- Material classification

- Plastic structures

- Steel and aluminum units

- Forced ventilation

- 1 The principle of operation of the ventilation hood

- Kinds

- Household and industrial hoods

- Mounting methods

- Design and installation features

- Why you need a deflector

- 2 Device classification

- 2.1 Do-it-yourself installation and calculation features

- Basic installation rules

- Varieties according to the principle of work

- Selection and installation

Material classification

Air ducts for equipment of the exhaust system are made of various materials. To determine which one is better to choose for a particular case, you need to study the characteristics of all the units on the market.

Plastic structures

Today, the most popular are plastic air ducts for kitchen hood. They are round and rectangular. The latter look quite aesthetically pleasing and neat. In turn, the installation of round products is easier and faster (in such situations, it is not necessary to use adapters to connect the air duct to the hood). The main advantages of plastic products:

- rust resistance;

- ease of assembly;

- low cost;

- smooth inner surface minimizes the risk of accumulation of grease and other contaminants;

- light weight, which makes installation much easier;

- no noise during operation of the hood.

Steel and aluminum units

In second place in the popularity rating are aluminum products. This material is also used to produce structures for ventilation system equipment. Main advantages:

- aluminum is a simple and versatile material;

- products are cheap;

- quick and easy installation;

- structures are resistant to high temperatures.

However, aluminum air ducts, like any other products, have a number of disadvantages. Some of them:

- The material has a high thermal conductivity. In a room where an aluminum duct is installed, condensation is often observed.

- Unrepresentable appearance. Often, such units are hidden in kitchen cabinets or masked with the help of special boxes.

- Aluminum is not very durable, due to mechanical stress it can be deformed.

Often you can find steel air ducts. In most cases, galvanized or stainless steel is used for the manufacture of such structures. If we talk about home use, galvanized products have shown themselves well here.

However, it is important to note that such units are no longer as popular as before. Every year, steel air ducts are becoming less in demand.

The main advantages of such models:

- Relative cheapness.

- Smooth base that does not interfere with the passage of air flows. In addition, dust deposits and soot do not accumulate in smooth products.

- Steel products are not subject to deformation under high-temperature influence.In addition, no harmful substances are released into the environment.

Some cons:

- for mounting on walls, the most stable and reliable fixing elements are required;

- to assemble a non-standard duct, you will need to additionally cut metal pipes;

- a lot of weight (especially compared to plastic structures), so you won’t be able to carry out the installation yourself;

- sealing the channels will require the use of special tools;

- during operation, there is a lot of noise.

Forced ventilation

The principle of forced ventilation in a private house is used in those rooms where natural ventilation is not able to fully provide fresh air. Such premises are in constant contact with a large amount of moisture, where fungus and mold can form - these are the kitchen, bathroom, basement and boiler room. Such ventilation is installed to remove unpleasant odors and excess moisture from the premises with the help of fans and forced exhaust hoods.

You can regulate the flow of fresh air using a special device called an inlet valve. In addition to the main function, it has the following advantages:

- Minimizes noise from the outside world;

- Provides air filtration;

- Provides thermal insulation of the body, which reduces the likelihood of freezing and condensation;

- The ability to control the process of the device with your own hands.

Each ventilation duct for the home will require additional installation of this device. In extreme cases, you can get by with one valve, provided that there is centralized ventilation.

The function of the valve depends on the temperature difference between the room and the outside world. During the period of forced exhaust operation, the adjustment is carried out in manual mode.

To install a forced ventilation system with your own hands, you will need:

- Calculate the required air exchange. The air exchange rate is taken at the rate of 10 m³ per hour per person;

- Determine the installation location of the equipment (dry utility room);

- Mark the location of the air inlet and outlet openings.

For air ducts, flexible, usually plastic pipes are used, but aluminum pipes are also suitable. With the help of fasteners, the channels are bred through the rooms of the whole house above the suspended ceilings. And the place where the duct pipes exit is closed with ventilation grilles.

Openings for air inflow and exhaust are arranged in opposite corners of the room. A pipe is inserted inside the hole and covered with bars from the outside. A non-return valve is installed from the inside. In the selected place, the air handling unit is fixed, ventilation ducts are attached to it using metal clamps.

