- Selection rules

- Types of taps for gas

- Variety #1: cork

- Variety #2: ball

- Getting Started

- Tools

- revision

- Replacement

- A special case

- Instructions for self-connection

- Step #1: Dismantling the old stove

- Step #2: Performing a Faucet Replacement

- Step #3: Connecting the Flexible Hose to the Stove

- Safety regulations

- Reasons for replacing a gas valve

- Main points for device selection

- HEALTH REQUIREMENTS IN EMERGENCY SITUATIONS

- Instructions for self-connection

- Step #1: Dismantling the old stove

- Step #2: Performing a Faucet Replacement

- Step #3: Connecting the Flexible Hose to the Stove

- When are gas valves replaced?

- Common gas stove failures

- Conclusions and useful video on the topic

- Conclusions and useful video on the topic

Selection rules

Italian gas valves lead the market

Italian gas valves lead the market

Before changing a gas valve, you should familiarize yourself with the main criteria that characterize the quality and reliability of products.

- Life time. Given the specifics of replacing a gas valve, it should be carried out as rarely as possible. Based on this, the minimum period is 10 years.

- Manufacturer. Preference should be given to trusted brands and dealers. It is not recommended to purchase products from China. The best choice would be products from Italy, Germany, Poland and France.

- Type of marking. All characters must be clear, without spaces, curvature and sagging. Plus, full information about the brand, size, pressure, material and standard.

- Quality. The inner element must completely cover the gap, have a perfect polish without mechanical damage. The presence of iron in the product is checked with a magnet.

When buying, you should ask the seller for a certificate to make sure that the product is not a fake.

Types of taps for gas

There are many types of locking devices that are installed on gas pipes. According to the features of their designs, two main groups can be distinguished:

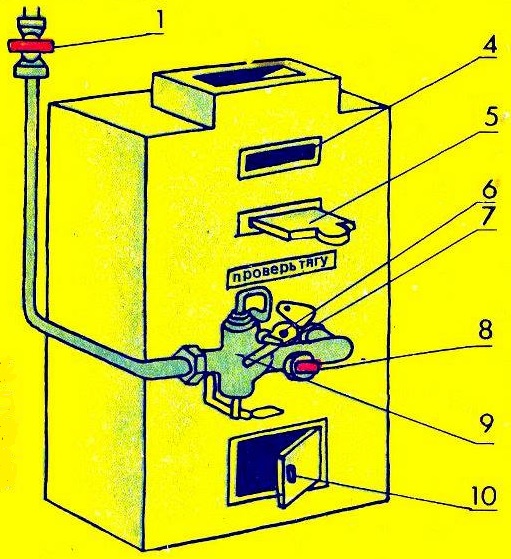

Variety #1: cork

Until recently - the most common type of gas taps. The central part of such models is a conical element (cork) with a hole.

The main body of a cork faucet is a cone-shaped insert with a hole in the middle. With its help, the gas flow is blocked or opened. They make taps from brass or cast iron - durable, wear and corrosion resistant materials (+)

The main body of a cork faucet is a cone-shaped insert with a hole in the middle. With its help, the gas flow is blocked or opened. They make taps from brass or cast iron - durable, wear and corrosion resistant materials (+)

When opening the device with a flywheel, the hole in the conical part is aligned with the one in the pipe, so that the gas passes to the equipment. A gland is usually used to connect plug valves to a pipeline to create tightness.

Variety #2: ball

The main part of this type of locking element is a spherical part made of strong metal. As in cork analogues, it has a hole, which, when the handle is turned, is combined with the pipe, which ensures the admission of natural fuel to the corresponding device.

Scheme of operation of a ball valve: the main operating element of such a device is a round part that blocks the gas admission in the closed state and ensures the passage of the flow in the open

Such valves appeared relatively recently and quickly gained popularity due to their many advantages, namely:

- low cost;

- excellent functionality and safety margin;

- long service life;

- ease of use;

- the ability to work in various environments at temperatures from -60 to +80 ° C.

