- How to choose a compressor for a septic tank

- Purpose of the compressor

- Device types

- Design features

- Compressor installation

- Device Selection Tips

- Compressor installation

- Homemade devices for aeration

- Material for the manufacture of a septic tank

- Sump chamber upgrade

- Purpose of units

- Why is it needed

- Astra 5

- Types of compressors

- Air compressor for aeration of a septic tank: principle of operation, characteristics and selection criteria

- How to choose an aerator for a septic tank: tips and tricks

- Which compressor to choose for aeration of a septic tank

- Device Installation Procedure

- Conclusion

How to choose a compressor for a septic tank

Septic tanks installed in private estates and cottages play an important role in the comfortable living of a person. On sale there is a huge number of models of septic tanks, both domestic and imported. Each homeowner can choose a suitable model for himself and install it on his suburban area. But do not think that just by installing a septic tank, the system will work perfectly. The fact is that for the complete decomposition of waste, it is necessary to equip the septic tank with additional equipment. One such addition is the compressor.To understand this device, let's consider its need, principle of operation, installation, and how to choose a compressor for a septic tank installed on your site.

Purpose of the compressor

To fully understand the purpose of a compressor, let's briefly review the operation of a septic tank. The operation of the device is to collect and process sewage. The equipment includes:

- capacity,

- pipe system,

- set of pumps and compressor.

Pumps handle the liquid waste in the system, and they are indispensable, and some people save money on the compressor. And this is wrong. Thanks to the compressor, air is supplied to the septic tank. When interacting with air, the activity of bacteria increases, which are involved in the decomposition of sewage.

Device types

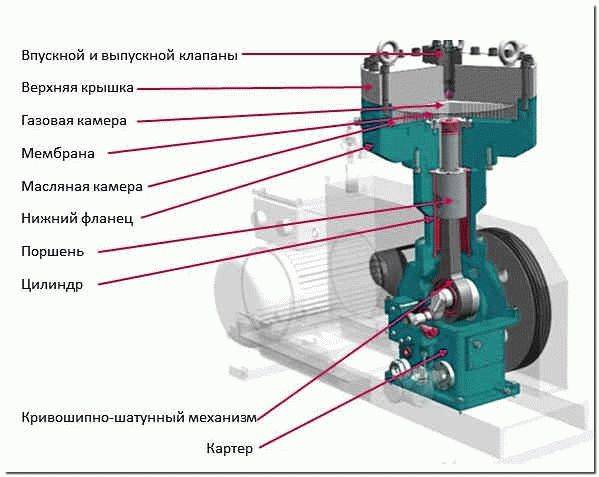

Compressors for septic tanks are of two types: screw and membrane.

- Screw compressors have two rotors. Rotating, they capture air and force it into the container. Due to their compactness, such models are installed in septic tanks with a small capacity. They are very economical and almost silent in operation.

- Diaphragm compressors are widely popular for septic tanks installed in cottages. Their feature is simple operation and ease of maintenance. The operation of this model consists in the coordinated operation of the membrane and valves, due to which pressure is created in the chamber. Directly from the chamber, oxygen enters the septic tank.

Note! Installation of reciprocating compressors in septic tanks is not practiced due to their high noise level.

Design features

All types of compressors for septic tanks are powered by electricity and are designed to force air into containers with sewage.Based on the fact that the capacities of septic tanks are different in volume, therefore, the compressor must be suitable in terms of power to supply the required amount of air. For large-capacity septic tanks, several compressors are installed. This allows for more complete wastewater treatment. Basically, the compressor is not mounted in the septic tank on its own, but together with pumping equipment that ensures its proper operation.

Compressor installation

If you study the manufacturer's instructions, then installing the compressor will not cause unnecessary questions. Installation is easy, and almost anyone can do it on their own:

- A compressor ready for operation is installed above the septic tank.

- An outlet pipe is connected to the aerator.

- The compressor is connected to the power supply, and the device is ready for operation.

Connectivity issue resolved!

Device Selection Tips

To complete the processing of sewage, they must settle and ferment in an airtight container, and air is not required for this process. But for aerobic decomposition, air supply is indispensable. For this purpose, you can install a biological treatment plant, which is quite an expensive pleasure.

