- Mounting methods

- 2.2. On the internal gas pipelines of hydraulic fracturing and boiler room

- Pro Tips

- Installing a plug in non-pressure and pressure networks

- Installing a plug in a pressurized system

- Fitting a plug for round pipes

- How to shut off a gas line

- Plug installation

- Shutting off gas for non-payment: description of the procedure, procedure and rules

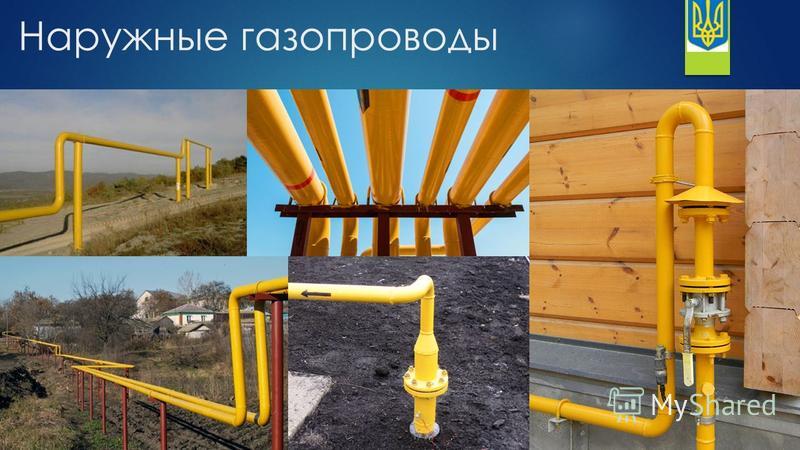

- Features of gasification of residential buildings

- The main types of installation errors

- materials

- Metal and chrome end caps

- Plastic and polyethylene plugs

- Rubber "plugs"

- Types of plastic plugs for a profile pipe

- 1 Material for manufacturing - what are the elements made of?

- Conclusions and useful video on the topic

Mounting methods

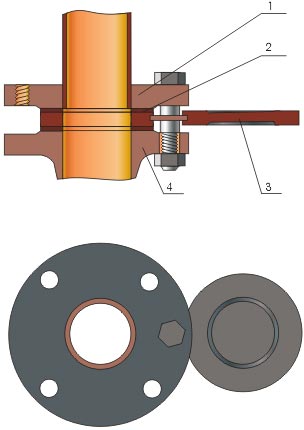

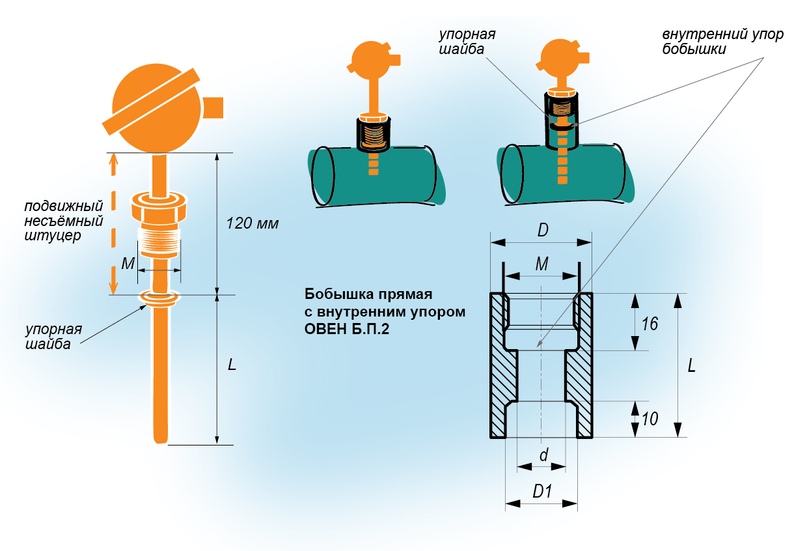

During installation, you must adhere to the following rules:

- Before welding, clean the ends of the parts to be welded with an iron brush from rust. Welding is carried out using manual or semi-automatic welding. To weld a plug to a pipe, it is necessary to perform a continuous seam, without tearing off the electrode from the metal. After welding is completed, pressurize the joint.