If a supply and exhaust ventilation scheme is used in a private house, its operation can be improved by installing a heat exchanger. Recuperator systems immediately, through one hole in the wall, remove the exhaust air and supply fresh air. This is an ideal solution if ventilation is taken care of after renovation or if it is necessary to solve the problem only in some rooms. The main thing is that these rooms have at least one wall facing the street.

The most suitable ventilation system for a private house is supply and exhaust ventilation.

Where air supply and exhaust is carried out by force.A house with an efficient ventilation system will ensure long-term operation of the housing structure and maintain a healthy microclimate for the whole family

Therefore, it is important to make the correct calculation of the project and select reliable materials.

For more than 10 years, UralSibMet has been supplying high-quality building materials and metal-roll at competitive prices and with the possibility of delivery in the Irkutsk Region, Buryatia and the Trans-Baikal Territory. Rolled metal products and building materials from UralSibMet will become a guarantee of the reliability of your home.

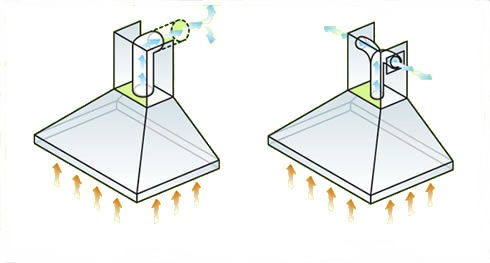

1 The principle of operation of the ventilation hood

This device works as follows. The air that is processed to become hot has a much lower density and therefore rises to the top to be replaced by cold air currents.

Then the air enters the pipe and passes through special grease filters, where it is saturated with a large amount of oil vapor, due to which it begins to cool over time.

In the end, passing through such a pipe due to strong temperature changes, the oil condenses, air flows begin to separate from it and allow the fat to drain into the bath through special channels.

In turn, the air, which after such a process is purified, enters the round or.

Kinds

All existing kitchen umbrellas differ in several ways:

| Appointment | Can be domestic and industrial |

| Mounting method | There are wall and island. |

| form | They can be rectangular, square or round. |

| device | As mentioned above, different models may have some design differences. |

Next, we will take a closer look at the features of each type of these devices.