Due to the combination of valuable qualities, at present, when equipping domestic gas systems, experts prefer spherical structures.

Unlike socket and flange models, which can be reused, the welded valve is a disposable device and cannot be repaired.

According to the method of connection to pipes, several subspecies of ball valves are distinguished:

- Threaded (coupling). In this case, the valve is connected to a section of the gas pipeline using a threaded part.

- Flanged. Fastening is carried out using flanges fixed with bolts. Such devices are most often used in the transportation of gaseous substances and oil.

- Welded. In this case, the valve is firmly welded to the pipe using an appropriate apparatus.

According to their purpose, ball valves are divided into three types:

- Three-way, used for the redistribution of gas flows;

- With heated housing, used in cold climates;

- With leakage control.

There is also a division according to the diameter of the passage.

According to this indicator, parts can be classified into two categories:

- DN 10-50 mm;

- DN over 50 mm.

Another classification takes into account the nominal pressure that the valve can withstand.

In this case, two types of devices are distinguished:

- PN 1.6 MPa 16 kg/cm2;

- PN 4.0 MPa 40 kg/cm2.

Ball valves can be made from different types of metal. The most widely used elements are made of brass, zinc, steel 20 and alloys (09G2S, 12X18H10T), plastic.

The best qualities are demonstrated by brass devices, which can be yellow or silver (the latter is typical for nickel-plated models). Devices made of this alloy can be recognized by their relatively heavy weight.

The most wear-resistant and resistant to external influences are gas valves made of brass or bronze. Such a device is characterized by small dimensions, reliability, ease of use, high working life.

Brass faucets, with a robust, versatile design, are durable, low maintenance and can be installed in any position.

Getting Started

Tools

What should be prepared before opening the gas pipeline?

- We have already mentioned a pair of gas keys. It is a couple - because in most apartments of the old stock, the connection to the stove is made with rigid pipes; to unscrew the locknut and coupling, you need to hold the squeegee in a stationary position, preventing it from turning the valve.

- To seal threads on gas, FUM tape or a synthetic thread with Tangit Unilok sealant can be used. Linen with paint is also suitable, but the paint is applied to the thread and winding for a relatively long time, and in our case the count will go for seconds.

- When repairing a faucet, a special graphite lubricant for gas valves or ordinary grease can be used.The graphite base is more practical: it retains its properties longer.

- In addition, when repairing the valve, you will need a 1/2-inch female plug and a flathead screwdriver.

If you are looking for how to lubricate a gas valve on a stove, pay attention to specialized graphite lubricants.

revision

So, what to do if the gas tap smells of gas and its replacement is not included in your plans?

- We close the valve by turning its handle perpendicular to the pipe.

- We fix the drive after the valve with one of the gas keys and further hold it in a fixed position.

- With the second key, we drive the locknut and coupling onto the long thread of the drive.

- Partially turn off the valve with a key - until the moment when it starts to rotate by hand.

- We completely unscrew the valve and immediately put a plug on the thread. Do not be afraid that excess pressure will interfere with you: it is only 3 - 5% higher than atmospheric pressure.

- We wind the thread under the plug and twist it by hand to the end.

- We unscrew the valve from the drive.

Do not forget to remove the layers of old winding and paint.

- We unscrew the plug with a slot for a screwdriver on the back of the valve and take out the spring hidden under it; then we push the conical plug out of the body.

- We clean the body and plug from the remnants of the old grease and apply a new one in a thick layer.

- We assemble the valve in the reverse order.

- We put it instead of the plug, not forgetting to replace the thread winding.

- We screw in the drive and, having rewound the threads, we drive the coupling and locknut into the working position.

