- Rules for the use of thermal sealants

- Working with thermal sealant for stoves and fireplaces

- Basic principles of working with high temperature sealant

- Top 5 best deals

- 3rd place - Soudal

- Types of sealants for furnace work

- Heat resistant sealing pastes

- Areas and order of application

- Viscous sealants

- Liquid sealants

- How to work with glue

- Pros and cons

- How to carefully apply heat resistant sealant

- Manufacturers

- Outline the scope

- The best synthetic sealants

- Application area

Rules for the use of thermal sealants

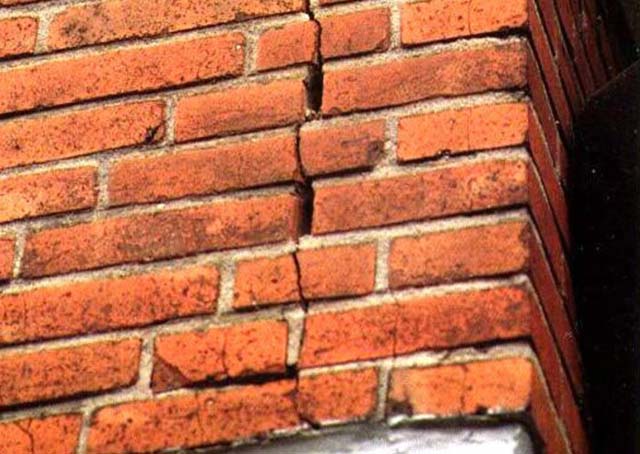

During the active operation of fireplaces and stoves, brickwork may crack. The risk of cracks increases if the brickwork is not tiled, protected with a plaster layer and not covered with heat-resistant paint.

Repair work cannot be postponed - using such a fireplace or stove becomes unsafe.

Depressurization of the walls of the furnace section, chimney or other elements of the furnace adversely affects the performance of the device and entails a number of dangerous consequences

Possible problems caused by the appearance of through cracks:

- fuel consumption increases due to the fact that additional air seeps into the combustion chamber;

- soot comes out from the cracks - a corresponding plaque appears on the ceiling, walls; in such situations, even cleaning the chimney does not solve the problem;

- combustion products that are hazardous to health enter the room - there is a risk of poisoning;

- periodic attenuation of the igniter flame - probably when the chimney is depressurized;

- fuel burns at low temperatures, which causes more soot to settle on the walls of the chimney pipes.

Depressurization of the heating system and an abundance of soot is a fire hazardous combination. Incoming oxygen provokes ignition inside the chimney.

With poor-quality thermal insulation of the exhaust duct, the likelihood of a fire increases significantly

Most manufacturers sell insulating compounds for furnaces in tubes. Before use, a cylindrical container is installed in a construction gun.

This option is most convenient when filling masonry joints and cracks formed. Sealants are easily squeezed out of the packaging due to their homogeneity and semi-liquid consistency

There are products in soft small tubes. It is advisable to use them for processing small areas. Any additional devices for applying the composition are not needed.

High-temperature sealants are produced in the form of one- or two-component compositions. The first category is most actively used in everyday life.

Two-component formulations are supplied in a set - hardener and paste. Substances are mixed before use in strictly indicated proportions.

This option is more often used in industrial conditions, when it is necessary to process large areas. In everyday life, two-component mixtures did not take root due to the technological complexity of the application.

The tactics of using silicone and silicate mixtures are similar to each other. However, there are also features that you should definitely remember when sealing furnace equipment.

In addition to the construction tool for work, you need to prepare: a rubber spatula, latex gloves, a brush.

The surface to be treated needs to be prepared:

- clean and degrease the base;

- it is desirable to treat metal elements with sandpaper to improve adhesion;

- wait for the surface to dry completely if water was used for cleaning.

It is desirable that the thickness of the extruded sealant be slightly less than the width of the seam or crack being processed.

For uniform hardening, the silicone composition must be provided with air access. Therefore, it is impossible to exceed the thickness of the sealant recommended by the manufacturer.

