- Rules for installing heating radiators

- Use cases

- Temperature control in the radiator

- Operation without power supply

- Improvement of the one-pipe system

- Installation order

- Is assembly required

- prefabricated models

- What is a bypass?

- Some installation features

- Installation on the pump

- Battery Tests

- Solving the problem with the distribution of the coolant

- What is bypass

- What does the regulation of heating batteries give?

- How to solve the problem without a valve on the bypass

- What is a battery jumper and what is it for?

- Bypass device and its functions

- What is a bypass for?

- Thermal head

- Features of the thermal head?

- Typical dimensions of thermal head taps

- Installation of thermal heads

- Features and differences between angled and straight cranes, their advantages

- Alternative ways

- Bypass device

- Application in batteries with one-pipe system

- Factory Ready Devices

- Conclusions and useful video on the topic

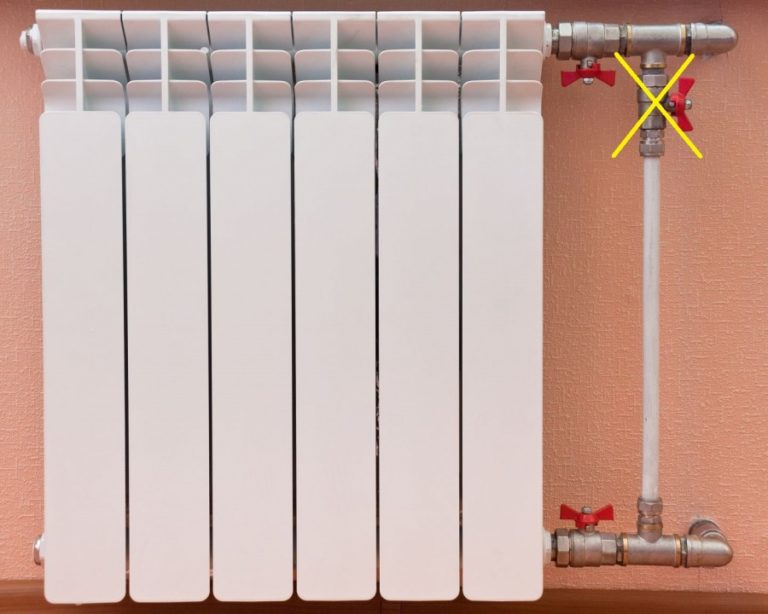

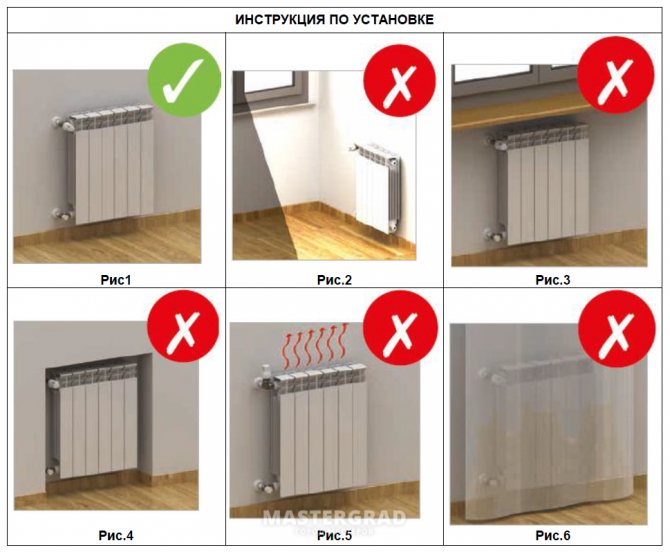

Rules for installing heating radiators

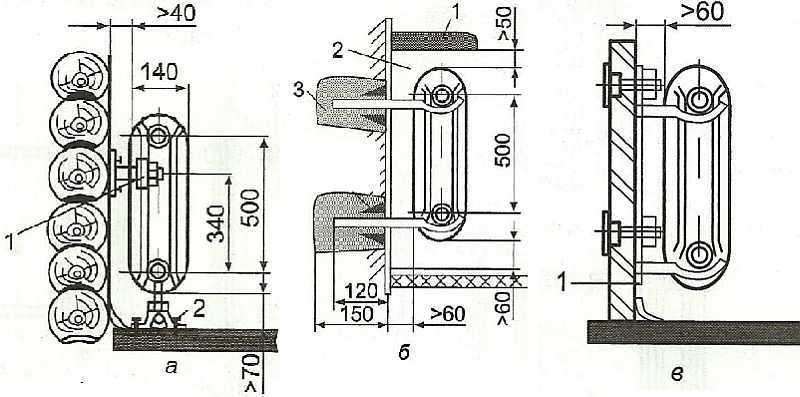

Length requirements are far from all recommendations. There are also rules for the location under the window relative to the floor, window sill and wall:

- It is required to place the heater strictly in the middle of the window opening. When installing, find the middle, mark it. Then right and left set aside the distance to the location of the fasteners.

- Distance from the floor is 8-14 cm.If you do less, it will be difficult to clean, if more, cold air zones form below.

- The radiator should be 10-12 cm from the window sill. With a closer location, convection worsens, and the thermal power drops.

- The distance from the wall to the back wall should be 3-5 cm. This gap ensures normal convection and heat distribution. And one more thing: at a small distance, dust will settle on the wall.

Based on these requirements, determine the most suitable size of the radiator, and then look for a model that satisfies them.

Mounting methods depending on the type of wall

These are general rules. Some manufacturers have their own recommendations. And take it as advice: before buying, carefully study the installation requirements. Make sure that all conditions suit you. Only after that buy.

To reduce non-production losses - for heating the wall - fasten a foil or foil thin heat insulator behind the radiator on the wall. This simple measure will save 10-15% on heating. This is how heat transfer increases. But keep in mind that for normal “work”, there must be a distance of at least 2-3 cm from the shiny surface to the back wall of the radiator. Therefore, the heat insulator or foil must be fixed to the wall, and not just leaned against the battery.

