- Installation: recommendations and diagrams, the main stages of the installation of the chimney

- General requirements

- Installation steps

- Video description

- Connecting a ceramic chimney

- Video description

- What material is better to choose a chimney?

- Stainless steel chimney

- Ceramic chimney

- coaxial chimney

- Brick chimney

- Asbestos-cement pipe as a chimney

- Place for installation of a gas boiler

- Installation standards according to SNiP

- Boiler installation approval

- 1. Specifications

- 2. Project

- 3. Coordination with the gas supply organization

- Basic moments

- What it is

- To whom does it apply

- The main stages of installation approval

Installation: recommendations and diagrams, the main stages of the installation of the chimney

The installation of the chimney is divided into several stages - this is the preparatory work, the installation itself, then the connection, start-up and, if necessary, debugging of the entire system.

General requirements

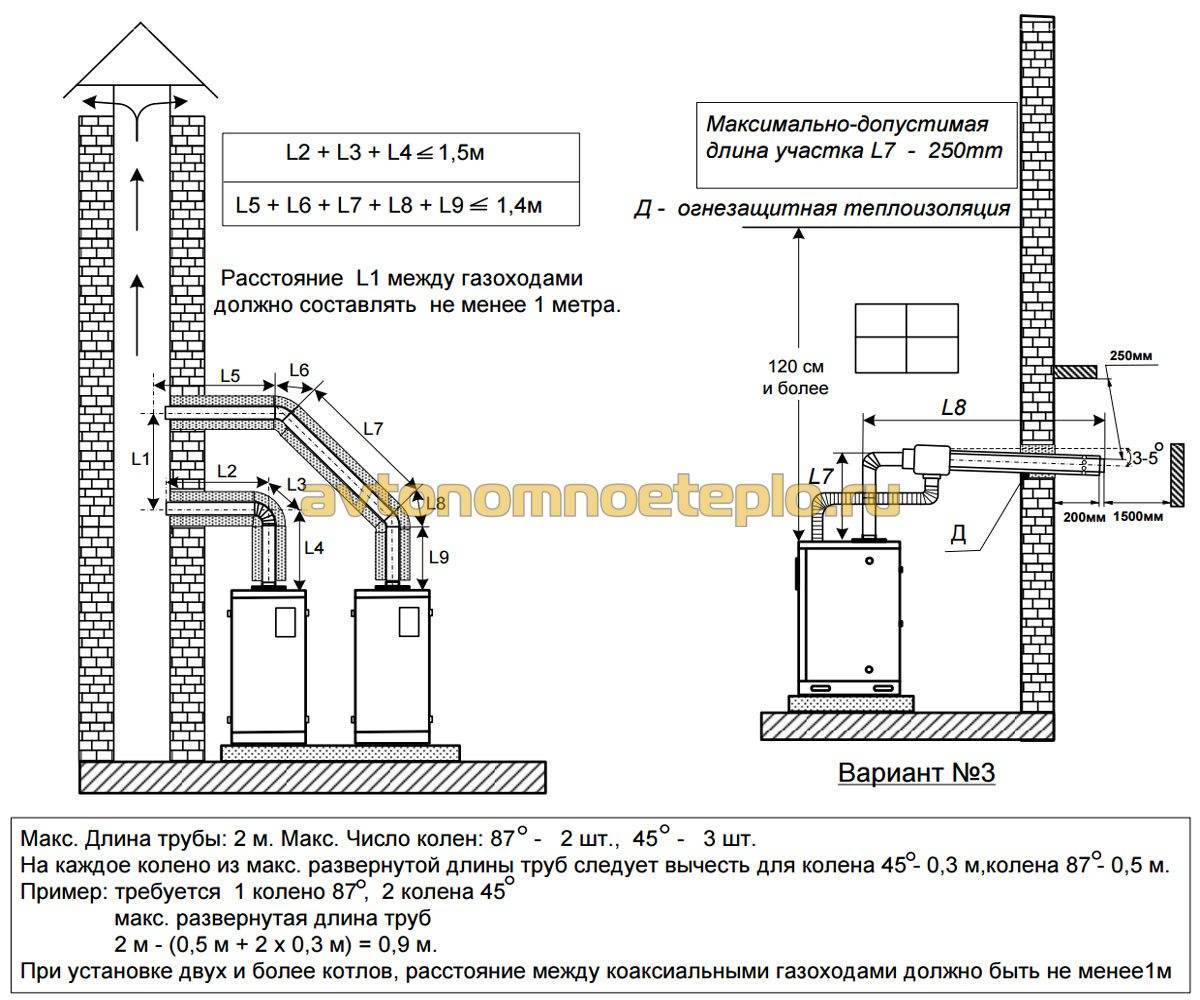

When combining several heat generating installations, a separate chimney is created for each of them. In exceptional cases, a tie-in to a common chimney is allowed, but at the same time, a difference in height of at least one meter must be observed.

First, the parameters of the chimney are designed and calculated, which are based on the recommendations of the manufacturers of gas boilers.

When summarizing the calculated result, the inner section of the pipe cannot be less than the diameter of the boiler outlet pipe. And according to the check according to NPB-98 (fire safety standards), the initial speed of the natural gas flow should be 6-10 m / s. And besides, the cross section of such a channel must correspond to the overall performance of the unit (8 cm2 per 1 kW of power).

Installation steps

Chimneys for gas boilers are mounted outside (add-on system) and inside the building. The simplest is the installation of the outer pipe.

Installation of an external chimney

Installing a chimney at a wall-mounted boiler is done as follows:

- A hole is cut in the wall. Then a piece of pipe is inserted into it.

- A vertical riser is assembled.

- The joints are sealed with a refractory mixture.

- Fixed with wall brackets.

- An umbrella is attached to the top to protect it from rain.

- An anti-corrosion coating is applied if the pipe is made of metal.