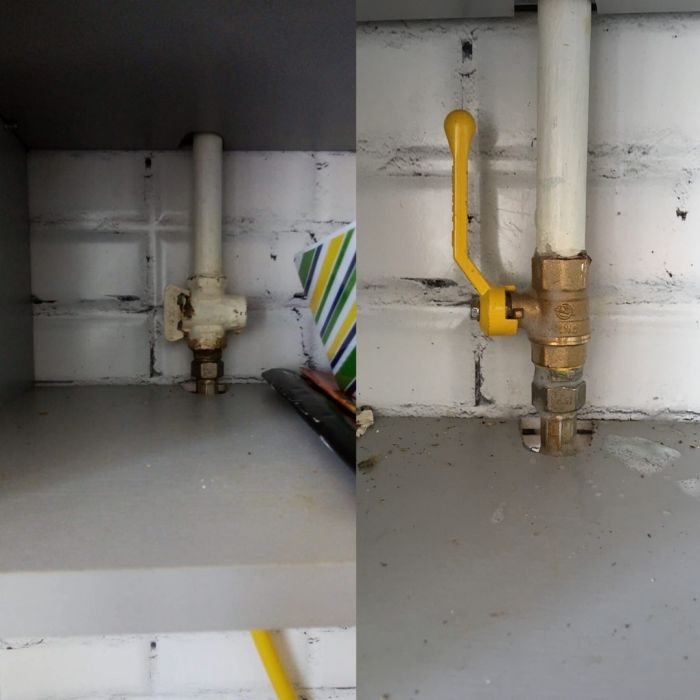

Replacement

What to do if the gas tap in the kitchen is leaking and you want to replace it with a new one?

If the new valve is the same length as the old one, the steps are completely the same as those described above - with the difference that, for obvious reasons, manipulations with the plug are made unnecessary.

The valve is turned until it stops by hand, then about 1 turn with a key.

How to change the gas valve in the apartment if its length does not match the length of the old one?

- The drive with the coupling and the lock nut is thrown out.

- The short thread after the drive is supplied with a short extension with internal and external threads. It will allow the flare nut to press the gasket against the flat and wide edge of the extension, and not against the serrated end of the pipe.

In the photo - extensions for threads.

The valve and the extension are connected by a gas hose "father-mother". Of course, with sealing of all threads.

A special case

How to change the tap on a gas cylinder if it cannot be turned off with an ordinary key? Heat the valve with a building hair dryer - and its expansion will make the effort required to unscrew it quite feasible.

Instructions for self-connection

Payment for the services of a gasman for installation work is not too high, but many home craftsmen prefer to do everything on their own. This is a feasible occupation that requires the purchase of components and theoretical knowledge.

And to connect, you will need to prepare the following tools and buy materials:

- keys: gas No. 1, adjustable 22-24;

- a screwdriver to tighten the clamp, if required;

- seals (thread loctite 55, linen, FUM - tape);

- gasket ½;

- gas sleeve;

- ball valve 1/2';

- brush and soap solution, which will be required to control the progress of work.

A rag and a plastic stopper will also come in handy. The rag will be used as a temporary cover against a gas leak.The narrowed edge of the plug must be adjusted to the opening of the supply pipe. If during the extraction process, a homemade part gets stuck, it can be easily removed with a corkscrew.

Step #1: Dismantling the old stove

Closing the crane on the descent is a top priority to ensure the safety of the work performed. Next, you need to unscrew the lock nut located on the outlet and remove the coupling. If the coupling and locknut of the old plate were previously painted, this will greatly complicate the process of their dismantling.

Sometimes this procedure cannot be performed, then you will need to cut the eyeliner with a grinder.

The dismantling of the gas stove is carried out after disconnecting from the pipe-conductor of the gas main. Difficulties encountered with unscrewing the locknut on a metal pipe are solved by trimming the liner

In the process of unscrewing the drive located in the lowering tap, it is necessary to hold the tap itself with a key. It will not have to be removed if the crane is not planned to be replaced. When it is planned to postpone the installation of the plate, an additional plug is installed on the descent.

