- 5 Sequence and calculation rules

- Device advantages

- Principles of operation of ventilation with recirculation

- 4 Equipment for local exhaust ventilation

- What are the regulations for ventilation systems

- Video description

- What formulas are used in calculations

- Video description

- Conclusion

- In bathroom

- Principle of operation

- 3 Methods and formulas for calculating the exhaust system

- Peculiarities

- Features and principle of operation

- Positive and negative points

- How to embed a hood in a wall cabinet?

- In the garage

- Installation rules

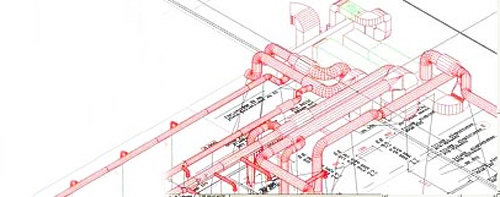

- Using the scheme of movement of air masses in the supply and exhaust ventilation and air conditioning system

- Prices for models from different manufacturers

5 Sequence and calculation rules

It is customary to start designing exhaust ventilation at the planning stage of the construction site. This rule does not depend on whether it is a residential building or an industrial complex. With this approach, connecting the hood to the ventilation duct will not be difficult.

We make a calculation

First, you should decide on the installation itself, eliminate potential foci of the spread of hazardous compounds.

The absence of such makes it possible to calculate the ventilation system according to the following formula:

O=m * n

where: n is the number of employees; m - the normalized value of the air volume per 1 employee, O - the volume specified in the sanitary standards.

Exhaust systems are designed in such a way that at least 30 m3 of air per hour per 1 employee (value m). Is it possible to implement a method whose scheme does not involve the influx of fresh air? - This option is possible, but on condition that 1 worker will have pure oxygen from 55-60 m3/hour.

The volume of air required to comply with the MPC is determined by the formula:

O \u003d Mv \ (Ko-Kp)

- Ko - the general level of concentration of a hazardous substance in the room;

- Kp - concentration of harmful suspension in the supply system;

- Mv is the approximate weight of a potentially hazardous composition.

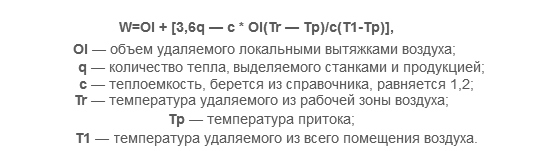

To determine the volume of supply oxygen, the level of excess heat is preliminarily set:

Knowing all the values, it will not be difficult to determine a specific product based on its parameters.

Device advantages

Filter hoods can afford a slightly lower power than exhaust air models. Naturally, this is reflected in the cost, and in favor of the buyer. At the same time, the equipment experiences minimal loads, which means it will be able to work much longer without failure.

Another plus in favor of an autonomous hood is that it does not create reverse thrust, which is sometimes the case with diverter models. In the absence of a special valve, ventilation equipment with a chimney brought outside allows air to pass back into the kitchen. This is especially felt in winter, when the hood suddenly turns into an air conditioner. With recirculation models, this is excluded.

The autonomy of the hood leaves room for maneuver when installing the hob.It can be placed where it will be more convenient to work, and not look for a place closer to the ventilation duct. And the appearance of the filter hood is more accurate and compact. And the absence of a ventilation pipe allows you to quickly and easily install appliances without damaging the interior of the kitchen.

