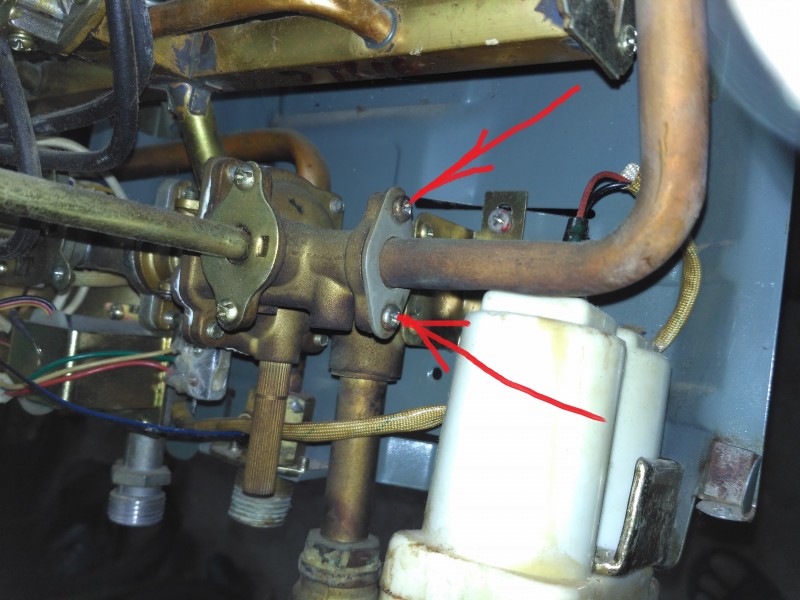

After installing the cover on the base, tighten the screws. We install the assembled gearbox in place (also in the reverse order), not forgetting about the sealing gaskets on the pipes and on the connection of the water-gas unit with the platform of the gas burner leg.

Screws should be baited and finally tightened without misalignment. To do this, they are installed and baited in pairs-crosswise and similarly screwed up to the stop.

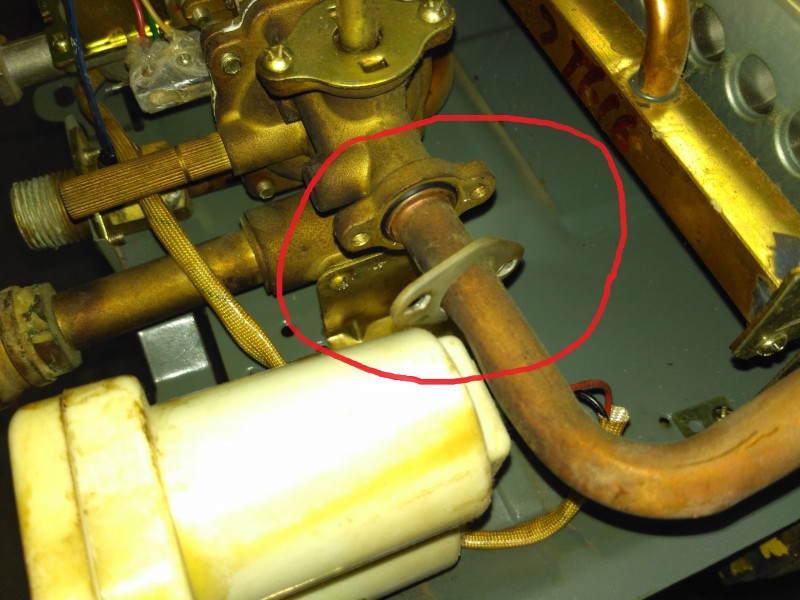

A gasket is installed in this place (between the burner and the gas unit). Be careful - the safety of the geyser is ensured by the tightness of this unit

Testing the repaired node

After installing the repaired frog, we check the operation of the water part without connecting the gas by opening the hot water tap.

Watching:

- whether drops have appeared on the connections;

- whether the flow rate is the same when hot and cold water are turned on separately;

- whether the burner igniter clicks;

- whether the stem moves normally when opening and closing the valve.

If not everything goes as it should, it is worth double-checking your work. However, sometimes the reason may lie not only in the water node.

Only after the mounted frog has passed the test can gas be supplied to the column. But do not forget about the safety rules when using the column. And if you smell gas, you should immediately shut off its supply, arrange ventilation and call the gas workers.

Features of batteries for the speaker and the nuances of choice

The work of modern models of speakers is tied to electricity. Power, thanks to the spark produced, provides ignition of the flame necessary for heating water, and also guarantees the operation of the display, which displays the current temperature and other information.