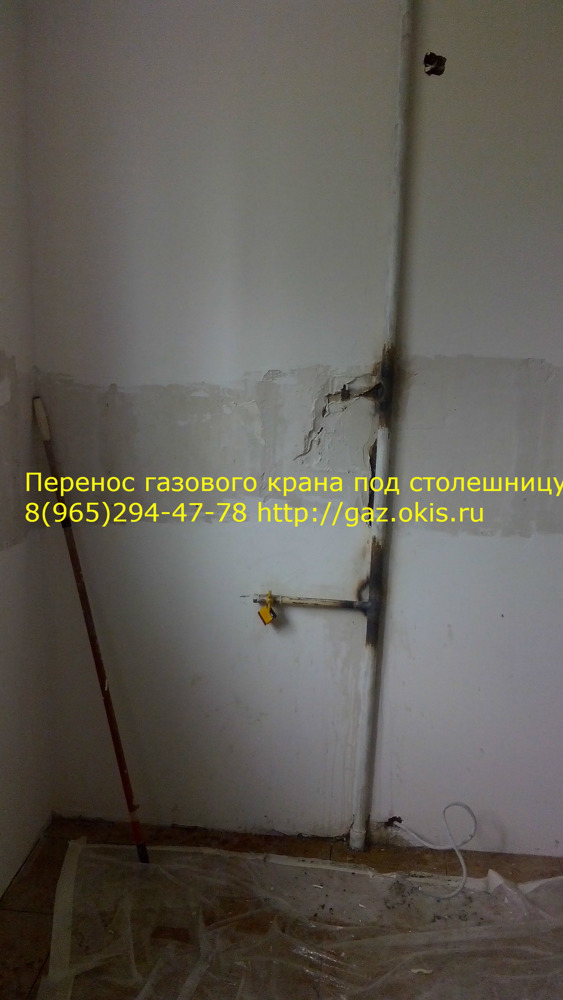

Step #2: Performing a Faucet Replacement

There are situations when the wall is located very close to the crane and there is no way to dismantle it. In this case, it is necessary to bend the fastening and install a wedge between the wall and the pipeline. However, this is done in such a way that it is possible to continue to do the work.

It is necessary to prepare a piece of rags sufficient to completely cover the pipe after dismantling the old faucet. The next will be its tearing without full untwisting. And you will also need to prepare the selected type of sealant. Do not forget to thoroughly ventilate the room during work to eliminate gas vapors.

After unscrewing the faucet, the outlet from the pipe is tightly fixed with a finger, and then with a wet rag. The main actions are aimed at the maximum elimination of gas exit from the pipe. In this case, the thread on the branch should not be closed, since it will be covered with the selected sealant.

