- Filling methods built-in mechanism and pumps

- Filling the heating with antifreeze

- Automatic filling system

- Features of installation of a closed heating system

- One-pipe heating scheme

- Feature of the horizontal pipe laying scheme

- Central horizontal heating

- Autonomous horizontal heating

- Advantages and disadvantages of a closed heating system

- Beam system with collectors

- Advantages and disadvantages of beam systems

- Features of installation of radiant heating systems

- Rules for the selection and installation of pipes

Filling methods built-in mechanism and pumps

Heating filling pump

How to fill the heating system in a private house - using the built-in connection to the water supply using a pump? This directly depends on the composition of the coolant - water or antifreeze. For the first option, it is enough to pre-flush the pipes. Instructions for filling the heating system consists of the following items:

- It is necessary to make sure that all shut-off valves are in the right position - the drain valve is closed in the same way as the safety valves;

- The Mayevsky crane at the top of the system must be open. This is necessary to remove air;

- Water is filled until water flows from the Mayevsky tap, which was opened earlier. After that, it overlaps;

- Then it is necessary to remove excess air from all heating devices. They must have an air valve installed. To do this, you need to leave the system filling valve open, make sure that air comes out of a particular device. As soon as water flows out of the valve, it must be closed. This procedure must be done for all heating devices.

After filling the water in a closed heating system, you need to check the pressure parameters. It should be 1.5 bar. In the future, to prevent leakage, pressing is performed. It will be discussed separately.

Filling the heating with antifreeze

Before proceeding with the procedure for adding antifreeze to the system, you need to prepare it. Usually 35% or 40% solutions are used, but to save money, it is recommended to purchase a concentrate. It should be diluted strictly according to the instructions, and only using distilled water. In addition, it is necessary to prepare a hand pump to fill the heating system. It is connected to the lowest point of the system and, using a manual piston, the coolant is injected into the pipes. During this, the following parameters must be observed.

- Air outlet from the system (Mayevsky crane);

- Pressure in pipes. It must not exceed 2 bar.

The whole further procedure is completely similar to the one described above. However, you should take into account the features of the operation of antifreeze - its density is much higher than that of water.

Therefore, special attention should be paid to the calculation of the pump power. Some formulations based on glycerin may increase the viscosity index with increasing temperature. Before pouring antifreeze, it is necessary to replace the rubber gaskets at the joints with paronite

This will greatly reduce the chance of leaks.

Before pouring antifreeze, it is necessary to replace the rubber gaskets at the joints with paronite ones. This will greatly reduce the chance of leaks.

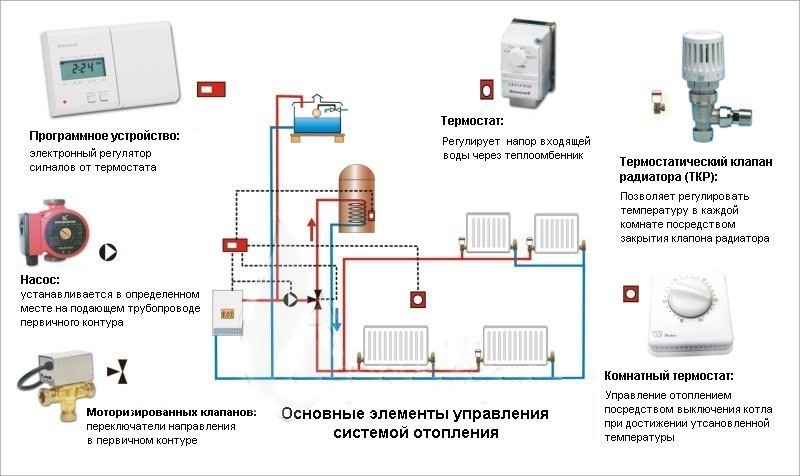

Automatic filling system

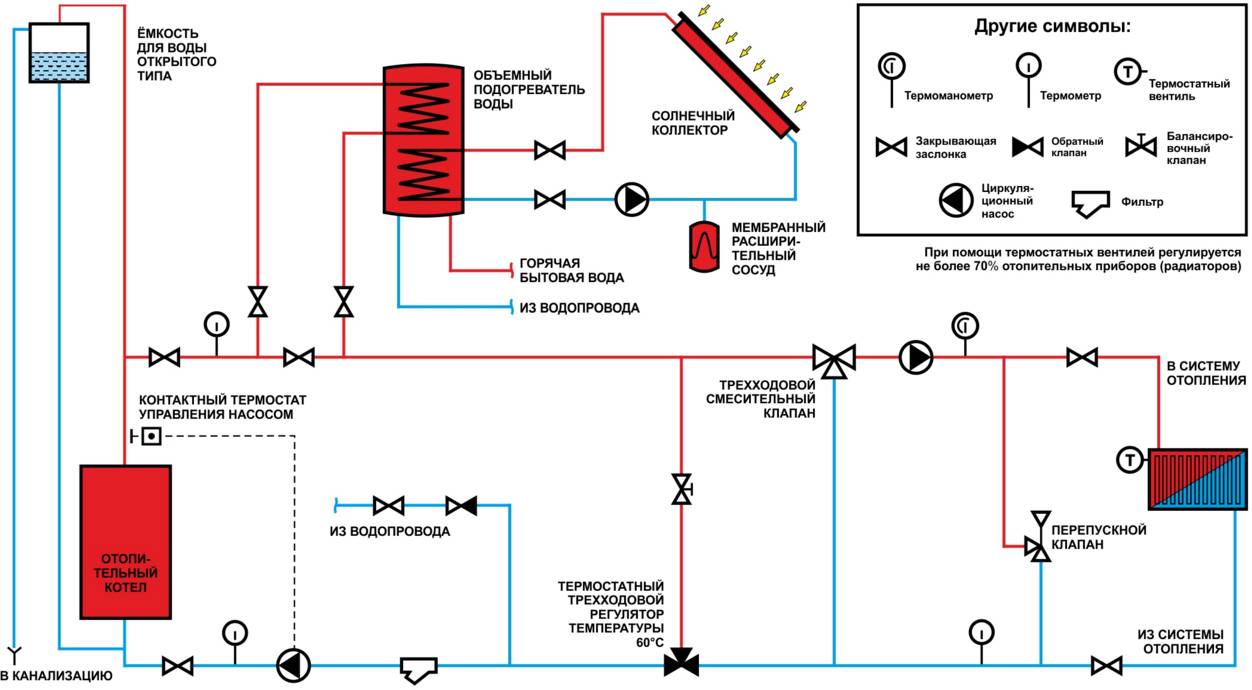

For double-circuit boilers, it is recommended to use an automatic filling device for the heating system. It is an electronic control unit for adding water to pipes. It is installed on the inlet pipe and operates fully automatically.