It is noteworthy that the ignition in the very first gas water heaters was carried out manually by a rather dangerous method - with the help of matches. Subsequent modifications of water heaters were equipped with a more ergonomic piezoelectric element, batteries or a hydrogenerator. There are also models of speakers with ignition from the network.

Now columns with ignition from batteries are most in demand. Analogue models with a hydrogenerator that replaces batteries are much less in demand. The rating of the best geysers, popular among buyers, we have given in this article.

The principle of operation of a hydroelectric generator is quite simple: the flow of water turns the blades, due to which an electrical impulse is produced.

Significant disadvantages of columns with a hydrogenerator:

- the cost of such equipment exceeds the price of battery-powered speakers;

- the generator mechanism and blades are extremely sensitive and often suffer from poor water quality, so they require regular cleaning;

- the pressure in the plumbing may not be sufficient to generate a strong spark.

At a direct ignition column, gas is immediately supplied to the burner, which is ignited by an electrical impulse created by the batteries.

Discharge of batteries is fraught with malfunctions in the operation of heating equipment. Insufficient charge level provokes a long inclusion or complete cessation of functioning

The need to replace the batteries in the geyser may be indicated by the popular “symptom” of incorrect operation of the equipment: the water heater starts idly several times in a row, making sounds characteristic of ignition. Some models are equipped with an indicator that indicates the wear of the batteries.

In fact, there are two types of batteries on the market: D-LR20 and D-R20. They differ from each other in price and “stuffing”: there may be salt or alkali inside the battery.

Salt batteries D-R20 are confidently losing ground, which is more of a plus than a minus. Cheaper power supplies are notorious for extremely fast discharge rates. Therefore, even a low attractive price does not make the purchase of the D-R20 worthwhile.

Alkaline D-LR20 alkaline batteries are more expensive, but do not require such frequent replacement, working properly for up to six months. A salt power source will last a couple of weeks at best.

To save as much money as possible on routine battery replacement, it is worth purchasing rechargeable batteries. Do not throw away used batteries and accumulators with household waste, as power supplies require special disposal.

Comparison of the appearance of batteries of different classes. Class D batteries look really impressive compared to other categories of power supplies.

For geysers, nickel-metal hydride versions of batteries are best suited - NiMH D / HR20. However, before installing, you should make sure that the voltage in each battery is 1.5 V.

The most win-win option not to make a mistake in choosing a product is to go to a store with old batteries and buy batteries of similar parameters.

When choosing, be sure to take into account the recommendations of the manufacturer and pay attention to the appearance of the product when buying it. However, this approach may not save you from buying low-quality units.

Additionally, you should pay attention to the following nuances:

Additionally, you should pay attention to the following nuances:

- compliance with the expiration date;

- package integrity;

- lack of scuffs and mechanical damage on the case;

- the correct form of the power supply.

The abundance of fakes on the market and storage of products in improper conditions without observing the correct temperature regime significantly affect the life of batteries and accumulators.

Methods and means of cleaning

The instructions necessarily describe in detail the rules for cleaning the components of the device, deviating from which can be life-threatening.If during the process of descaling or burning, damage to one of the elements of the device occurs, and a gas leak occurs, you must immediately contact the emergency gas service.

If, after weighing all the pros and cons, you have decided to clean the device yourself, we suggest that you familiarize yourself with industrial preparations and folk remedies that will effectively get rid of pollution.

In the video below, you can see in more detail how to flush the water heater radiator with citric acid:

Before starting work, be sure to turn off the gas and water supply.

With your own hands you can clean:

- burner from soot and soot;

- internal parts from dust;

- scale heat exchanger;

- water pipes.

Basic cleaning products:

| Problem | folk recipe | industrial facility |

| Scale in the heat exchanger | An aqueous solution of citric acid (100 g of the substance per 0.5 l of hot water) | Calgon, Antinakipin |

| Carbon deposits on the heat exchanger | A solution of table vinegar and warm water (1: 3) | 7-10% hydrochloric acid solution |

| Dust on internal parts | Warm soapy water | Ordinary household vacuum cleaner |

Descaling

You can eliminate scale with the help of chemicals, following the manufacturer's recommendations, as well as folk remedies.

If the second option is chosen, the following procedure must be followed:

- disconnect the device from gas and water;

- disconnect the heat exchanger, remove it from the wall, drain the water;

- using a pear or syringe, pour a cleaning agent (a solution of soda or vinegar) into the pipes of the heat exchanger;

- then the whole part is immersed in a deep basin with the same mixture and left for several hours.

After the contaminants are completely eliminated, the heat exchanger is connected back and the column is started. The pressure of water will finally clean the inner surface of the pipes, making them perfectly clean.