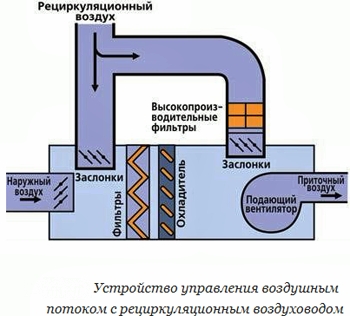

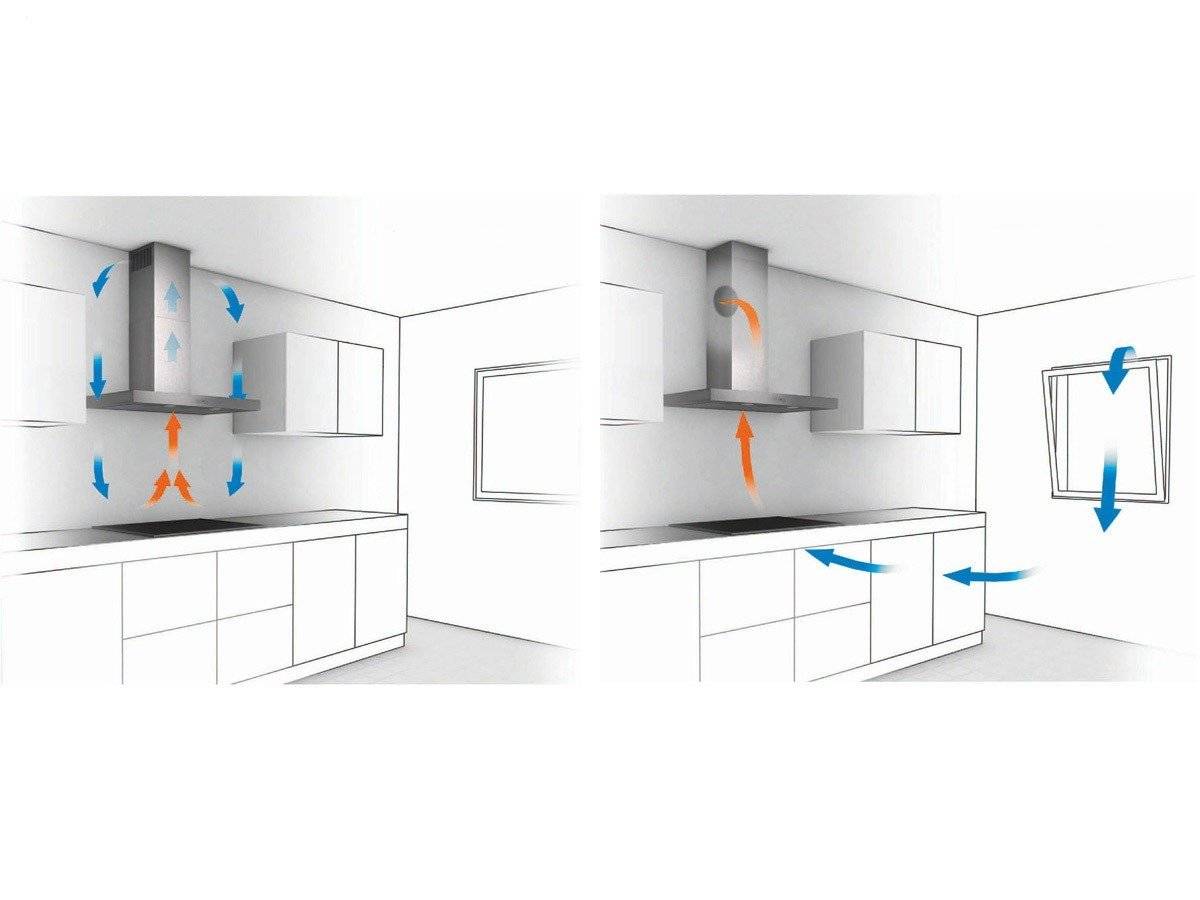

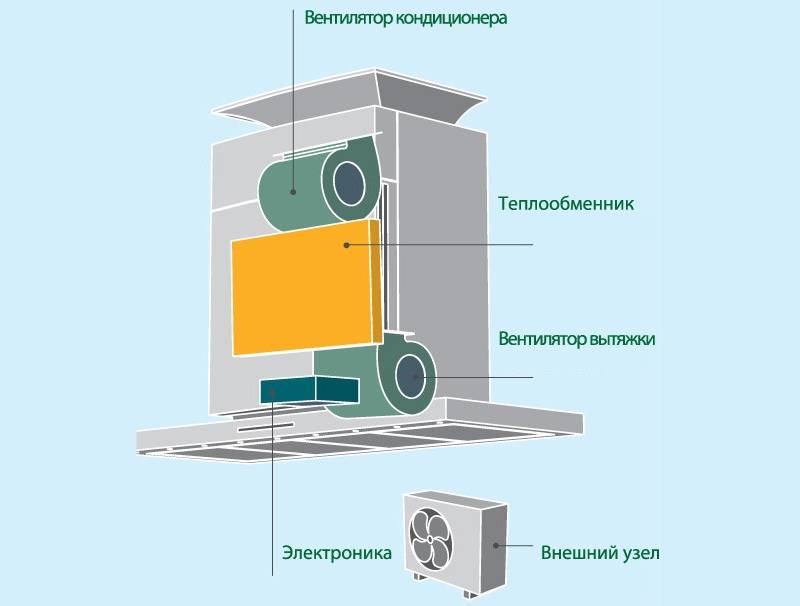

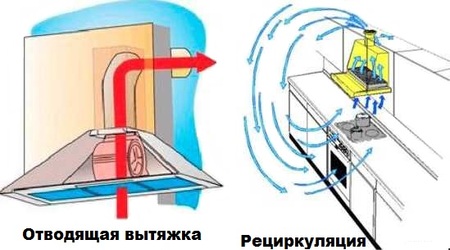

Principles of operation of ventilation with recirculation

The general scheme of operation of the supply and ventilation system with recirculation is as follows: through the inflow, street air is supplied to the room, which after some time is drawn into the exhaust system. Part of it is irretrievably thrown out into the street, and part enters the mixing chamber. There the air mixes with the fresh influx, cooling or heating it (depending on the type and settings of the system), then it enters the heater or air conditioner, from which it again enters the room through the ventilation pipes. The main purpose of recirculation is to reduce the load on air treatment systems (heaters, air conditioners, etc.).