The main advantage of this device is the automatic maintenance of pressure by the timely addition of water to the system. The principle of operation of the device is as follows: a pressure gauge connected to the control unit signals a critical pressure drop. The automatic water supply valve opens and remains in this state until the pressure stabilizes. However, almost all devices for automatically filling the heating system with water are expensive.

A budget option is to install a check valve. Its functions are completely similar to the device for automatic filling of the heating system. It is also installed on the inlet pipe. However, the principle of its operation is to stabilize the pressure in pipes with a water make-up system. When the pressure drops in the line, the pressure of tap water will act on the valve. Due to the difference, it will automatically open until the pressure stabilizes.

In this way, it is possible not only to feed the heating, but also to fully fill the system. Despite the apparent reliability, it is recommended to visually control the coolant supply.When filling the heating with water, the valves on the devices must be opened to release excess air.

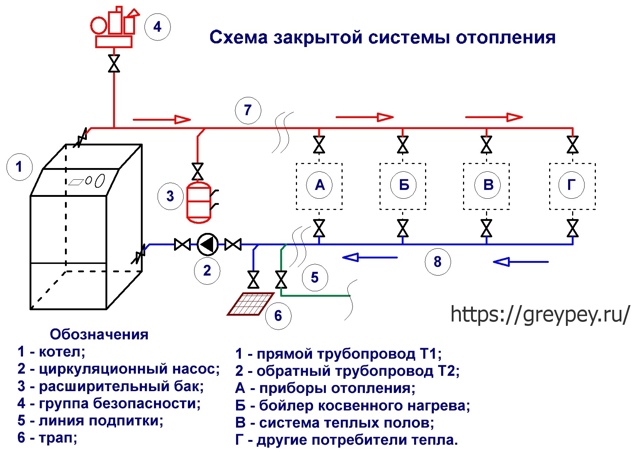

Features of installation of a closed heating system

A closed heating system requires a very specific installation. The fact is that it requires that each heater can be turned off separately, without turning off the system as a whole or completely draining the coolant from it. It is for this reason that specialists use special shut-off valves for this. They must be installed both at the inlet and outlet of each of the heating devices.

In addition, during installation, a spare line should also be provided, and the installed manual taps will allow you to adjust the temperature regime if necessary.