When should radiators be installed? At what stage of the installation of the system? When using radiators with side connection, you can first hang them, then proceed with the piping. For the bottom connection, the picture is different: you only need to know the center distance of the nozzles. In this case, radiators can be installed after the repair is completed.

Attach foil to the wall to increase heat output

Use cases

Bypasses have several purposes.

Temperature control in the radiator

To control the temperature in a system with a bypass, the following elements are installed on the heater (after the shut-off valve):

- Control valve for manual temperature change. Turning the knob changes the area of the orifice in the valve. Accordingly, the amount of HP entering the heater and its temperature also change.

- Valve with thermal head for automatic temperature change. The regulator sets the position corresponding to the desired temperature. To increase the temperature, the valve is moved to the “open” position and the HP passes through to heat the heater. Otherwise, the valve is moved to the "closed" position so that the heater cools down.

Both elements regulate the flow of coolant through the heater, directing its excess around the radiator through a shunt jumper.

Operation without power supply

If the gravity heating system is equipped with a central heating system with a bypass, then during a power outage HP circulation continues through the bypass. With a non-return valve on the bypass, this happens automatically, the ball valve must be opened manually.

Attention! If the ball valve is not opened in time when the pump is stopped (while the solid fuel boiler is running), this can lead to circulation disturbance and damage to the boiler equipment. Therefore, an uninterruptible power supply with a battery life of 5-10 minutes is installed for the CN. This is enough time to open the tap after a power outage.

This is enough time to open the tap after a power outage.

Therefore, an uninterruptible power supply with a battery life of 5-10 minutes is installed for the CN. This is enough to have time to open the tap after a power outage.

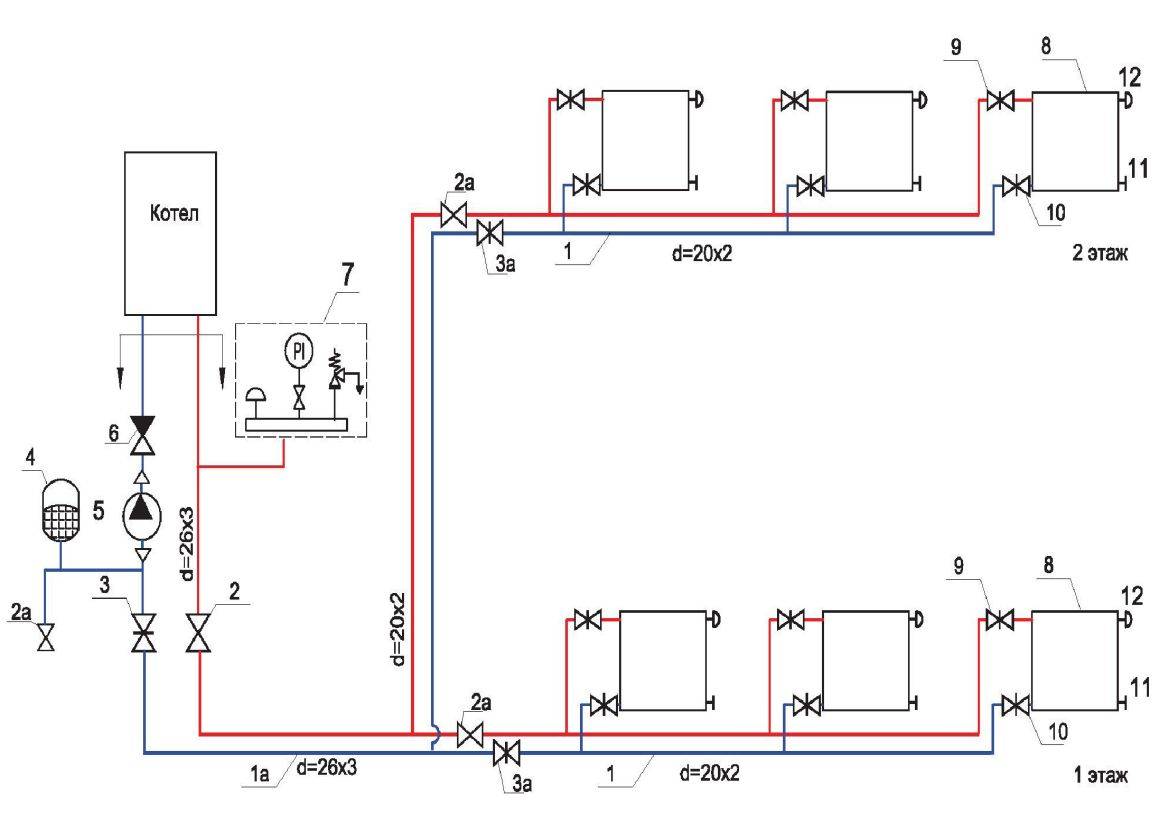

Improvement of the one-pipe system

For a comprehensive modernization of a single-pipe system, technical solutions are used:

- Each radiator in the house is equipped with a shunt jumper and a valve with a thermal head for uniform heating of all heaters.

- Each riser after the last battery is equipped with a special thermostatic regulator with an external temperature sensor. When the regulators on the riser batteries are closed, the return temperature is higher than the calculated one. In order not to waste the heated HP in vain, the thermostatic regulator closes the riser. This allows you to balance all the risers in the house in terms of HP flow depending on the temperature.

As a result of comprehensive modernization, the real HP consumption may decrease from 500 liters per hour to 100 liters per hour while maintaining a comfortable temperature.