The time of complete polymerization depends on the conditions. The packaging indicates the curing rate at optimal rates: humidity - 50%, temperature - 23 ° C. In practice, the values differ significantly. The lower the temperature in the room, the longer the sealant will “set”.

Adhesive tape is necessary to protect the outer coating - the sealant dries quickly, and then it will be problematic to remove it from the base

Surfaces are prepared in the same way as before applying the silicone composition: they are cleaned, degreased, the metal is “sanded” with an abrasive.

Technological nuances of using silicate sealant:

- the porous base must be dedusted and slightly moistened;

- work is carried out only at a positive temperature, optimally - over 20 ° C;

- when applying the mixture, adhere to the insulation thickness recommended by the manufacturer;

- excess sealant must be removed immediately, without waiting for the mixture to dry;

- the masking tape is removed after applying the composition.

Some oven sealants require many hours of drying at different temperatures. This information must be specified in the instructions for the product.

Working with thermal sealant for stoves and fireplaces

You can use different sealants for fireplaces and other brick heating structures, but in any case, you will need the following tools and materials:

- rubber spatula;

- knife;

- masking tape;

- rubber gloves.

First, we “load” the gun. Cut off the tip of the tube and put a cap on it. We insert the balloon into the gun. Before applying the silicone sealant, the surface must be prepared: cleaned from dirt, dust, residues of polyurethane foam. The surface is cleaned if it is very smooth. This is necessary for better adhesion. All work is best done at positive air temperature.

Sealant is not applied on a damp surface. After cleaning with water, it is necessary to dry everything well.

For the application of heat-resistant sealant for boilers, similar preparation procedures are carried out. Then a masking tape is glued along the crack on both sides and it is filled with paste. The excess that got into the tape is removed with a rubber spatula. At the initial stage of compaction (after a few minutes), the masking tape is removed, the time is waiting, which is prescribed in the instructions.

Basic principles of working with high temperature sealant

The composition is packed in tubes that have a capacity of 300 milliliters. Before opening the material, it is necessary to prepare the surface, that is, clean it from dirt, clean it with sandpaper, and degrease it.

If sealing will be carried out on the roof, at the junction of the roofing material and the chimney, then the prepared surface is covered with masking tape. Then gradually open and fill with the composition, this will avoid contamination of the cleaned surface.

Holes filled with sealant should be no more than 3 centimeters wide, this indicator should be indicated on the package. Before using a silicate-type sealant, the surface is moistened.

With a heat-resistant type of sealant, they work only at a positive temperature; it dries faster at 20 degrees. During such work, it is necessary to wear gloves, if the material gets on the skin, it is washed with water.

The oven must not be heated to full temperature immediately, this must be done gradually, otherwise the sealant may crack.

In order to remove excess composition or level it, use a rubber spatula. The surface around the repaired hole is covered with masking tape to avoid contamination, after the sealant has hardened, it is peeled off. The hardening of the material may take a different time, from several hours to a day, these data should be indicated on the packaging.

Top 5 best deals

The demand for high temperature silicone and silicate sealants is very high, so these products are present in the product lines of many manufacturers. In order not to get confused in the variety of offers, here is a list of the most worthy and popular compositions from foreign and domestic companies.

We suggest you familiarize yourself: Do-it-yourself brush for cleaning the chimney pipe

The first place was given to the silicate composition from the Estonian manufacturer Penosil.Despite the declared high technical characteristics, the sealant is relatively inexpensive.

Professional heat-resistant agent is intended for sealing joints, sealing cracks in chimneys, stoves, fireplaces

Penosil is suitable for outdoor, indoor use, contact with stone, brick, concrete, metal is acceptable.

Specifications:

- temperature resistance - 1500°C;

- mobility - 0%;

- color - dark gray;

- application temperature - 5-40 ° C;

- hardening time - about 24 hours;

- volume - 310 ml.

