- Areas of use

- The best synthetic sealants

- Peculiarities

- How to carefully apply heat resistant sealant

- Popular brands

- Makroflex company

- Brand Soudal

- Firm Krass

- Producer Renosil

- Scopes of sealants on the basis of silicate:

- Types of sealants and materials

- Peculiarities

- Composition of refractory dyes

- Scope of application

- How to choose

- Popular synthetic products

- IRFIX +1500 High Temperature Sealant

- Mix "Pechnik"

- Terracotta

- PalaTERMO 601

- How to accurately and correctly apply sealant

- Features of sealing sandwich chimneys

Areas of use

Any furnace design is a whole organism in which all parameters must be coordinated - from the size of the furnace and blower window to the height of the pipe. Cracks that appear in different sections violate the sealing of the walls of the chimney, the furnace section and other areas involved in the removal of combustion products. As a result of such violations, traction becomes worse, and smoke, which contains many substances dangerous to humans, can enter the home.

Such processes often lead to tragic consequences, because carbon monoxide can cause deadly harm to the body. In addition, damaged stoves are a fire hazard.The most harmless thing that can happen if the seal is broken is to significantly reduce the efficiency of the unit.

In this video you will learn the pros and cons of sealant:

The traditional method of repairing damage is to putty with clay mortar, but this procedure has a temporary effect and does not provide a strong seal. In addition, the repaired part must be constantly monitored, because at any time new cracks may appear at the patch sites. Therefore, a more reliable method of getting rid of cracks is the use of special sealants for high temperatures.

Read also: how to work with refractory fireclay clay.

Equally important is the sealing of chimney pipe joints made of ceramic or metal, as well as those made of sandwich panels. Not only the efficient operation of structures, but also the safety of the entire room depends on the quality of the docking. In addition, sealants are needed to organize the passage of the chimney pipe through the roof and rafters. Here, the compositions are used as an additional element that fills the gaps between the frame apron.

Without such mixtures, it is impossible to completely close all the cracks in the passage of the chimney, therefore, earlier, bituminous mastic was used for these purposes, or they came up with their own methods of sealing joints.

Furnace restoration:

If a depressurization occurs in a metal chimney from a gas-fired boiler, the flame in the gas burner will regularly die out. This problem is quite common when operating gas units. The main reason for such situations is the violation of sealing at the joints of the chimney sections. In this case, refractory silicone is the best repair tool.

The best synthetic sealants

- Polyurethane Sealant Sazilast 25 Used for sealing gaps, cracks, joints in the construction and repair of buildings. Maintains temperatures from -60 °C to +70 °C.

- Universal Radiator Sealant Done Deal DD6855. It is applied to sealing of radiators of cars. Resistant to vibrations and all types of antifreeze.

- Polyurethane sealant Sazilast 25. It is used for external sealing of buildings. Operating temperature range from -60 °С to +90 °С Durable and resistant to all atmospheric phenomena, predicted service life up to 25 years.

Having orientated a little in all the variety of adhesives and sealants, we again turn to the question “which one is better?”. There is no universal answer to this question, just as there is no magic glue for all occasions. In some cases, an ordinary glue stick may turn out to be the best glue - the price, the promotion of the brand and the intrusive advertising of one or another composition do not matter here. As already mentioned, our review includes products from different companies and price categories, and the list was compiled not by the cost of the compositions and brand promotion, but by the number of stars in the rating and consumer reviews

Therefore, it is important to select the compositions specifically for a specific situation. We hope that this review will help you choose exactly “your”, the most suitable composition.

And we, in turn, promise to regularly publish tips that may be useful and we are waiting for you again.

Peculiarities

The task of any sealant is to form a strong insulating layer, therefore, many requirements are placed on the substance. If you need to create insulation on highly heated elements, you will need a heat-resistant material. There are even more requirements for it.

Heat-resistant sealant is made on the basis of a polymeric material - silicone and is a plastic mass. During production, various substances can be added to sealants, which give additional characteristics to the product.

In specialized stores, you can see a two-component composition that should be mixed before use. It has strict operational requirements: it is necessary to strictly observe the quantitative ratio and not allow even drops of components to accidentally fall into each other in order to avoid an immediate reaction. Such compositions should be used by professional builders. If you want to do the work yourself, get a ready-made one-component composition.

The heat-resistant sealant has a very wide range of applications in a variety of construction and repair work, due to its remarkable properties:

- silicone sealant can be used at temperatures up to +350 degrees C;

- has a high level of plasticity;

- fire-resistant and non-flammable, depending on the type, it can withstand heating up to +1500 degrees C;

- able to withstand heavy loads without losing its sealing properties;

- high resistance to ultraviolet radiation;

- withstands not only high temperatures, but also frosts down to -50 - -60 degrees C;

- has excellent adhesion when used with almost all building materials, while the main condition is that the materials must be dry;

- moisture resistance, resistance to acid and alkali formations;

- long service life;

- safe for human health, as it does not emit toxic substances into the environment;

- when working with him, the use of protective personal equipment is optional.