The heat exchanger can be cleaned without dismantling. To do this, remove the front panel and disconnect the device from the water supply hose. After that, a cleaning solution is poured through the inlet into the pipes. In this form, the device is left for 2-3 hours, after which the liquid is drained and everything is returned to its place.

Elimination of soot and soot

It is possible to clean the surface of parts from soot without disassembling the column in just a few minutes. To do this, you must adhere to the following procedure:

- turn off the gas and remove the front of the case;

- wipe the internal parts with a damp cloth or vacuum;

- assemble the column back.

From the video below, you will learn how to quickly and effectively clean soot from burners:

Nozzle cleaning

If the column starts to burn weakly, the nozzle is most likely clogged. You can find it on the gas manifold near the pressure sensor. For cleaning use a thin wire or a stiff brush.

After the work is completed, it is imperative to check the column and exclude the possibility of gas leakage. To do this, lubricate the burner with soapy water and make sure that there are no bubbles.

Cleaning the water intake

In addition to the water heating part, any geyser is equipped with a water intake unit, the main task of which is to prevent large solid particles from entering the heat exchanger. Over time, the mesh filter and the membrane become dirty, which is responsible for the automatic supply of gas when the water is turned on.

To clean the water intake, you must:

- remove it from the column body;

- rinse the filter under running cold water;

- inspect the membrane for the presence of curvatures and bulges (if there are defects, the membrane must be replaced with a new one).

After research and washing, all parts are installed in place, and the water intake is closed with a lid.

This is interesting: Do-it-yourself installation of drywall partitions - we will write down the main thing

Device assembly

In the old Neva and Astra water heaters, we put the top cover of the water regulator in place and tighten eight screws one opposite the other. We determine where the entrance to the regulator is and put it to the pipe through which water enters the column. The water unit is inserted into the gas unit and three screws are screwed in, with which they are attached to each other. It is advisable to change the gaskets at the inlet and outlet. After that, the cap nuts are tightened with a 24 wrench.

In new water heaters, we tighten four screws on the water regulator, fasten the water-gas unit to the burner. Next, we fasten the burner block to the back wall, connect the ignition and ionization electrodes and tighten the union nuts with a wrench.

We check after assembly. With the hot water tap open, gradually turn on the water at the column inlet. Make sure there are no leaks anywhere. You can double-check by running dry wipes on the union nuts. After a few minutes, we close the tap and check the same connections, but already under pressure. If everything is in order, the gas valve opens and the operation of the column is checked

It is important to check the gas connections by applying a soapy solution. If there are no leaks anywhere and everything works, you can attach the column casing

Also, the process of replacing the column membrane Astra HSV-21 1-V11-UHL 4.2, see the video:

What are membranes for geysers

The life of a person should be comfortable. To achieve convenience, many equip their homes with various modern devices. Some of them must be in every home, because without them the standard of living is significantly reduced.

With the right choice of column and its use, you can be sure of a long service life. But it also happens that the column breaks. In such situations, owners often do not know where to start with repairs. If the outlet water is not warm enough, the problem is definitely the membrane, which may have become unusable.

What is a membrane:

- In most speakers, the diaphragm is made of rubber.

- The membrane for a geyser quite often becomes unusable, the material wears out, which leads to its rupture.

- The membrane is installed in the water node of the device. It controls the water pressure.

- If the column is turned on, the membrane flexes.

- Gas is supplied to the burner, starting the process of heating water.

If the membrane is damaged, the column ceases to heat water efficiently, since cold water does not enter the heat exchanger. After a membrane failure, many owners are wondering how to find a new membrane, what quality it should be, and how to match the membrane to a specific column model. It should be noted that in most cases the speaker arrangement is similar.

Signs of broken membrane

How do you know when it's time to change the rubber diaphragm? You need to pay attention to:

- The pressure force of gas and water in the system. Open the tap, count how many liters are consumed per minute. Normally, there should be at least two or three liters. The gas supply can be calculated visually by looking at the strength of the fire.

- Flame location.In appliances with wick ignition, the fire should burn from the edge of the burner, be at least 3-5 centimeters high. Does not match? Then check the jets for blockage. After cleaning, look at the flame again. If the situation has not changed, the problem is in the diaphragm.

- The piezo ignition technique should click when the button is pressed. This means that the diaphragm has worked. If no sounds are heard, the part may be damaged or torn.

- In some models, a rod that controls the operation of the control unit will help determine the breakdown. Remove the protective cover and open the water. If the stem is not moving, the diaphragm needs to be replaced.

After you have found a breakdown, you need to choose the right part for replacement.