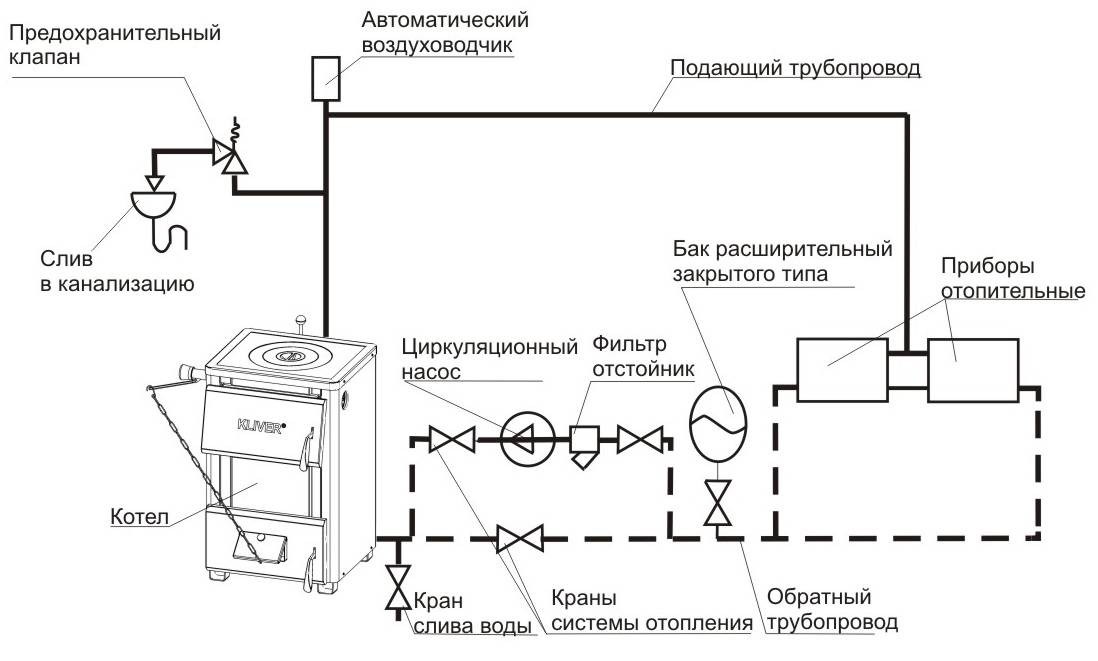

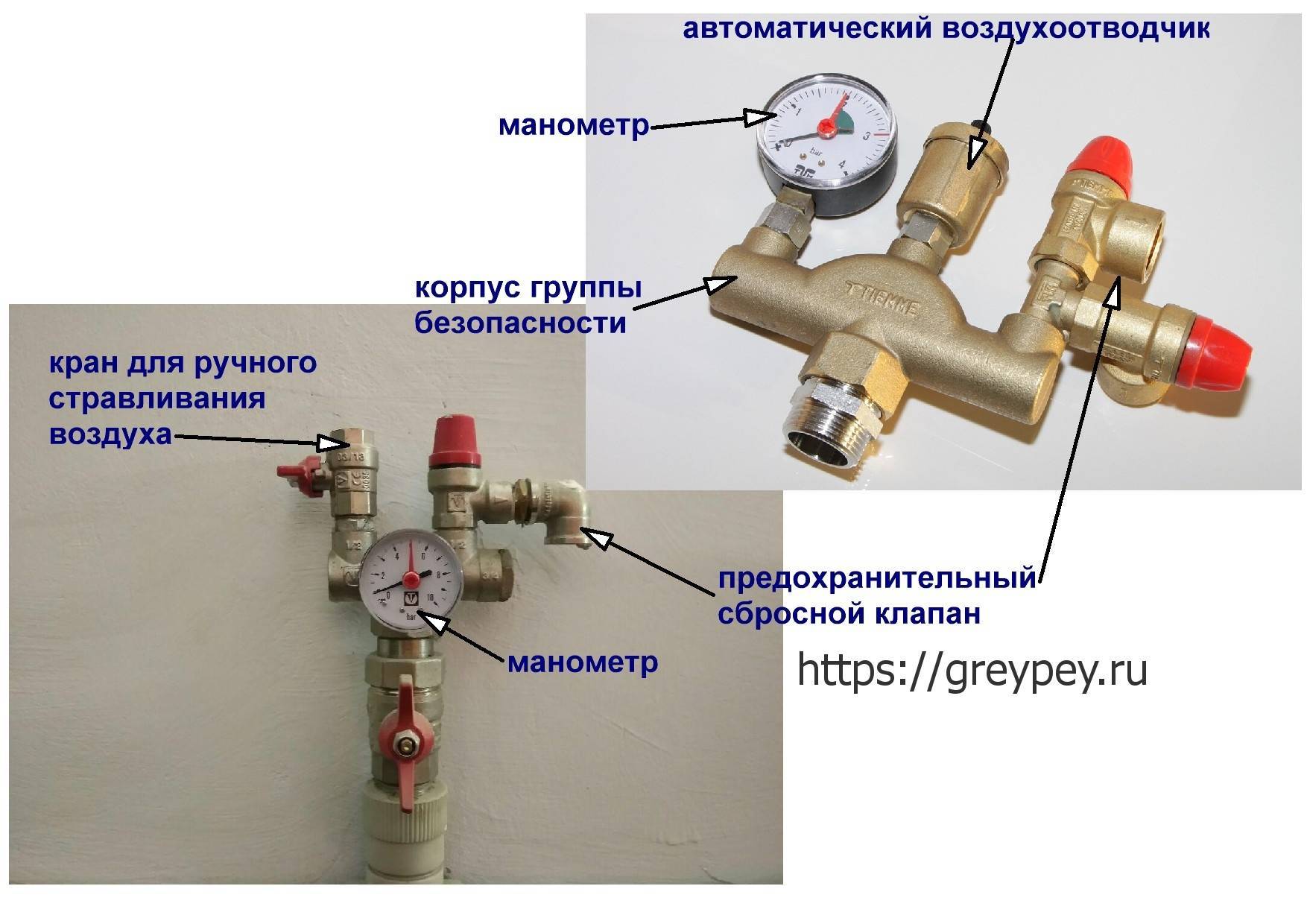

Another feature of the installation work is the safety group mentioned above. Such a group is installed at the outlet of the heating boiler, and its main function is to reduce pressure if, for one reason or another, it exceeds the permissible norm. A security group consists of the following elements:

- Air vent - as the name suggests, it will vent air when air locks form in the circuit.

- A manometer is a device that will control the working pressure.

- A safety valve that will lower the pressure if it reaches the maximum level.

Note! When installing a closed heating system, no shut-off valves must be located between the boiler and the safety group!

Note also that a closed system will last much longer than an open one.The last variety of such systems quickly fails precisely because it is in direct contact with the external atmosphere.

The main engine of the heating system is the boiler, so we will talk about how to choose it for installation work.