Installation order

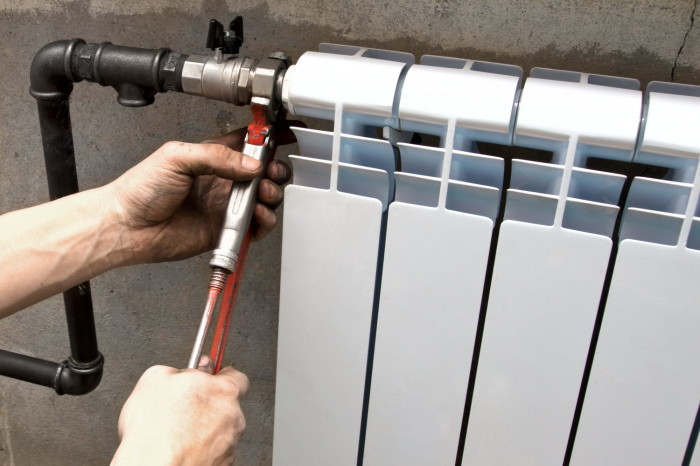

The easiest way to install a flanged ball valve is a very popular design. To install such a crane, you must:

- Choose a suitable location.

- Wrap the tap thread with a sealant, for example, FUM tape.

- Screw on the tap.

- Check connections for leaks.

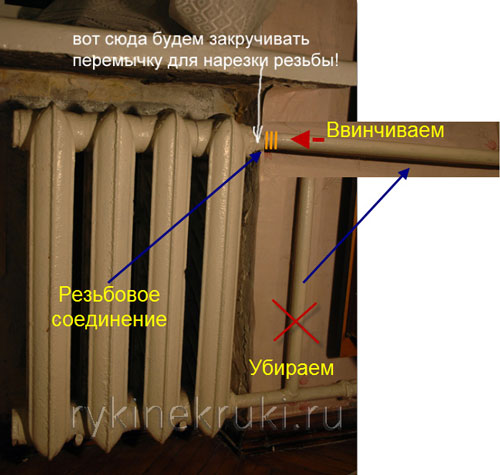

When figuring out how to properly put the crane on the battery, you should take into account a number of nuances that will help you correctly perform these operations. For example, if a faucet is being cut into an existing system, a small portion of the pipe should be cut out and a suitable thread cut, if one is not available.For more useful information on installation, you can peep in the video:

Of course, before starting work, you will need to remove the coolant from the heating system. Owners of private houses with individual heating will not have any problems, but apartment residents will have to coordinate this event with the management company.

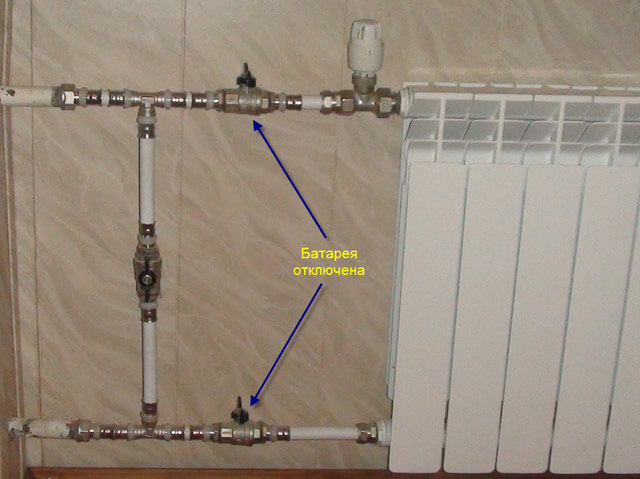

The ball valve is installed in the area between the battery and the bypass - a special jumper that ensures the circulation of the coolant in the system, even when the valve is closed

The valve is installed in front of the battery and behind the jumper that connects the “inlet” and “outlet” of the coolant so that when the flow is blocked, the coolant does not stop circulating through the system. If such a jumper (professionals call it a bypass) is missing, this problem must be solved when installing a tap on a radiator. When installing a crane, two points should be considered:

- There should be no obstacles for the adjusting knob set to any position.

- The user must have free access to the crane.

Before purchasing a faucet, of course, you should make sure that the diameter of the faucet and the pipe on which it will be installed match. It is also worth specifying the type of thread. For a flanged valve, these elements can be made as follows:

- both threads are internal;

- both threads are external;

- a combination of internal and external threads from different sides.

Flanged valves have a special marking in the form of an arrow, which indicates the direction of the flow of the working medium, i.e. coolant. Do not neglect these instructions when installing the faucet.

To avoid leaks, FUM tape or other suitable sealant should be used correctly.When the crane is installed for open pipe (it is clear that the thread on the valve flange will be closed), the seal is wound clockwise. In this case, the master is located facing the pipe hole. If the open thread is on the flange, the seal is also wound clockwise, but already facing the tap, and not the pipe.

When the FUM tape is wound correctly and in sufficient quantity, noticeable efforts will be required to screw the thread. At the end of the work, part of the sealant may protrude slightly at the junction, this is a completely normal situation, characteristic of good sealing. If the tap turns easily, too thin a layer of sealant is used. In this case, wind a little more FUM tape, and then screw the tap tightly to the pipe. Compliance with these simple rules will help install the faucet correctly and provide a sufficiently high seal.

At the end of the work, it is imperative to check the connection by filling the system with water, preferably at elevated pressure. Neglect of this rule may lead to flooding of the premises due to improper sealing of the joints. Most often, residents of apartment buildings suffer from the consequences of dishonest work, since filling the heating system with water before the start of the heating season is usually carried out without warning on a weekday.

Is assembly required

If the radiators are supplied assembled, it is enough to install the plugs and the Mayevsky crane. Most models have four holes located at the four corners of the case.They are used to connect heating lines. In this case, any scheme can be implemented.

Before the installation of the system begins, it is necessary to close the extra holes using special plugs or air vent valves. The batteries are supplied with adapters that must be screwed into the manifolds of the product. Various communications should be connected to these adapters in the future.