- When installing flange plugs, distortion must not be allowed when tightening the connection bolts. Tightening should be carried out in a staggered manner in two stages, first pre-tightening all bolts to partial strength, and then perform the final tightening.Before installation, it is necessary to lubricate the sealing gasket with lithol.

- Before installing the threaded plugs, the threads must be cleaned of rust and washed with diesel fuel or gasoline. A FUM tape is wound onto the thread in the direction of the thread with an overlap of half the width of each turn. The cork is screwed first by hand, and then with a key until it stops. Conical plugs are installed without winding the FUM tape.

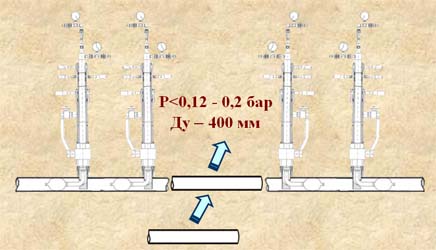

2.2. On the internal gas pipelines of hydraulic fracturing and boiler room

2.2.1. Before

start of work on the installation of plugs

The work manager must:

—

make sure that the foreman has received a work permit for production

gas hazardous work and got acquainted

with the conditions for the production of works,

—

specified in the work permit;

—

get acquainted with the results of air pollution control in the production area

works and in the control room

hydraulic fracturing room or boiler room,

specified in the work permit;

—

instruct all team members on the necessary safety measures during production

work and the procedure for evacuating victims from the danger zone, after which each member of the brigade who received instructions must

sign the work permit;

—

check the availability and serviceability of personal funds

safety for each member of the brigade (conditions for the use of gas masks

determined by the work permit);

—

check the availability of the tool, its serviceability

and completeness, and

equipment with material and technical means;

—

together with the foreman, receive instructions from the person allowing to work on safety measures when working near

operating equipment, the order of work and passage to the venue

work and withdrawal of the brigade during regulated breaks in work and

in case of emergencies;

—

to be carried out together with the foreman of the work and who can bypass the place of work and make sure that

that the measures specified in the work permit for the preparation of the workplace and measures

safety measures are fully implemented (the gas pipeline is purged with compressed air and

there is no overpressure) and that:

—

locking devices in front of the place of installation of the plug are in a closed

position, and there is no excess pressure in the gas pipelines;

—

equipment remaining in operation located near the installation site of the plug

and under tension

pressure, high temperature, marked

safety signs in accordance with the instructions of the work permit;

—

control the results of the analysis of air samples taken from the premises and from

sampling point of the purge gas pipeline (presence of gas in air samples,

selected from the premises, should not exceed values of more than 0.1% (according to

volume), and in samples taken from the gas pipeline, more than 1% (by volume);

—

together with those who allow the brigade to be allowed to the place of work;

—

ask each member of the team how they feel;

—

if the values of gas contamination in samples taken from the premises and from the gas pipeline,

do not exceed the maximum allowable values (0.1% by volume), give a command to loosen

flange connection and installation of a plug on the gas pipeline.

2.2.2. If a

the amount of gas content in the sample,

selected from the premises exceed the maximum allowable values, then when

excess of air pollution

indoors more than 0.1% (by volume),

but less than 1%, work should

be carried out when available at the workplace, prepared for immediate

the use of hose-type gas masks, and a tool that does not give sparks upon impact

(copper-plated). If the air pollution in the room is more than 1%, but less than 3% (according to

volume) work should be done in hose gas masks using

copper-plated tool and

observers, when air pollution is more than 3%, perform work prohibited.

2.2.3.

If the values of gas content in the sample taken

from the gas pipeline exceed the maximum allowable value (1% by volume), then

close the upstream shut-off valve on the gas supply side and open the purge

gas pipeline between two closed shut-off devices (valve switching

carried out by operating personnel).

If not

it is possible to achieve a gas content level that does not exceed the maximum allowable

value (1% by volume), then the gas pipeline should be filled with gas again and start

loosening of the flange connection when the oxygen content in the gas is not more than 1%

and in the absence of excess

pressure in the disconnected area

gas pipeline. Work should be carried out with copper

tool.

2.2.4.

Installation of plugs on internal gas pipelines

and the closing of the work permit is carried out similarly to these Guidelines.

