- Useful tips and possible mistakes

- Replacing batteries with gas welding is a guarantee of high-quality seams!

- The advantage of replacing batteries with gas welding

- How to replace gas welding heating batteries

- Differences from other mounting methods

- Training

- Starting the heating system

- Replacing heating batteries for welding: what you need to know

- More about the differences

- Basic Battery Replacement Steps

- Performing preparatory work

- Assembling a new design

- Gas connection

- Seam cleaning and finishing

- Differences from other mounting methods

- Replacing heating batteries with gas welding: operation algorithm

- How to get work permits?

- How to legally change the heating in the apartment

- What is necessary?

- Tools

- Dangers when carrying out welding work in the apartment

- What should be considered in advance?

Useful tips and possible mistakes

To properly cook heating pipes, one should not neglect the recommendations of specialists:

- it is more convenient to weld hard-to-reach places with a bent electrode, using a mirror for control;

- when changing the electrodes, the suture continues with a 1.5 cm covering of the already applied one;

- the quality of the welded joint will improve if the upper seam is performed in the opposite direction from the lower one, ending it in a different place;

- direct polarity when welding with direct current provides better heating of the metal than reverse polarity.

The reason for the appearance of defects is often the inattention of beginners and the self-confidence of experienced welders. For example, even a slight deviation of the seam to the side leads to a violation of the tightness of the connection. Changing the length of the arc during welding ends with the formation of voids and lack of penetration

Beginners do not notice these nuances, and experienced ones believe that such trifles should not be paid attention to. For reasons beyond the control of the welder, defects are formed due to poor-quality equipment and pipe material

Replacing batteries with gas welding is a guarantee of high-quality seams!

The appearance of new proposals on the heating equipment market prompts the population to think about replacing old batteries with new heating radiators

In order to carry out the replacement, it is important to correctly determine how the installation of heating radiators will be performed. There are many options by which the work can be done, but the most effective is to use gas welding.

This is due to the fact that replacing batteries with gas welding has many advantages, such as:

- Increased degree of reliability. Provided that the work is done by a highly qualified craftsman, the resulting seam will be reliable, thanks to which it can ideally serve for many years. The welded seam, in addition, will not require additional attention, as is observed when performing installation using mounted joints. This is due to the fact that the junction does not have an additional seal, which, as a rule, is short-lived in operation.

- Neat appearance.After the welding work is completely finished, the seam remains almost invisible, so that it does not spoil the external design of the room and can remain in the open.

Only an experienced craftsman should be trusted to install heating radiators, since the efficiency and economy of the heating system will depend on the quality of the work performed. The masters of our company are able to perform the installation of radiators using gas welding with high quality and accuracy.

| 1 | Departure for a replacement | PCS | is free |

| 2 | Consultation and estimate | PCS | is free |

| 3 | Procurement and delivery of material | PCS | is free |

| 4 | Replacing batteries with gas welding from 20 pcs | PCS | 2500 |

| 5 | Replacing batteries with gas welding from 10 pcs | PCS | 3000 |

| 6 | Replacing batteries with gas welding from 4 pcs | PCS | 3500 |

| 7 | Replacing batteries with gas welding from 2 pcs | PCS | 4000 |

| 5 | Replacing one battery with gas welding | PCS | 5000 |

The advantage of replacing batteries with gas welding

Welding is a special process in which molten metal is poured between the edges of parts heated to a certain temperature.

It is important to note that the edges are heated to a temperature that is required by the technology and the characteristics of the material itself.

Gas welding works are carried out for welding metal parts of various shapes, in addition, welding is used to eliminate defects from a metal surface, regardless of its shape and size.

Gas welding battery replacement work consists of:

- preparatory part;

- welding (sealing);

- elimination of cracks and shells from the surface of a metal part;

- smoothing seams (if necessary).

Only specially trained specialists are allowed to perform gas welding work, since only they are able to weld metal surfaces together as correctly and efficiently as possible.