Among the main advantages of refractory sealant are noted: low cost, excellent quality, ease of use, versatility. User reviews are mostly positive, Penosil copes with the task. Minus - the duration of hardening, the oven can be turned on a day after processing.

Makroflex TA145 is characterized by high adhesion, elasticity, weather resistance

It is undesirable to use the composition for processing metal elements prone to corrosion (lead, copper). During the curing process, the sealant releases acetic acid fumes.

- stable heat resistance - 60-260°С, short-term exposure is permissible - up to 315°С;

- the width of the applied layer is 6-30 mm, the depth is from 2 mm;

- hardening time - about 2 days;

- application conditions - temperature in the range of 5-40 ° C.

During polymerization, it is necessary to ensure good ventilation in the room - inhalation of acid vapors can lead to poisoning. After drying, the sealant is safe.

3rd place - Soudal

Sealing paste based on sodium silicate.There is no asbestos in the composition, therefore, after hardening, the insulating layer does not crack or crumble. Soudal temperature resistance – 1500°С.

Scope of application - sealing of fireplace inserts, sealing around chimneys, conservation, repair and installation of furnace equipment, heating boilers

Suitable for concrete, metal, brick substrates.

- mastic color - black;

- maximum heat resistance - 1500°С;

- operating temperatures - 1-30°C;

- deformation during movements - no more than 7%;

- film formation time - 15 minutes at 20°C and 65% humidity;

- cartridge volume - 300 ml.

Heat-resistant composition based on silicate. Sealant is inert to chemical influences and perfectly resists atmospheric factors.

Once cured, Kraftflex FR150 forms a durable refractory layer. Sealant can be used indoors and outdoors

There are no special restrictions on the use of Kraftflex FR150. It is suitable for sealing elements exposed to direct flames, fixing refractory bricks and air ducts.

- paste color - black;

- the maximum allowable heating temperature is 1500°С;

- film formation time - 15 minutes;

- curing speed - 2 mm / 24 hours;

- operating temperature - 5-40 ° C;

- packing - 300 ml.

Sealant is irreplaceable for the objects operated in extreme conditions. The composition can withstand temperatures down to -40°C. Cons Kraftflex FR150: drying time, relatively high price.

Germent is suitable not only for sealing joints in chimneys and furnaces, but also for sealing joints between metal elements, except for lead and copper parts.

Use on mirror and stone surfaces is undesirable.

In practice, Germent showed reliable adhesion with various materials. The silicone insulator is petrol and oil resistant, not afraid of UV radiation.

- remains stable at -65°С… 260°С, short-term temperature jumps up to 315°С are acceptable;

- film formation time - 10 minutes;

- polymerization rate - 1.5 mm / day;

- color - brick red;

- elongation at break - 115%;

- bottle volume - 300 ml.

The fifth place in the rating is due to the high cost of the product. In practice, Germent proved to be good - it is easy to apply, dries quickly enough, and forms a reliable coupling with materials.

Types of sealants for furnace work

A through crack that has appeared in the body of the furnace or the wall of the smoke channel leads to depressurization of the combustion chamber or flue. As a result, smoke begins to enter the room, the chimney draft decreases, and the overall efficiency of the furnace deteriorates. Of course, cracks can be covered up with clay mortar in the old fashioned way, but this will not help for long. It is more convenient and reliable to use high-temperature sealants for furnaces for this purpose.

Although dozens of types of similar compositions are offered on the modern market, only 2 of them are suitable for use in the furnace business:

- based on silicone (heat-resistant compounds);

- on a silicate basis (heat-resistant compositions).

As you might guess, in both cases, modern polymers come to the aid of stove-makers. The product is ready-made pastes with different characteristics and colors, sold in tubes. In addition, there are heat-resistant sealants, consisting of two components. But working with them is more troublesome, it is necessary to accurately dose and mix before use, this will affect the quality of the seal and the service life of the seam.

Heat resistant sealing pastes

The basis of these pastes is silicone. Working temperature — from 250 ֩С to 315 ֩С. The reddish-brown color of the paste is due to iron oxide, which is part of the composition. It does not affect the appearance of the heating unit.