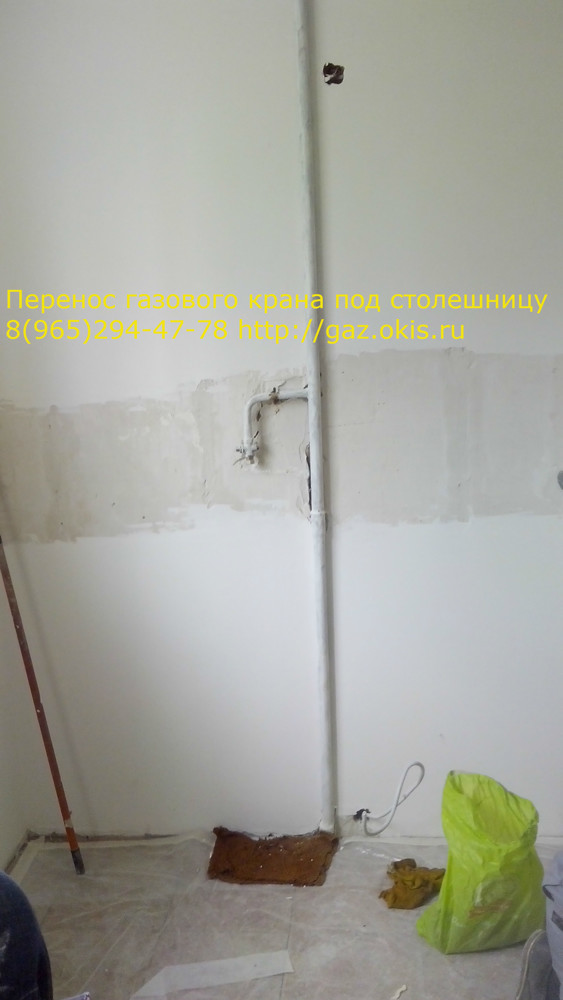

Before winding the sealant, the thread on the descent must be thoroughly cleaned. Further, its winding is carried out directly. This process ensures a secure and airtight fixation of the new faucet, which is then tightly twisted. The last step is to install the previously removed handle on the faucet.

With the help of soap foam, the tightness of the connection of the faucet and the gas pipe is checked. If the work has been carried out correctly, the installation of the gas hose can be continued.

If the gas equipment is connected to the main for the first time, it will be necessary to call the gas master. In his presence, a control check of the equipment for gas leakage with the valve open is carried out. In the event that the gas service employee did not find any violations, he must enter the established stove brand in the register.

Step #3: Connecting the Flexible Hose to the Stove

Using a sealant, the external thread of the hose fitting is wrapped around. After that, it must be screwed into the faucet on the branch pipe. The connection of the flexible hose to the manifold is carried out at the finishing stage.

Next, the stage of test opening the faucet on the descent for gas leakage is mandatory. Using soap foam, the docking points are processed with a brush. If foaming occurs when the gas valve is opened, the work must be redone.

It is necessary to check the thread located on the plate manifold. Quite often it is 3/8′.In this case, you will need to install a 1/2 ′ adapter, with a seal

If the work on replacing the gas hose is carried out in a private house where bottled gas is used, an additional replacement of the nozzle with a smaller diameter will be required. If this is not done, the burners will release too much soot, which likes to settle on furniture and utensils in the kitchen.

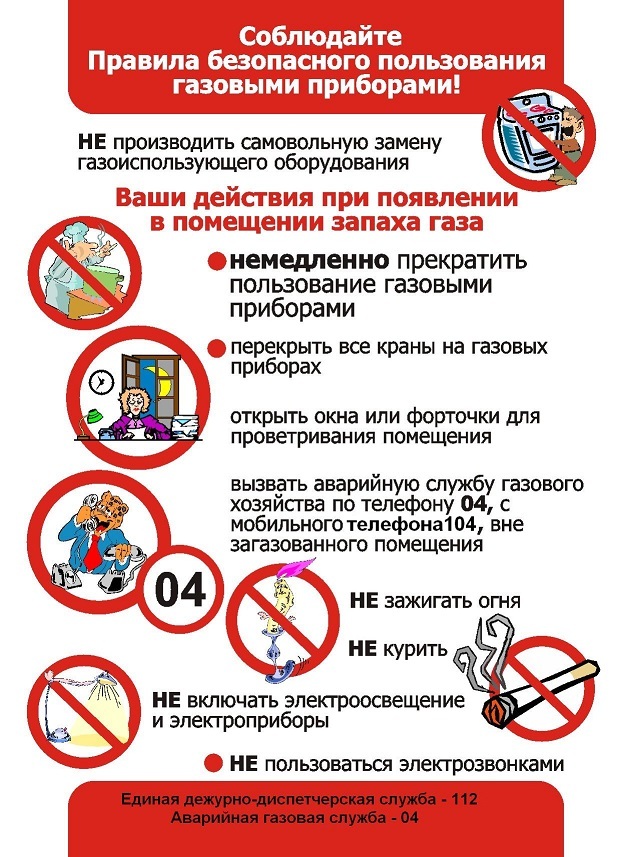

Safety regulations

Working with gas equipment has an increased level of danger, so you must follow safety rules. When carrying out independent work to replace or repair a valve on a pipe, adhere to the following rules:

All manipulations with gas equipment are carried out with open windows.