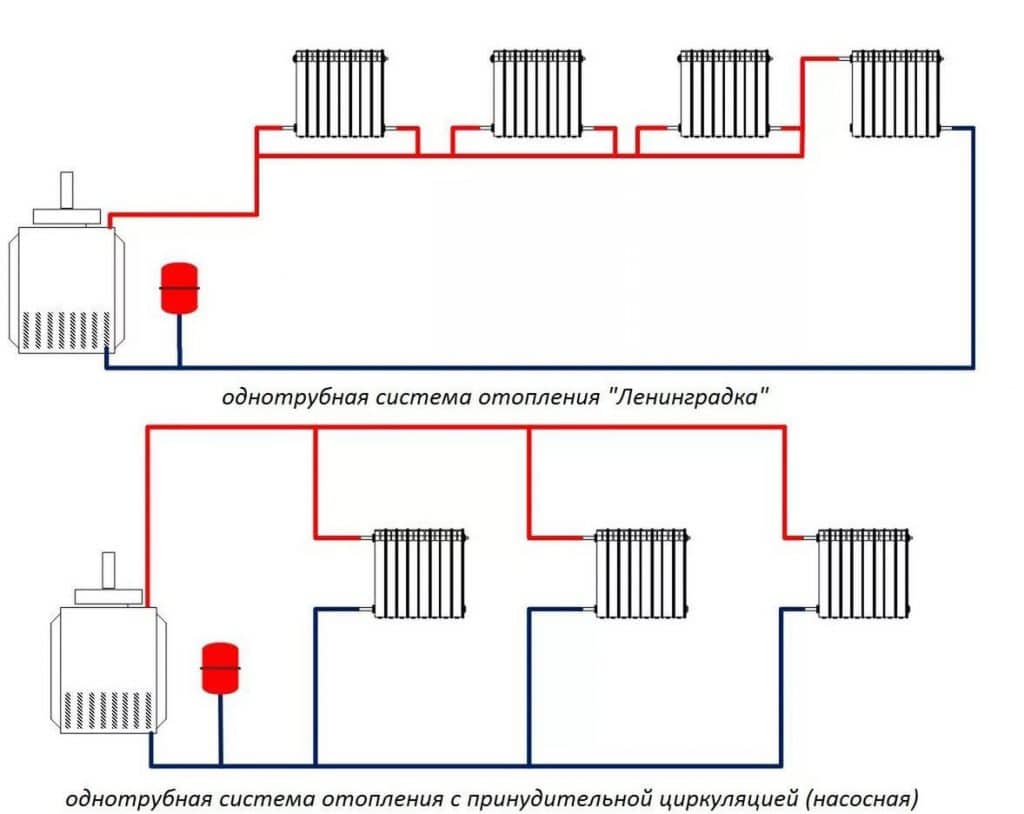

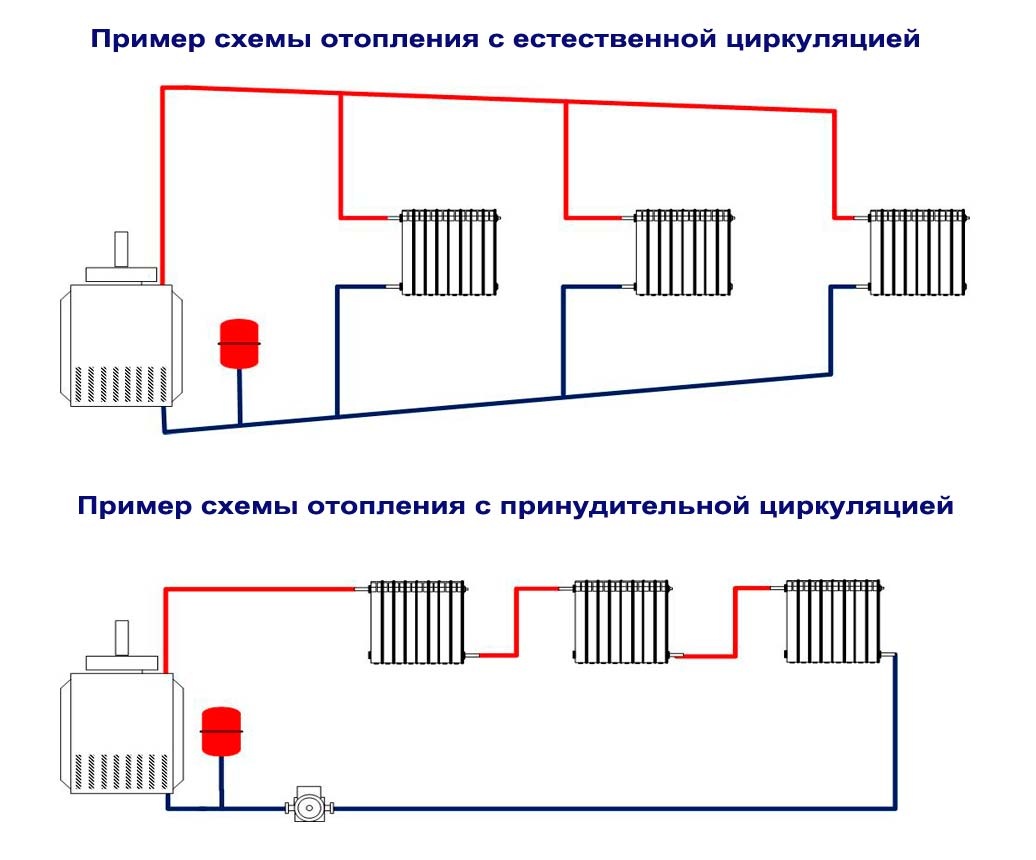

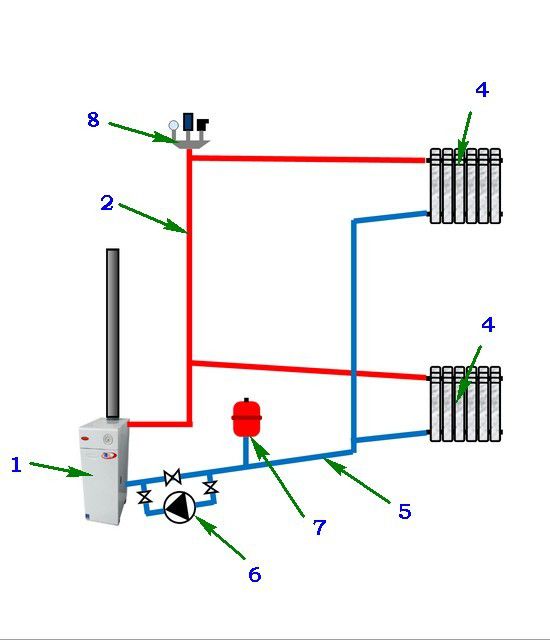

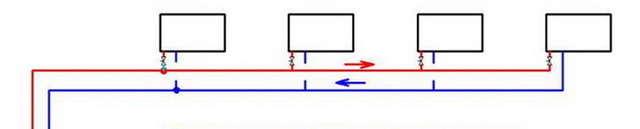

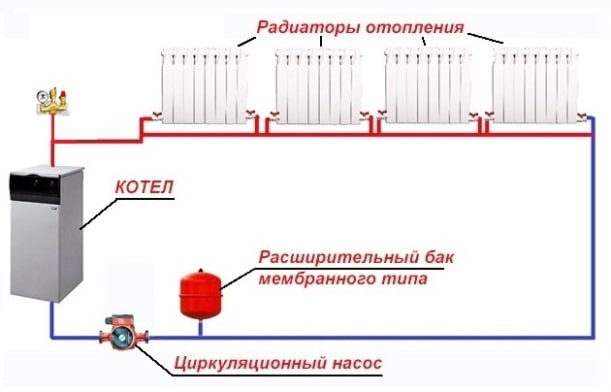

One-pipe heating scheme

From the heating boiler, you need to draw the main line representing the branching. After this action, it contains the required number of radiators or batteries. The line, drawn according to the design of the building, is connected to the boiler. The method forms the circulation of the coolant inside the pipe, heating the building completely. The circulation of warm water is adjusted individually.

A closed heating scheme is planned for Leningradka. In this process, a single-pipe complex is mounted according to the current design of private houses. At the request of the owner, elements are added to:

- Radiator controllers.

- Temperature controllers.

- balancing valves.

- Ball valves.

Leningradka regulates the heating of certain radiators.