Not every device model can fit your septic tank model

When purchasing a compressor, you need to pay attention to some parameters:

- Don't buy a cheap device. This will quickly affect the quality of work, and maybe even fail. It is better to buy a compressor from a company that has proven itself in the market for its quality and reliability.

- All parts of the compressor must be resistant to corrosion.

- Branded compressors, as a rule, have a long service life.

- Quiet operation of the device.No one will like the constant noise of a running compressor in their summer cottage.

- Compressor size should match your system model. Compressor power mismatch can lead to mismatch in the amount of oxygen supplied to the septic tank. Such an imbalance will affect the vital activity of microorganisms living in the septic tank, which entails a deterioration in the quality of sewage processing.

Popular device models

How to choose a compressor for a septic tank Find out how to choose a compressor for a septic tank. The article discusses the various types of compressors that need to be selected in accordance with the capacity of the septic tank.

Compressor installation

You can install and connect the compressor with your own hands. The installation of the compressor unit is carried out in the following way:

- choose a place to install the device. The compressor is recommended to be installed inside (in the upper part) of the septic tank, and not on the outside of the treatment plant. This will avoid the negative impact of weather conditions on the installation. If there is no separate chamber for biological treatment in the septic tank, then it is advisable to first install a partition or install an additional container next to the existing septic tank;

- the compressor is installed on a special shelf, which can be made with your own hands from improvised materials or purchased in specialized stores;

The correct location of the compressor in the septic tank

- any type of compressor will require the installation of additional equipment - an aerator, through which air will flow into a container with drains. You can make your own aerator.This will require a small piece of metal pipe, in which holes are drilled at equal distances from each other, with a diameter of 1 - 2 mm. The average number of holes is 300 pieces. The end of the pipe is closed with a plug;

Do-it-yourself additional equipment for a compressor

If the holes are unevenly distributed over the surface of the pipe, then the effluents will be saturated with oxygen unevenly, which will lead to a decrease in the efficiency of bacteria in certain places of the tank.

- the aerator is connected to the compressor outlet with a hose. The connection must be as tight as possible so that there is no loss of oxygen;

Compressor connection with a factory-made aerator

- the aerator descends into the tank;

- the compressor is installed on a shelf and connected to electricity. If the outlet is located next to the septic tank, then it should be protected as much as possible from the action of precipitation;

- the container with the compressor is closed with a lid to protect bacteria and installed equipment.

The compressor can be connected via an automatic relay that will turn the device off and on if necessary, as well as protect it from overheating.

The compressor is replaced in the same way.

The compressor requires periodic maintenance, which consists in replacing the filters installed on the outlet pipes (at least once a year). If the compressor began to work incorrectly or consume excessive amounts of electricity, then it is recommended to contact specialists to fix the problem.

Homemade devices for aeration

For septic tanks with a small volume of tanks, a low-performance supercharger (up to 20 l / min) is suitable. Craftsmen learned how to use refrigerator and car compressors to aerate such structures. Cheap, affordable, simple.

Perforated the hose is easy to make from plastic pipe. One end of a homemade aerator is put on the outlet pipe of the supercharger, the other is sealed or sealed with a plug. Enough holes are made in the body of the pipe for correct operation with the applied model of the unit.

The disadvantage of such devices is a small working resource. They are not designed for continuous operation. With the air flow, the lubricant quickly leaves the fixture, the installation of oil separators has little effect on the situation. Using a homemade device, you need to be prepared for its failure, be able to eliminate common breakdowns, and perform the necessary maintenance. And it is desirable for cases of critical breakdowns to have in mind a serial model with the necessary parameters.

Nevertheless, it is recommended to complete septic tanks with professional equipment from reliable manufacturers.

Material for the manufacture of a septic tank

It is not difficult to find many factory treatment plants on the market. But you will have to spend a lot of money on purchases, so they often try to equip a septic tank on their own. They use mostly inexpensive and affordable materials for work.