To keep indoor air fresh and breathable, when using recirculation in the ventilation system, the following conditions must be observed:

- The volume of clean air supplied from outside must be at least 10% of the capacity of the air handling unit;

- The air entering the room should contain a maximum of 30% of harmful substances from their maximum permissible concentration.

4 Equipment for local exhaust ventilation

A set of covers for exhaust systems can consist of several types of devices:

- solutions blocking the zone of release of potentially hazardous substances;

- structures outside the source of pollution;

- reblowing.

Local view of equipment

From a practical point of view, the most effective are the intake solutions located above the source. On most production lines, this principle of ventilation is simply impossible to implement. For such cases, there are a number of additional devices:

- display, shaped and side suctions;

- umbrellas;

- specialized cabinets with integrated hoods;

- a mechanism that removes secretions from the working area.

Onboard suction

Side suctions. The main scope of their application is objects where it is impossible to place an exhaust system in a vertical plane, since it is occupied by a source of pollution (chemical laboratories, electroplating shops). The design consists of several air ducts, the inlets of which are not more than 10 cm in size, they are zoned at the edges of the tray, bath.

Umbrellas

Umbrellas. The most affordable, common and simple product. They are mounted above the source of hazardous compounds, fumes. They can be based on both natural and forced draft (depending on the scale of the production price, the size of the object).

Drawer cabinets. A variety of solutions that effectively remove dangerous mixtures, with minimal air exchange. From the point of view of the implementation of the exhaust element, cabinets are:

- with side outlet;

- with a combined suction, from which gases and heavy vapors are collected;

- with a top fan - for the rapid absorption of hot air masses.

The presence of a sufficiently powerful engine, working in conjunction with a productive fan, allows the formation of air turbulence, which eliminates the possibility of the spread of unwanted gases or dust throughout the room, workshop, room. It is these options for exhaust systems that are installed at welding posts.

Closet (powered by suction of polluted air)

suction panels. The main scope of application is areas where heat, dangerous gases, unwanted dust are constantly released. The structure itself should be placed in such a way that it is at the maximum distance from the human face. The panels can absorb hazardous substances from one or both sides. From the place of work, they are suspended at a maximum distance of 3.5 m.

Experts recommend maintaining the following values of the speed of propagation of air masses:

- 2 - 3.5 m / s - in the case of non-dusty and poisonous consistency;

- 5 - 4.5 m / s - when interacting with dust heated to a high temperature.

What are the regulations for ventilation systems

The recommended air exchange parameters depend on various conditions and are prescribed in the relevant regulations, which must be taken into account when designing. In general terms, for domestic premises, when rooms for different purposes are concentrated on the same floor, the following amount of air should change in an hour:

- office - 60 cubic meters;

- common living rooms or halls - 40 cubes;

- corridors - 10 cubes;

- bathrooms and showers - 70 cubic meters;

- smoking rooms - over 100 cubic meters.

In living rooms, the air mass exchange is calculated per person. It should be more than 30 cubes per hour. If the calculation is based on living space, then the standard is 3 cubic meters per 1 meter.

For non-residential premises, the average standard is 20 cubic meters per square meter. If the area is large, then the ventilation systems include a multi-component system of paired fans.

Video description

Visually about the standards for ventilation, see the video:

What formulas are used in calculations

The main parameter that needs to be calculated in any system is how much air should be changed within an hour.

For residential apartments, the value is determined according to the living area: V \u003d 2xSxH, where S is the area of \u200b\u200bthe living room, 2 is the multiplicity factor for the exchange of air mass in 1 hour, H is the height of the room.

For working premises, the calculation is made based on the number of personnel: V = Nx35, where N is the number of people who are simultaneously in the room.

In calculating the power of the ventilation station, the following formula is used: P = ΔT * V * Сv / 1000, where V is the volume of air mass consumed per hour, Сv is the heat capacity of the air mass, ΔT is the temperature difference of the air mass at the ends of the pipeline. The accepted value of heat capacity is 0.336 W * h / m³ * °C.

Another important indicator is the cross-sectional area of the duct, measured in square centimeters. There are 2 types of section: square and rounded. Having calculated the cross-sectional area, it is possible to determine the width and height of a rectangular pipe or the diameter of a round one.