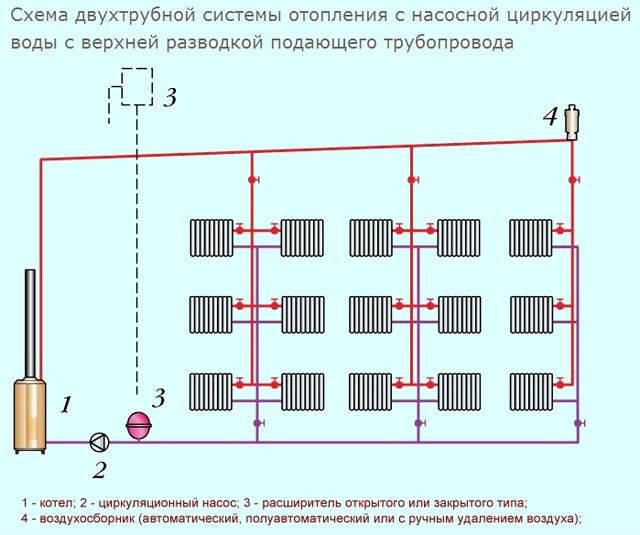

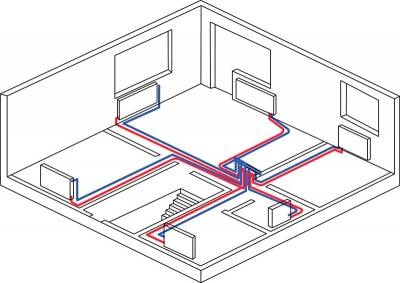

Feature of the horizontal pipe laying scheme

Scheme of horizontal heating in a two-story house

In the vast majority of cases, a horizontal two-pipe heating system with bottom wiring is installed in one or two-story private houses. But, besides this, it can be used to connect to centralized heating. A feature of such a system is the horizontal arrangement of the main and return (for a two-pipe) line.

When choosing this piping system, it is necessary to take into account the nuances of connecting to various types of heating.

Central horizontal heating

To draw up an engineering scheme, one should be guided by the norms of SNiP 41-01-2003.It says that the horizontal wiring of the heating system should ensure not only proper circulation of the coolant, but also ensure its accounting. To do this, two risers are equipped in apartment buildings - with hot water and for receiving cooled liquid. Be sure to calculate a horizontal two-pipe heating system, which includes the installation of a heat meter. It is installed on the inlet pipe immediately after connecting the pipe to the riser.

In addition, hydraulic resistance is taken into account in certain sections of the highway.

This is important, since the horizontal wiring of the heating system will only work effectively while maintaining the appropriate pressure of the coolant.

In most cases, a single-pipe horizontal heating system with a lower wiring is installed for apartment buildings. Therefore, when choosing the number of sections in radiators, one must take into account their distance from the central distribution riser. The further the battery is located, the larger its area should be.

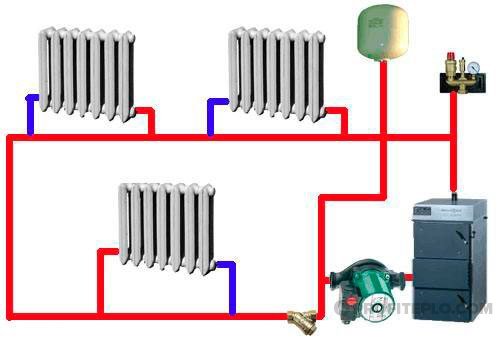

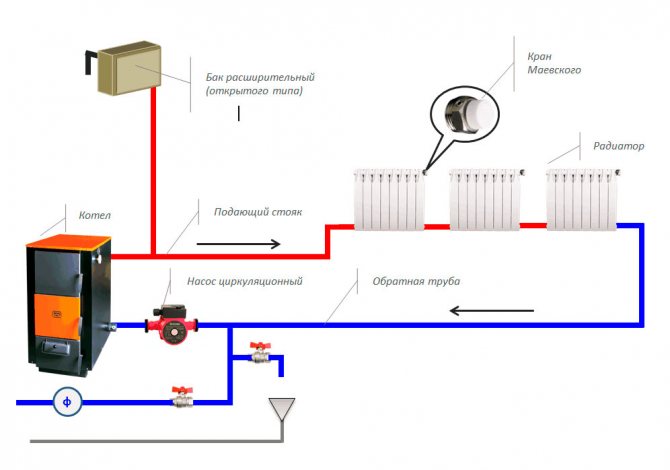

Autonomous horizontal heating

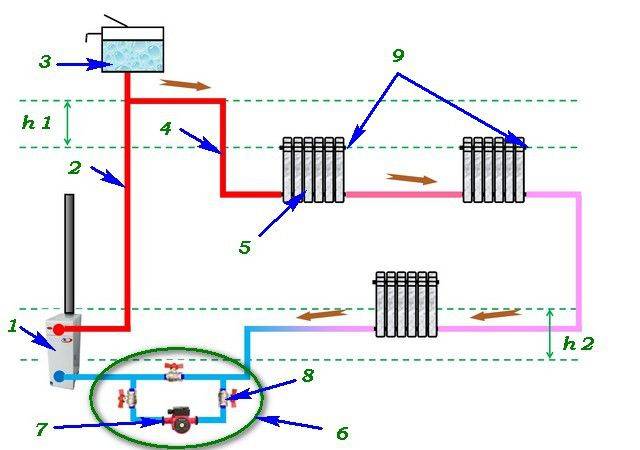

Heating with natural circulation

In a private house or in an apartment without a central heating connection, a horizontal heating system with a lower wiring is most often chosen. However, it is necessary to take into account the mode of operation - with natural circulation or forced under pressure. In the first case, immediately from the boiler, a vertical riser is mounted to which horizontal sections are connected.

The advantages of this arrangement for maintaining a comfortable temperature level include the following:

- The minimum cost for the purchase of consumables.In particular, a horizontal single-pipe heating system with natural circulation does not include a circulation pump, a membrane expansion tank and protective fittings - air vents;

- Work reliability. Since the pressure in the pipes is equal to atmospheric pressure, the excess temperature is compensated with the help of an expansion tank.