Purpose and structure of the water node

The membrane is an important detail in the regulation of gas supply. To understand its purpose and principle of operation, it is necessary to study in detail the device of the water block of the column, of which it is a structural element. This knowledge will help when replacing the membrane, because in order to get to it, you have to dismantle the entire assembly and disassemble it.

We also recommend that you get acquainted with the general arrangement of the geyser, so that it is easier to find a water block in its design. But first things first.

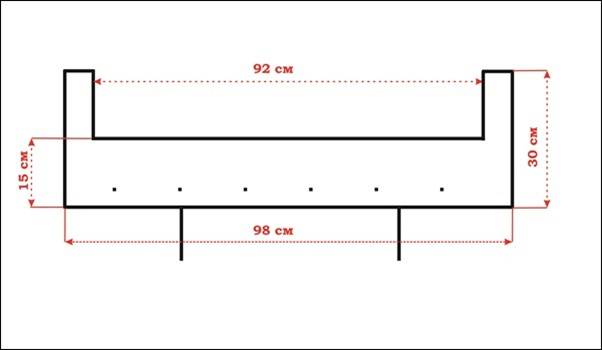

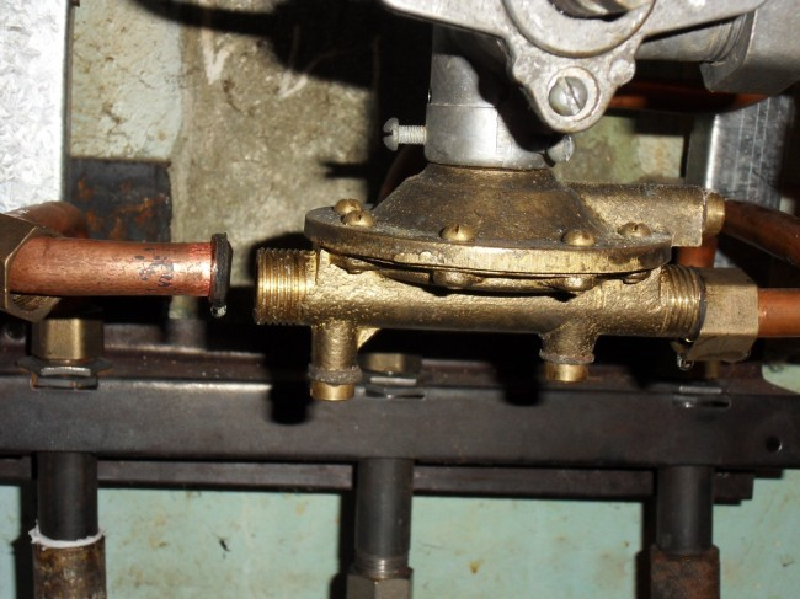

Water reducer device

One of the nodes of almost any gas heat exchanger is a water reducer (water node - WU, water regulator). It is designed to regulate the uniform supply of water and gas. The practically designed shape of the regulator (in common parlance - “frogs”) contributes to the compact placement of the unit in the column body. A technically simple device works automatically.

The functions of the reducer are as follows:

- starting and stopping the operation of the gas column when opening / closing the tap;

- regulation of water and gas supply;

- protection of the column from overheating in case of insufficient water pressure.

The design of the gearbox is well thought out and visually uncomplicated. The body is made of brass, polyamide (containing fiberglass), silumin or plastic.

Details of the water unit: cover (1) and base (2) connected with screws; plate (4); stem opening/closing gas valve (5); membrane (6); venturi fitting (7); gland nut (8); water outlets (9); adjusting screw (10); fixing screws (3); mesh filter (11); retarder ball (12)