Pro Tips

Installing a plug in non-pressure and pressure networks

In an emergency, you can carefully cut the plastic pipe, heat it up with a soldering iron, flatten the end with pliers and wait 2-3 minutes until polymerization occurs - this is enough to live until morning and serious repairs.

It is not difficult at all to temporarily close the hole in the free-flow sewer socket - wrap the rag with polyethylene and temporarily drown it out - there will be no smell.

Installing a plug in a pressurized system

It is impossible to weld plastic in the presence of pressurized water in the system. It is better to call the city emergency gang, shut off and drain the water. Therefore, you can only use the grandfather's method: wrap the pipe with a crack with rubber and fix it tightly with clamps, or at least with wire. If there is a need to block the end of the pipe or close the hole, you can try to cut a cork out of wood, wrap it with FUM tape, hammer it into the hole and fix it with improvised means. Wood swells from water and better closes the hole.

Fitting a plug for round pipes

If you need to close the ends of round pipes, you can easily pick up improvised materials for corks: use plugs for furniture (cabinet) of a suitable diameter, roof rails, even use wine corks - in general, you can let your imagination run wild.

How to shut off a gas line

But if no one uses gas heating. #15 IP/Host: 81.22.62. Re: disconnection of gas from individuals HELLO! WE DO NOT AGREE FOR A DEBT FOR GAS GOR GAS DOES NOT AGREE TO PAY OFF THE DEBT IN PARTS 2 TIMES THE HEAD OF GAZ GOR FORMS TO TAKE A LOAN AND THREATEN TO CUT OFF THE GAS IN THE APARTMENT AND I HAVE A SMALL CHILD 2 YEARS IS IT LEGAL TO PAY? DO NOT REJECT PARTS #16 IP/Host: 87.238.233.

Re: gas shutdown for individuals Hello! My relative's gas was turned off, they put a seal. She has accumulated debt, now she has paid half of the amount, in the near future she will pay off the rest of the amount.

But here’s the question, she has an old housing stock, there are two stoves in the house, one doesn’t work, and five years ago the gas workers put a seal on it (everything is intact, the gas workers were convinced when they came to turn off the gas). -household needs of citizens. The main provisions of this NPA are:

- regular maintenance of gas equipment (stove, column, gas meter, chimney, etc.) by competent specialists (usually employees of the gas supplier company) and a fee for this service;

- such service is mandatory and residents at their own discretion have no right to refuse it;

- installation, dismantling, transfer of gas equipment is carried out exclusively by competent specialists;

- for non-compliance with the rules of this NLA, penalties are provided, both on the part of the supplier and on the part of the state in the form of administrative sanctions.

Thus, the use of gas and gas equipment must be under the constant supervision of competent specialists.

Head Tenant I don't live in the apartment, it's empty. I want to put a cap on the heating, so as not to pay.

Tell me how to do it legally!? read answers (1) Subject: Living in an apartment They put a plug on my gas pipe for non-payment, the last payment was in February, were they entitled? (at the time when they put the plug, there was no one at home) read answers (1) I have such a question for water supply debt we live in a communal apartment and I have two minor children in addition to the owner of the room a disabled child. read answers (2) Topic: Debts for utility bills Question Hello, please tell me why they demand money for the work of a locksmith, in view of the fact that earlier there was a suspension of gas supply and set to plug answers (1) Topic: Money for work I put a plug on the meter, came to Vodokanal to seal this plug and they billed me for the filling.

Payment and disconnection of gas in a private house, but in the district gas we were told that because of the stove we have to pay for heating as well. but the stove is only on the veranda and it is unrealistic to heat the whole house. the controller said that you can measure the veranda and pay only for its heating. but then they changed their minds and say that after the fire they should have turned off all the gas. but the board is fine. I understand that the questions will disappear after the installation of the meter, but this requires a project that is being prepared for more than 1 month. Gas shutdown 07.2013 The gas shutdown was in 2010 for non-payment, the debt was settled, but the plugs were not removed and the payment was calculated as connected and in this case the central pipe was cut off and the debt was calculated for the last half a year when 04/08/2014 The contract of sale stipulates the numbers of the premises of our townhouse, which each owner owns. Each has a separate contract with the servicing gas company.