Silicone sealant has significant disadvantages.

- Silicone sealant should not be applied to wet surfaces as this will reduce adhesion.

- Surfaces should be well cleaned of dust and small debris, as the quality of adhesion may suffer.

- Quite a long hardening time - up to several days. Carrying out work at low temperatures in air with low humidity will entail an increase in this indicator.

- It is not subject to staining - the paint crumbles from it after drying.

- They should not fill very deep gaps. When cured, it uses moisture from the air, and at a large depth of the seam, hardening may not occur.

It should be remembered that the sealant, like any substance, has a shelf life. With increasing storage time, the time required for curing after application increases. Higher requirements are imposed on heat-resistant sealants, and in order to be sure that the declared characteristics correspond to the quality of the goods, purchase the product from reliable manufacturers: they will definitely have a certificate of conformity.

How to carefully apply heat resistant sealant

To make it convenient to repair the stove or chimney using a sealant, you need to prepare some tools and materials.

So, you will need:

- Construction mounting gun or syringe.

- Rubber spatula.

- Stationery knife.

- A gas burner and, accordingly, a filled canister for it.

- Sealing compound in the cartridge.

- Masking tape.

- Rubber gloves.

In the case when the paste is purchased in a tube, a construction syringe is not required, and when using a heat-resistant sealant, there is no need to prepare a burner and a gas cylinder for work.

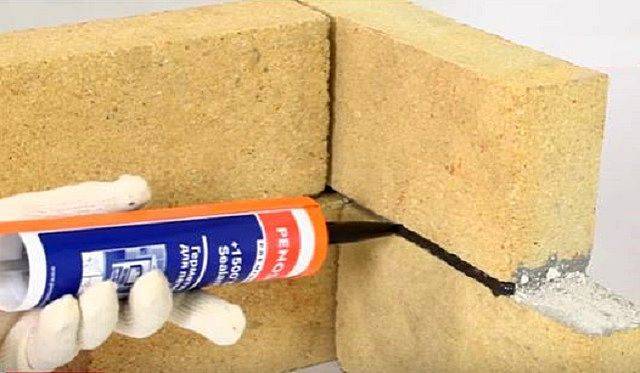

Sealing joints between bricks requires special care

When applying the sealant on the surface, special care is required to fill the seams or cracks, especially if it is necessary to maintain a neat appearance of the masonry made “for jointing”

For the quality of such work, it is advisable to take into account a couple of tips from experienced craftsmen:

In order not to stain the surface of the brickwork with sealant, it would be a reasonable solution to seal it with masking tape, leaving only gaps along the line of the seams to be sealed.

So that the sealant does not get on the surface of the brick and, but fills only a crack or seam, the surfaces can be sealed with masking tape of the desired width. The adhesive tape is glued along the seam line, then the gap is filled with sealing paste, about one centimeter deep. If necessary, the sealant is leveled with a rubber spatula and you can not be afraid that the dark composition will stain the surface of the wall. After setting the paste, the tape is removed. This method will allow you to keep the seams in their original width and not spoil the neat appearance of the brickwork with dark paste.

The nose of the tube is cut so that the hole is slightly beveled, and its diameter is slightly less than the width of the seams to be sealed.

You can solve this problem in another way, without using adhesive tape. To do this, when preparing the tube for work, you should not immediately cut off its nose to the maximum.In addition, the cut must be made at a slight angle and so that the hole is 2 ÷ 3 mm smaller than the joint width - this will help control the amount of sealant squeezed out. True, with this approach, there remains the risk of accidentally getting the composition on the surface of the brick, so using adhesive tape is definitely the best solution.

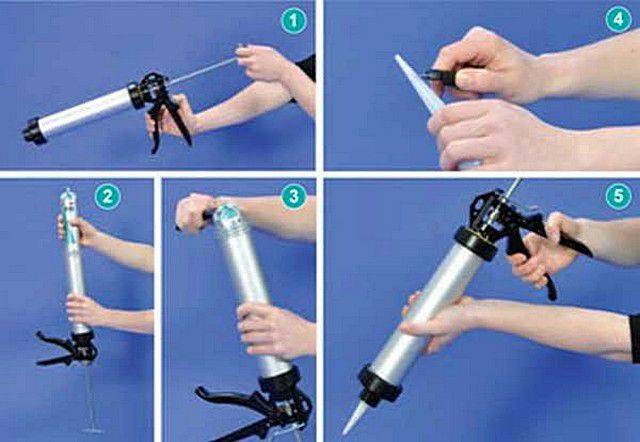

Taking into account these recommendations, you can proceed directly to the process of applying the sealing compound. Work is carried out in the following order: The first step is to cut off the hermetic cap that closes the tube using a sharp knife from the cartridge.