Mandatory ventilation of the air in the room when working with gas

- Electricity must be completely turned off throughout the apartment.

- During work it is forbidden to smoke, light matches.

- Repair work is carried out only during daylight hours, with good daylight.

- The door to the room where the equipment replacement activities are being carried out must be tightly closed.

- The public access valve must not be blocked. This increases the concentration of propane and the danger of an explosion.

- It is better to work as a team. This will speed up the process and minimize errors.

- If the gas equipment and pipe are old, there are visible signs of corrosion, you should not carry out any manipulations yourself.

- It is necessary to provide the place of repair work with fire-fighting equipment.

Having a fire extinguisher in the kitchen will keep your home safe

Compliance with safety rules is not just a requirement for reinsurance.These measures will help keep the house and people's health safe and sound.

So, replacing a gas valve on your own requires the owner to have certain knowledge and skills in this area, the availability of the necessary tools, as well as reliable, high-quality lubrication for the crane. The sealant will allow the safe use of the gas valve, increase the life of the entire system.

Reasons for replacing a gas valve

There can be many technical and aesthetic reasons for replacing a gas faucet in the kitchen.

The most common are the following:

- A leak. This is the most dangerous condition that occurs in the system. The gas entering the room can cause poisoning, which is fraught with a deterioration in well-being, the death of the tenants of the apartment. The worst consequence is an explosion that can destroy an entire staircase and bring the entire building into disrepair.

- Tight turning, jamming. This phenomenon indicates contamination of the internal parts of the valve. Since the product is non-separable, it must be changed. A faulty faucet can break down completely, depriving the apartment owners of the opportunity to turn off the gas when necessary.

- Inconsistency with the interior. Old, bent and covered with several layers of paint products do not fit into the style of modern rooms.

- End of the warranty period for the operation of the valve. It is not worth the risk in such cases, it is better to make a replacement.

Main points for device selection

When choosing a locking mechanism for a gas pipeline, you should pay attention to such characteristics as:

- Pipe diameter. The tap must completely block the flow of gas into the apartment.If the locking element does not fit snugly against the walls of the gas pipe, then its tightness will be only partial, which can lead to serious consequences.

- Coincidence of the diameter and thread pitch on the pipe and tap. In this case, the installation of the device is quite easy. Installation of a locking element with a mismatched thread and diameter is, in principle, possible using adapters, but this will require additional material and time costs for the purchase and installation of additional parts.

- Hull integrity. The outer shell of the element must be free of cracks, chips, sags and other defects. Their presence indicates a violation of the rules for the transportation, manufacture or storage of parts, due to which internal malfunctions are possible, as well as a reduction in the period of operation.

You should also pay attention to the quality of products, giving preference to models of well-known companies.