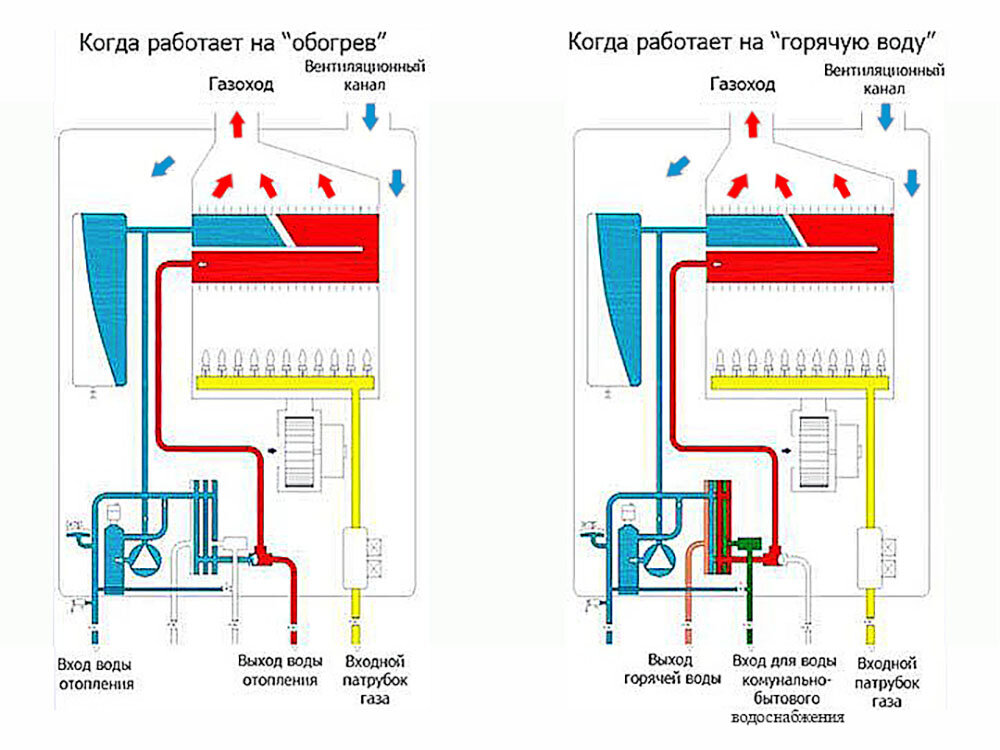

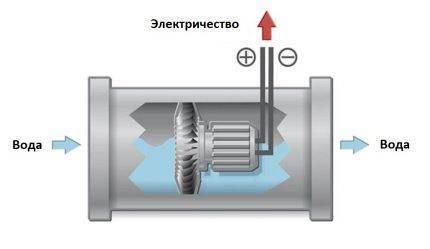

The principle of operation and the meaning of the regulator

The hollow cavity of the gearbox divided in two by a membrane is filled with water. Water enters the cavity from the plumbing. From the lower part, passing through the Venturi fitting, it enters the upper compartment through the bypass. However, the water coming from the water supply to the lower part always presses on the membrane with the pressure force of the water in the pipeline, and in the upper part the pressure force changes, depending on whether the water flows through the heat exchanger.

The fact is that in pipelines with narrowed sections, the pressure of the flowing fluid in the bottleneck decreases. When the tap is opened and water passes through the Venturi fitting, the pressure in front of the local constriction (nozzle) of the fitting increases.

Due to the increase in the flow velocity in a narrow place, the pressure decreases both in the fitting and in the upper cavity of the frog. It's like flattening the end of a garden hose.With a difference in the diameters of the choke nozzle (0.3 cm) and the main chamber (2 cm), the pressure difference reaches 1 atmosphere. This is enough for the membrane to bend upward and press on the plastic plate, which is rigidly fixed on the stem axis. The rod with force presses on the gas valve, causing the valve to open and gas flows to the gas burner.

When the membrane is raised, water from the upper compartment begins to exit through the bypass channel, where the steel retarder ball is located. The ball, moving to the right, partially blocks the channel, so the gas is switched on and supplied to the burner smoothly. Smoothness is regulated by means of an adjusting screw.

The Venturi nozzle is located in the outlet pipe (on the right side of the frog). This is a local constriction that provides a pressure drop when the valve is opened. Clogged fitting must be cleaned

When the hot water (DHW) tap is closed, the flow of water stops and the pressure in the Venturi nozzle equalizes with the pressure in the cavity under the membrane. Due to the action of the springs, the rod together with the plate are shifted down, and the membrane returns to the middle position.

The gas valve closes automatically. The gas valve is turned off quickly, since the ball is displaced to the upper cavity (to the left) by the reverse flow of water in the culvert and ceases to impede the flow of liquid. We recommend that you look at information on what to do if the gas valve does not work.

If the hot water flow is less than 2-3 l / min, the required pressure drop does not occur, and the springs do not allow the stem to open the gas valve at all or it is enough to fully heat the water. Also, there is no necessary pressure difference in violation of the integrity of the membrane.

The water regulator, based on the principle of the Venturi nozzle, is a safety device, as it allows the water heater to be turned on only when sufficient water flows through the heat exchanger. Thus, the reducer automatically protects the geyser from overheating.

The overflow hole connects the Venturi nozzle and the upper cavity of the frog. This hole must be left open when installing the diaphragm in order for the gearbox to work correctly.

Switching on the device

The first step is to install the batteries. To do this, open the battery compartment and install them, observing the polarity. Then you need to open the cold water valve and gas. Open a hot liquid faucet at the nearest faucet.

At the moment when the liquid flows through the water unit, a spark ignition occurs and, due to this, the burner is ignited. If it is turned on for the first time or after a long period of inactivity, air may accumulate in the gas line, in order to remove it, you will need to open the mixer several times with a hold for a minute, and then close it.