How to replace gas welding heating batteries

As already noted, with the help of gas welding, it is possible to install heating radiators with the highest quality and reliability. The main explanation for this is that the metal edges of the pipe and radiator are connected by molten metal, which is formed as a result of the melting of the filler wire. With the help of gas welding, it is easy and most importantly quickly possible to connect steel pipes to a radiator, the outer diameter of which does not exceed 100 millimeters. The attachment points (weld seam) are reliable and able to withstand high operating pressure in the system, which eliminates the possibility of a breakthrough. It should also be noted that the seam made by the master looks very neat compared to the fittings and other available

A question that sooner or later arises in front of almost every tenant, whether it is an apartment in an apartment building or your own house in the private sector.

Among the variety of existing types of heating batteries and how to install them, it is difficult to make the right choice without having special knowledge and experience in this area.

Therefore, will it be produced replacement of heating batteries with gas welding or threaded method, and what type of radiators to use, it is better to decide together with qualified specialists. There is a high risk of costly property damage if replacement and installation work is not carried out properly.

Differences from other mounting methods

An alternative for connecting pipes when replacing batteries is the threaded method. It is especially popular among home craftsmen who do not have in their arsenal such expensive equipment as a gas welding machine and the skills to work with it. In this case, the installation of the system is carried out using threaded threads and special connecting elements - tees, fittings, nuts and other adapters.

Installation using threaded technology is impossible without drops and visible fasteners - when replacing one radiator, more than 12 seams come out, while with gas welding - only 5-6

The main (and perhaps the only) advantage of the threaded method over the gas welding method is the ability to quietly and without fire-hazardous heating assemble the system with your own hands, without resorting to the expensive services of professional craftsmen. And in the future, such a structure can also be disassembled if it becomes necessary to clean or replace any element.

But the assembly process requires detailed study, precise fitting and the correct selection of all connecting elements. And even if you manage to do everything right and start the system, over time it will still fail - the water will quickly find "weak points", undermine the seals and break through. Therefore, in high-pressure lines, threaded connections quickly “surrender” under the onslaught of water hammer.

Another popular alternative to gas welding is electric heating. Both technologies work on a similar principle - heating to the melting point and joining metals. At the same time, electric welding costs a little less, and the scale of “destruction” after such work is small, since the heated area of \u200b\u200bthe electric device is much smaller.

But, despite such advantages, gas welding has an important feature - the ability to control the melting rate by changing the angle of the flame. Unlike almost instantaneous heating by electric welding, gas technology works gradually, without violating the structure and strength qualities of the metal.

That is why gas welding leads by a good margin when choosing a battery replacement method among those who like to make repairs with high quality and reliability.

Training

First you need to do the preparation of pipes. The surfaces to be welded must be cleaned and degreased. This is the only way to avoid defects in the seams.

Products must have an appropriate edge opening angle, the perpendicularity of the plane of the end face of the product axis must be observed. The preparation of heating pipes of large diameter is carried out using milling machines or gas-acid cutting.

Dimensions, compliance with the thickness of products, chemical composition, mechanical properties - everything must be combined with the requirements of GOST.

It should be noted that often the value of blunting is about 2 mm, and the opening angle is about 65 degrees.

An important stage of preparation is the choice of materials.

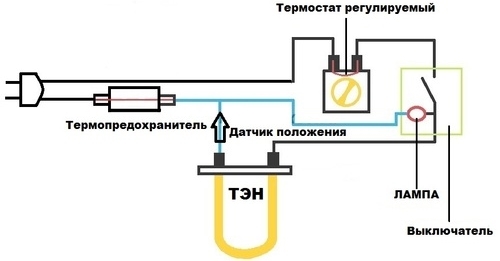

Starting the heating system

In order to avoid rupture of the heating device and water hammer during pressure testing, it is necessary to close the air release valve and all shut-off valves. Wait until the coolant fills the system and the pipelines become hot

After that, slowly open the shut-off valve, carefully unscrew the head of the air valve and keep it open until water appears.This means that the radiator is completely filled with water, and there is no air lock in it.