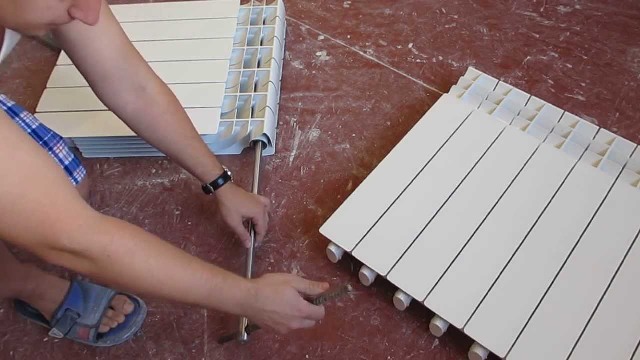

prefabricated models

Battery assembly should begin with laying the entire product or its sections on a flat surface. Best on the floor. Before this stage, it is worth deciding how many sections will be installed. There are rules that allow you to determine the optimal amount.

The sections are connected using nipples having two external threads: right and left, as well as a turnkey ledge. The nipples should be screwed into two blocks: at the top and at the bottom.

When assembling the radiator, be sure to use the gaskets supplied with the product.

It is necessary to ensure that the upper edges of the sections are correctly located - in the same plane. The tolerance is 3 mm.

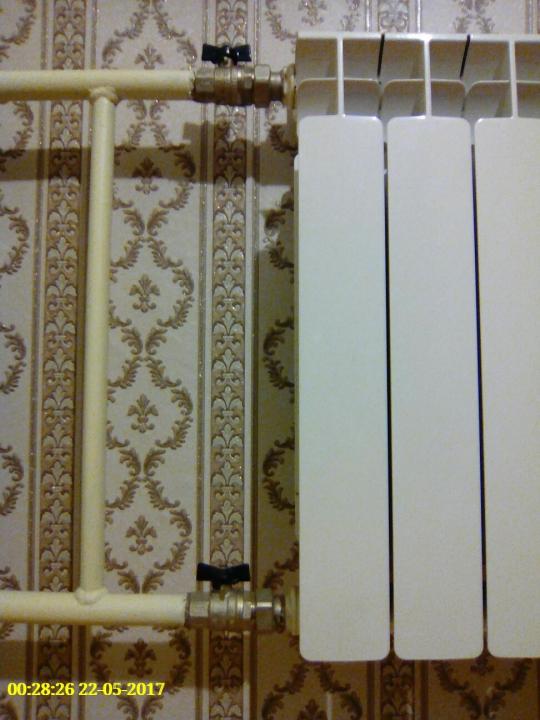

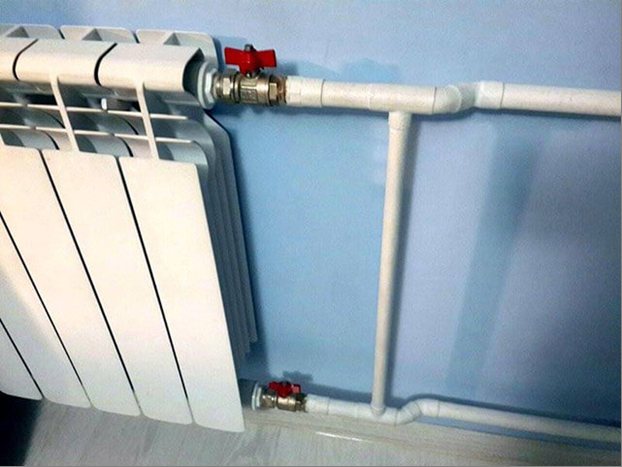

What is a bypass?

Probably, every self-respecting master in the installation of heating systems necessarily explains to customers what a bypass is from the point of view of a simple layman. And, as you know, repetition is the mother of learning, therefore, we will literally characterize this important structural element of the heating system in a nutshell.

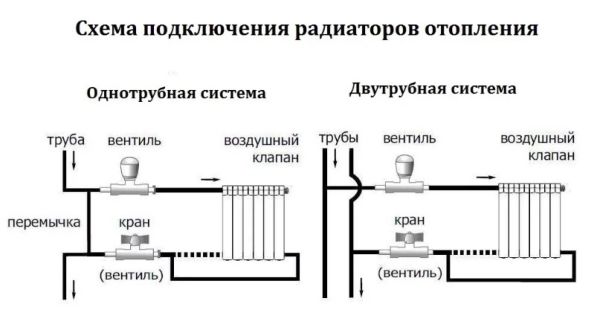

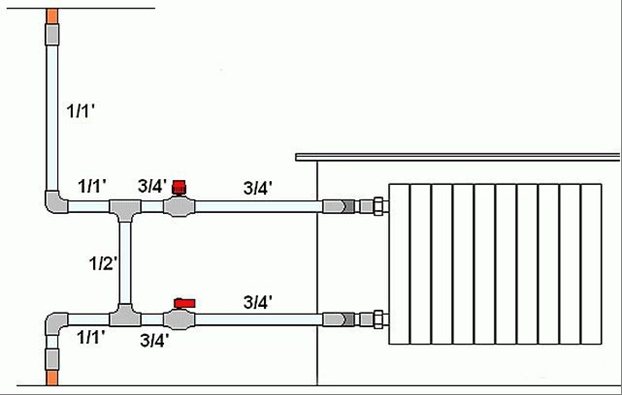

A bypass is a jumper in the form of a piece of pipe that is installed between the direct and return wiring. conventional heating radiator. The transverse diameter of the bypass must be one caliber smaller than the diameter of the supply pipes. As a rule, a half-inch pipe is used for the bypass device.

Such a bypass can be bought at any store, and inexpensively.

Some installation features

Using information from the Internet when designing a system and doing your own installation, remember that a large amount of material read and watched video increases your chances of successfully completing what you started. But the best way to organize heating with your own hands would be to attract, at a minimum, a professional practitioner for consulting support.