Proper installation of the chimney guarantees its impermeability, good draft, and prevents soot from accumulating. Installation performed by specialists will significantly reduce the cost of maintaining this system.

In the case of arranging an opening for a pipe in the roof of a house, special boxes with aprons are used. In this case, the design as a whole is influenced by such factors as:

- The material from which the pipe is made.

- Exterior design of the chimney.

- Type of roofing.

The main factor influencing the choice of design is the temperature of the gas that passes through the pipe. At the same time, according to the standards, the distance between the chimney pipe and combustible materials must be at least 150 mm. The most advanced is the assembly system by segments, where all elements are assembled by cold forming.

Video description

How the chimney pipe is installed, see the following video:

Connecting a ceramic chimney

Ceramic chimneys themselves are almost eternal, but since this is a rather fragile material, you need to clearly imagine how the connection (docking) of the metal part of the chimney and the ceramic one is correctly performed.

Docking can only be done in two ways:

By smoke - a metal pipe is inserted into a ceramic

It is important to remember here that the outer diameter of the metal pipe should be smaller than that of the ceramic one. Since the thermal expansion of the metal is much greater than that of ceramics, otherwise the steel pipe, when heated, will simply break the ceramic one.

For condensate - a metal pipe is put on a ceramic one.

For both methods, specialists use special adapters, which, on the one hand, are equipped with a gasket for contact with a metal pipe, and on the other, which contacts directly with the chimney, are wrapped with a ceramic cord.

Docking should be carried out through a single-wall pipe - it has a higher heat transfer coefficient. This means that the smoke will have time to cool down a little before it reaches the adapter, which ultimately extends the life of all materials.

Video description

Read more about connecting to a ceramic chimney in the following video:

VDPO shows great requirements for chimneys for gas boilers, because of this, it must be installed by specialized teams. Since competent installation guarantees not only long-term operation of the device, but also makes living conditions in a private house safe.

What material is better to choose a chimney?

There are many materials used in the production of chimneys for private houses today.