As soon as water appears, the valve will need to be closed.

It's time to update the interior of your apartment, which means that the old heating batteries also need to be replaced. In this type of work, there is a lot of prejudice about when it is better to change the batteries. Summer, winter, autumn or spring? During the heating period or during the summer season? In this article, we will try to explain all the pros and cons of each possible option. Well, you decide for yourself when you feel better.

Let's start with the most popular misconception. “In the summer it is better to change, because there is no need to turn off the heating risers and drain the water,” the overwhelming majority think so. And that's not true.

As you and I know, there is a heating season (autumn-winter), but there is a non-heating season (spring/summer). During the non-heating season, the heating risers in our apartments are cold, but does this mean that there is no water there and you don’t need to contact the DEZ or ZhEK in order to drain the water? Doesn't mean at all. In 99% of cases, there is water in the risers and leave it there so that the pipes do not “overgrow” with rust. Water just "stands" in the pipes and does not circulate. Of course, there are times when there is no water in the system, but this is usually when local utilities are conducting targeted preparations for winter, altering pipes in the basement or replacing pumps. It is impossible to determine on your own the presence or absence of water in the risers. Only the chief engineer in the DEZ or the Management Company can know this.Therefore, you will need to make sure that the water in the risers is drained for the time of replacement a few days before the work.

So how to be? When is the best time to change batteries?

The main advantage of carrying out work in the non-heating season is that it is very easy to agree on the discharge of water, because. no one needs hot batteries at a temperature of + 20C outside. In fact, this is where the advantages of carrying out work in the non-heating season end and a huge minus begins: water will not be supplied to the pressurized risers until the start of the heating season, which means that the quality of the work carried out and the level of heating of the radiator can be checked only after a few months. (Heating is usually served on the 20th of September)

Now consider the option of replacing batteries in the autumn-winter season.

During the heating period, the risers are always filled with coolant, and in order to carry out work, it is necessary to agree with the DEZ or ZhEK to turn off the risers. In fact, doing it is as simple as in the summer. It is enough just to contact the chief engineer by phone or with a paper application. Then he will give you a receipt, which can be paid at any branch of the Bank or via the Internet. That's all! All the difficulties in merging the risers with the help of the DEZ or ZhEK are behind. We really like to draw in our heads the evil employees of the housing and communal services, who, at any of our requests, snort with displeasure and are constantly rude. In matters of draining water from risers, there is no such problem, because it simply costs money, and everyone needs money. DEZ and ZhEK are no exceptions, but ... we digress a little from the topic.

The most important advantage of replacing batteries during the heating season is that you can immediately check the quality of welding and threaded connections immediately after completion of work (in our case, the tap is screwed to the pipe and to the radiator, and everything else is welded). You do not have to wait for water supply in the fall to make sure that the batteries heat well and the installation is done really well.

Plus, during the heating period, the cost of work falls somewhat compared to summer. There are seasonal discounts.

Isn't the saved nerves and money enough to pay for replacing batteries during the heating season?

In winter, changing batteries is a little more difficult, but cheaper and more reliable.

In summer, changing batteries is a little easier, but more expensive.

Replacing heating batteries for welding: what you need to know

In order to save some money, some users try to replace the batteries in their home themselves. However, it should be borne in mind that replacing batteries requires the master not only knowledge and skills, but also compliance with certain rules. Violation of the battery installation process can lead to an accident and additional financial costs. Therefore, welding of radiators should be carried out only with the use of modern equipment and only by a qualified specialist. The welding process is as follows

First of all, it is important to find out what operating pressure is in the heating system, if it exceeds 8 atmospheres, then you should buy bimetallic batteries