Video description

More about the calculation of ventilation on the video:

Ssec \u003d V * 2.8 / w, where Ssec is the cross-sectional area, V is the volume of air mass (m³ / h), w is the air flow velocity inside the line (m / s) (average from 2 to 3), 2, 8 – dimension matching factor.

For installation, it is necessary to calculate how many diffusers (intake and outlet openings) and their parameters are required. The dimensions of the nozzles are calculated based on the cross-sectional area of the main pipeline, multiplied by 1.5 or 2.To calculate the number of diffusers, the formula is used: N=V/(2820 * W * d2), where V is the volume of air mass consumed per hour, W is the speed of movement of the air mass, D is the diameter of the round diffuser.

For rectangular diffusers, the formula is converted as follows: N=π * V/(2820 * W * 4 * A * B), π is the pi number, A and B are the section parameters.

In any case, calculations of ventilation systems should be carried out by professionals - if something is forgotten or not taken into account, then the price of an error is the need to redo the calculations and work.

A full calculation of supply ventilation is done on specific software

Conclusion

Installation of a ventilation structure of a supply and exhaust type will allow maintaining an optimal microclimate inside the premises. This increases the efficiency of people living in the house and simply improves their well-being. The issue of ventilation is especially relevant for owners of modern houses with hermetically sealed windows and doors, because along with getting rid of drafts, natural air exchange also disappears. In such houses, it is desirable to provide for a supply and exhaust ventilation system at the design stage.

Source

In bathroom

The best option for improving the throughput of exhaust vents in bathrooms is a household fan. It is not difficult to make sure that it is necessary - just bring a strip of newsprint to the ventilation grille. If it sticks to it, then the intensity of gas exchange can be considered sufficient. When the strip of paper does not stick or deviates only slightly, you should consider buying a household fan.

Unlike other rooms, sanitary rooms are an area of increased risk of mold. High-quality ventilation of a bathroom, toilet or combined bathroom is the basis for comfort and environmental safety of the room. Humid environment plus stale air - ideal conditions for the development of pathogenic bacteria

Therefore, it is very important to ensure that such areas are well ventilated.

Sometimes even the purchase of a household fan does not help to achieve the required level of ventilation of sanitary premises. The reason for this may be tight doors. The air is not removed from the room due to the fact that the new one has nowhere to come from. The fan removes the gas, creating an area of low pressure. And the resulting pressure difference is equalized due to the air that goes into the ventilation duct from other apartments. Holes in the doors or the creation of a leaky doorway that does not prevent air from the apartment from entering the bathroom can correct this situation.

Choosing the best household fan for the bathroom is easy to do, based on the following recommendations:

- The performance of the device must be at least 90 m3 / h.

- The fan must be waterproof.

- A system with an on-off device timer is better than a device that only works when the light is on.

- A household fan with a non-return valve is noticeably more reliable than exhaust devices without it.

Using these tips, you can choose a quality appliance for use in kitchens, bathrooms, bathrooms or other areas with high humidity.