Picture 4. Brick septic tank

Picture 4. Brick septic tank

The pros and cons of the most popular building materials can be seen in the table.

| Material | Positive properties | Flaws |

| RC products | Inexpensive material, long service life, good resistance to ground pressure, large volume | Requires the involvement of lifting equipment, possible loss of tightness |

| Monolithic concrete tank | Inexpensive material, long service life, no seams, which reduces the risk of loss of tightness | Work that requires a lot of time and labor |

| brick construction | Inexpensive material, availability due to the possibility of using second-hand material, | Possible loss of tightness, time-consuming and labor-intensive work |

| plastic containers | Light weight, the possibility of using used eurocubes, long service life, complete tightness | Possibility of floating due to low weight, low resistance to soil mass, high price |

Picture 5. Septic tank from reinforced concrete products

Picture 5. Septic tank from reinforced concrete products

Sump chamber upgrade

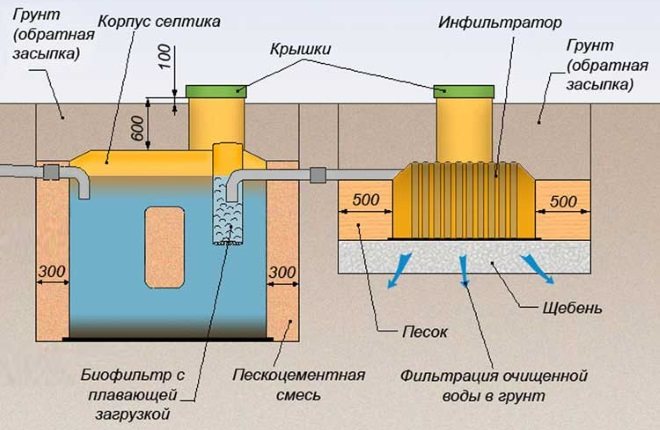

If the sump chamber is to be upgraded with a compressor, the septic tank is supplemented with an aeration tank

If the sump chamber is to be upgraded with a compressor, the septic tank is supplemented with an aeration tank. This will require:

- determine the location for the new section;

- dig a hole where to install a container or concrete ring;

- put a home-made or purchased compressor made for a septic tank;

- be sure to lead a perforated pipe sealed from below into the aeration tank.

Important! Such a pipe can be made from any suitable length. Drill holes, placing them evenly and monitor the appearance of air bubbles on the surface at startup - this means that the compressor installed for septic tanks is working normally

By supplementing the whole plant with a mixing structure, it is possible to improve the distribution of masses so that the air flow flows evenly, this will improve the process of decomposition and processing of accumulations.As a means for post-treatment, the arrangement of an additional chamber will help a lot, where the effluents will be settled and clarified.

Purpose of units

Disinfection and disinfection of the contents of cesspools is carried out with active substances. Their danger to the environment and humans has been proven. Therefore, sane owners are moving to a safe biological way to deal with pollution using colonies of live bacteria. Feeding on organic matter from household and household waste, bacteria break it down into water, carbon dioxide and safe sludge.