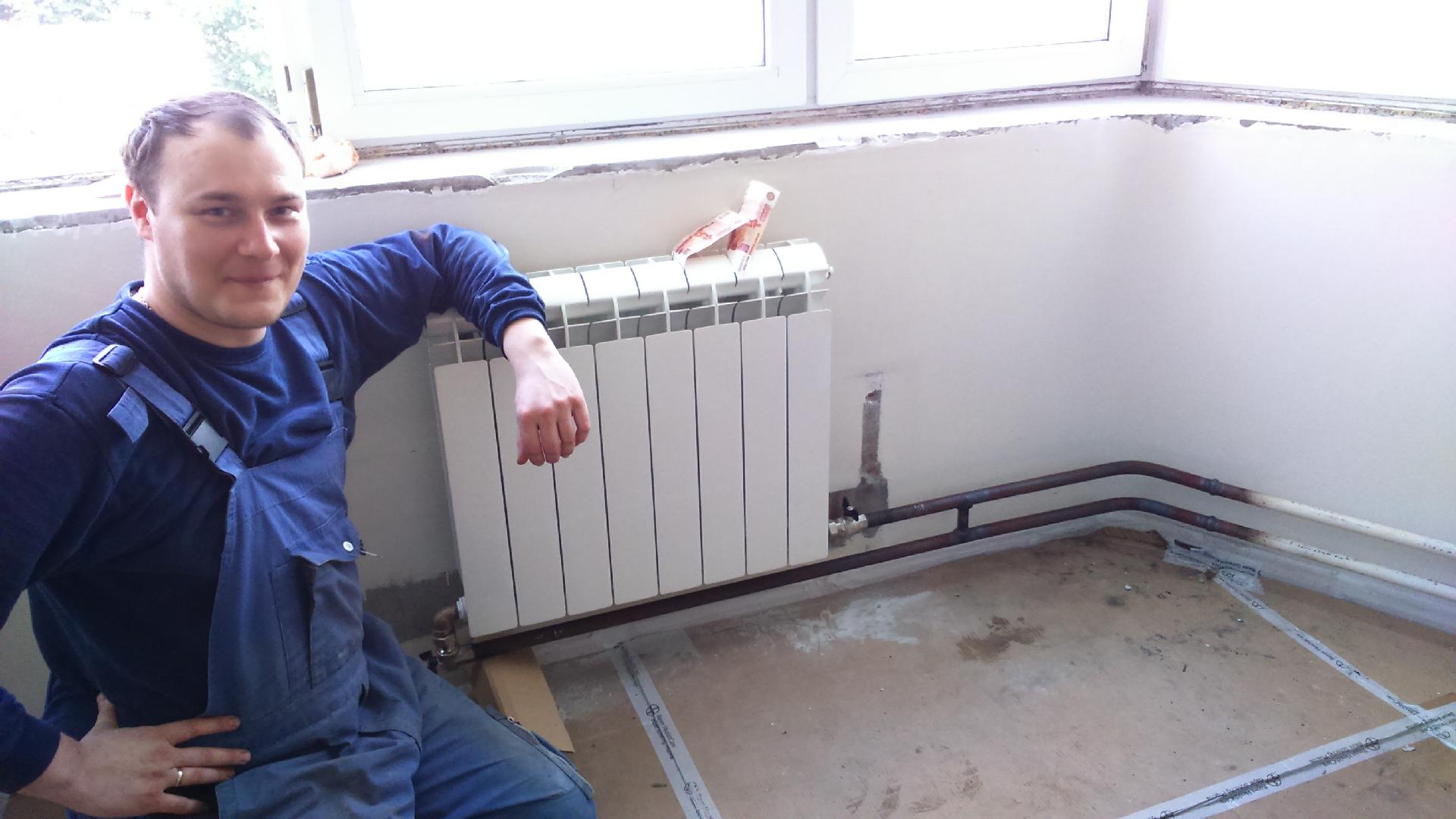

Water is completely drained from the heating system, after which the old batteries are cut out by the grinder.The ends of the pipes are thoroughly cleaned of dirt and rust, after which a new battery is installed in the vacated space and welded to the pipes of the heating system using a welding machine.