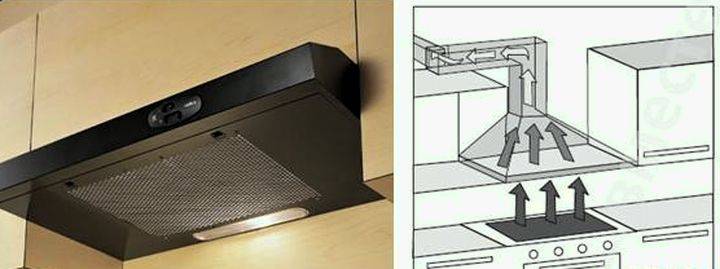

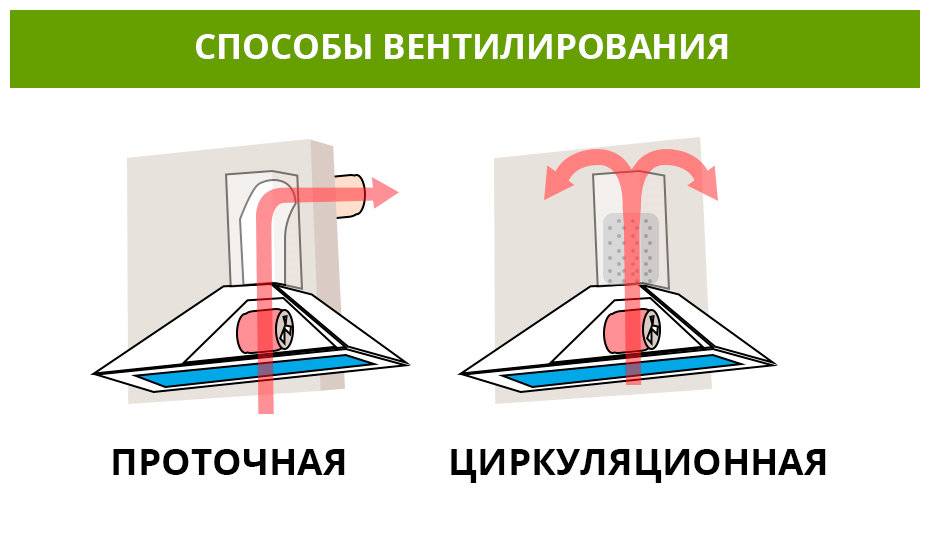

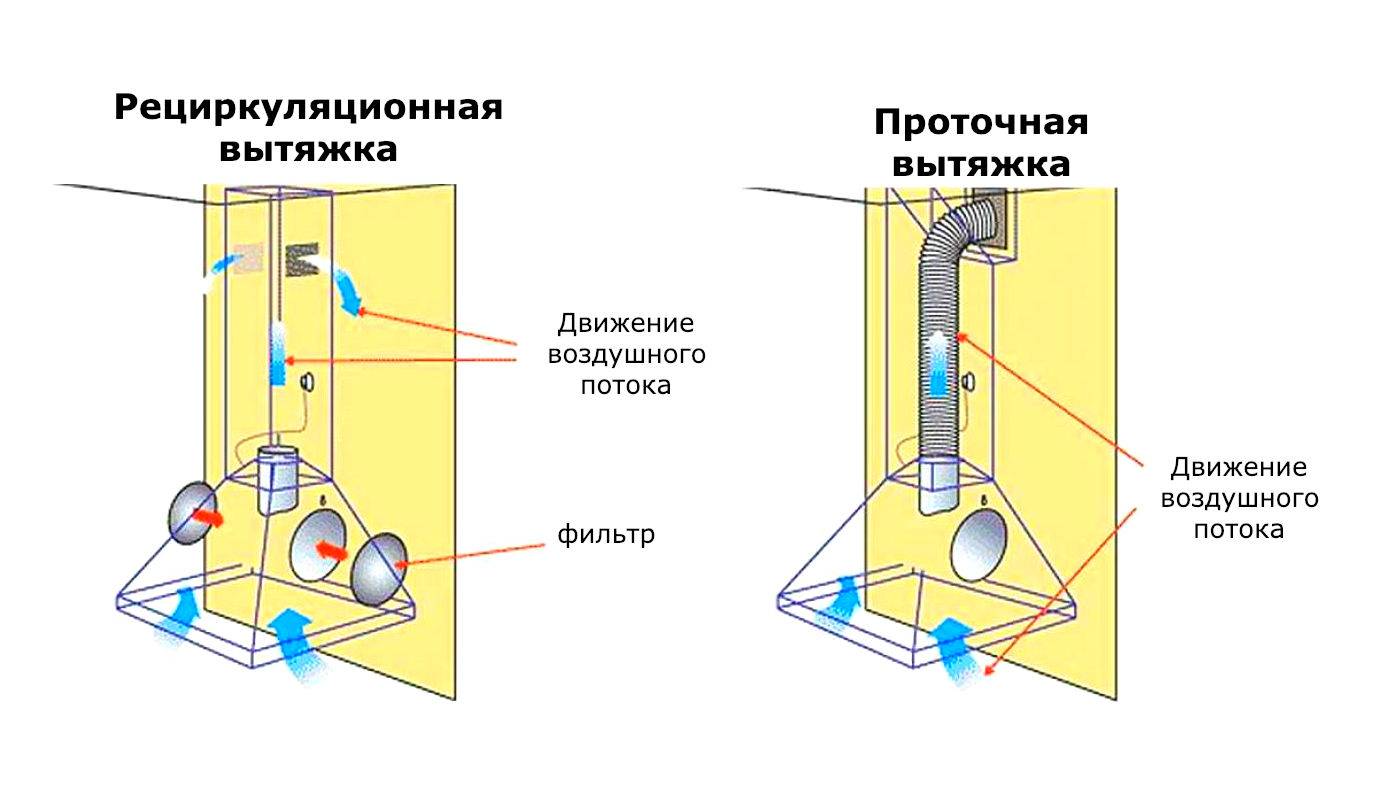

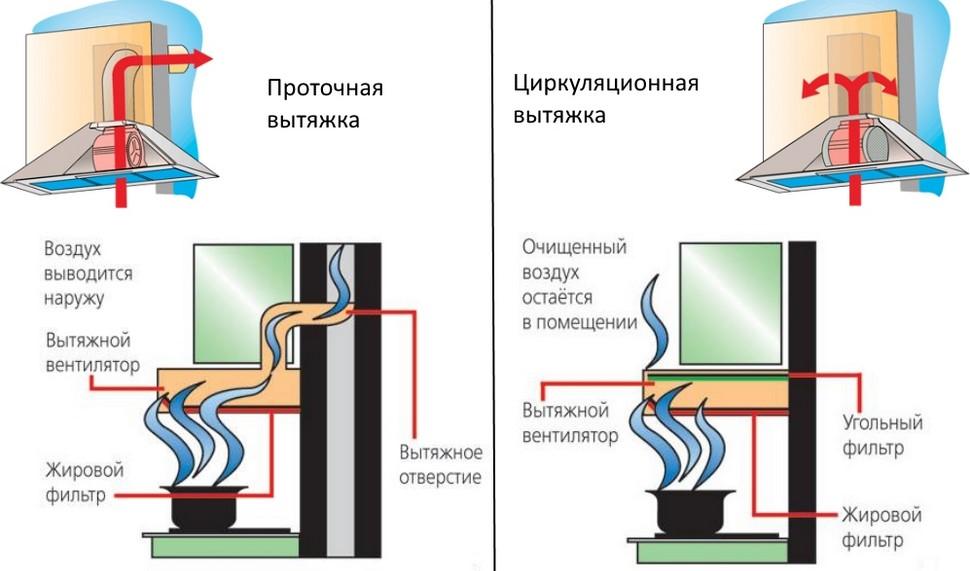

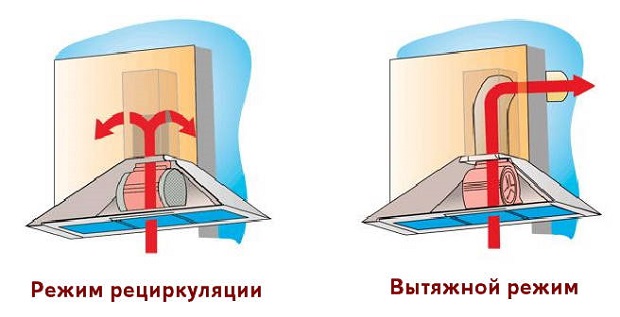

Principle of operation

If for some reason you cannot run an air duct in your room, you should not look for ways to equip it in other areas of the kitchen. It is enough to purchase a hood with recirculation properties, as it will perfectly cope with its main task even in a small isolated space.

Features of the operation of this type of hood are to process the air directly inside the exhaust duct.

The recirculation mode in the hood allows the air to be quickly cleaned - and returned to the room. Contaminated air enters the hood and passes through one or more filters.

Such an extract quickly cleans the air of pollution and has enough power to clean the rooms in which they cook often and a lot.

The quality of air recirculation in the hood largely depends on how many filters are installed in it. Modern hoods use two types of filters. The first - fatty - is attached outside the hood: as a rule, it is made of metal and serves to retain fat deposits on the surface. It is enough to periodically clean such filters with detergents.

The second type of filter - carbon - serves directly to clean the air penetrating deep into the air. Filters of this type cannot be cleaned, so they will have to be updated approximately every 3 months of operation of the hood. On average, one high-quality filter of this type will cost about 200 rubles.

Attention! Despite the high efficiency of work, the hoods with the recirculation mode also have disadvantages.The main one is the impossibility of completely getting rid of unpleasant odors in the room. Difficulties during operation can also arise with the replacement of filter systems

It will not be difficult to install them on your own, but it is not always possible to predict the need for replacement in time.