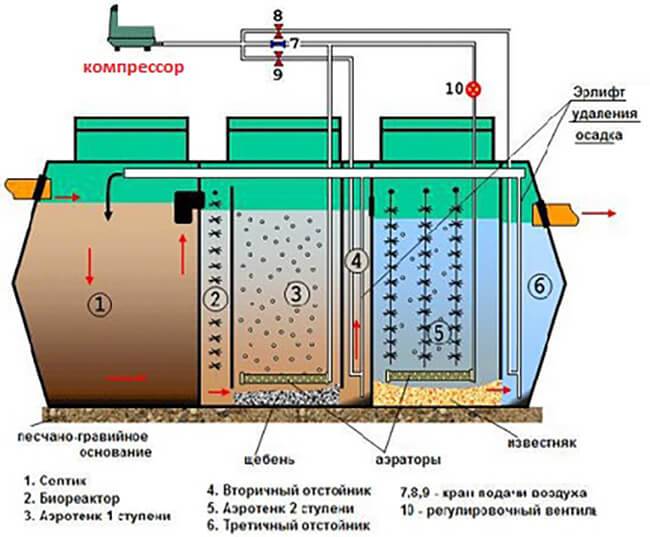

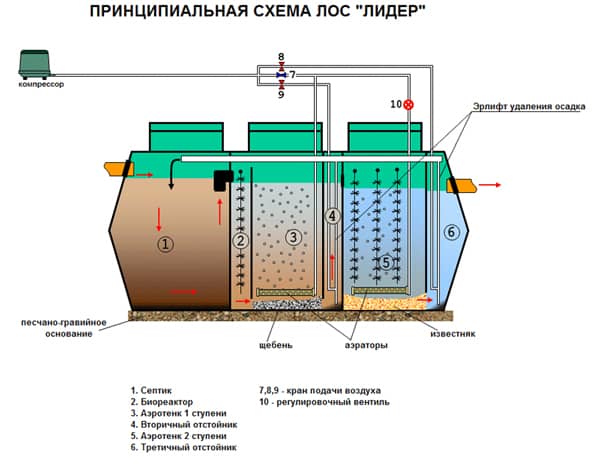

Biological preparations for septic tanks contain one of two types of microbes - anaerobic, aerobic, or a combination of both (used in the simplest single-chamber structures). Heavy solid waste settles in the first chamber. They are occupied by anaerobic microorganisms capable of surviving without oxygen and decomposing (oxidizing) effluents to low molecular weight compounds. Cleaner wastewater with fine particles enters the second and third septic tanks. For their processing, aerobic bacteria are taken, the vital activity of which is impossible without the access of molecular oxygen. The activity of microorganisms increases with an increase in the volume of supply air.

Compressors for autonomous septic tanks, connected to aerators, are necessary for the uninterrupted pumping of oxygen through the volume of waste fluid with aerobic microflora. This is an electrical device for moving gaseous mixtures - it pumps air into the aerator. The latter is a perforated pipe or hose that is laid at the bottom of the tank. Through the openings of the pipe, the supplied air escapes from the aerator and moves upwards.On the way through the thickness of the liquid, part of the oxygen dissolves in it and provides the vital activity of microorganisms.

This is interesting: How to choose a universal cutter - we state all the nuances

Why is it needed

Most modern wells use biological cleaning system. For this, filters with aerobic and anaerobic bacteria are installed in them. The key difference between these microorganisms is the need for oxygen.

- Anaerobic do fine without it, but they are rarely used to equip septic tanks. Due to the high price and low performance, these filters are not suitable for processing large volumes of wastewater;

- Aerobic are more convenient to use, they are quickly able to clear even large volumes. However, they also need oxygen.

The compressor is needed specifically for aeration of the septic tank. Biological sewage wells are initially equipped with two types: sealed and open. Sealed are characterized by a completely closed container into which sewer outlets are connected. From them, water enters the sump and is pumped out already in a purified form. Open drives are not much different from classic cesspools. They do not have a bottom, and most of the waste simply seeps into the ground, sinking to a depth. This is not only unsafe, but also impractical: such settling cannot provide complete cleaning.

Photo - the principle of operation of a septic tank with a compressor

For a closed septic tank, it is necessary to install a special blower. It will provide air circulation, saturation of water with oxygen and aeration of the bacterial environment.A compressor for a biological septic tank must have a number of qualities, since it works in an aggressive and dangerous environment:

- Reliability and strength of materials. Therefore, most blower devices are made of dense plastic, which is not corroded by drains and is not subject to destruction under the influence of moisture;

- Durability of work. This is also a very important point, because from the moment the compressor breaks down, the septic tank will not be able to function normally;

- Noiselessness. Most biological storage devices (Topas, Astra and Tank) are used for installation in a small courtyard of a private house. So that the operation of the sewer system does not affect the life of the owners of the site, the aerator must pump air silently.

Photo - installation diagram

Astra 5

Add to cart Compare Add to favorites Go to catalog Aerobic microorganisms can decompose organic waste much better than anaerobic ones. As a result, the water that has been purified using this method is much cleaner, suitable for household needs, and does not harm the environment. The cleaning process depends on the amount of incoming air.

Air is supplied to the branch pipe, then to one of the compartments. The unit is constantly in a humid environment. As such, it must meet the following requirements:

- resistance of materials to moisture, chemicals, corrosion

- silent operation, as the device is close to home

- minimum vibration.

With the combined action of both types of bacteria, complete processing of wastewater is ensured, which makes it possible to obtain water suitable for irrigating garden crops and use sludge as a fertilizer after purification.

Types of compressors

The unit consists of a body, an engine, elements for aeration. Its action is to suck in air from the external space, throwing it into a tank with drains. The device must be in the liquid to be cleaned.