But since we need a reliable chimney specifically for a gas boiler, when choosing, you should pay attention to the following criteria:

- It is necessary to choose a material that will be resistant to various external factors, for example, fire, moisture, various acids that can be released during combustion;

- Gas permeability must be zero - this is one of the most important selection criteria when buying a chimney for a gas boiler;

- Material weight: it is best to choose those options that will not affect the walls and foundation of the house.

Under the criteria described above, a chimney made of acid-resistant stainless steel is most suitable - it meets both the criteria for strength and lightness of construction.

Let's take a closer look at each of the materials presented on the market today.

Stainless steel chimney

As we found out, this type of material is the most successful solution for a gas boiler. Stainless steel is resistant to various kinds of external factors, while providing a good level of traction. If desired, this type of chimney can be installed without problems on your own, since it has a very small weight. In addition to these advantages, a steel chimney also has another indisputable advantage - a long service life. With proper operation, such a chimney can last up to 15 years.

There are also chimneys made of galvanized steel, which are in many ways inferior to the previous ones.The main difference lies in the resistance to hot and humid fumes with high acidity - galvanized steel quickly collapses under such influence, which means that replacement will be required much faster.

Ceramic chimney

The undisputed leaders among chimneys in terms of service life - they can last up to 30 years. There are also models with an external steel contour of European production.

The design also has serious drawbacks: an impressive weight is not suitable for all buildings, and such a chimney must be installed strictly vertically to form the maximum level of thrust, which is also not realistic in all cases.

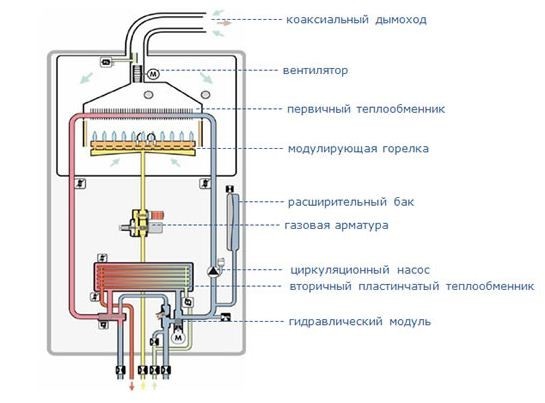

coaxial chimney

One of the most modern versions of chimneys. It has a high efficiency and safety level, but also a fairly high cost.

Such a chimney for a gas boiler, due to its design, with the help of two pipes, immediately takes air for the combustion process and blows out smoke. Such chimneys are required when installing a boiler with a closed combustion chamber, but, as already mentioned, they are difficult to attribute to the budget price segment.

Brick chimney

One of the most unsuitable designs for such equipment as a gas boiler, as it is quite difficult to install, short-lived and requires regular maintenance.

There is a version with a steel hull inside, that is, with the so-called "sleeve", which allows you to achieve better traction. This option is suitable for those who install a gas boiler in a house where a brick chimney has long been installed. Thus, the brick walls will perform protective functions, while the main task of creating traction will fall on the stainless steel interior.

Asbestos-cement pipe as a chimney

It also refers to inefficient solutions, as it has a short service life, the complexity of installation and installation, and with prolonged use, asbestos-cement material can cause a fire or explosion. Asbestos-cement pipes are rarely used today for a reason - there is a large selection of much safer and more reliable models on the market that do not cause concern about their service life.