Difficulties during operation can also arise with the replacement of filter systems. It will not be difficult to install them on your own, but it is not always possible to predict the need for replacement in time.

In order for buyers not to forget about changing filters, manufacturers equip modern models of hoods with special sensors that notify them of contamination.

As you can see, the main advantage of using a recirculating hood is that you don't need a ventilation shaft. In addition, when equipping an island kitchen, it can be difficult to determine the optimal location of hoods with an air vent.

In order for such equipment to serve you as long as possible, do not forget about timely cleaning and careful maintenance. Since there will be moisture in the room when recirculating hoods, there is a possibility of mold in the room. Regular ventilation of the kitchen will solve this problem.

A powerful recirculating hood without an air vent will cost very little, but it will do the job of cleaning the air in your kitchen. Therefore, experts consider this version of technology one of the most successful among all economy class hoods.

3 Methods and formulas for calculating the exhaust system

Let's take a closer look at how the calculation is performed. local exhaust ventilation for industrial premises. It should be noted that umbrella-shaped suctions are used to absorb potentially harmful substances.These elements are supplied with exhaust ventilation, however, they can be made with your own hands.

hanging umbrella

The best way is to calculate the dimensions of the umbrella using the formulas below. You must first set the following values:

- a,x, b - the estimated size of the ejected area;

- V3 - approximate speed of air intake inside the umbrella;

- Z is the height of the structure above the contamination zone;

- Vv - the speed of movement of air masses in the work area.