To ensure high-quality heating of the extreme radiators in the chain, the number of their sections should be increased.

For the gravity version of the system, pipes of significant diameter are necessarily used. And the total length of the circuit should not exceed 30 m.

The installation of the supply main pipe must be carried out at a slight slope. The radiators themselves are installed at the same height and do not distort the “geometry” of the room at all.

The vertical wiring of the "Leningrad" and the long "horizontal" will definitely require the introduction of a circulation pump into the system.

When installing a supply pipe in the thickness of the floor with your own hands, you should remember about the need to insulate it with heat-insulating roll materials. This will save you significant money during the operation of the system and will not lead to overheating of the "underground" space.

Photo of a needle type crane

ball valve

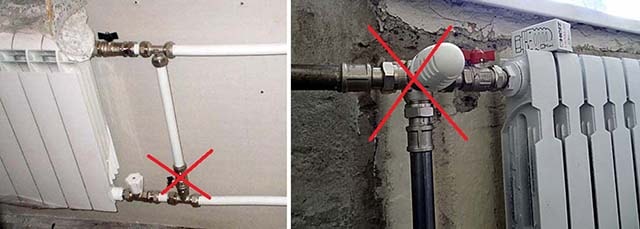

Only needle-type valves should be used as shut-off valves on bypasses and auxiliary circuits of the system. They are able to smoothly regulate the flow of fluid through themselves. The use of ball valves is not allowed here, as they are not designed for "semi-open" operation. They are either closed or completely open.Only in these two positions is their long-term performance preserved. There are enough videos on the net on this topic.

Finishing a long stream of thoughts, we want to note that the single-pipe “Leningradka”, which has long been proven for decades of use, with a modern “upgrade” with a circulation pump and control valves on bypasses, allows you to get the benefits of a more complex heating system with its real simplicity and low investment. Ensure its correct installation with your own hands and spend the cold seasons in the warmth and comfort of your private home.

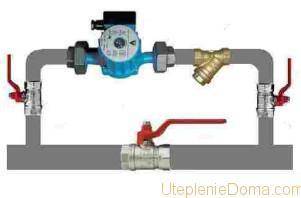

Installation on the pump

Bypass for circulation pump with ball valve

What is the bypass for? heating system for the area where the electric pump is installed? It would be more accurate to say that the pump is installed directly on it. This is practiced when an electric supercharger is placed in the gravitational circuit, the one in which the circulation is carried out by gravity. It increases the flow rate and thus the efficiency of the circuit becomes higher. This is due to the fact that at a higher speed the coolant reaches the extreme radiator with less heat loss.

Options bypass settings for circulation pump two:

- to a new circuit;

- to an existing circuit.

There is no difference in installation.

What you need to pay attention to is the presence of shut-off valves on the central line between the bypass pipes. This is necessary so that the coolant passes through the bypass for the circulation pump, and also so that a reverse flow is not created. To understand why, let's take a step-by-step look at how it works:

To understand why, let's take a step-by-step look at how it works:

- when the pump is running, it accelerates the coolant;

- water from the bypass enters the main and begins to move in both directions;

- in one direction (necessary), it leaves unhindered, and in the second side it encounters a check valve;

- the valve closes and thus prevents circulation in both directions.

That is, the water after the pump presses on the valve plate more than before it, since the speed of the coolant behind the pump will be higher. As planned, when the pump is turned off, the coolant stops pressing on the check valve and does not close it. This allows water to circulate by gravity along the main line without entering the bypass. In practice, a bypass for heating with a check valve does not work as it should.

Therefore, before installing a bypass in heating system with check valve you need to understand that in fact, installing a pump on a bypass will not make any sense. With such success, it could be put directly on the highway, while deliberately refusing to use the heating circuit autonomously. Do I need a bypass in the heating system in this case? It turns out that no.

If instead of a check valve you put an ordinary ball valve, then you yourself will be able to control the vector of water circulation along the circuit. Let's look at how to bypass the heating system on which the pump will be installed. In such a scheme, it consists of separate elements:

- threaded pipes that are welded into the line;

- ball valves - installed on both sides;

- corners;

- coarse filter - placed in front of the pump;

- two American women, thanks to which the pump can be removed for inspection or repair.

If you make a bypass in the heating system with your own hands, it is important to observe the correct location of the pump on it. The axis of the impeller must be horizontal, and the cover terminal box look up. If the terminal box cover faces downwards when installed correctly, its location can be changed by unscrewing the four screws on the housing

Such an arrangement is necessary so that there is free access to the terminals responsible for connecting the power supply, and also to prevent the coolant from getting on them in the event of a leak.

If, when installed correctly, the terminal box cover faces downwards, its position can be changed by unscrewing the four screws on the housing. Such an arrangement is necessary so that there is free access to the terminals responsible for connecting the power supply, and also to prevent the coolant from entering them in the event of a leak.

Battery Tests

The assembled radiator is subjected to a hydraulic test on a specialized stand. Using some special devices, the battery is connected to the press, it is filled with water and at the same time, gas or air comes out of the device. At the same time, the hydraulic press creates pressure from 4 to 8 kgf/cm2.

If there is no leak, then the pressure gauge of the press does not decrease and the battery is considered to have passed the test.

If leaks appear, then tighten the nipples and this eliminates them.

Next, the heater is painted, but it is pre-treated with soil.

Solving the problem with the distribution of the coolant

This problem can be solved in several ways:

The first option promises serious costs - large batteries are more expensive than small ones. The second option solves the problem far from completely - even very intensive circulation is unlikely to raise the temperature in the final section to the required norm.