Heat resistant sealant containing iron oxide

Depending on the surface with which the heat-resistant silicone paste will interact, there are:

- acid. Not suitable for concrete, cement, metal. Upon contact with these surfaces, substances are formed that prevent the effective functioning of the seam and can let water or air particles through. During solidification, acetic acid is formed.

- Neutral. Ideal for concrete, cement and metal. When dry, the seam becomes completely sealed. This happens due to water and alcohol, which evaporate after hardening.

A simple process of preparing the work of a gun with sealant.

Heat-resistant sealing solutions have the following properties:

- UV resistant, suitable for outdoor work;

- strong coupling with brick, ceramics, glass, concrete, plastic, wood;

- ability not to pass moisture;

- resistance to small deformations and vibrations;

Some points to consider when choosing a sealant:

- The curing time of the sealant with silicone lasts from a couple of hours to more than a day. This is affected by the production time, composition, temperature and humidity of the room.

- Before using the paste, it is necessary to carefully prepare the surface: clean, rinse, degrease, dry.

- There are no transparent silicone pastes.

Areas and order of application

Viscous sealants

Everything is simple here: they can only be used to seal threaded connections. Applying sealant, for example, to a radiator gasket when connecting sections is also practiced (mainly by beginners), but does not give any noticeable effect.

How to use silicone sealant with your own hands:

- We apply a little composition to the surface of the external thread.

- We wind a strand of sanitary flax on it along the turns.

- On top of the tightly laid flax, we apply another thin layer of sealant.

When assembling the joint, the polymer composition evenly impregnates the flax and further reliably protects it from rotting and fading at high temperatures.

Liquid sealants

They are used to eliminate those leaks that are difficult to eliminate by more traditional means:

- In case of leaks along the longitudinal seams of electric-welded pipes or conventional welds.

- In case of leaks at the connection of a metal-polymer pipe with a fitting embedded in a wall or floor.

- With the already mentioned leaks of boiler heat exchangers.

- With intersectional leaks of radiators of various types in conditions of difficult dismantling of heating devices.

High-quality polymerizing sealant for radiators (for example, German BCG) is more than expensive: the price of a liter package is 9-10 thousand rubles.

- The leak is relatively small. . No sealant will fill a fistula the size of a dime.

- It is impossible or very difficult to localize and eliminate by more familiar means. . Say, with an intersectional leak of the radiator, it will be much cheaper to simply replace it with a new one.

How to use a radiator sealant if all of the above is relevant to you? First, determine what kind of composition you need.At the same BCG, the buyer is offered the following varieties:

In the photo - the most popular BCG24.

Then the approximate amount of coolant is estimated.

In a balanced system, it is approximately equal to 13 liters per kilowatt of boiler power; more accurately, the volume can be determined by draining water or antifreeze into any volumetric utensils.

- All filters are removed or cut off by taps. All throttling and shut-off valves are fully opened.

- A pressure test pump is connected to the heating circuit. For connection, you can use any control valve or an unscrewed Mayevsky tap on one of the first radiators along the coolant.

The heating system starts up and warms up to 60C at a pressure of at least 1 kgf/cm2. Everything is ready for the application of our composition.

How to fill the sealant into the radiator after these procedures?

Here is the instruction:

- Through any vent we pour into two different buckets of 8-10 liters of hot coolant.

- After stirring the sealant, add it to one of the buckets. Stir the solution again.

- We pump it into the heating system. Then we pump in the same coolant from the second bucket. This is necessary to flush the pump from the sealant.

- We bleed air. If it remains in the circuit, it can provoke the formation of clots at all where they are needed.

- Having raised the pressure to 1.5 kgf / cm2, we leave the system in circulation at a coolant temperature of about 60C. To fix a leak, the sealant must be in the system for at least a week.

How to work with glue

Each type of glue has its own characteristics of operation. However, there are general recommendations, the implementation of which will ensure a reliable connection and repair.