Our specialists use only high-quality and reliable equipment that allows you to quickly dismantle and install the battery. Our welding equipment is stable and high quality, so that there are no complications in the battery welding process. The masters of our company have vast experience in welding, which allows them to perform work of any complexity with the highest quality and accuracy.

More about the differences

Replacing batteries by gas welding differs from the threaded method in several ways. So, in addition to the already mentioned aesthetics and the absence of massive nuts and fittings, gas welding allows you to create very strong connections.

The welding connection is indispensable, since this is the only way to replace batteries in high-pressure systems: in such cases, the thread simply cannot withstand the load and the pipes break through.

When replacing radiators, many owners use an effective and reliable method of connecting pipes using gas welding. After welding, strong seams are formed that can withstand any pressure of water and any temperature.

Basic Battery Replacement Steps

To dismantle radiators in an apartment on an open heating system, you should obtain permission from the local housing office and heating networks. Separately, you need to agree on the modernization of the design, for example, if you plan to move the batteries to another place, add or remove several sections.

Welding work, as already mentioned, is allowed to be carried out only by specialists with permission and vocational education - independent initiatives can result in a decent fine. Therefore, we will consider the main stages of the upcoming repair in order to avoid unpleasant surprises.

Performing preparatory work

To begin with, it is worth minimizing the possible consequences of the operation of a gas welding machine. Furniture close to the radiators must be taken out or closed from possible damage. Also protect the area of the floor and wall adjacent to the battery.

Then water is drained from the heating system. If we are talking about a private house or other room with autonomous heating, a special tap is used, which must be provided for in the design.

In an apartment with central heating, it is impossible to independently turn off and drain the coolant from the system - you should call a specialist from the service organization. Next, you need to disconnect the radiators that have served their time. The easiest way to do this is with a grinder.

But even here you will need a good skill with the tool, because in order to connect new heaters with a minimum of effort, it is important to make a neat and even cut.

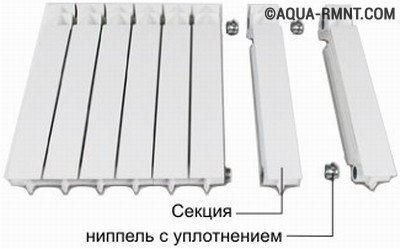

Assembling a new design

Next, the new radiator is packed. If you want to save on the services of masters, this work is quite feasible to do yourself.

Required materials and tools:

- A set of nuts (for radiators).

- American ball valve.

- Mayevsky crane.

- Wrench.

- Packing paste.

- Sealant (flax or fum-tape).

To assemble the battery, you need to seal the nuts, process with paste and screw onto the pipes at the junctions. The layout of the radiator is completed by installing cranes.

On the side of the connection with the heating system, an "American" is mounted in order to be able to block the access of the coolant to a specific battery. From above, on the opposite side of the pipe inlet, a Mayevsky crane is screwed with a wrench, with which it will be possible to remove the “plugs”, dumping air accumulations from the system.

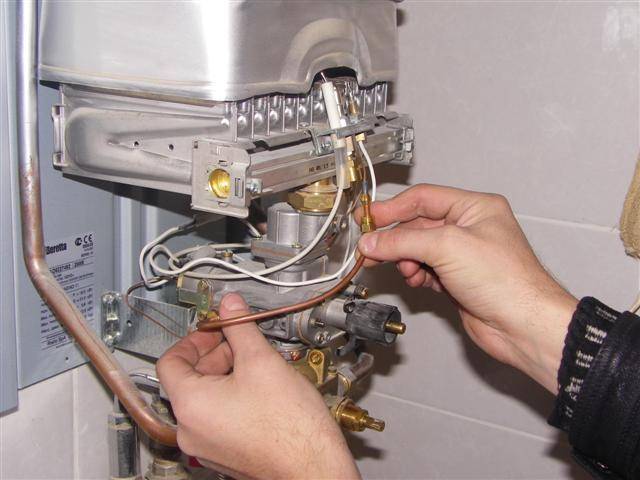

Gas connection

The assembled radiator is suspended in place of the old battery using special fasteners, and the evenness is checked without fail with a building level. Before starting welding, the ends of the elements to be joined should be thoroughly cleaned of dirt, dust and degreased.