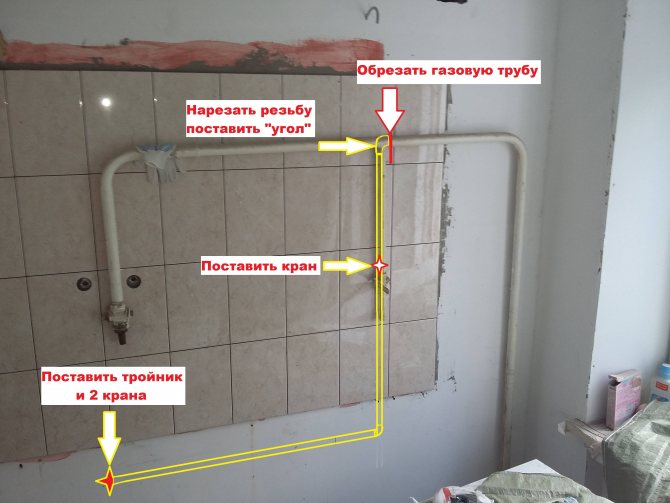

Plug installation

Now consider how to put a cap on the pipe. In most cases, this operation does not cause difficulties even for people who do not have special knowledge.

An external plug for pipes is installed based on its design features. When installing fittings, the following rules must be followed:

- it is advisable to use a sealing material to seal threaded connections. For example, a fum tape is optimal for water supply pipes;

Material for sealing and insulating pipe joints

- when installing a pneumatic plug, safety rules and control of the amount of incoming air are required. Otherwise, the device may "burst";

- if an elliptical plug is mounted, then the fitting installer must know the simplest welding methods and strictly observe the safety precautions when working with the welding machine;

- for flanged plugs, the fixing bolts must exactly match the dimensions of the prepared holes. Otherwise, the stub will not perform its function.

You can watch the video on the selection and installation of plugs using the example of fence pipes.

Shutting off gas for non-payment: description of the procedure, procedure and rules

The subscriber needs to provide unhindered access of specialists to the equipment and pipeline

It is especially important not to create obstacles for the employees of the service enterprise if it is necessary to localize or eliminate the consequences of accidents. In emergency situations, access to specialists should be provided at any time upon presentation of their certificate

Consumer misconduct can create a safety hazard for other residents and their property.What happens to the body of a person who does not have sex? Sex is almost as basic a need as eating. At least once you start doing it, you won't stop.

Even if you keep... Sexuality What to do after intimacy: 9 rules You are done having sex. Maybe it was good, maybe it was bad, but that's not the point. The process has ended.