Compressors differ in a number of characteristics. The choice of them must be approached, having previously familiarized themselves with them.

Apparatuses operating on the principle of increasing the volume of air with a decrease in the volume of productivity are volumetric. There are piston and screw types. In piston types, pressure is pumped by pistons. Screws are equipped with screw blocks, they are compact, silent operation, minimal vibration, durability.

Air compressor for aeration of a septic tank: principle of operation, characteristics and selection criteria

Any self-built septic tank can be made to process wastewater as efficiently as possible. Two types of bacteria take part in the process of decomposition of fractions and clarification of liquids: anaerobic and aerobic.

The vital activity of the first is completely independent and does not need human participation. For the operation of aerobic microorganisms, air is needed, the delivery of which is carried out by a compressor (aerator) for a septic tank.

How to choose an aerator for a septic tank: tips and tricks

The joint activity of anaerobic and aerobic bacteria provides multi-stage wastewater treatment, after which the liquid becomes safe and can be used for technical needs (for example, irrigation). Therefore, the correct choice of a compressor that maintains the optimal amount of air in the septic tank is so important.

A compressor is a device designed to compress and supply gases under pressure.Air is pumped into a chamber specially designed for this purpose and held in it, after which it is supplied to external devices (in our case, to a sealed chamber for wastewater treatment).

There are aerator installations consisting of a compressor, a drive and auxiliary devices (air dryer, intercooler). To modernize septic tanks, these more complex devices are not needed: for this purpose, the simplest unit is enough

But among them there are devices that are different in principle of operation and performance, therefore it is important to know exactly how to choose a compressor for sewage

Types of compressors

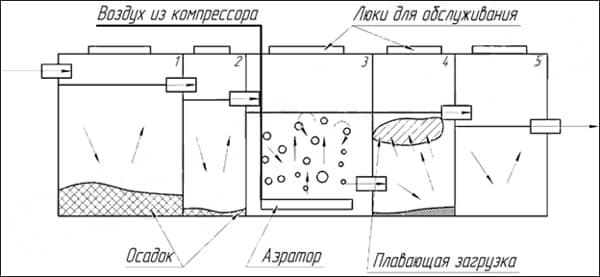

Units that increase the pressure of a gas by reducing its volume are called volumetric. Among them are piston and screw (rotary) installations. They differ in the principle of gas injection into the working chamber. Piston types provide pressure through the movement of pistons, screw - using a screw block. The latter are more compact, have a low level of vibration and are more durable.

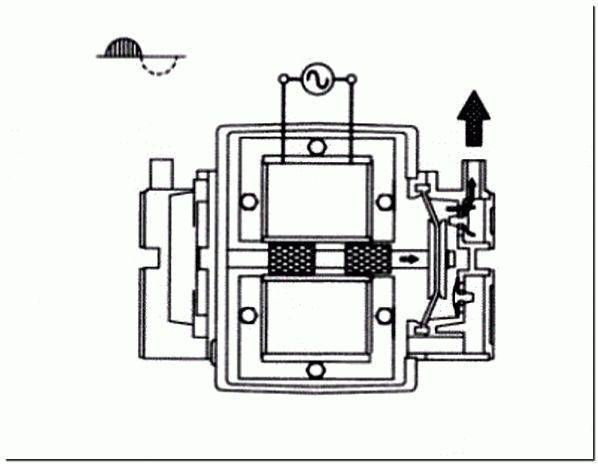

A variety of piston is an electromagnetic membrane (diaphragm) compressor for local sewage. The main advantage of this device is the ability to pump excess pressure at low performance characteristics.

The principle of operation of the compressor is as follows: the magnetic core moves back and forth in an alternating electromagnetic field and actuates the diaphragms that pump air.

The second type of compressors is dynamic.These units provide air injection by initially increasing its speed and converting it into increased outlet pressure. Among the dynamic devices are mainly centrifugal, which are radial and axial. All these units are more bulky, noisy, and expensive. Therefore, they are not considered as an aerator for a septic tank.

Which compressor to choose for aeration of a septic tank

To ensure autonomous treatment and post-treatment of wastewater, the best choice is a membrane-type apparatus. The distribution network presents a number of models, including mini compressors, which are widely used for autonomous sewers.