HEALTH REQUIREMENTS IN EMERGENCY SITUATIONS

4.1. In the event of a sudden power outage, the occurrence of extraneous noise during the operation of gas equipment, stop work, stop the operation of the equipment, post a poster "Do not turn on!" and notify your immediate supervisor. 4.2. Do not start work until the problem is completely eliminated. 4.3. If a fire or ignition is detected, immediately stop work, shut off the gas supply, turn off electrical installations, report the fire to the fire brigade by calling 101 and proceed to extinguish the fire using the available fire extinguishing equipment. 4.4. In case of fire of electric motors, electric cables, it is not allowed to extinguish the flame with water.In this case, it is necessary to turn off the damaged electrical installation, and then proceed to extinguish it using fire extinguishers. 4.5. If an accident occurs, the eyewitness of which is a locksmith, he should immediately withdraw or take the victim out of the danger zone, report the incident to the management of the organization, and provide first aid to the victim, call an ambulance by phone 103, help arrange delivery to the nearest medical facility. 4.6. If the accident happened to the locksmith himself, he should stop working and, if possible, contact a medical institution, report the incident to the management of the organization or ask someone around to do it. 4.7.Each employee must be able to provide first aid to the victim: - in case of bruises, ensure complete rest, put cold on the bruised place; if the abdomen is bruised, do not give the victim to drink; - in case of bleeding, raise the limb, apply a pressure bandage, tourniquet (in summer, the tourniquet is left for 1.5 hours, and in winter - for 1 hour); - in case of a fracture, apply a splint; - in case of thermal and electrical burns, close the burnt place with a sterile bandage; in order to avoid infection, you should not touch the burned areas of the skin with your hands and lubricate them with ointments, fats, etc.; - if acid or alkali gets into open areas of the body, immediately wash them with a neutralizing solution, and then with cold water and soap; in case of contact with alkali - with a solution of boric acid; - if acid and alkali get into the eyes, immediately rinse them with a neutralizing solution and contact a health center or a doctor; - in case of all poisoning, immediately remove or remove the victim from the poisoning zone, unfasten clothing that restricts breathing, provide fresh air, lay him down, raise his legs, cover him warmer, give him a sniff of ammonia and immediately transport the victim to a medical facility; - in case of electric shock, release the victim from the action of the current, if necessary, perform artificial respiration or closed heart massage; - it is possible to transport the victim only with satisfactory breathing and a steady pulse.

Instructions for self-connection

Payment for the services of a gasman for installation work is not too high, but many home craftsmen prefer to do everything on their own. This is a feasible occupation that requires the purchase of components and theoretical knowledge.

And to connect, you will need to prepare the following tools and buy materials:

- keys: gas No. 1, adjustable 22-24;

- a screwdriver to tighten the clamp, if required;

- seals (thread loctite 55, linen, FUM - tape);

- gasket ½;

- gas sleeve;

- ball valve 1/2';

- brush and soap solution, which will be required to control the progress of work.

A rag and a plastic stopper will also come in handy. The rag will be used as a temporary cover against a gas leak. The narrowed edge of the plug must be adjusted to the opening of the supply pipe. If during the extraction process, a homemade part gets stuck, it can be easily removed with a corkscrew.

Step #1: Dismantling the old stove

Closing the crane on the descent is a top priority to ensure the safety of the work performed. Next, you need to unscrew the lock nut located on the outlet and remove the coupling. If the coupling and locknut of the old plate were previously painted, this will greatly complicate the process of their dismantling.

Sometimes this procedure cannot be performed, then you will need to cut the eyeliner with a grinder.

In the process of unscrewing the drive located in the lowering tap, it is necessary to hold the tap itself with a key. It will not have to be removed if the crane is not planned to be replaced. When it is planned to postpone the installation of the plate, an additional plug is installed on the descent.

Step #2: Performing a Faucet Replacement

There are situations when the wall is located very close to the crane and there is no way to dismantle it. In this case, it is necessary to bend the fastening and install a wedge between the wall and the pipeline.However, this is done in such a way that it is possible to continue to do the work.

It is necessary to prepare a piece of rags sufficient to completely cover the pipe after dismantling the old faucet. The next will be its tearing without full untwisting. And you will also need to prepare the selected type of sealant. Do not forget to thoroughly ventilate the room during work to eliminate gas vapors.

After unscrewing the faucet, the outlet from the pipe is tightly fixed with a finger, and then with a wet rag. The main actions are aimed at the maximum elimination of gas exit from the pipe. In this case, the thread on the branch should not be closed, since it will be covered with the selected sealant.

Before winding the sealant, the thread on the descent must be thoroughly cleaned. Further, its winding is carried out directly. This process ensures a secure and airtight fixation of the new faucet, which is then tightly twisted. The last step is to install the previously removed handle on the faucet.

If the gas equipment is connected to the main for the first time, it will be necessary to call the gas master. In his presence, a control check of the equipment for gas leakage with the valve open is carried out. In the event that the gas service employee did not find any violations, he must enter the established stove brand in the register.

Step #3: Connecting the Flexible Hose to the Stove

Using a sealant, the external thread of the hose fitting is wrapped around. After that, it must be screwed into the faucet on the branch pipe. The connection of the flexible hose to the manifold is carried out at the finishing stage.