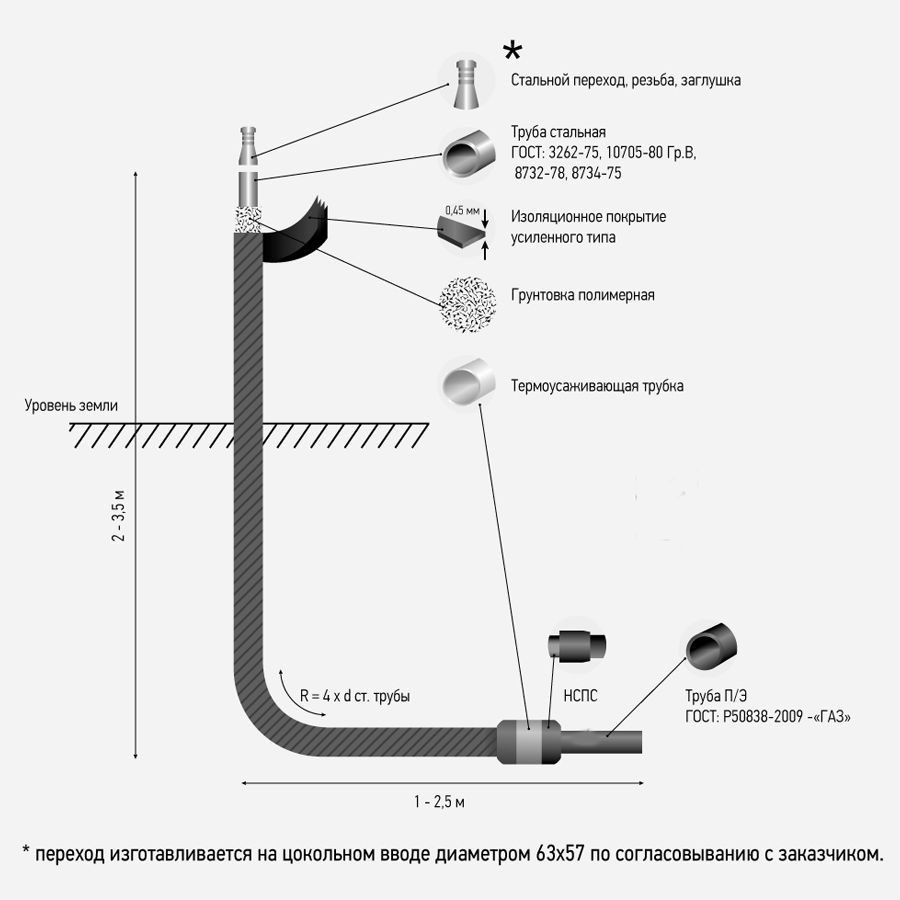

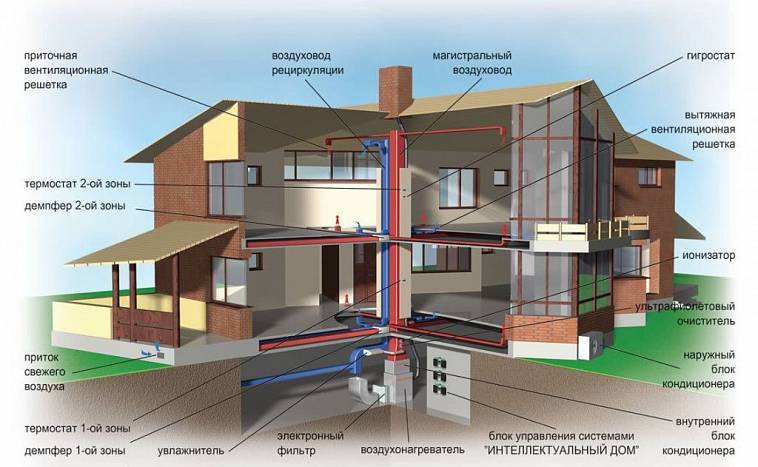

Features of gasification of residential buildings

With the help of gas in the house, you can successfully organize heating, hot water heating, and cooking. Gas equipment is reliable and diverse, and the cost of blue fuel is usually lower than the use of electricity, solid or liquid fuel for the same purposes.

In addition, gas lines fail extremely rarely, but power outages are common. Stocks of firewood, coal, diesel fuel and other similar energy carriers have to be constantly replenished.

The main problem with natural gas is its danger to human health and its ability to explode. Even a small leak can lead to poisoning or an explosion. That is why the requirements for the installation of gas communications are very high, you should not even think about doing all the work yourself.

To begin with, experts do not recommend saving on materials or system elements. Pipe laying of dubious quality and unprofessional installation are unacceptable.

Gas pipes almost always need to be laid in an open way (except for underground sections of the highway).They cannot be hidden under any decorative elements to improve the interior.

It is recommended to avoid plug connections whenever possible. All places where pipes are connected must be located in such a way that at any time the point of contact can be examined and repaired if necessary.

Do not lay gas pipes inside the walls or in the thickness of the foundation. This rule also applies to other elements such as architraves, door frames, window frames, partitions, etc.

In some cases, it is allowed to lay a gas pipe in a wall niche, but this point must be clearly reflected and justified in the project. Special requirements are also imposed on the slope of the pipes. Horizontally, the position of the line is allowed to deviate by only 3 mm towards gas appliances.

Vertically, no deviations are allowed, but the riser may have a slight slope: no more than 2 mm per meter. It should not pass through living quarters, through a toilet or bathroom. The gas riser should be located in the stairwell, often through the kitchen.

You will also have to carefully monitor the installation of shut-off valves. So, the position of the central axis of the plug must be strictly parallel to the wall along which the pipe runs. When choosing the position of the valve, make sure that the position of the locking device is not blocked by the wall. From the ceiling and from the walls, the gas pipe should be located at a distance of 100 mm.