Starting the appliance and adjusting the temperature

To properly set up hot water in the device, you must:

- Fully open the mixer for hot water supply;

- Using the water switch, select the required temperature value;

- Shut off valve.

According to the advice of professionals:

- Wait for the moment when the pressure drops in the line, but the column will still work;

- Turn the handle of the water tumbler to the maximum;

- Turn the gas regulator to the minimum value until the temperature is as you need.

For the final preparation, it is worth adjusting the gas supply.To do this, you need to look at the technical data sheet and find out the minimum value for this brand.

The toggle switch is turned to the minimum value.

Turn on the gas supply valve. U" and "Ariston" do this after joining the network. The gas water heater "Oasis", "Junkers" and "Bosch" is connected when batteries are installed.

Turn on the hot valve and the device starts to work.

How to set the water temperature

Turn on the mixer and check the temperature of the water heating. It must be twenty-five degrees larger than the original. It should be noted that the water in the gas boiler heats up gradually. The gas column is adjusted using the gas lever.

Professionals do not advise heating water over fifty-five degrees. This has a bad effect on the device, as scale is formed.

pressure problems

Setting up a geyser takes some time. Accordingly, the result will be visible later. After each stage, it is worth pouring out the water and letting it heat up again in order for the values to be correct. Reduced pressure in the device can interfere with normal operation.

If there are problems with pressure, it is worth performing the following manipulations:

- Remove the casing from the device;

- Loosen the locking bolt, use a pressure gauge to check;

- Remove the seal from the adjusting screw;

- Turn on the boiler;

- Set the values \u200b\u200bto the maximum, unscrew the hot water taps;

- Set the required pressure.

The Bosch geyser, namely its pressure in the nozzles, is regulated in the following way:

- Remove the casing;

- Attach a manometer;

- Loosen the locking screw;

- Attach a manometer to check the pressure in the nozzles to the nozzle.

Further, the Bosch geyser with maximum heat output is regulated by:

- Remove the seal from the screw;

- Turn on the device;

- Turn on hot water taps;

- Adjusting screw adjust the pressure in the nozzles;

- Put the seal in place.

There are brands where there is a special "Winter-summer" mode with temperature adjustment. On this handle made below. The Oasis geyser adjustment is located on the front panel. The peculiarity of the regime is that in winter the power is higher than in summer. The force of heating the liquid in the column is directly related to the temperature of the inlet stream. In winter, the regulator is set to "maximum", the heating will be the highest. In summer, the inlet flow temperature is higher and set to the minimum position. This saves resources.

It is easy to remove bad pressure when checking.

To do this, perform the following manipulations if the device has already been in use:

Pay attention to the rubber membrane. The performance of this part is directly related to the pressure in the line

At the moment of violation of the integrity of the membrane, namely when it is produced, the gas does not flow and the burner does not turn on. The problem is solved by replacing the part.

Pay attention to the mesh filter. It is located at the entrance to the water block. The water pressure becomes lower due to clogging of the part with debris. The problem is solved by cleaning.

What are membranes for geysers

The life of a person should be comfortable. To achieve convenience, many equip their homes with various modern devices. Some of them must be in every home, because without them the standard of living is significantly reduced.

The membrane for the geyser is a rubber or silicone gasket of a round shape

The membrane for the geyser is a rubber or silicone gasket of a round shape

With the right choice of column and its use, you can be sure of a long service life. But it also happens that the column breaks. In such situations, owners often do not know where to start with repairs. If the outlet water is not warm enough, the problem is definitely the membrane, which may have become unusable.

What is a membrane:

- In most speakers, the diaphragm is made of rubber.

- The membrane for a geyser quite often becomes unusable, the material wears out, which leads to its rupture.

- The membrane is installed in the water node of the device. It controls the water pressure.

- If the column is turned on, the membrane flexes.

- Gas is supplied to the burner, starting the process of heating water.

If the membrane is damaged, the column ceases to heat water efficiently, since cold water does not enter the heat exchanger. After a membrane failure, many owners are wondering how to find a new membrane, what quality it should be, and how to match the membrane to a specific column model. It should be noted that in most cases the speaker arrangement is similar.

Recommendations for maintenance and repair

All elements of the column design are subject to destruction due to various factors. Any gas equipment needs regular maintenance. If during preventive maintenance defects were identified, they should be eliminated as quickly as possible. Of course, some repairs should be entrusted to a professional, but some can be done independently.