Next, the inlet and outlet pipes are welded with a verified slope, which helps prevent the formation of air pockets. To do this, the connecting segment is heated with a burner, while using a filler wire that fills the gaps between the fragments of the system.

The type of seam and the heating rate are chosen by the master, based on the wall thickness, pipe material and other professional nuances.

Seam cleaning and finishing

After the work of the gas welder, the pipes look unaesthetic: black marks and stains are unlikely to become an interior decoration. But this is fixable.

To process the welding site, you need to act according to the following algorithm:

- Clean the pipe with sandpaper with grain size 3 or 4. With the inaccurate work of the welder, there may be a thick influx at the junction, which some try to even out with the help of the same grinder.But you should not do this - you can violate the strength qualities of the seam.

- Dust the pipe - wipe it with a damp and then dry cloth.

- Degrease with white spirit.

- Coat with anti-corrosion primer in 2 layers.

- Paint with heat-resistant enamel also in 2-3 steps (the lighter and more transparent the paint, the more layers may be needed to mask the black).

Of course, all painting work should be carried out before connecting the system, on cold pipes. If the batteries were replaced during the heating season, it is necessary to block the access of the coolant and wait for the system to cool completely.

You can decorate only pipes or the entire structure complete with a radiator. The color is usually chosen white, silver, bronze or to match the tone of the walls. But for some interior styles, you can also apply a contrasting shade, for example, dark chocolate, glossy black or spectacular red.

It is possible to open the system and fill the circuit with coolant only after the paint has completely dried.

Differences from other mounting methods

An alternative for connecting pipes when replacing batteries is the threaded method. It is especially popular among home craftsmen who do not have in their arsenal such expensive equipment as a gas welding machine and the skills to work with it.

In this case, the assembly of the system and the installation of the batteries selected for replacement is carried out using threaded threads and special connecting elements - tees, fittings, nuts and other adapters.

The main (and perhaps the only) advantage of the threaded method over the gas welding method is the ability to quietly and without fire-hazardous heating assemble the system with your own hands, without resorting to the expensive services of professional craftsmen.And in the future, such a structure can also be disassembled if it becomes necessary to clean or replace any element.

But the assembly process requires detailed study, precise fitting and the correct selection of all connecting elements. And even if you manage to do everything right and start the system, over time it will still fail.

As a result, water will quickly find "weak spots", undermine the seals and break through. Therefore, in high-pressure lines, threaded connections quickly “surrender” under the onslaught of water hammer.

Another popular alternative to gas welding is electric heating. Both technologies work on a similar principle - heating to the melting point and joining metals. At the same time, electric welding costs a little less, and the scale of “destruction” after such work is small, since the heated area of \u200b\u200bthe electric device is much smaller.

But despite these advantages, gas welding has an important feature - the ability to control the melting rate by changing the angle of the flame. Unlike almost instantaneous heating by electric welding, gas technology works gradually, without violating the structure and strength qualities of the metal.

That is why gas welding leads by a good margin when choosing a battery replacement method among those who like to make repairs with high quality and reliability.

Replacing heating batteries with gas welding: operation algorithm

If it becomes necessary to carry out gas welding work in the apartment, you must obtain permission to perform them. Before you start welding radiators, you need to prepare the room - remove all flammable objects from the place of welding, close the floor and furniture from sparks.

In addition to the gas welding machine, to replace the radiators, you will also need a grinder with a circle for metal, a tape measure, a set of nuts, an adjustable wrench, investment paste and linen.