For aeration of local septic tanks, you can use screw compressors designed to operate around the clock. Many manufacturers of sewage treatment plants equip them with these units. When choosing on your own, it is not recommended to buy dry compression screw apparatuses, as they are large in size and require professional maintenance.

About performance

Companies producing compressor equipment indicate two characteristics of their performance: input and output power. Depending on the type of unit, these figures may be almost the same value or differ significantly.

The optimal compressor performance for aerating a septic tank is as follows:

- for chambers with a volume of 2-3 m3 - 60 l / min;

- for septic tanks with a volume of 4 m3 - 80 l / min;

- for a volume of 6 m3 - 120 l / min.

Device Installation Procedure

It is not difficult to supplement the design of a septic tank with a compressor, but you still have to work hard.If the septic tank is two-chamber, then it is better to add a third compartment to it, designed for aeration of wastewater and called an aeration tank. It is here that the effluent will be saturated with air and cleaned with the help of aerobic microorganisms.

To do this, you will have to go through all the stages of creating a septic tank: dig a pit, install a sealed plastic container, concrete or other suitable material, connect it to the sewer pipe leading from the house, connect it with an overflow to other sections of the septic tank, install a cover, etc.

In the VOC of industrial production, a separate protected space is provided for the installation of a septic tank so that the device does not come into contact with the contents of the sewer

It is better to mount the compressor at the top of the tank, and not outside, so that the device is reliably protected from the weather. To do this, inside, at the lid itself, a special shelf is made, on which the compressor is subsequently placed.

It will even be safer to make a more insulated compartment to protect the device from accidental wetness and other damage.

To use the compressor in a homemade septic tank, it is necessary to make an additional compartment - an aeration tank, into which O will be supplied.2. In this case, concrete rings or other suitable materials can be used, but the walls from the inside should be waterproofed with lime or clay

There must be a hole in the cover for the compressor electrical cable. You will also need another hole through which air will enter the compressor.

Inside the aeration tank you need to install a plastic pipe. Its lower end should be hermetically sealed, and the walls should be perforated.Usually it is enough to make about three hundred holes or a little less.

It is better to do this with a drill with a two-millimeter drill. Through these openings, compressed air will enter the wastewater column, saturating them with oxygen and crushing large solid waste. The holes should be roughly evenly spaced so that the air is evenly distributed. The upper part of the pipe is connected to the compressor with a hose.

The aerator for the compressor is made of an ordinary plastic pipe with a hermetically sealed end and uniform perforation on the surface.

When all the elements are prepared, the following steps should be performed:

- Lower the aerator into the aeration tank.

- Install the compressor in the place provided for it.

- Connect the aerator with a hose to the compressor outlet.

- Connect the device to the power supply.

- Turn on the compressor.

- Close the lid of the septic tank.

Now it remains only to regularly inspect the device and periodically, about twice a year, clean the air filter. It is not difficult to perform this operation. The location of the filter is indicated on the device diagram in the manufacturer's instructions.

It is necessary to unscrew the protective cover, usually it is held by mounting bolts

Then carefully remove the filter, rinse it and dry it. After that, the cartridge is put in its original place and closed with a lid.

During conservation septic tank for the winter the compressor should be disconnected from the aerator and power supply and stored in a heated room

If, upon inspection of the septic tank, it is found that the operating compressor is noisier than usual or some extraneous noise is detected, this is a cause for concern. If you leave everything as it is, the compressor will soon break down.

Sometimes the standard cleaning of the air filter helps. But if the noise does not decrease, you should invite a specialist to diagnose the problem or apply for warranty service.

If the septic tank is located in a country house or in a country house where the sewage system is not used all year round, it is necessary to preserve the septic tank, with the obligatory shutdown and removal of the compressor.

Conclusion

Septic tanks today are a necessary component of almost any suburban area. Treatment equipment is supplied by many companies, so consumers do not have any difficulties with choosing a septic tank. But such a system will work only when equipped with additional equipment that accelerates the decomposition of wastewater. This includes compressors. When choosing such a unit, you should be guided by its noiselessness, reliability, resistance to rust and durability, because the equipment operates in a fairly aggressive environment.