- Careful calculation of the number of sections - accordingly, the lower the temperature of the coolant, the more sections are needed to transfer the required amount of heat to the room;

- Installation of a circulation pump - it will provide forced circulation, thereby ensuring a quick supply of coolant to distant radiators;

- Installing a bypass on the radiator - bypass units are mounted on all batteries, connecting their inputs and outputs.

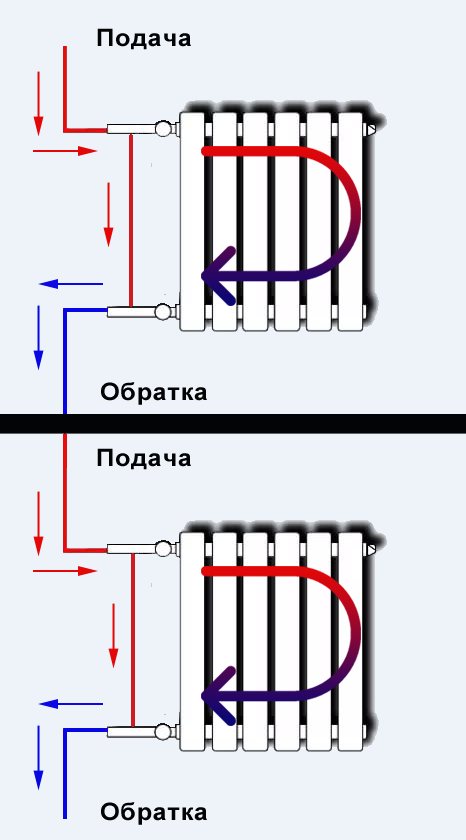

Bypass installation in the system heating would be the best option. Connecting the inputs and outputs of the radiators, the bypass line will provide hot coolant supply to distant devices. Consider the advantages of such a scheme:

- Optimal distribution of heat in the system - part of the coolant will flow further, practically without changing its temperature;

- The possibility of separate temperature control in each room - for this, the batteries are equipped with thermostatic valves;

- Ease of repair without stopping the entire heating system - the bypass system will ensure unhindered flow of coolant to the next batteries, while a broken radiator can be easily dismantled for repair or replacement.

Thus, the third option is optimal.

The temperature in the circuit drops when using the bypass, but not by much, which increases the length of one line. Often a combination of a bypass line and a circulation pump is used.

What is bypass

It is sometimes believed that the bypass is a complex part that only an experienced specialist can install. The reason lies in the complex name of the element. However, many have seen it in the heating system.

In plumbing, a bypass is a kind of jumper pipe. The node crashes into the bypass of the heater. With its help, it is possible to alternatively direct the flow of the coolant. Depending on the design, the jumper is of two types:

- unmanaged or open. The jumper is permanently open or has valve arrangements. In the latter case, if necessary, automatic redirection of the water flow is carried out.

- Managed. Taps or valves are installed on the jumper. It becomes possible to manually block or, conversely, open the path for the flow of heating fluid.

Bypass is installed in various parts of the system. Often they are used for tying heating radiators. In country houses where an autonomous system is mounted, the jumper is included in the circulation pump assembly. In a collector-type communication, the tube is part of the mixing unit. Sometimes the part is used for piping solid fuel boilers.

The jumper performs certain functions

The jumper performs certain functions

Now the purpose of the bypasses is clear. Single-pipe heating is simply unthinkable without this element.

Often the element is combined with radiators

Often the element is combined with radiators

What does the regulation of heating batteries give?

Possibility to adjust the temperature of heating radiators

provides you with several benefits for your needs:

- Create a comfortable room temperature for its residents. There is no need to constantly open windows, create drafts and spend money on heating the street.

- Savings on heating are significant and can range from 25 to 50%. However, before adjusting the temperature of the heating battery in the apartment, it is recommended to carry out a number of energy-saving measures. Put plastic windows, insulate interpanel seams, make thermal insulation of walls. It is necessary to carry out all these activities before the start of the heating season, so as not to carry out work in an emergency mode later.

- Airing of pipes is removed, the coolant moves freely inside and effectively transfers heat to the room.

- The ability to evenly distribute heat in all rooms.

- If necessary, you can maintain different temperature conditions in different rooms. Let's say you set the temperature in one to 25℃, and in the other it's enough to maintain 17℃.

Comfortable room temperature is the main advantage

Comfortable room temperature is the main advantage

It is obvious here that if it is possible to adjust

temperature of the radiators, then you must definitely use this. We hope

that our article will help you do it right.

How to solve the problem without a valve on the bypass

To prevent the bypass from taking away precious heat, you need to install a transition pipe with a diameter smaller than the inlet and outlet pipes. The fluid always follows the path of least resistance, the lower the pipe diameter, the greater the pressure and vice versa. The water entering the apartment is immediately divided into two streams, the first goes down, the second passes through the battery. Therefore, the rules for the use of thermal appliances are recommended to set the diameter of the jumper one unit less than that of a straight-through pipe. For example, if the pipe diameter is 1 inch, you need to install a three-quarter jumper.This will get rid of the effect of too hot first and rather cold last sections of the radiator. Since the liquid moves into the drainage system with some resistance, the pressure on the inlet to the batteries increases, and all sections receive an equal amount of heat. Narrowed bypasses are provided for by the norms, the local HOA or housing cooperative will not have any claims.

What is a battery jumper and what is it for?