Household ventilation round umbrella

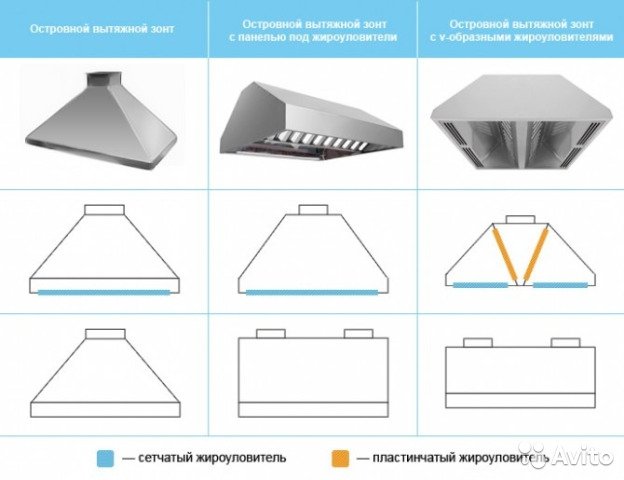

Household and industrial hoods

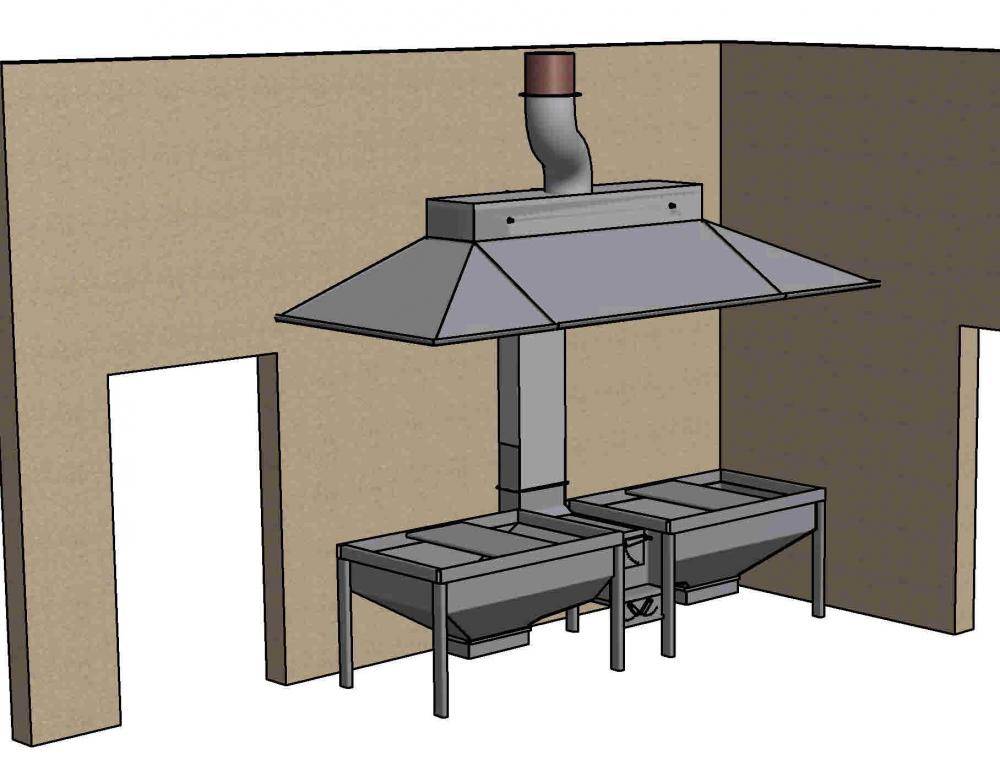

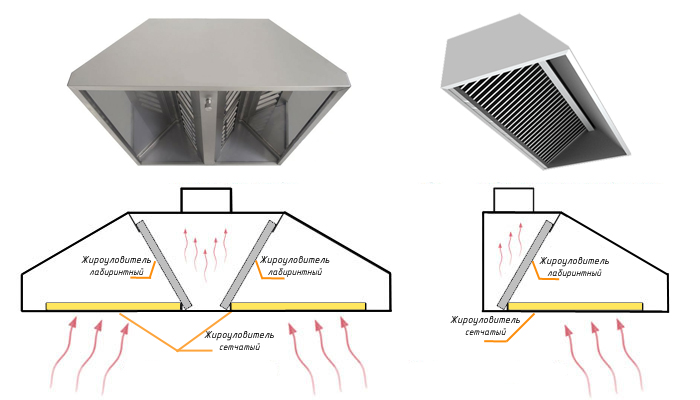

An industrial exhaust hood for ventilation is in many ways similar to household hoods.

The difference is only in a few points, such as:

- Size - industrial devices have much larger dimensions, as they cover the area of \u200b\u200bindustrial furnaces.

- Fan power is much higher.

- Filters - industrial hoods have special grease traps, from which the settled impurities drain into a special glass. Such a drive must be periodically emptied and washed with soapy water. Household devices, as a rule, have paper and fibrous disposable filters.

I must say that the difference between industrial and domestic hoods is sometimes not very pronounced. For example, devices are often installed in cottages, which are very similar in their characteristics to industrial hoods.

wall construction

Mounting methods

As mentioned above, there are two types of hoods according to the installation method:

- Island ventilation umbrellas - suspended from the ceiling. They are often installed above kitchen stoves located in the middle of the room. As a rule, such devices contain several rows of filters.

- Wall-mounted - as you might guess from the name, they are mounted to the wall. Such structures are often installed above stoves located near the wall. Do-it-yourself installation of such a hood is quite simple.

Here, perhaps, are all the main differences between local exhaust installations, knowing which, you can choose the most suitable device for a particular case.