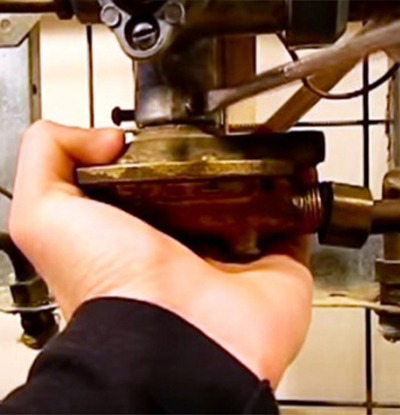

Dismantling and adjustment of the gearbox

You must first turn off the fuel and water supply. Only then can preventive or repair work be started. To remove the gearbox, you must perform several actions:

- water is drained from the heat exchanger;

- using an adjustable wrench, gas and water pipelines are disconnected from the column;

- if no mistakes were made at the previous stages, then the gearbox can be easily dismantled.

Cleaning the water unit

This event must be held at least once every 12 calendar months

When unscrewing the fixing bolts located on the assembly cover, care must be taken not to damage the folds. When the cover is removed, it is necessary not only to clean the inside of the gearbox, but also to perform the following procedures:

- All solid residues from the bottom of the part must be removed, and the coarse water filter must also be rinsed.

- It is advisable to lubricate the stem with grease or castor oil.

- If it is suspected that the gasket has lost its former elasticity, it must also be lubricated.

With regular maintenance of the unit, you can significantly increase its service life. Most often, the stem seal and diaphragm fail. The first element must be changed once every 3 years, and the second - after the appearance of gaps or microcracks. In addition, during intensive work, the spring for returning the stem to its original position may break.

Having carefully studied the device and the principle of operation of the gas column, all preventive measures can be performed independently. If there is no self-confidence, then you should seek the help of professionals. When working with the unit, you must strictly follow the instructions.

Repair of heat exchangers of geysers

One of the most severe cases of column damage is considered to be burnout, fracture or through corrosion of a copper heat exchanger. In the first two cases, the repair is performed only by replacing the part with a new spare part. In the case of through corrosion, thin, 02.0.5 mm holes are formed on the walls of the heat exchanger, through which water flows out of the circuit.

The defect, as a rule, is detected by intense soot formation, water leakage and pressure drop in the circuit when the tap is closed.

To repair the heat exchanger, you will need to remove it from the gas column mount. Next, the copper surface is cleaned of deposits of soot and scale and subjected to a hydraulic test.

The easiest way is to identify the place of corrosion by pumping air or water under excessive pressure. For example, the outlet of the heat exchanger is silenced with a rubber plug, and air pressure is supplied at the inlet by a hand pump. The heat exchanger of the gas column is immersed in a container of water and the location of the damage is determined.

You can repair the damage at home by soldering with copper-silver tin solder. The first is used to restore the hottest spots located close to the flame front. To seal with tin, the copper surface is etched with a solution of zinc in hydrochloric acid, heated with a torch and tinned with a massive piece of solder. For normal operation, the thickness of the tin patch must be at least 0.5-0.7 mm.

After the repair, the heat exchanger is checked twice more - using traditional air injection and holding under the operating pressure of water after installing the unit on the gas column. The pressure in the circuit must not drop for at least 15 minutes.

How to get rid of limescale?

Experts recommend regularly turning on the hot water jet at full power, leaving it for 20 minutes. This method allows you to remove the upper layers of limescale. Additionally, you can clean it yourself with a thin, hard copper wire.

To effectively clean the water heater, a flushing solution is made from several types of detergents. They are mixed in equal proportions in one liter of boiling water. Then, using a funnel, it is necessary to pour liquid into the coolant until it flows through another pipe.

The washing agent is left in the heat exchanger for two hours, adding new portions of the cleaning solution through the watering can every 30 minutes.

At the end of the process, a shower hose must be connected to one of the nozzles by disconnecting the funnel. Then turn on a strong pressure of clean water to thoroughly flush the system.

In addition to regular cleaning, the use of a water filter contributes to an increase in the life of a gas boiler. In this case, it is necessary to call the gas service specialists at least once a year for a complete diagnosis of the equipment. Only they are able to carry out high-quality cleaning, troubleshoot and replace the necessary unit in the gas boiler.