Installation of exhaust ventilation is carried out only after determining the installation height of the intake structure, since the efficiency of the system as a whole depends on this indicator. How to do it right? – Hang the umbrella as low as possible to allow all hazardous suspensions to escape.

The dimensions of the product are determined by the formulas:

A=0.8*Z+a, B=0.8*Z+b or D=0.8*Z+d

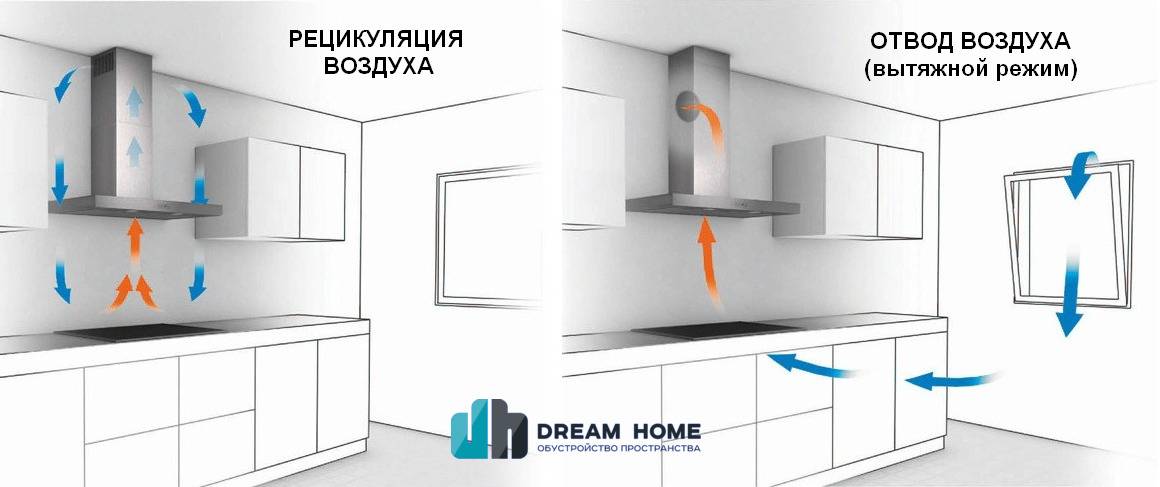

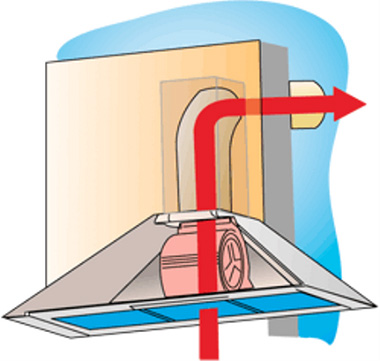

Peculiarities

Hood for ventilated kitchens allows you to renew the air in the room in full and prevent the deposition of fat and soot on horizontal and vertical surfaces.

The difference between this device and an autonomous hood operating on the principle of recirculation lies in the fact that it brings air masses outside. Thus, there is a faster cleansing of the space from the smells of cooking food, and at the same time, it is not necessary to periodically replace the filters.

For large kitchen areas, manufacturers offer large-sized devices equipped with not one, but two engines. Such devices are designed specifically for use in catering establishments.

As you can see in the photo of the hood for ventilation, it consists of a control panel, a deep filter, an air duct and a housing.

Features and principle of operation

How do such devices work? Usually they are installed above the stove or panel. Rising air with particles of dirt and grease is drawn in by the device, cleaned with special filters and blown back. These devices are in no way inferior to equipment with an air vent.

In addition, they have a number of advantages:

- Easy installation and operation;

- Long serve;

- No chimney or air outlet required;

- They have high efficiency and productivity.

Often, ventilation devices fail prematurely and do not cope with their task due to the heavy load. In addition, over time, the air outlet channels become clogged, which leads to a decrease in the efficiency and performance of the device.

Positive and negative points

Despite the fact that filter hoods have a small capacity, they have many advantages. These include:

- ease of installation and operation;

- unlimited choice of slab placement, tk. a ventilation shaft is not needed for this;

- easy care.

These exhaust devices also have disadvantages. This is a small efficiency - up to 70%, the need for frequent replacement of disposable filters - 3-4 times in 24 months. The hood does not affect the level of humidity in the room. The electric drive of the device in the on state creates a certain noise.