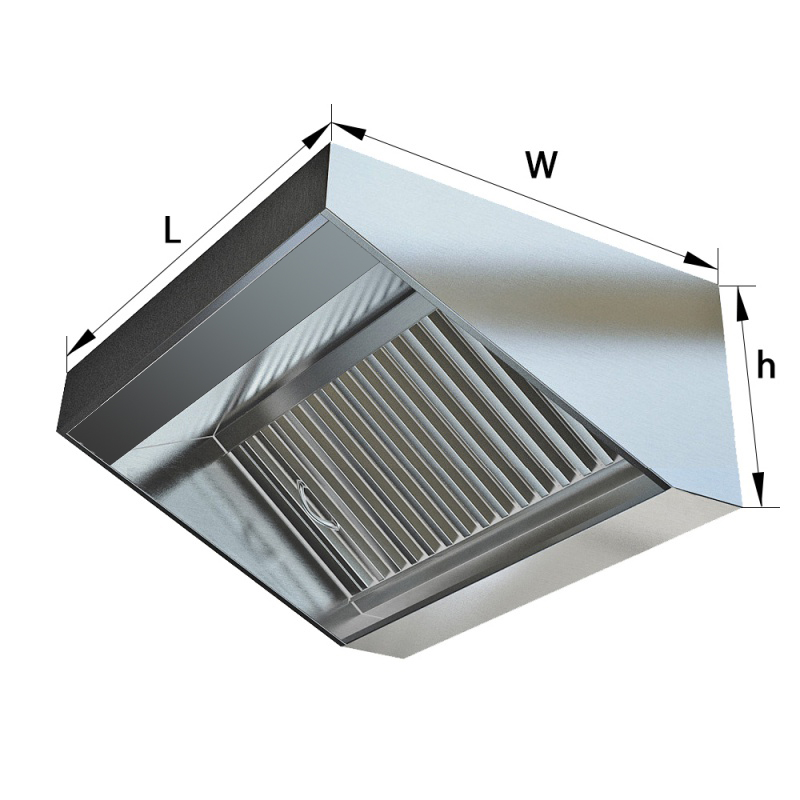

Design and installation features

According to the type of construction, exhaust hoods are wall-mounted and island. Wall models are mounted directly on the wall, directly above the work surface. Island ones have a more complex design, as they are attached to the ceiling and hang over the equipment located near the center of the room, away from the walls. The wall dome has one row of filters, and the island dome has two.

If the wall umbrella has a significant mass and dimensions, additional hangers, brackets and chains are used for auxiliary fixation of the device. To give the structure rigidity and stability, its shape is given a trapezoidal profile. This allows you to increase the maximum allowable area of the dome for hanging over large equipment.

Island-type ventilation units circulate air flows in a much larger volume than wall-mounted ones. Therefore, they are excellent not only for forced ventilation of air in the center, above objects remote from the walls, but also for ventilation of the entire volume of the room as a whole.

The quality and stability of the ventilation dome depends not only on the choice of its type and modification, but also on the correct installation of the unit above the working area. The fume hood must be suspended exactly above the location of active kitchen, industrial or laboratory appliances that pollute the air: stoves, deep fryers, braziers, burners, chemical containers, etc. It is necessary to ensure the coincidence of the centers of the umbrella and the active surface.

For conventional kitchen appliances, a couple of centimeters of difference is sufficient, and for larger installations, standards require an increase in the size of the dome by 10 cm or more. The height of the suspension of the structure above the working surface should be from 70 to 110 cm.

Why you need a deflector

For a better understanding of the issue, we present data from the reference literature. The value of local resistance to air flow in ventilation systems is characterized by a dimensionless coefficient ξ. The greater its value, the stronger the shaped element - an umbrella, a knee, a gate - slows down the movement of gases through the pipeline.

For our cases, the coefficient is:

- at the outlet of the air flow from an open pipe of any diameter ξ = 1;

- if the channel is covered with a classical cap, ξ = 1.3–1.5;

- a Grigorovich umbrella with a diffuser is installed on the pipe (expansion of the section), ξ = 0.8;

- Volper nozzle cylindrical or star-shaped "Shenard", ξ = 1;

- TsAGI-type deflector, ξ = 0.6.

So, the deflector is a nozzle that, under the action of the wind, creates a vacuum at the outlet of the vertical ventilation duct and thus reduces the aerodynamic resistance to flow. That is, it acts as a traction booster.