- Preparing details.Surfaces must be cleaned prior to application of adhesive. Old rust, dirt, previous composition is removed. When facing works, the surface is primed.

- Some mixtures can be applied to wet elements. But if it is not indicated on the package, the parts should be dried well.

- The solution is usually distributed in a thin layer on both elements. Liquid products set quickly. Therefore, there is no more than 2–5 minutes to correct the position. Dry mixes for finishing works can allow changes up to 15–20 minutes.

- Details are pressed against each other. If possible, they should be left in a fixed state for an hour.

- After the final setting, the surfaces can be painted.

When mixing the solution yourself, strictly follow the manufacturer's recommendations. Technological deviations can affect the quality of connections.

Pros and cons

The most common area of application of heat-resistant sealants are high-temperature joints of stoves, fireplaces, boilers, chimneys, and they are also used to repair various systems inside automotive and other equipment.

Like any product, heat-resistant sealing materials have their advantages and disadvantages.

positive properties.

- The operating mode of using a heat-resistant sealant is in the range from 1200 to 1300 degrees, however, its composition is able to withstand an increase in the working environment up to 1500 degrees for a short period of time.

- The use of heat-resistant sealing compounds is universal - they are suitable for almost any surface, you just need to choose the right type of sealant.

- Manufacturers of silicone sealants now produce products with a variety of colors, which greatly simplifies the task for the buyer when choosing.

- Heat-resistant sealants containing sodium silicate are currently successfully replacing asbestos products from the market, which are recognized worldwide as carcinogens.

- The use of sealant makes it possible to increase the degree of protection against fire of structures and structures. Often, sealants are used when installing ventilation ducts, arranging underfloor heating, and installing door panels.

negative properties.

- The vast majority of high-temperature sealants contain iron oxide, therefore, upon contact with working surfaces during polymerization, they can be painted in a rusty-brown color, which is undesirable under certain conditions and does not look quite aesthetically pleasing.

- Silicone, which is part of the sealant, does not allow paint to be applied to the sealing layer - it does not adhere to it. This is not always convenient, for example, when repairing a car.

- The sealant, which contains silicone, dries at a rate of approximately 2-3 millimeters per day. Thick seams may not freeze inside at all, since air access is important for the polymerization process.

- It is possible to work with heat-resistant sealants only at temperatures above zero, low temperatures during installation work will lead to disastrous consequences due to a violation of the polymer process technology.

How to carefully apply heat resistant sealant

To make it convenient to repair the stove or chimney using a sealant, you need to prepare some tools and materials.

So, you will need:

- Construction mounting gun or syringe.

- Rubber spatula.

- Stationery knife.

- A gas burner and, accordingly, a filled canister for it.

- Sealing compound in the cartridge.

- Masking tape.

- Rubber gloves.

In the case when the paste is purchased in a tube, a construction syringe is not required, and when using a heat-resistant sealant, there is no need to prepare a burner and a gas cylinder for work.

Sealing joints between bricks requires special care

When applying the sealant on the surface, special care is required to fill the seams or cracks, especially if it is necessary to maintain a neat appearance of the masonry made “for jointing”

For the quality of such work, it is advisable to take into account a couple of tips from experienced craftsmen:

In order not to stain the surface of the brickwork with sealant, it would be a reasonable solution to seal it with masking tape, leaving only gaps along the line of the seams to be sealed.

So that the sealant does not get on the surface of the brick and, but fills only a crack or seam, the surfaces can be sealed with masking tape of the desired width. The adhesive tape is glued along the seam line, then the gap is filled with sealing paste, about one centimeter deep. If necessary, the sealant is leveled with a rubber spatula and you can not be afraid that the dark composition will stain the surface of the wall. After setting the paste, the tape is removed. This method will allow you to keep the seams in their original width and not spoil the neat appearance of the brickwork with dark paste.

The nose of the tube is cut so that the hole is slightly beveled, and its diameter is slightly less than the width of the seams to be sealed.