Replacing radiators step by step:

- Draining water from the heating system. If the coolant is not removed from the old batteries, during dismantling, water will flow directly into the room and a flood may occur.

- Dismantling of old radiators. The pipes are cut with a grinder with a metal nozzle, while you need to follow the safety rules - use goggles and gloves.

- Packing a new battery. At the joints, the nuts must be sealed with flax, lubricated with packing paste and tightly screwed onto the pipes protruding from the battery. In the place where the pipes are attached to the heating system, an American crane and a Mayevsky crane are screwed on.

- Installing batteries. The new battery is put in place of the old one, after which all connections to the heating pipes are adjusted by welding. After all welding work is completed, the seams are cleaned.

When the work is completed, you need to check the heating system for strength. All joints must be airtight and well sealed so that the seams are not damaged when the coolant is supplied.

How to get work permits?

Only professional gas welders who have a certificate of education in this specialty are allowed to install heating batteries using gas welding. In addition, the welder must have a valid fire safety permit. It is desirable that the specialist has experience (excellent, if many years) in gas welding.It affects the quality of the final result and the equipment used, which must be not only serviceable, but also meet the established safety requirements.

Gas welding work is carried out in overalls, in special glasses with a protective shield that prevents the eyes from catching "bunnies", as experienced welders say. We must not forget about gloves that protect the skin of the hands from the effects of negative factors.

The mandatory equipment of a gas welder includes such protective equipment as goggles, a shield, and work gloves. All listed items are intended for gas welding work.

Please note that at the moment in apartment buildings there is a ban on gas welding without obtaining permission from the authorized bodies. Violators of this legislation face a hefty fine.

How to legally change the heating in the apartment

Replacement of radiators in the apartment must be carried out with the consent of the management company. To do this, it is necessary to write an application to the chief engineer of the Criminal Code, where to petition for consideration of the possibility of replacing the radiator for certain reasons.

With the consent of the management company, you will have to order a project for the reconstruction of the heating system in the organization that has the approval of the SRO. Further, the chief engineer of the management company agrees on the project or sends it to the interdepartmental commission. After the MVK, the chief engineer again takes over.Next, to replace the pipe, hire an organization with an SRO approval (even if your relative is a certified welder, he can replace the radiator in the apartment only if he has a welder’s certificate and a fire safety permit). Copies of all documents are kept by the management company.

Welder's certificate

In case of refusal, you can go to court or insist on the management company fulfilling its obligations, including replacing the heating system in an apartment building.

This is interesting: Which pipes to choose for heating: which options are better and why?

What is necessary?

In all other cases, the participation of a specialist is desirable. We must not forget that a violation of the tightness of the weld in the heating system can lead to very unpleasant consequences (damage to property, including someone else's, burns, etc.).

Tools

The set of tools and equipment necessary for the production of welding work is determined depending on the type of pipes used to equip the heating system, as well as the chosen welding method.

First of all, it is a manual welding machine.

Detailed wiring diagram for aluminum radiators here.

A device for connecting polypropylene pipes is also sometimes called a soldering iron. For domestic needs, a device with a power of 650 watts is quite suitable. It can be used to connect plastic pipes up to 60 mm in diameter. Nozzles are included with the device.

Manual welding machine

Welding of metal pipes is carried out using an electric or gas apparatus. For cutting, a "grinder" or a cutter is used.In addition, you will need the usual equipment of a welder: a mask, a canvas suit, gloves, asbestos, a hammer, electrodes, wire, etc.

Electric and gas welding machines

Dangers when carrying out welding work in the apartment

Any type of welding work is associated with high temperatures. An electric welding electrode and a gas welding torch have a temperature of several thousand degrees Celsius. In addition, welded or cut metals of pipes and metal structures of the apartment are heated to almost the same temperatures.

As a result, any contact of flammable objects, things, substances with welding can lead to a fire.