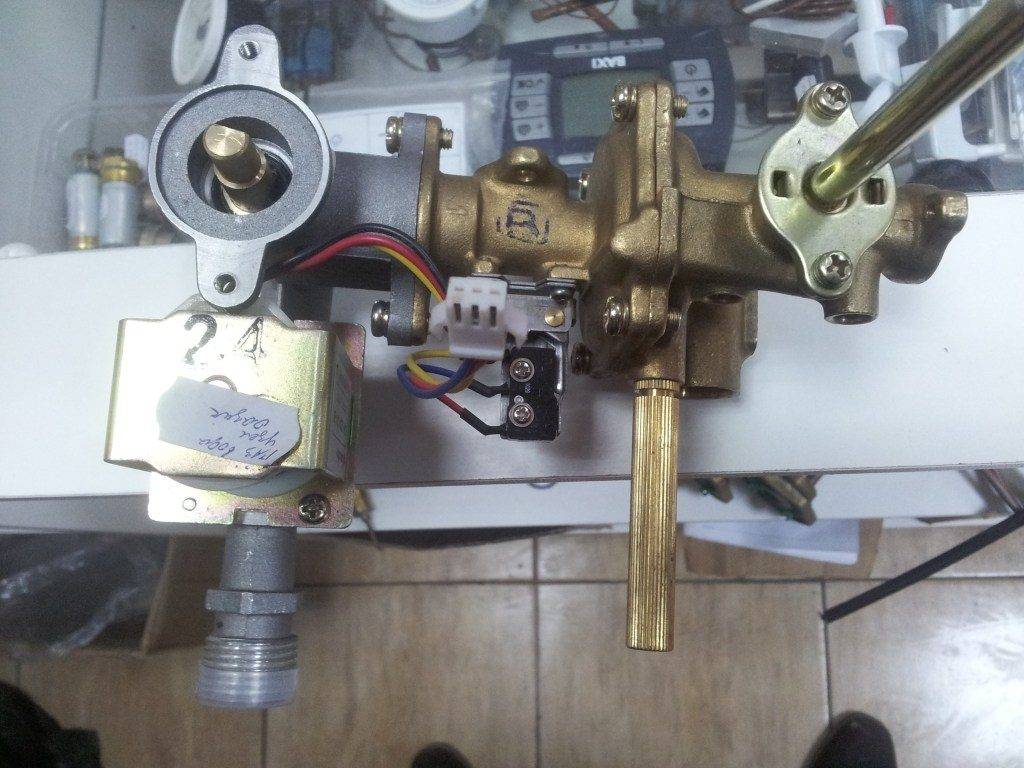

Water-gas group device

To start disassembly, select the appropriate set of tools for the job:

- wrench 19 and 24 mm;

- wrench;

- several screwdrivers of various types;

- rubber hose with a metal clip;

- special anti-scale agent;

- basin or bucket.

Complete water and gas group

Disconnect the water and gas supply pipes from the water-gas group, having previously blocked the gas and water at the entrance to the apartment.Open the shower faucet to drain any remaining water from the system.

After draining the water, disconnect the outlet pipes.

Disassembly of the water-gas group

To check the condition of the membrane, follow the following step-by-step instructions:

- Unscrew the two bolts or screws that secure the bar with the ignition electrodes and the ionization electrode from the burner.

- Unscrew the bolts (4, 6 or 8 pieces depending on the model) that secure the water-gas unit to the body.

- Disconnect in sequence:

- heat exchanger tube;

- ground wire;

- microswitch connector;

- gas valve connector;

- wires going to the batteries.

- Pull out the water-gas block together with the burner.

- Unscrew 4 or 6 bolts connecting two plates, in the middle of which there is a membrane. In the people, this detail is called a frog.

Membrane or diaphragm

Inspect and check the elasticity of the membrane. In inexpensive water heaters, especially those made in China, the membranes are rubber, which do not have a long service life. Therefore, change them to silicone without hesitation.

Having reached the membrane, the stem of the gas valve of the gas unit will open in front of you. Since the stem is constantly moving, opening and closing the gas, the hole is sealed with a gland assembly. The oil seal wears out from friction, and the safe operation of the water heater depends on it. If it is stuck due to calcium deposits, the stem may remain in the upper position and open the gas, even if the water is turned off.

Diaphragm installed in the water unit

Tips: When the stem is stuck and the column does not turn off, first open the faucet in the bathroom so that hot water can freely leave. After that, turn off the gas at the entrance to the apartment, and wait until the flame goes out. Then there are two options for events:

- Call a repairman to your home.

- Disassemble the water-gas group, getting to the gas valve stem.

Assembly is carried out in reverse order.

Selection Tips

- When choosing a suitable membrane for a gas-fired water heater, you need to take into account the brand of the device, since some columns have round diaphragms, while others have parts with a rather complex shape.

- If you could not find a round diaphragm specifically for your column, it is acceptable to purchase and install in its place a part of the same diameter for a column from another manufacturer, for example, a diaphragm with a diameter of 73 mm.

- If the column has been serving you for more than five years, buy the membrane right away with the plastic parts that adjoin it (plasticizers are washed out of them over time, which leads to brittleness).