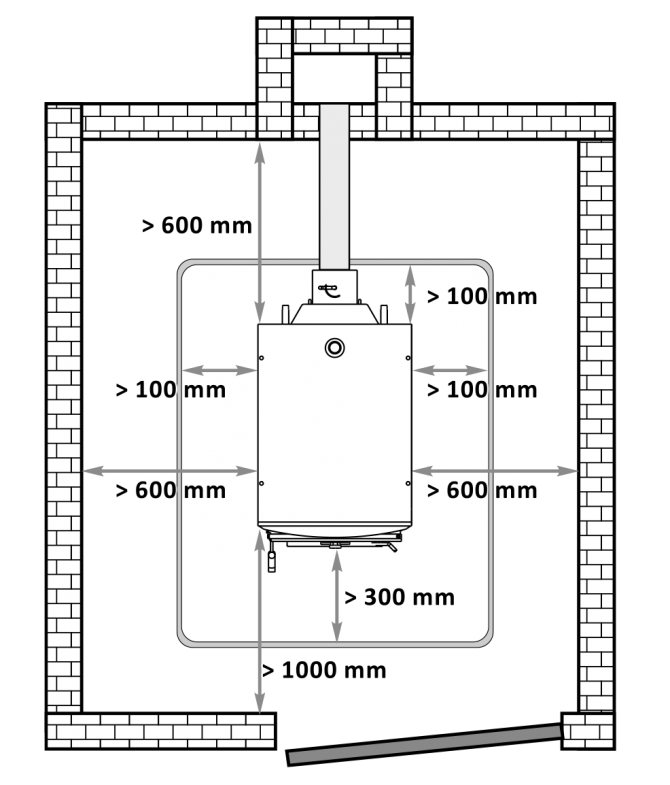

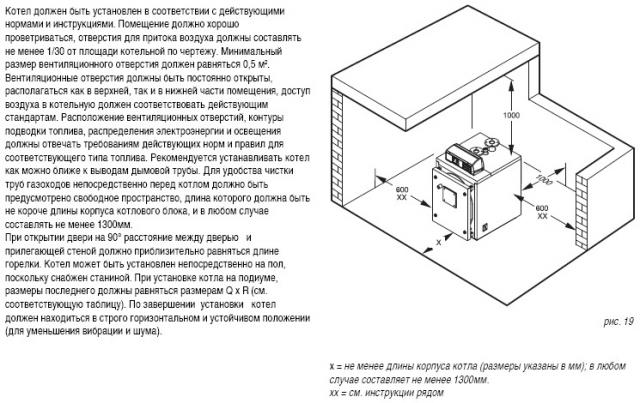

Place for installation of a gas boiler

Speaking specifically about apartments, they install gas boilers in them mostly in the kitchens. There are all the necessary communications: water supply, gas, there is a window and an extractor hood. It remains only to determine a suitable place for the boiler. For such an installation, wall-mounted (mounted) boilers are used. They are mounted on several hooks attached to the walls (they usually come with the kit).

As for installation in other rooms of an apartment or house, as a rule, none of them meets the requirements. For example, the bathroom does not have a window with natural light, the corridor usually does not fit in size - there are not enough tolerances from the corners or to the opposite wall, there is usually no ventilation at all or it is not enough. With pantries the same trouble - there is no ventilation and windows, there is not enough volume.

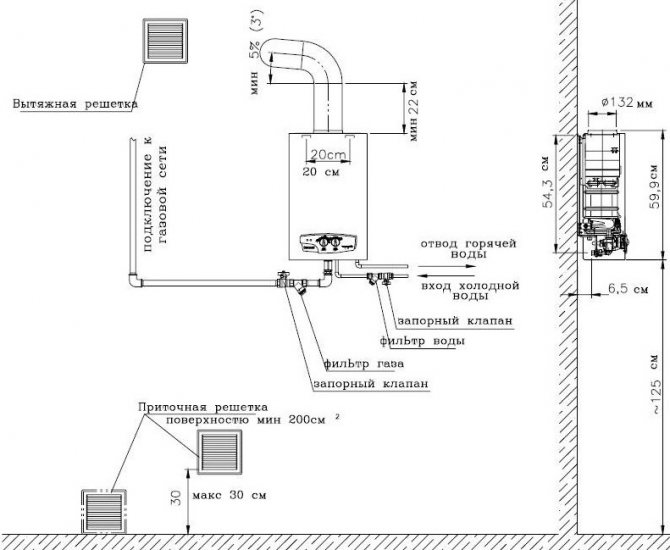

The exact distance from walls and other objects is indicated in the boiler operating instructions.