You can solve this problem in another way, without using adhesive tape.To do this, when preparing the tube for work, you should not immediately cut off its nose to the maximum. In addition, the cut must be made at a slight angle and so that the hole is 2 ÷ 3 mm smaller than the joint width - this will help control the amount of sealant squeezed out. True, with this approach, there remains the risk of accidentally getting the composition on the surface of the brick, so using adhesive tape is definitely the best solution.

Taking into account these recommendations, you can proceed directly to the process of applying the sealing compound. Work is carried out in the following order: The first step is to cut off the hermetic cap that closes the tube using a sharp knife from the cartridge.

The first step is to cut off the sealed cap from the cartridge using a sharp knife, which closes the tube.

This cap is cut off completely, to its entire width.

- Next, a spout is wound on it, which is already cut off as recommended above.

- In the next step, the tube is installed in the mounting gun, which is prepared for work in accordance with the peculiarity of its design.

When working with a mounting gun, you must rely on the instructions for its use - there may be differences

Further, before applying the sealant to the seam, crack or gap between the brick and the cast iron part, the surface must be carefully prepared:

— Clean from dust and dirt.

- Surfaces that are too smooth should be sanded to increase adhesion and then cleaned again.

- After that, the surfaces are degreased and completely dried. To speed up this stage of work, you can use a building hair dryer for drying.

Filling the seam between bricks with heat-resistant sealant

- When the surface is dry, you can start filling the gap with a sealing mixture.

- Further, if a heat-resistant paste was used for sealing, then it is left to dry for a while. The packaging usually indicates the exact duration of the drying period of the sealant before the next stage of work can begin. Usually this period is about a day.

After the specified instructions for the hardening of the composition, it is recommended to burn it with a flame of a gas burner

The final step is the firing of the hardened sealant layer with a portable gas burner. After such processing, the material during operation will be able to withstand temperatures up to 1500 degrees.

Of course, only one of the sealants offered for sale was shown for example. For other compositions, there may be some differences in the application technology. In any case, you must carefully study the instructions supplied by the manufacturer.

Manufacturers

Heat-resistant sealants in Russia can be purchased both domestic and foreign production. According to analysts, in recent years Russian manufacturers tend to oust foreign suppliers.

The largest manufacturers of sealants in our country, producing products based on their own developments or foreign technologies, include the following companies:

- Lipetsk company Fenzi - the company produces sealants and adhesives using Italian technology. An example is the one-component Butilver sealant, which operates at temperatures from +120 to + 150 degrees.

- The Bashkir company "Moment" produces sealants using the technology of the German brand Henkel. The products are packaged for professional and home use. A product called "Moment Germent" is produced on the basis of silicates, the operating parameters for heating reach +315 degrees.

- Vladimir Research and Production Company "Adhesive" develops and produces adhesives, sealants, elastomeric coatings. An example of this is the one-component sealant "Advaflex", which operates in the temperature range up to + 90 degrees.

- The Nizhny Novgorod company "Germast" - the manufacturer develops and produces sealants for various purposes. Sealant "Vikar" is designed for a wide range of applications, is available in the form of a cartridge with a volume of 310 ml and can withstand temperature loads up to +140 degrees.

- The Moscow company "Sazi" is the largest enterprise that specializes in the production of sealing products. The range includes all types of sealants, ranging from household to highly specialized.

- Trademark Hobby. Germetik-Trade is its distributor in Russia and sells a line of sealants on the Russian market, among which, as an example, we can highlight the heat-resistant silicate sealing product Hobby 1250c used for fireplaces, stoves and chimneys. The composition of the sealant is able to work at temperatures up to +1250 degrees.

- Trademark Abro industrials - under this trademark, the American company began to produce in Russia high-quality temperature-resistant sealants in small packaging for use in the installation and construction industry and automotive repair.

- The Hilti brand produces sealants that are used for joints and seams of structures exposed to high temperatures. The most popular are the grades "P-301S, СР-606 - sealing seams from these products withstand deformation well and paint can be applied to them.