In addition, heated metal has the properties of spreading during welding and even dripping onto the floor and falling onto the walls. As a result, during welding work in a residential area, burnouts of floor and wall finishing materials, as well as furniture burns, are possible.

Cylinders for gas welding are of particular danger. Improper storage does NOT cause a fire, but an explosion.

One more danger should not be forgotten when carrying out welding work in an apartment - these are neighbors. As I already mentioned, drops of molten metal from welding can get into neighbors' apartments. For example, when carrying out welding work on the balcony. Or carrying out work in the bathroom to replace the risers of the water supply or install a welded bypass.

What should be considered in advance?

If the decision to carry out repairs of this type is made, a number of questions should be answered:

- When and by whom will the work be carried out?

- What type of radiators should be used?

- Is it necessary to replace the pipes leading from the battery to the riser?

- How many sections will be needed for each room?

It is best to carry out such an alteration in the summer, because to start work, you must obtain permission from the local housing office. In winter, officials are extremely reluctant to give such permissions, because they will have to block the common riser and leave other apartments without heating for some time.

But even outside the heating season, getting permission can be difficult. Those who have already solved similar problems talk about the need to wait for several days, trying to get an appointment with the right employees, etc. Some faced pressure: they were recommended to hire plumbers from the Housing Office to do all the work.

There are no restrictions on this issue. The main thing is that the replacement of heating batteries is performed by an experienced plumber with the appropriate qualifications. It is possible to identify all the flaws made during inept installation only during operation.

Old radiators get dirty inside and out over time, cleaning does not always solve the problem of insufficient heating, replacement is a more effective option

It is best to go to the housing office in the summer, and not in the fall, which is the peak of the queues. By this time, all the necessary materials need to be purchased, pre-assembly of radiators, tools prepared, agreed with the team, if necessary.

If the house is connected to a central heating system, you should contact the maintenance service to agree on the alteration. Here they can perform the necessary calculations to accurately name the number of radiator sections, as well as clarify other technical issues.

Shut-off valves that are installed on the “supply” and “return” are necessary so that at any time you can turn off the water and remove the battery for repair or replacement

The lack of correct calculations can lead to an imbalance in the home heating system.

Previously, for the calculations, you will need information that is in the DEZ:

Most often, old batteries are replaced with new modern models, usually aluminum or bimetallic. Although cast iron, copper and steel products are also on sale. The type of radiator is needed when performing calculations.

When choosing a suitable radiator for a house or apartment, you need to focus on its main characteristics, which are detailed in the product data sheet.

You will need such indicators as the pressure that the device can withstand, the maximum temperature of the coolant, heat transfer and other data. They can usually be found in the technical data sheet.

If not only radiators, but also pipes leading to them are to be replaced, a suitable material should be selected. Usually it is steel, metal-plastic or polypropylene. Some masters strongly recommend using only steel communications for centralized systems.

Depending on the type of pipes chosen, you will need the appropriate equipment for welding them. MP and PP pipes are easier to install than steel. To work with metal, you need not only a welding machine, but also a device for threading. Therefore, if the old pipes are clean enough, it is recommended to leave them and replace only the battery.

Old cast-iron radiators retain heat well, but slowly release it, in addition, they are heavy, which complicates installation, so bimetallic and aluminum models are more popular

The weak point of metal-plastic structures is connections. They must be performed very carefully, installation errors often lead to leaks.The popularity of MP pipes is explained by their relatively low price. Plastic is more expensive, but more reliable, if the welding is done correctly, the tightness of the joints will be very high.

Under the selected radiator, you need to select suitable fasteners. In this case, it is necessary to take into account both the type of radiator and the material of the wall on which the installation will be performed: brick, concrete, etc. Batteries are usually supplied with brackets of the appropriate type.

To install one radiator, two brackets are usually used at the top and one at the bottom. Their position is carefully checked by a level in order to eliminate the possibility of distortion during battery installation. However, some models are set with a slight slope to ensure the removal of air that has entered the system. If there are more than twelve sections, another top bracket may be needed.