If there are stairs to the second floor in the house, the owners often want to put the boiler under the stairs or in this room. In terms of volume, it usually passes, and ventilation will have to be made very powerful - the volume is considered to be in two levels and it is necessary to ensure its triple exchange.This will require several pipes (three or more) of a very large cross section (at least 200 mm).

After you have decided on the room for the installation of a gas boiler, it remains to find a place for it. It is selected based on the type of boiler (wall or floor) and the requirements of the manufacturer. The data sheet usually details the distances from the wall to the right / left, the installation height relative to the floor and ceiling, as well as the distance from the front surface to the opposite wall. These may vary from manufacturer to manufacturer, so read the manual carefully.

Installation standards according to SNiP

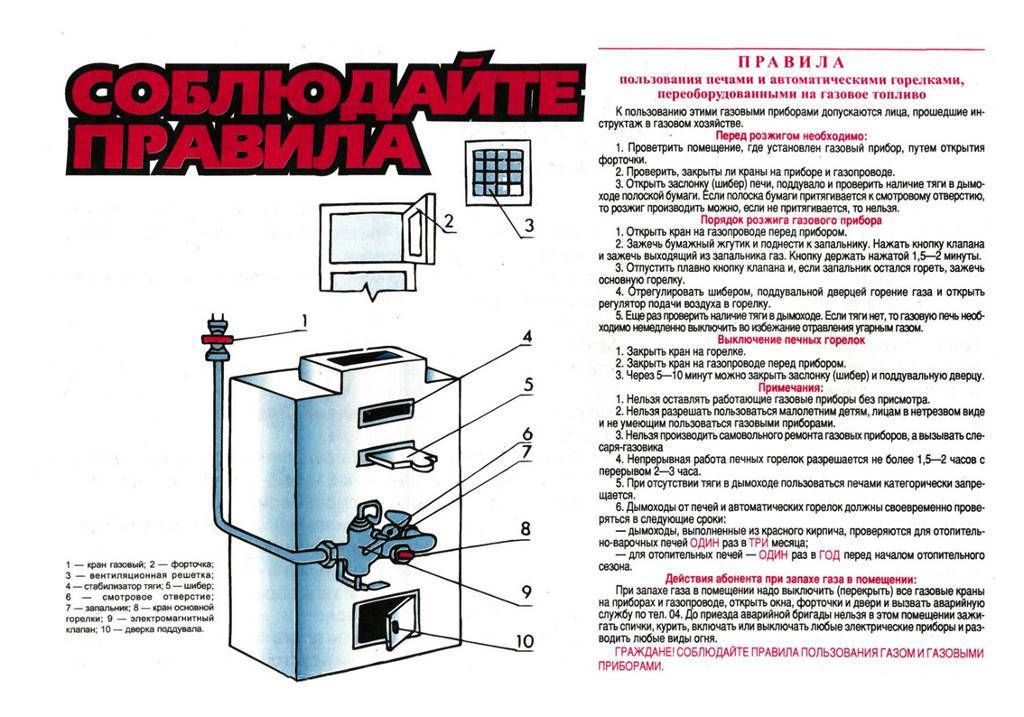

In the absence of such recommendations in the equipment passport, the installation of a gas boiler can be carried out according to the recommendations of SNiP 42-101-2003 p 6.23. It says:

- Gas boilers can be installed on fireproof walls at a distance of at least 2 cm from it.

- If the wall is slow-burning or combustible (wooden, frame, etc.), it must be protected by fireproof material. This may be a three-millimeter sheet of asbestos, on top of which a sheet of metal is fixed. Plastering with a layer of at least 3 cm is also considered as protection. In this case, the boiler must be hung at a distance of 3 cm. The dimensions of the fireproof material must exceed the dimensions of the boiler by 10 cm from the sides and bottom, and from above must be 70 cm more.

Questions may arise regarding the asbestos sheet: today it is recognized as a material hazardous to health. You can replace it with a layer of mineral wool cardboard. And keep in mind that ceramic tiles are also considered a fireproof base, even if they are laid on wooden walls: a layer of glue and ceramics just give the required fire resistance.