Next, the stage of test opening the faucet on the descent for gas leakage is mandatory.Using soap foam, the docking points are processed with a brush. If foaming occurs when the gas valve is opened, the work must be redone.

When work on replacing a gas hose is carried out in a private house where bottled gas is used, an additional replacement of the nozzle with a smaller diameter will be required. If this is not done, the burners will release too much soot, which likes to settle on furniture and utensils in the kitchen.

When are gas valves replaced?

A gas valve is a shut-off valve on a gas riser. Since the valve is a movable mechanism, it tends to wear out and become unusable. Various signs can be manifestations of this: jamming, excessive rotation, the appearance of a sharp smell of gas. However, only a gas service specialist can reliably determine whether a gas valve needs to be replaced in the house, based on the results of a visual inspection and maintenance.

If you have identified such signs during operation, invite the master for unscheduled maintenance. Scheduled inspections are carried out annually, so if there are signs of a malfunction, a technician or master will identify them on their own.

For replacement of gas equipment he has only three grounds (clause 10 of the Rules, approved by Government Decree No. 410 of 05/14/2013):

- The end of the service life established by the project or the manufacturer. For valves, such periods are usually not set; if they are in good technical condition, they are used indefinitely.

- Establishing a malfunction of the valve and recognizing it, according to the results of maintenance, as unsuitable for repair.

- Submission of an application for replacement by the owner of the equipment. Yes, the tap can be changed on your own initiative.

Common gas stove failures

According to the rules for the safe use of gas appliances, all repairs must be carried out by a qualified gas service specialist. In case of serious breakdowns of the gas stove, the consumer is obliged to contact the company with which he entered into an agreement for the maintenance of gas equipment.

However, this applies to extremely difficult situations, when any unauthorized intervention in the operation of gas equipment can endanger all residents of the house.

In the event of a gas leak, you should not try to fix the breakdown yourself, but you must urgently call the gas service specialists to carry out repair work.

In the event of a gas leak, you should not try to fix the breakdown yourself, but you must urgently call the gas service specialists to carry out repair work.

If the failure of the gas stove did not occur due to a leak of blue fuel, then there are quite real chances to make repairs without the help of a master.

Some of the most common problems that you can deal with yourself include:

- lack of flame when igniting individual burners;

- failure or clogging of the electric ignition;

- unstable functioning of gas control;

- broken oven door fasteners;

- tight turning of the gas valve.

Before repairing a gas stove, it is imperative to block the access of gas to the room, even if the breakdown is in no way related to the problem of fuel supply. As an additional reinsurance, it is better to slightly open the window or front door.

Gas workers strongly recommend completely turning off the piezo ignition during repairs so that in the event of accidental damage to gas equipment, it does not provoke an explosion.

Conclusions and useful video on the topic

Preparation of the countertop and the nuances of mounting the hob:

Video instruction and useful tips:

Rules for connecting to a gas pipe:

Whatever actions you take with gas equipment, they must meet installation requirements and rules safety technology.

Before starting work, we recommend that you study the provisions of SNiP 42-01-2002, and then the manufacturer's instructions. Any deviations from the norms remove the equipment from the warranty and threaten trouble with the gas workers, the smallest of which is a fine.

Please tell our readers about your experience with connecting or replacing a gas hob. Leave your comments, upload photos, ask questions - the contact block is located under the article.

Conclusions and useful video on the topic

The video shows in detail the process of replacing a tap on a pipe leading to a gas stove:

Replacing a faucet is a simple but very responsible process. Even if you have experience in carrying out similar work, according to the norms, you cannot do it yourself - you need to contact specialized services. There are employees who have been trained and received the necessary permission to repair gas systems.

Please write comments in the box below. Interested in stories about how the crane was replaced on your gas branch. Ask questions, share your impressions about the information provided by us, post photos on the topic of the article.

Source