In addition, the exhaust device solves the following tasks:

- protects the duct from precipitation;

- does not allow the wind to blow inside the pipe;

- prevents reverse thrust (rollover).

The principle of operation of any deflector is based on two effects: rarefaction from the wind load and ejection (entrainment) of a slow flow of gases by a faster one. Although some foreign manufacturers implement mechanical motivation - they simply equip the umbrella with an electric fan. Consider the device of each design separately.

In this view, it is clearly seen that the cross section of the lower nozzle of the nozzle does not decrease, which means that the speed and pressure of the gases do not change.

2 Device classification

Today, two types of rectangular umbrellas are used for the chimney:

- Hoods. Their main purpose is the complete elimination of unnecessary gases, substances, combustion products from the chimney. Heavily heated air streams are drawn in by an umbrella, after which they are transported through a pipe where grease filters are placed and are eventually transported back to the air duct, with the help of which they are removed from the building. All this can be easily done by hand.

- Supply and exhaust umbrellas. Thanks to them, both the exhaust of polluted air and the supply of new, clean air into the room are ensured. These umbrellas are best used in those rooms where, due to certain circumstances, the flow of clean air is limited. It is always necessary to carry out the calculation, taking into account the fact that the volumes of supplied and exhausted air flows will always differ from each other. Therefore, in no case should you rely on the fact that exhaust hoods will contribute to the complete destruction of odors, gases and other substances. Although the chimney, of course, will work much more efficiently.

There is also a classification according to the type of construction. So, exhaust and supply-exhaust rectangular and round umbrellas are divided into island and wall.

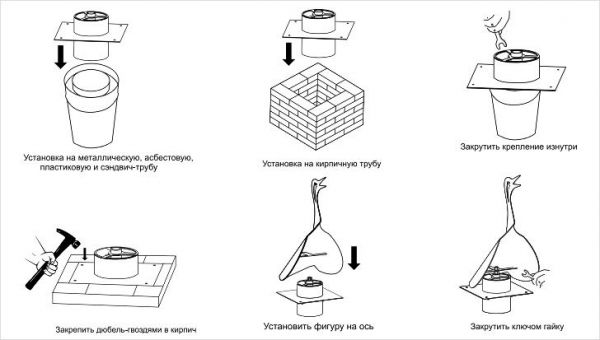

2.1

Do-it-yourself installation and calculation features

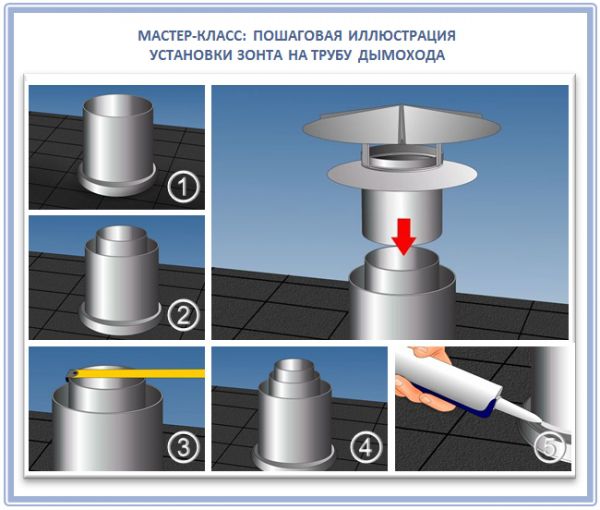

I would like to note that installing such umbrellas with your own hands is quite real, since in fact there is nothing complicated in such work.Below are some of the most popular ways to install a chimney umbrella.

Method number 1. Installation of wall exhaust hoods using anchors. After a certain calculation, the length of the umbrella is selected and 2 or 3 equal holes are drilled in the back of the wall. Using enlarged models of washers, the exhaust hood is first attracted, and then installed on the wall

It is very important that the wall is perfectly flat.

Do-it-yourself installation of rectangular umbrellas through collets and studs to the ceiling. At the very beginning, it is necessary to drill 4 identical holes for the studs. All these holes are drilled strictly along the edges of the umbrella, after which the device is attached directly to the ceiling

A modern chimney works perfectly if this option is used. The only negative, the calculation of the ceiling height to the standard length of the stud, does not allow the use of this technology if the height of the room is more than 4 meters.