A gas boiler can be hung on wooden walls only if there is a non-combustible substrate

The installation of a gas boiler relative to the side walls is also regulated. If the wall is non-combustible, the distance cannot be less than 10 cm. For combustible and slow-burning, this distance is 25 cm (without additional protection).

If a floor standing gas boiler is installed, the base must be non-combustible. A non-combustible stand is made on a wooden floor. It must provide a fire resistance limit of 0.75 hours (45 minutes). This is either bricks laid on a spoon (1/4 of a brick), or thick ceramic floor tiles that are laid on top of an asbestos sheet fixed to a metal sheet. The dimensions of the non-combustible base are 10 cm larger than the dimensions of the installed boiler.

Boiler installation approval

You need to go through several instances to get approval for the installation of a gas-fired boiler. Independently, without approvals, the installation process will be illegal and unsafe, and not only for the owner of the home, but also for the rest of the residents of the house, if the boiler is installed in a high-rise building.

1. Specifications

To connect a private house or apartment to the gas supply, you will have to obtain technical conditions from the gas supply organization that allow this procedure. For this, an application is written to the controlling organization. It must indicate the approximate demand for the volume of gas per hour. The application process takes seven to fourteen days. Upon successful completion of this event, a document will be issued - the technical conditions for the installation of gas-fired equipment. This is the permit for preparatory construction and installation work.

2. Project

With the technical specifications in hand, you can proceed to the second step - the development of project documentation. The gas supply project includes schemes for laying a gas supply pipe from the boiler installation site to the central gas pipeline.

The project will also indicate sections of the gas pipeline crossing the section

If the dwelling is located in the private sector, and the pipeline must cross the land, then a diagram of the gas pipe is also drawn up on the site, which indicates the place of its entry into the wall of the house. The project is developed by engineers licensed for such activities, based on the provisions of the GOS.

3. Coordination with the gas supply organization

The finished project is submitted for approval to the organization that controls the gas supply in the applicant's area of residence. Project approval takes from seven to one hundred days - it depends on the volume and complexity of the document. The following materials regarding the heating device are attached to the project:

- examination of the compliance of the boiler with all the requirements that are necessary to ensure normal operation and safety;

- technical passport of the device;

- certificates of compliance with technical and sanitary requirements;

- operating instructions.

All documents specified in the list are drawn up by the manufacturer and must accompany any product of this type without fail.

They are transferred by the seller to the buyer when purchasing the device - special attention should be paid to this

If the project was rejected for the first time, the applicant is issued a document that indicates the reasons for the rejection and a list with a detailed listing of all project problems that need to be corrected.

If the project is approved, it is certified by the signature and seal of the responsible person. This document is the final approval for the installation of the heater.

Basic moments

Not all lawyers agree with the obligation to draw up an VDGO agreement. According to Art. 26 of the Law on Gas Supply in the Russian Federation, suppliers or their intermediary organizations are prohibited from imposing contract terms that are not directly related to gas supply and require consumers to pay for an additional service in order to receive the main one.

A sample of the VDGO agreement can be downloaded here.

It is forbidden to violate the pricing procedure, which puts consumers in unequal conditions for receiving the same service. Gas utilities are required to check the equipment at least once every 6 months.

According to paragraphs. 55-62 of the Decree of the Government of the Russian Federation of July 21, 2008, the check should be free of charge. The law does not provide for the obligatory conclusion of an agreement for the subscription service of the VDGO, but, nevertheless, regional legislation obliges to draw up such a transaction in order, first of all, to protect homeowners from equipment breakdown and possible accidents.

According to Art. 16 of the Consumer Rights Protection Law, the supplier has no right to force the consumer to pay for maintenance services. To protect your rights, you can try to contact the territorial department of the Federal Antimonopoly Service of the Russian Federation for a specific region with a statement on bringing the supplier to administrative responsibility under Art. 14.6 of the Code of Administrative Offenses of the Russian Federation, as well as file a complaint with Rospotrebnadzor.