Small compact hoods are becoming more and more popular as they save space. You can install this design anywhere

The hoods of the latest releases, as a rule, can work both in the mode of removing air masses and as recirculation ones. Such a device must be connected to a ventilation shaft. Since an autonomous hood does not provide fresh air, after turning it off, it is necessary to ventilate the room.

How to embed a hood in a wall cabinet?

Built-in hoods are mounted in recirculation mode in a hanging kitchen cabinet (above the stove). On top of the case, each manufacturer provides holes for attaching the device to the bottom shelf of the cabinet. The fasteners themselves are usually included in the kit. The cabinet is bought without a bottom. The lower shelf in it is hung in such a way that the attached hood is completely hidden. Outside, only the lower surface remains - a reusable grease filter and, if any, a retractable panel.

Another question arises if you use the hood in recirculation mode. How to build in a cabinet so as not to block the outlet? Make a hole in the top of the cabinet or in the side wall and use a round corrugation and a pair of adapters to connect the hood outlet to it.

In the garage

The garage is often mistakenly considered a non-residential area, which does not require a separate ventilation system. Even with a fairly rare use of the room, it is necessary to create mechanical air exchange in it. The comfortable stay of the owner in the garage, which is considered non-residential premises, is not the main reason why the premises need high-quality air extraction.

Good forced air exchange in the garage allows you to solve a number of problems familiar to many owners of such real estate:

- Prevent the development of mold and fungus on the walls.

- Ensure high-quality removal of exhaust gases and harmful volatile mixtures.

- Remove excess moisture brought into the room with the car.

- Keep walls, inspection pit, tools, etc. as dry as possible.

- Protect your vehicle from corrosion caused by condensation.

High-quality forced ventilation of the garage allows you to maintain the performance of everything that is stored in it. And saving on ventilation can lead to higher costs for car repairs, the purchase of a new tool, or the replacement of other damaged items that were stored here.

Installation rules

The installation requirements for the hood are the same for all types of models. Since the device is an electrical appliance that collects accumulations of grease and moisture, a breakdown of current through the body of the equipment may occur. To protect yourself during installation, you must properly ground the hood.

Usually, modern houses are equipped with a ground loop and there should be no problems with this: you can insert the plug into the socket and the device is ready to work. If such a circuit is missing, it is necessary to make it. In no case should the ground wire be connected to pipes or radiators, as not only family members, but also neighbors can be injured by receiving an electrical discharge through the risers.

Before purchasing the hood, you need to measure the hob of the stove - length and width. For the device, these dimensions should be larger or, in extreme cases, match. A hood with a smaller area will not cope with the high-quality removal of polluted air.

Another rule to remember when installing the hood is to maintain a distance from plate surface up to device.Above electric and induction ovens, the height should be 65-75 cm, above gas - at least 80 cm. If these parameters are not taken into account, inconvenience in working at the stove or fire hazard situations may occur due to overheating of the device.

The fixture of the device to the wall must be made firmly and reliably, otherwise the device may break and injure one of the family members. Therefore, covering the walls with drywall during repairs, you need to strengthen the place and fill the wooden blocks in the intended area for attaching the hood.

Using the scheme of movement of air masses in the supply and exhaust ventilation and air conditioning system

If the exhaust and supply valve is in the closed position, and the recirculation valve is open, then we see a recirculation system in which air masses move in a closed circle.

When the air inlet and outlet valves are not fully opened, a supply and exhaust air circulation system is formed with the addition of clean supply air. In this way, it is possible to achieve the content in an apartment or a manufacturing enterprise of such an amount of oxygen and carbon dioxide, which will be quite enough for normal life.

The positive side of this scheme is that it makes it possible to maintain the optimum temperature regime in extreme cold or excessive heat, by cooling or heating air masses.

Prices for models from different manufacturers

The cost of this type of hood will depend on the material, design, additional features, reliability of filter systems, as well as on the brand of the manufacturer. We suggest you familiarize yourself with the most budget options.

A Hansa flat recirculation hood will cost you about 3 thousand rubles. A Liberty Base hood with similar properties will cost about 4.7 thousand. The Pyramida technique is popular today: recirculation hoods from this manufacturer are estimated at 5 thousand rubles or more.

You can purchase even better options for hoods from the manufacturer Ventolux - such models will cost from 8.5 thousand rubles. The minimum cost of a Gorenje hood with recirculation mode is about 7.5 thousand rubles.

More well-known models with high functionality and modern design will cost you much more. For example, an inclined Electrolux recirculation hood will cost approximately 40 thousand, and Bosch equipment will cost an average of 55 thousand rubles.

Tip: For maximum efficiency in cleaning the air in the kitchen, purchase a recirculating hood with air extraction. Such models are the most expensive.