But there are also disadvantages to be noted. The main one is the inertia of the system. Even a well-designed horizontal single-pipe heating system of a two-story house with natural circulation will not be able to provide rapid heating of the premises. This is due to the fact that the heating network begins its movement only after reaching a certain temperature. For houses with a large area (from 150 sq.m.) and with two floors or more, a horizontal heating system with lower wiring and forced circulation of the liquid is recommended.

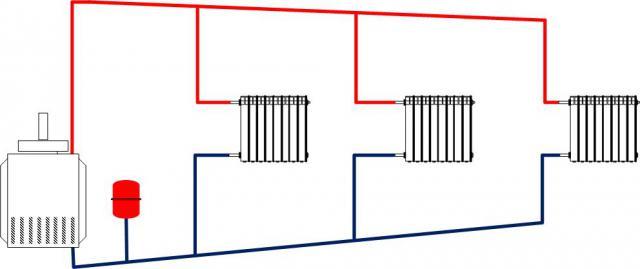

Heating with forced circulation and horizontal pipes

Unlike the above scheme, for forced circulation, it is not necessary to make a riser. The pressure of the coolant in a horizontal two-pipe heating system with bottom wiring is created using a circulation pump. This is reflected in the improvement of performance:

- Rapid distribution of hot water throughout the line;

- The ability to control the volume of coolant for each radiator (only for a two-pipe system);

- Requires less space for installation as there is no distribution riser.

In turn, the horizontal wiring of the heating system can be combined with a collector. This is true for long pipelines.Thus, it is possible to achieve an even distribution of hot water throughout all rooms of the house.

When calculating a horizontal two-pipe heating system, it is necessary to take into account the rotary nodes, it is in these places that the greatest hydraulic pressure losses are.

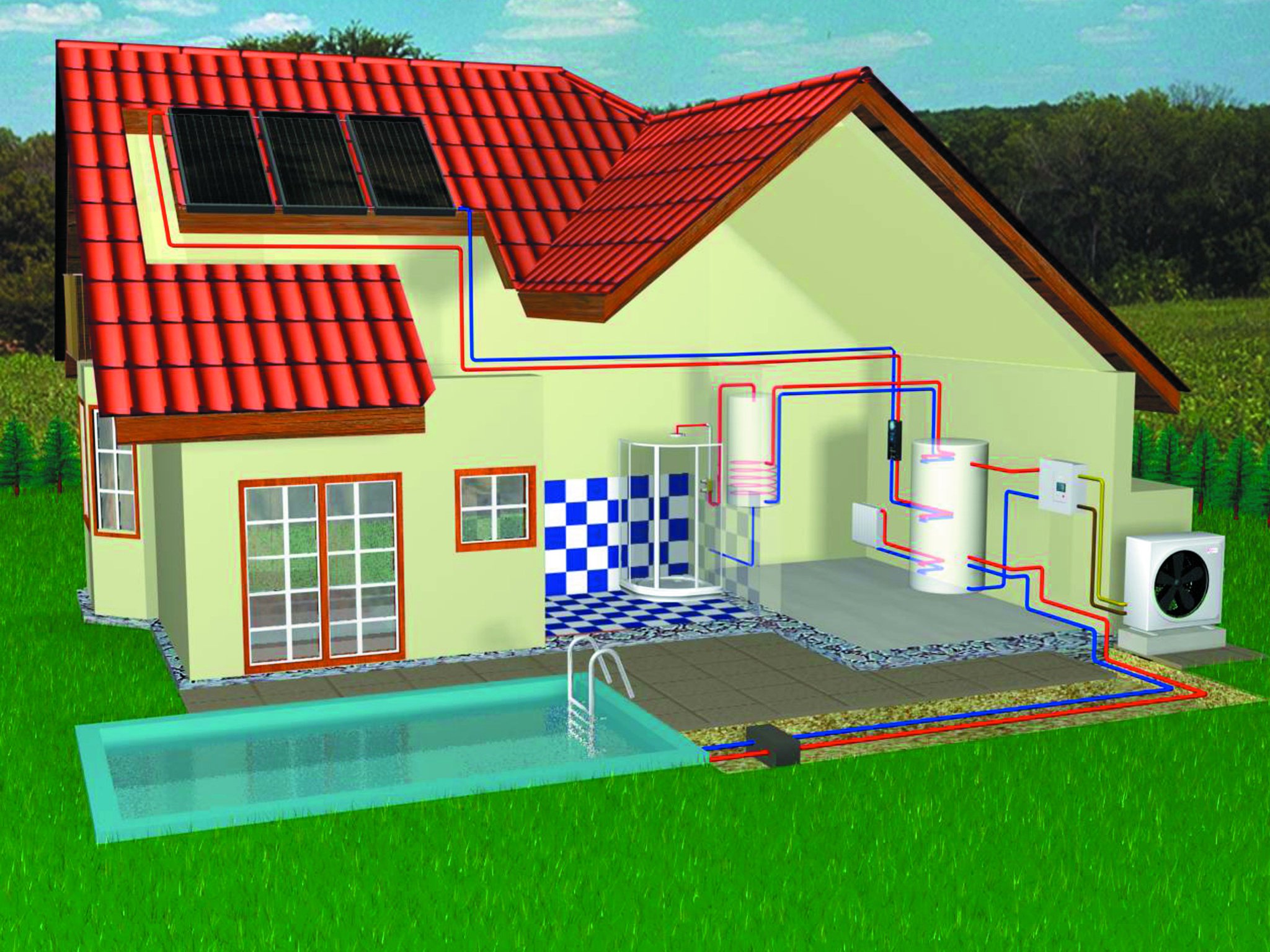

Advantages and disadvantages of a closed heating system

First of all, there is no evaporation of the coolant

This gives one important advantage - you can use not only water, but also antifreeze in this capacity. Therefore, the possibility of freezing of the system during forced interruptions in its operation is eliminated, for example, if it is necessary to leave the house for a long time in winter.

Compensation tank can be placed almost anywhere in the system

Usually, a place is provided for it directly in the boiler room, in the immediate vicinity of the heater. This ensures the compactness of the system. An open-type expansion tank is often located at the highest point - in an unheated attic, which will require its mandatory thermal insulation. In a closed system, this problem does not exist.