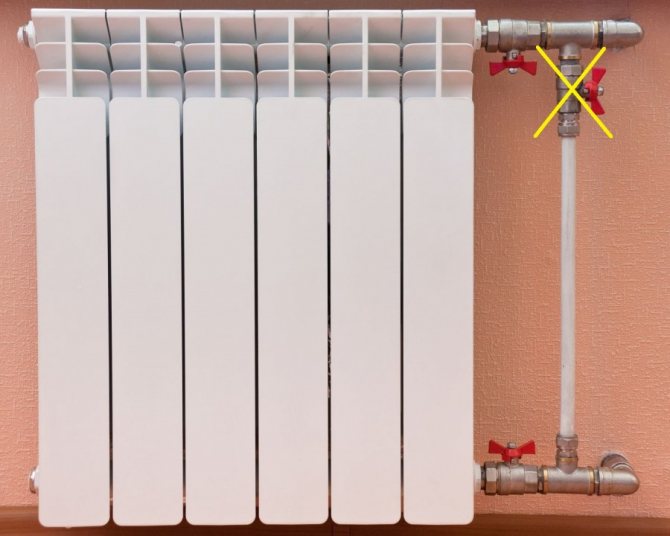

First of all, in order to determine why a bypass to a heating radiator is needed, it is worth saying that it is not installed on all heating systems. The fact is that in an apartment building equipped with a two-pipe heating system, such devices are not installed. The coolant in a two-pipe system enters the battery from the hot water supply pipe, and is discharged immediately into the return pipe, so if it is necessary to turn off the battery on one of the floors, nothing bad will happen to the system, the taps will simply be closed at one point, and the coolant will continue to circulate in system.

Another thing is when the building is equipped with a single-pipe heating system. Here the issue is more difficult to solve - the coolant flows through the pipes to the highest point, where the wiring is done through the risers. The riser pipe is supplied to the battery, the coolant, passing through the radiator registers at the outlet, enters another section of the pipe, which descends to the floor below. Then the scheme repeats, and so on to the basement. It would seem that everything is simple - fewer pipes, it is easier for the coolant to move through the system. But, as you know, there are no perfect systems, there are flaws in this, at first glance, simple scheme.First of all, this is the cooling rate of the coolant - it turns out with each battery, it becomes colder and colder. The second point is that in the event of a breakdown of one battery, you will have to block the entire riser, because by blocking water inlet and outlet tap from the radiator, the entire chain is interrupted and the riser stops working. A way out of this situation was found - a jumper on the radiator. Simple and rational.

Bypass device and its functions

In winter, blocking the common riser is not allowed, the only exception is emergency situations. The presence of a bypass allows you to carry out repairs without turning off the heating system of your neighbors. The device is arranged from pipes with a smaller diameter than the supply and discharge lines. Two ball valves allow you to properly close the battery and in case it is hot, directing the circulation of water through the bypass.

When replacing the radiator, the water is blocked, and after completion of work, it opens again. If the room is hot, the bypass again allows you to temporarily shut off the system: hot water stops flowing into the battery and the room cools down. But it is better to install thermostatic valves to regulate the temperature, maintaining the normal temperature in the room.

With such a device, the radiator can be properly disconnected from the system at any time when painting, flushing, battery replacement, and when changing gaskets and nipples are required without closing the risers.

The bypass functions, depending on the type of heating system, are as follows:

- Energy regulation. When the room temperature is above normal, the thermostat reduces the supply of hot water, which adversely affects the operation of the entire system.This device serves to return the coolant that has not entered the battery to the system.

- Emergency regulation of coolant circulation in a system with an electric pump. When there is a power failure, the bypass with a valve shuts off the hot water supply to the pump through the bypass pipe, at this time the valve opens and the coolant is directed through the central pipe. In this simple way, the system goes into a state of natural circulation without the participation of a pump.

- Resuscitation of a single-pipe system. It works quite effectively: the apartments are warm, even hot. The bypass also helps in this situation, allowing you to reduce the supply of hot water, thus acting as a thermostat.

The bypass must be installed near the radiator. It is recommended that the bypass pipe be made on site during installation using a welding machine. You can also use ready-made equipment on threaded connections. The expansion valve or radiator thermostat must be located between the radiator inlet and the bypass.

What is a bypass for?

A bypass is a bypass pipeline that serves to organize the flow of coolant around the main path. Usually, some equipment is mounted on the bypass section. In this case, one end of the bypass is connected to the inlet end of the pipe, and the other to the outlet. In the interval between the bypass pipe (bypass) and the inlet to the device, a shut-off valve is installed.

In order for the device to be completely turned off, a tap is mounted at the outlet end of the pipe.(it is located between the outlet of the equipment and the bypass)

The basis of the work is that any device installed by means of a bypass can be disconnected from the entire system simply by closing the inlet and outlet valves. Disabled equipment can be repaired or replaced. And at the same time, the continuity of the coolant current will be preserved. There are several applications for a bypass pipe.

Thermal head

The next kind of crane for the radiator is a thermal head for the radiator heating.

If there is a need to ensure the regulation of temperature indicators in an automatic way, then the use of thermal heads together with a thermostatic valve will come in handy. This variety allows you to adjust the optimum temperature without any human intervention.

Features of the thermal head?

The thermal head functions in inverse proportion to the air temperature in the room. If the temperature indicators rise (much higher than the comfortable and optimal temperature - this phenomenon can be observed with a large number of people in the room, the operation of many electrical appliances), then the thermal head bellows expand. The expansion of the bellows of the thermal head leads to the fact that a certain part of the valve (stem) begins to move and there is a decrease in the flow of the heat generator through the radiator. If the air temperature, on the contrary, decreases, then this mechanism works in the opposite direction, in order to increase the temperature for a comfortable and optimal room.

Typical dimensions of thermal head taps

Basically, the typical and most common head size is M30 * 1.5.But the dimensions are individual for each model. To date, manufacturers in most cases mark the cranes, indicating their exact dimensions and production characteristics. The marking indicates special designations with which the indicators are deciphered.

Installation of thermal heads

- With the help of certain rods, the plate is fastened to the wall.

- The thermal head is fixed on the plate itself.

- Next, fixation is made on the wall of the capillary tube.

- The thermal head is installed according to certain marks.

- Produce twisting, fixing the bolt.

Features and differences between angled and straight cranes, their advantages

What are the positive characteristics of angle valves?

- There is a guaranteed possibility to disconnect the battery.