The gap between the wall and the pipe can vary from the size of the pipe radius to a limit value of 100 mm. This clearance is necessary so that the structure can be easily examined. A distance of 2.2 m should be maintained from the floor.Gas pipes are placed on special strong supports; sagging of the structure is unacceptable.

Therefore, it is necessary to make sure that there are no gaps between the bracket and the pipe. All these important points are taken into account in the design of the gas supply system, which must first be drawn up by specialist engineers.

Gas pipes should be laid at least 30 cm from the electrical panel, and at least 25 cm from open wiring. From the hidden cable should retreat at least five centimeters.

The main types of installation errors

The main purpose of the plugs is to ensure tightness and protect the inside of the product from dirt and dust. Therefore, defects, depending on the type of plug, may be as follows:

- Leaks can occur when flange plugs are used. This may be due to improper tightening of the connection, damage to the gasket, or a defective part. The defect is corrected by replacing damaged parts or tightening the bolts.

- If it digs out of the connection after installing the screw plug, then it is necessary to tighten the thread, and if this does not help, disassemble and replace the winding of the FUM tape.

The main malfunction of these products is the lack of tightness during installation. It can occur due to poor-quality installation or marriage of the part itself.

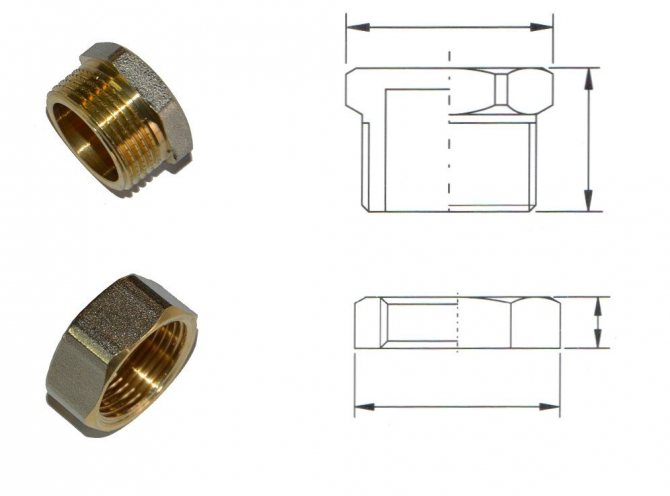

materials

Modern industry offers the buyer a huge selection of shapes and materials. This applies to both pipes and the plugs connecting them. As for the fittings for the communication system, among them are the options described below.

Metal and chrome end caps

Pipe fittings made of this material are currently used very widely.With their help, they lay water and gas systems made of cast iron and steel. They are ideal for industry. A significant disadvantage of the damping elements of metal systems is their sensitivity to corrosion and rusting.

With external influences, chrome-plated metal plugs do a good job. It not only protects the main structure from outside influences, but also performs a decorative function. Such elements of the pipeline give gloss and genuine beauty to all structures. Sometimes such constructive parts of communications become the center of the entire interior. The only disadvantage of the described option is the rather high cost.

Variations made of brass save pipelines from rust. A significant disadvantage of this option is the very high cost and complexity of the production procedure. They are replaced by modern counterparts.

Plastic and polyethylene plugs

Inexpensive "plugs" made of plastic materials are characterized by high resistance to rust and corrosion. However, they are afraid of sunlight and high temperatures. For this reason, plastic systems are used exclusively for interior work. And also they are well suited for the role of "lids" for the fence. Only here they are not suitable for sewerage.

Rubber "plugs"

There is a rubber version of the "silencers" They are unable to securely fasten any structure. The reason for this is the plasticity of the material. However, rubber products protect pipelines well from debris and dirt.

Types of plastic plugs for a profile pipe

By the presence of structural features, several main types of parts for insulation are distinguished:

- Threaded plugs. Such parts are installed on the pipe using threads on the fitting and on the profile itself.

Threaded fittings are usually made of metal, but some manufacturers also produce plastic products of this kind. Threaded plugs are only suitable for round profiles.

- Pneumatic elements that are fixed in the pipe with a pump.

The plug is inserted into the pipe, inflated with air and, increasing in size, completely closes the pipe lumen.