The practice of recent years shows that the FAS makes decisions not in favor of consumers. When setting prices for maintenance, the gas monopolist practically does not limit anything. The tariffs established at the federal level are advisory in nature and may vary depending on the region.

In addition, officials often refer to the absence of a provision obliging gas workers to bring to the attention of consumers the cost of a single technical manipulation (service).

You should keep track of who is doing the work on the part of the contractor. They are not always experienced and competent in resolving issues and often require money for their work in excess of the amount paid for the contract. They are justified by the fact that maintenance does not include the repair of complex equipment.

In such a situation, one should be guided by the Order of the FTS dated December 27, 2013 No. 269-e / 8, which lists the full list of works and the recommended cost of each service. Tariffs indicated at the regional level should not be higher than the general federal indicators recommended in the guidelines of the FTS.

What it is

The contract for the maintenance of internal house gas equipment is a transaction under which the performer (contractor) has the obligation to perform maintenance in a timely manner, including repair, restoration, and preventive maintenance of units and assemblies of the relevant engineering networks.

The contract may be accompanied by a schedule and annexes with detailed prices, as well as a list of necessary measures. The contract is often public in nature, that is, the subscriber accepts the already existing terms of the transaction and undertakes to timely pay for the maintenance of networks and devices.

The deal is valid for 1 year, with unlimited renewal periods. Unilateral cancellation of the contract is only possible if the consumer refuses the gas supply service.

To refuse, it is necessary to notify the resource supplying organization no later than 1-2 months in advance. The terms of the transaction can be specified depending on the type of object. The average cost of service varies by region.

To whom does it apply

Owners and owners of cottages, townhouses, duplexes are obliged to conclude an agreement for the maintenance of gas equipment in a private house. The contractor (executor) fulfills the terms of the transaction.

It can be simultaneously an organization that supplies gas. The law does not prohibit drawing up an agreement with a third-party service organization, including one that sells gas equipment - water heaters, boilers, metering devices, etc.

The main stages of installation approval

Installation of gas boilers must be carried out by specialized organizations. If the user has decided to change the boiler to a similar model that was previously prescribed in the technical conditions for gas supply, he will not have problems with the preparation of permits. If this is a more powerful unit, he needs to get new documents to put the boiler equipment into operation.

Usually this process takes from two weeks to three months, but often many users cannot cope with the red tape, rightly calling it "the three circles of hell."Recently, the practice has become widespread when a specialized organization for replacing the boiler is also entrusted with the work of issuing permits, which makes life easier for the customer and does not lead to a significant increase in the cost of the project.

The basic norms and rules that guide when replacing a boiler unit in a domestic environment are enshrined in SNiP documents on gas supply, heating, hot water supply and safe operation of boilers NoNo 42-01-2002, 31-02-2001, 2.04.08-87, 41- 01-2003, 21-01-97, 2.04.01-85.

The main stages of installation approval:

- Obtaining technical conditions in the gas service of the city.

- Development of the installation project: a diagram of the installation and laying of a gas pipeline from the point of tie-in to gas networks with a layout of internal gas networks at the user's site and determining the costs, how much it will cost to change the unit.

- Coordination of the project with local authorities, the architectural department, Gorgaz and organizations owners of engineering networks: water, sewerage and electrical networks.

Package of documents for gas inspection:

- Project;

- registration certificate of the gas boiler;

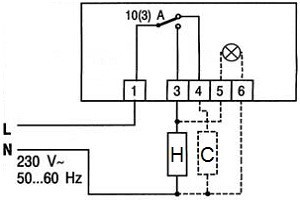

- factory instructions for its operation and wiring diagrams;

- certificates of compliance with state standards, presented by the equipment manufacturer when purchasing the boiler.

Note! In case of refusal, the organization must provide a clear reason and a list of requirements for the project change. An unauthorized project for the reconstruction of a gas boiler is prohibited at the legislative level, as it can endanger the lives of a large number of people