Installation of exhaust hoods for the chimney using various cables and chains through anchors and brackets to the ceiling. In order to do everything with your own hands, you need to weld 4 brackets of the required parameters to the upper horizontal part of the umbrella, after which, using a carabiner, securely fix the chain or cable. The second end of such a chain or cable must also be securely connected to the ceiling. Among the disadvantages of this method, one can note the precariousness of the structure, so it is not at all easy to tie it with air ducts, but such a scheme is perfect for a chimney.

All these holes are drilled strictly along the edges of the umbrella, after which the device is attached directly to the ceiling. A modern chimney works perfectly if this option is used.The only negative, the calculation of the ceiling height to the standard length of the stud, does not allow the use of this technology if the height of the room is more than 4 meters.

Installation of exhaust hoods for the chimney using various cables and chains through anchors and brackets to the ceiling. In order to do everything with your own hands, you need to weld 4 brackets of the required parameters to the upper horizontal part of the umbrella, after which, using a carabiner, securely fix the chain or cable. The second end of such a chain or cable must also be securely connected to the ceiling. Among the disadvantages of this method, one can note the precariousness of the structure, so it is not at all easy to tie it with air ducts, but such a scheme is perfect for a chimney.

As you can see, it is not at all difficult to do the installation yourself. The main thing is to adjust the umbrella as close as possible to the chimney pipe and take into account some of the nuances.

Application area

Supply and exhaust and exhaust hoods of ventilation systems are widely used today by industrial enterprises and not only. Such systems are widely used in public catering establishments, such as restaurants, canteens, bars, food processing plants, cafes and so on.

Also, the installation of umbrellas is carried out over all kinds of devices of thermal equipment, in particular, this applies to deep fryers, gas stoves, and ovens. If the calculation allows you to install such umbrellas, then they are also used in various industrial premises - food, pharmacological, physical, chemical.

Basic installation rules

The installation of a smoke umbrella directly depends on the design features of the additional element and the chimney pipe, as well as the material used in the manufacture.Based on standard rectangular steel sheet, it is easiest to create a four-sided pyramidal umbrella by bending a sheet of material a couple of times in a diagonal direction.

This option is traditional for arranging chimney pipes on hipped roofs, but for attaching racks and further installation, it is necessary to use additional elements in the form of corners, as well as drill holes.

Wind vane installation

A less complex design has simple vaulted umbrellas with a minimum number of folds and incisions. The fastening of such a smoke umbrella on an oval chimney pipe is carried out due to the presence of racks bent from sheet steel of sufficient thickness or made using standard metal corners.

Regardless of the manufacturing method, racks can be fixed in several ways:

- on metal and asbestos chimney pipes, you can use a metal clamp or make a regular wire frame yourself;

- the wire for the frame base should be as strong and reliable as possible;

- mounting holes are drilled in the racks;

- the outlet parts of the twisted wire frame are passed through the mounting holes on the racks and twisted until the smoke umbrella is completely fixed.

On brick chimneys, even standard galvanized nails of sufficient length, implanted directly into the masonry, can be used to fix the "umbrella". However, as practice shows, it is best to drill holes in the brickwork using pre-drilled holes in the umbrella racks, and then fix the cap on the chimney pipe with steel pins or galvanized self-tapping screws.

Mounting an umbrella

In this case, if necessary, it will be possible to quickly and with minimal effort independently dismantle the umbrella for cleaning or replacement.

CAREFULLY!

It should be remembered that when using a gas system as an autonomous heating system, it is strongly not recommended to install an umbrella on the chimney.

Varieties according to the principle of work

The difference between modern exhaust devices can be traced in the very principle of their functioning. Despite the versatility, hoods are used for strictly defined purposes.

For example, a snail hood is a great option for cleaning rooms in country houses with no ventilation system. Such models are also used for industrial purposes, when the question arises of cleaning huge areas with a high degree of pollution.

In the kitchen, it is better to use forced exhaust, but even here it is important to understand that the optimal cleaning method is determined taking into account the nature of the equipment used.

Attention! In addition to exhaust devices for gas and electric stoves, gas column hoods are also widely available, which solve the issue of air ventilation in isolated rooms.