Forced circulation in a closed system provides heating of the premises much faster from the moment the boiler is started. There are no unnecessary losses of thermal energy in the area of the expansion tank.

The system is flexible - you can adjust the heating temperature in each specific room, selectively turn off some sections of the general circuit.

There is no such significant difference in the temperature of the coolant at the inlet and outlet - and this significantly increases the period of trouble-free operation of the equipment.

For heating distribution, pipes of a much smaller diameter can be used than in an open system with natural circulation without any loss in heating efficiency. And this is both a significant simplification of installation work, and significant savings in material resources.

The system is sealed, and with proper filling and normal operation of the valve system, there should simply be no air in it. This will eliminate the appearance of air pockets in pipelines and radiators. In addition, the lack of access to oxygen contained in the air does not allow corrosion processes to actively develop.

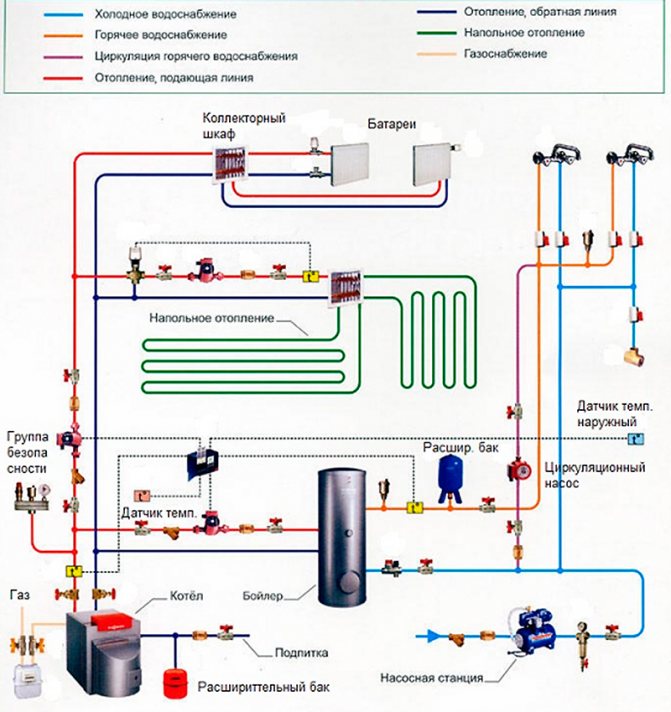

Underfloor heating can also be included in a closed heating system

The system is highly versatile: in addition to conventional heating radiators, it can be connected to water “warm floors” or convectors hidden in the floor surface. A domestic water heating circuit is easily connected to such a heating system - through an indirect heating boiler.

The disadvantages of a closed heating system are few:

- The expansion expansion tank must have a larger volume than with an open system - this is due to the peculiarity of its internal design.

- It will require the mandatory installation of the so-called "safety group" - a system of safety valves.

- The correct operation of a closed heating system with forced circulation depends on the continuity of the power supply. It is possible, of course, to provide, as with the open type, switching to natural circulation, but this will require a completely different arrangement of pipes, which can reduce a number of the main advantages of the system to zero (for example, the use of "warm floors" is completely excluded). In addition, the heating efficiency will also decrease sharply.Therefore, if natural circulation can be considered, then only as an “emergency”, but most often a closed system is planned and installed specifically for the use of a circulation pump.