- Resuming the operation of the heating system at any convenient time interval if necessary.

- Guaranteed ability to independently adjust the temperature, which will be comfortable and optimal for being indoors (if there are temperature fluctuations in the street, and so on).

- The corner tap is very convenient to use, especially when draining the heat generator. This greatly reduces the time for this procedure.

- Simple service.

When choosing between angled and straight faucets, it is generally recommended to use angled faucets because of the above positive features.

Alternative ways

One of the alternative ways to protect against excessive heat in a residential area will be the purchase and installation of a special valve. Such a simple device allows you to adjust the level of thermal energy supplied to the battery and save its value in ruble terms.The principle of saving becomes important for apartment owners, as the distribution of heat will become possible depending on atmospheric conditions.

The current state of the market for plumbing fixtures and fixtures allows you to purchase a special protective screen that operates on the principle of blinds. One turn of the shutters of such a screen helps to reduce the amount of thermal energy distributed throughout the apartment, as well as to minimize the risk of burns from an excessively hot battery. Another advantage of placing a louvered screen is the simplicity of its device, which allows not to carry out complex installation work. Installing this kind of device will not take more than 10 minutes of your time.

The most radical way to limit the supply of heat to your apartment will be to contact the office of the management company. Such treatment will reduce the thermal effect from the apartment battery by covering the corresponding common house valve. This method is not a panacea if you only need to limit the heat supply to the apartment. Using this option will also affect your housemates, who may not be hot.

Bypass device

A bypass is a bypass part of the pipeline, which ensures the movement of the coolant along a trajectory that bypasses a certain section of the pipeline. One edge of the bypass is connected to the supply pipe, and the second - to the opposite. Various elements of the heating system, such as pumps, are usually installed on the bypass.

At the connection point of the bypass and device inlet, which must be bypassed, stop valves are mounted.Its presence makes it possible to direct the fluid current parallel to the device itself and to regulate the intensity of the coolant supply. A valve is also installed on the return pipe, which allows you to exclude a section of the pipeline from the system without the need to stop it.

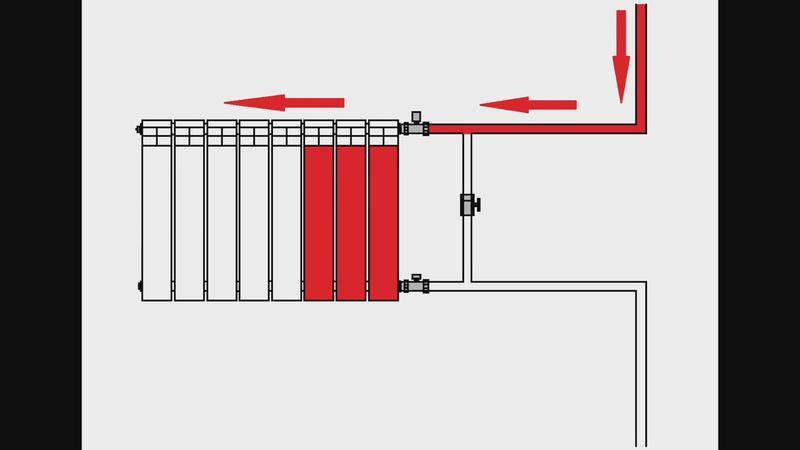

Application in batteries with one-pipe system

In such a system, all heaters are mounted in series: the output of one battery is connected to the input of another. The single-pipe system has a number of disadvantages:

- The last battery in the VT chain is already chilled.

- If one battery fails, the HP circulation stops.

To eliminate these shortcomings, a single-pipe system is equipped with shunt jumpers connecting the supply and return:

- A part of the heated HP, which has passed through the jumpers, approaches the last batteries.

- When the battery fails or is turned off by shut-off valves, the HP circulates around the jumper.

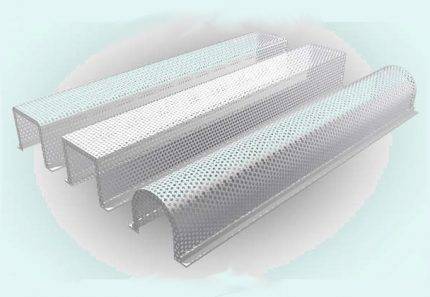

Factory Ready Devices

Such devices are purchased in specialized stores, where a large assortment of products of different colors, sizes and designs is presented. In shape, such structures can be angular, rounded or rectangular.

The first option is especially convenient in the corners of the room to mask risers, and also if the heating system is located close to the ceiling or floor. Other modifications are perfect for pipes that are laid along the perimeter of the walls and a free-standing riser.

There are a variety of options for such products. The most common are plastic boxes that are easily installed around pipes on a metal profile frame.

When choosing such options, it is advisable to pay special attention to the quality of the material, since low-grade polymers under the influence of heat can turn yellow, swell and lose their appearance.

Boxes made of ordinary or perforated metal look very impressive. If a practical goal is pursued, it is better to give preference to the second option, since thanks to the holes, metal elements provide better heat dissipation.

Another option is budget MDF structures, which have an attractive appearance and good performance. The disadvantages include a small model range, which is dominated by "deaf" devices without holes, which reduces heat transfer.

Conclusions and useful video on the topic

A video about the difference between natural and forced circulation of the coolant in the heating system:

A video that clearly demonstrates the differences between different schemes of the heating system:

Scheme of effective connection of heating batteries with a two-pipe system:

The heating efficiency directly depends on the choice of the battery connection scheme for your home. With the right option, heat loss is minimized. This allows you to get the maximum effect with the least use of fuel. Battery installation can be done by hand

It is important to take into account the features of the building so that cold batteries do not interfere with a comfortable life in a cozy house.

If you are interested in the material we have proposed for consideration, if you have any questions and a reason for discussion, we invite you to post comments.