Standard types of hoods for the kitchen, depending on the method of air purification, include three models.

- recirculation hood;

- flow type hood;

- mixed exhaust model.

The first option is suitable for those who do not need to install a high-power hood, since cleaning using this technique occurs by passing air through external and internal filters built into the housing.

The external filter is designed to purify the air from grease elements: as a rule, grease filters are made of durable metals so that you can clean their surface from contamination yourself.

Internal filters can have a different composition, but most often they have a carbon structure, which contributes not only to thorough air purification, but also to the elimination of extraneous odors in the room. That is why hoods with circulation mode are often called coal hoods for the kitchen.

Internal filters cannot be cleaned of contaminants, so they must be periodically replaced with new ones to ensure the quality of the exhaust devices.

During the purchase process, make sure that the required filters are freely available, as it is not always possible to find the right option in a timely manner.

Tip: if you do not have the opportunity to install a large hood of this type, pay attention to telescopic hoods with a sliding panel. As a rule, such models have higher performance compared to other hoods operating in recirculation mode.

To do this, the hood is connected to the ventilation shaft using a strong air vent pipe (most often from corrugation)

Flow hoods cannot purify the air on their own: they are designed to effectively remove contaminants from the room. To do this, the hood is connected to the ventilation shaft using a strong air vent pipe (most often from corrugation).

Experts recommend additionally installing anti-return valves to prevent contaminants from flowing back into the kitchen.

It is important to remember that connecting any system to general ventilation requires a preliminary study of its operation. Flow type hoods can be connected in this way only if an individual ventilation duct is connected to your apartment

Otherwise, ensure that the polluted air exits directly outside.

Mixed models are the most powerful and highly efficient, but they can occupy large areas. Nevertheless, it is this version of exhaust devices that is most popular and is available in a wide price range (starting from 3.5 thousand rubles).

When installing hoods with exhaust and circulation, first consult with experts about all the pros and cons of such an installation, taking into account the placement of your kitchen.

Selection and installation

The model of the exhaust hood should be chosen based on the operating conditions. It is necessary to take into account the size of the equipment and the location. If it is located next to the wall, then you need to install a model of a wall-mounted exhaust hood.

If the equipment is located in the center of the room, then you can not do without installing the so-called island umbrella. Dimensions should be selected as follows:

- The umbrella should protrude from the edge of the equipment by about 10 cm.

- The height from the equipment to the umbrella should be about 1 meter.

How is the installation done?

There are several basic mounting options:

1. Directly to the wall

For this, anchor bolts are used. If necessary, holes are made on the wall of the umbrella at the back

It is important to make sure that the structure is securely attached to the wall.

2. To the ceiling

Installation is also carried out using anchor bolts, with the only difference being that the hood is attached to the ceiling close to the wall.

3. With chains

As a rule, chains or cables are attached in cases where anchors cannot be used. This method is less preferable, as it does not allow for a good fixation of the exhaust hood.

4. With metal frame

In this case, a structure is made of metal corners or profile pipes. It is firmly attached to the floor and the exhaust hood is installed directly on it.

In some cases, it is more advantageous to install several small hoods than one large one. This design is easier to dismantle and transport.

Hood selection

The following factors must be taken into account:

- Room area;

- Types and quantity of equipment generating hot steam, smoke or soot;

- Availability and type of ventilation system available;

- Possibility of installation of an exhaust umbrella on a wall.

It is advisable to invite a specialist who will inspect the place taking into account all factors and recommend specific parameters of the exhaust hood

It is important to understand that in order to obtain the desired result, it is not always enough to choose the appropriate model, since it may be necessary to redo the ventilation system to the required conditions.

![Do-it-yourself exhaust hood for barbecue: drawing, [10 photos + 2 videos]](https://fix.housecope.com/wp-content/uploads/6/b/0/6b08d552aa2b6df1f58fbe62d3b6838b.jpg)

![Do-it-yourself exhaust hood for barbecue: drawing, [10 photos + 2 videos]](https://fix.housecope.com/wp-content/uploads/0/7/1/07155f8491b08df3548fee805b125977.jpeg)