- Elliptical plugs. They are made only of metal, they can be installed using a welding machine.

More often, such fittings are used for installation on sewer pipes, in addition, they have found application on round support pillars.

The range of plugs is very large. When choosing them, they are guided by the dimensions and cross-sectional shape of the profile pipes. They are square, for example: a plastic cap for a profile pipe 80x80, a plastic cap for a profile pipe 60x60, a plastic cap for a profile pipe 50x50, a plastic cap for a profile pipe 40x40, a plastic cap for a profile pipe 15x15.

There are plugs for rectangular profiles, for example, a plastic plug for a 40x20 profile pipe. They produce plugs and round shapes of different diameters.

There are various stiffening ribs on the plugs: straight or converging into a cone. The latter are easier to install. There are plastic products for oval profiles with converging stiffeners with an entry depth of 22 mm.

Plastic plugs for profile pipes are made not only for a one-time permanent installation. Transport pipes are installed on pipes during their transportation in order to preserve them. End - for temporary use, which for convenience are made of rubber or flexible plastic.

1 Material for manufacturing - what are the elements made of?

Now there is a huge variety of elements of interest to us. They are divided into different groups depending on certain indicators and performance characteristics. First of all, pipe caps are classified according to the materials from which they are made. From this point of view, they are:

- metal;

- rubber;

- polyethylene and plastic;

- chromed.

Perhaps the most common today are metal plugs. They are installed on sewer and water supply steel and cast iron mains, used in pipelines through which gas is supplied. Metal products are indispensable for industrial purposes. In household networks, they are also used very actively. Metal plugs have high strength and operational reliability. But they have a serious drawback - they are prone to rust.

Therefore, now, when building household and municipal water supply networks, as well as cast-iron sewers, instead of metal plugs, they are trying to use more modern plastic plugs, which are characterized by a high degree of anti-corrosion protection. Metal plugs are most often brass and steel structures. Brass products are sufficiently resistant to corrosion manifestations. But their cost is high. Steel plugs have a lower price. But, as we said, they rust.Yes, and the installation of such products is always a time-consuming procedure.

Modern plastic drain plugs

Modern plastic drain plugs

Corrosion is not terrible for polyethylene and plastic plugs on pipes. True, under the influence of the rays of the sun and elevated temperatures, they are able to deform. The undoubted advantage of such traffic jams is their low cost. Most often they are used as internal plugs for pipes (for profile and round ones) and as plugs for fences.

Note! It is undesirable to use polyethylene and plastic plugs for sewer pipes

Rubber products cannot be securely fastened. They are very plastic. Therefore, it is unrealistic to use them as holding fittings. As a rule, rubber structures are installed on various highways with one purpose. They protect sewer and water networks from debris and dirt. Rubber plugs (round and other shapes) are mounted elementarily - they are simply pushed into the pipeline in the desired area.

Steel products with a special chrome coating are a kind of ordinary metal plugs. They are decorative designs. Their appearance is shiny and radiant, ideal for adding beauty to various structures. Such decorative fittings are often used to decorate a pipe fence protecting a private area, or a fence around a public facility. Steel chrome fittings are not afraid of corrosion, characterized by a long service life. At the same time, the cost of such plugs for pipes is objectively high. This is due to the high costs of manufacturers for their production (complex technology, high cost of chrome plating).

Conclusions and useful video on the topic

According to the established requirements, gas work is carried out with the utmost care, the gas content of the air should not exceed 1 percent by volume. The following video will discuss how to properly cut a gas pipe and what problems you may encounter:

The following video will discuss how to properly cut a gas pipe and what problems you may encounter:

Choosing a plug is not the most difficult task; installing the product on a gas pipe will be more difficult. After all, you must follow all safety measures and do not forget to shut off the gas valve before the installation process. It would be better if you still turn to specialists.

You are familiar with this problem, then please share your experience in installing plugs on gas pipes. If you have any questions, please ask them in the box below.

Pipe plugs can be used for a wide variety of purposes. They are most commonly used for the safe transport of pipes, to prevent leaks, and as decorative elements. What are the plugs and how to choose a device that meets certain requirements, read on.

Fittings for temporary or permanent closure of various pipes