- The Penosil trademark belongs to the Estonian company Krimelte. This brand specializes in the production of mounting foams, various types of adhesives, sealants and other polymer products. The company's products are quite popular in Russia and are used for professional and domestic needs. An example of a fire-resistant sealant is "Penosil Premium Sealant + 1500c" - the product is used to seal the seams of chimneys, chimneys, fireplaces, boilers, stoves. It can withstand temperatures up to +1500 degrees.

Outline the scope

There are many sealing pastes sold in construction supermarkets for use in heating, plumbing and sewage systems. It must be understood that conventional food and plumbing sealants are not high-temperature, although they are used for mounting some elements of chimneys.

Water and heat resistant sealants are used for steel stoves, masonry and fireplace repairs. Application options:

- Sealing cracks and holes in the walls of a combustion chamber built of brick or welded from metal.

- Sealing chimneys during repair or installation.

- Exterior decoration of brick fireplaces and stoves.

- Gluing heat-resistant gaskets (asbestos and graphite-asbestos cords) to metal fittings - doors, latches, iron ovens and cast-iron stoves.

- Waterproofing of the junctions of the roof to the chimneys made of metal and brick.

A crack in the furnace masonry or a welded joint of a steel furnace leads to smoke in the heated room and the formation of soot in the defect zone. The traditional way to eliminate it is to shift the stove or cover the through hole with clay. Modern high-temperature sealant allows you to solve the problem much faster and more efficiently.

The suction of street air into the chimney is a very unpleasant phenomenon. More condensate and soot fall on the walls, which can catch fire at any time from the high temperature of the flue gases. Hence, it becomes necessary to seal the connections between the elements of the chimney. We will describe in detail about other methods of application in the process of considering repair compounds.

The best synthetic sealants

- Polyurethane Sealant Sazilast 25 Used for sealing gaps, cracks, joints in the construction and repair of buildings. Maintains temperatures from -60 °C to +70 °C.

- Universal Radiator Sealant Done Deal DD6855. It is applied to sealing of radiators of cars. Resistant to vibrations and all types of antifreeze.

- Polyurethane sealant Sazilast 25. It is used for external sealing of buildings. Operating temperature range from -60 °С to +90 °С Durable and resistant to all atmospheric phenomena, predicted service life up to 25 years.

Having orientated a little in all the variety of adhesives and sealants, we again turn to the question “which one is better?”. There is no universal answer to this question, just as there is no magic glue for all occasions.In some cases, an ordinary glue stick may turn out to be the best glue - the price, the promotion of the brand and the intrusive advertising of one or another composition do not matter here. As already mentioned, our review includes products from different companies and price categories, and the list was compiled not by the cost of the compositions and brand promotion, but by the number of stars in the rating and consumer reviews

Therefore, it is important to select the compositions specifically for a specific situation. We hope that this review will help you choose exactly “your”, the most suitable composition.

And we, in turn, promise to regularly publish tips that may be useful and we are waiting for you again.

Application area

Furnaces, fireplaces have a different device. All domestic hearths have a firebox where organic raw materials are burned, and a chimney. Depressurization of any area is dangerous due to the possibility of carbon monoxide entering the room.

Carbon monoxide is often the cause of occupant poisoning because it is odorless and colorless. It is impossible to feel the increase in gas concentration. The integrity of the furnace, chimney should be carefully checked; control traction in the system.

In addition to all the risks, due to depressurization, the efficiency of the furnaces is significantly reduced. Part of the energy released during combustion escapes uncontrollably into space.

Some modern chimneys are made from ceramic, metal fragments. Sandwich constructions are gaining popularity for removing smoke from stoves.

When installing chimneys, it is necessary to ensure a monolithic connection of all components, excluding leakage of hot products of combustion of fuel.To gain confidence in the safety of using stoves, fireplaces, you can only correctly apply a refractory sealant during the initial installation and repair.