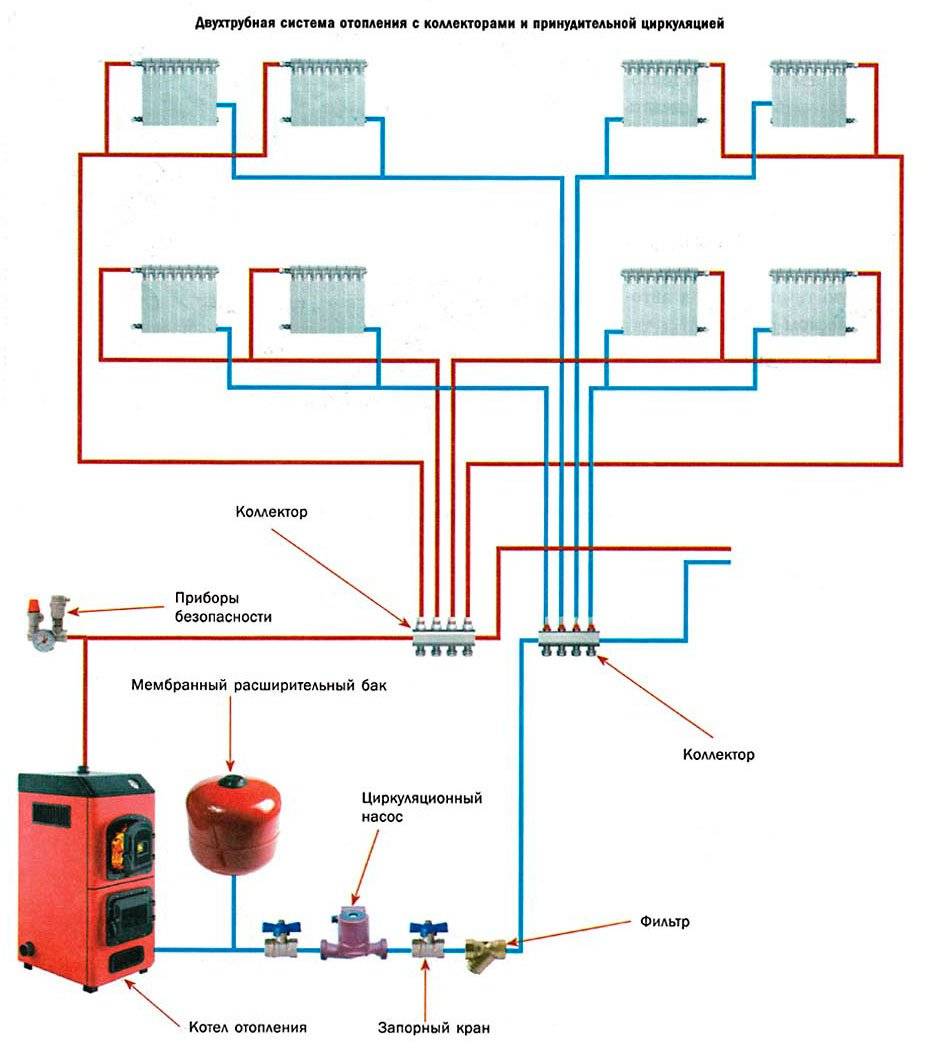

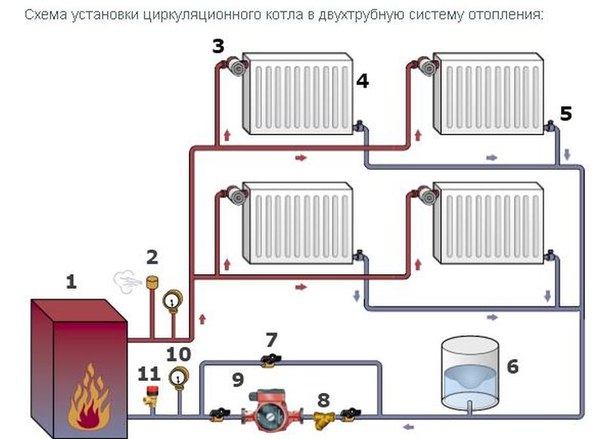

Beam system with collectors

Radiant heating system using a collector.

This is one of the most modern schemes, which involves laying an individual line to each heater. To do this, collectors are installed in the system - one collector is the supply, and the other is the return. Separate straight pipes diverge from the collectors to the batteries. This scheme allows for flexible adjustment of the parameters of the heating system. It also makes it possible to connect underfloor heating to the system.

The beam wiring scheme is actively used in modern homes. The supply and return pipes here can be laid as you like - most often they go in the floors, after which they go to one or another heating device. To regulate the temperature and turn on / off the heating devices, small distribution cabinets are installed in the house.

According to heating engineers, such a scheme is ideal, since each heater operates from its own line and is almost independent of other heaters.

Advantages and disadvantages of beam systems

There are many positive qualities:

- the ability to completely hide all pipes in walls and floors;

- convenient system setup;

- the possibility of creating remote separate adjustment;

- the minimum number of connections - they are grouped in distribution cabinets;

- it is convenient to repair individual elements without interrupting the operation of the entire system;

- almost perfect heat distribution.

When installing a radiant heating system, all pipes are hidden in the floor, and the collectors are in a special cabinet.

There are also a couple of drawbacks:

- the high cost of the system - this includes the cost of equipment and the cost of installation work;

- the difficulty in implementing the scheme in an already built house - usually this scheme is laid down at the stage of creating a homeownership project.

If you still have to put up with the first drawback, then you can’t get away from the second.

Features of installation of radiant heating systems

At the stage of project creation, niches for laying heating pipes are provided, points for mounting distribution cabinets are indicated. At a certain stage of construction, pipes are laid, cabinets with collectors are installed, heaters and boilers are installed, a test run of the system is carried out and its tightness is checked. It is best to entrust all this work to professionals, since this scheme is the most complex.

Despite all the complexity, the radiant heating system with collectors is one of the most convenient and efficient. It is used not only in private houses, but also in other buildings, for example, in offices.

Rules for the selection and installation of pipes

The choice between steel or polypropylene pipes for any circulation occurs according to the criterion of their use for hot water, as well as from the standpoint of price, ease of installation and service life.

The supply riser is mounted from a metal pipe, since water of the highest temperature passes through it, and in the case of stove heating or a malfunction of the heat exchanger, steam can pass through.

With natural circulation, it is necessary to use a slightly larger pipe diameter than in the case of using a circulation pump. Usually, for space heating up to 200 sq. m, the diameter of the acceleration manifold and the pipe at the inlet of the return to the heat exchanger is 2 inches.

This is caused by the slower water velocity compared to the forced circulation option, which leads to the following problems:

- reduction in the volume of heat transferred per unit of time from the source to the heated room;

- the appearance of blockages or air jams that a small pressure cannot cope with.

Particular attention when using natural circulation with a bottom supply scheme must be given to the problem of removing air from the system. It cannot be completely removed from the coolant through the expansion tank, because

boiling water first enters the devices through a line located lower than themselves.

With forced circulation, the water pressure drives the air to the air collector installed at the highest point of the system - a device with automatic, manual or semi-automatic control. With the help of Mayevsky cranes, heat transfer is mainly adjusted.

In gravitational heating networks with a supply located below the appliances, Mayevsky taps are used directly to bleed air.

All modern type heating radiators have air outlet devices, therefore, to prevent the formation of plugs in the circuit, you can make a slope, driving air to the radiator

Air can also be removed using air vents installed on each riser or on an overhead line that runs parallel to the mains of the system.Due to the impressive number of air exhaust devices, gravity circuits with lower wiring are used extremely rarely.

With a low pressure, a small air lock can completely stop the heating system. So, according to SNiP 41-01-2003, it is not allowed to lay pipelines of heating systems without a slope at a water velocity of less than 0.25 m / s.

With natural circulation, such speeds are unattainable. Therefore, in addition to increasing the diameter of the pipes, it is necessary to observe constant slopes to remove air from the heating system. The slope is designed at the rate of 2-3 mm per 1 meter, in apartment networks the slope reaches 5 mm per linear meter of a horizontal line.

The supply slope is made in the direction of the water flow so that the air moves to the expansion tank or air bleed system located at the top of the circuit. Although it is possible to make a counter-slope, in this case it is necessary to additionally install an air vent valve.

The slope of the return line is made, as a rule, in the direction of the chilled water. Then the lower point of the contour will coincide with the inlet of the return pipe to the heat generator.

The most common combination of flow and return slope direction to remove air pockets from a natural circulation water circuit

When installing a warm floor in a small area in a circuit with natural circulation, it is necessary to prevent air from entering the narrow and horizontal pipes of this heating system. An air extractor must be placed in front of the underfloor heating.