The first step is to cut off the sealed cap from the cartridge using a sharp knife, which closes the tube.

This cap is cut off completely, to its entire width.

- Next, a spout is wound on it, which is already cut off as recommended above.

- In the next step, the tube is installed in the mounting gun, which is prepared for work in accordance with the peculiarity of its design.

When working with a mounting gun, you must rely on the instructions on its application - there may be differences

Further, before applying the sealant to the seam, crack or gap between the brick and the cast iron part, the surface must be carefully prepared:

— Clean from dust and dirt.

- Surfaces that are too smooth should be sanded to increase adhesion and then cleaned again.

- After that, the surfaces are degreased and completely dried. To speed up this stage of work, you can use a building hair dryer for drying.

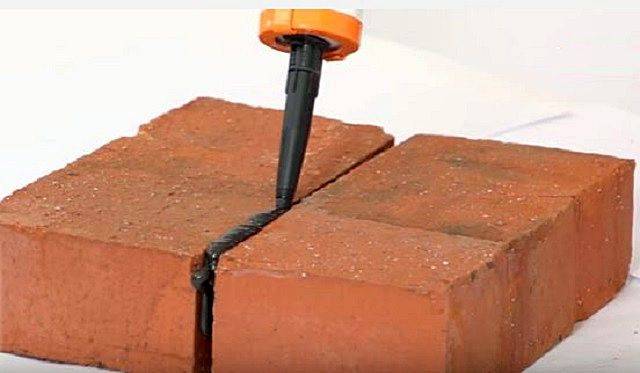

Filling the seam between bricks with heat-resistant sealant

- When the surface is dry, you can start filling the gap with a sealing mixture.

- Further, if a heat-resistant paste was used for sealing, then it is left to dry for a while. The packaging usually indicates the exact duration of the drying period of the sealant before the next stage of work can begin. Usually this period is about a day.

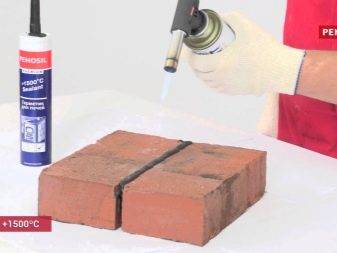

After the specified instructions for the hardening of the composition, it is recommended to burn it with a flame of a gas burner

The final step is the firing of the hardened sealant layer with a portable gas burner. After such processing, the material during operation will be able to withstand temperatures up to 1500 degrees.

Of course, only one of the sealants offered for sale was shown for example. For other compositions, there may be some differences in the application technology. In any case, you must carefully study the instructions supplied by the manufacturer.

Popular brands

Today, in specialized outlets, you can see many different compositions of both domestic and foreign production. Some mixtures have received recognition from Russian users, and are in high demand.

Makroflex company

This is an Estonian manufacturer that produces various insulating materials, as well as sealants. The range is represented by various heat-resistant and refractory compounds, which have long been in demand for repair and construction, and have many positive reviews.

A popular inorganic refractory agent is Makroflex HA 147. After the water evaporates, the sealant cures, resulting in a rigid and high temperature resistant joint.The mixture has a number of advantages - fire resistance, high adhesion with many types of building materials, resistance to shrinkage, lack of smoke and fumes. In addition, after hardening, the seams can be painted.

Every sealant company has its own unique history.

Every sealant company has its own unique history.

Brand Soudal

The Belgian company produces silicate products for fireplaces and stoves. They are resistant to temperatures, the maximum value reaches 1500°C. The material does not crumble or crack, in addition, there is no asbestos in the composition.

The paste is black in color, so it is convenient to use it for sealing cast iron furnace parts. Paint adheres well to the frozen seams, so they can be decorated to match the color of any surface. The maximum dimensions of the gaps that can be sealed must be no more than 5 mm. When large cracks appear, it is first necessary to treat them with a different composition, and only then with a sealant.

Often used for such work:

- waterproofing and sealing of chimney-to-roof connections;

- installation of furnaces, repair of boilers;

- elimination of gaps between brick and cast iron surfaces.

Some sealants do not contain asbestos

Some sealants do not contain asbestos

Firm Krass

"Krass fireplaces and stoves" is a domestically produced sealant, characterized by high resistance to fire. The composition is used for the repair and construction of brick ovens, as well as other heating appliances that are exposed to fire. The mixture is resistant to high temperatures, the maximum value is 1250 degrees.

Black paste is made on the basis of liquid glass. The latter forms a rigid seam, wear-resistant and gas-tight.The composition is characterized by high adhesion with ceramics, stone, metal and brick. The solution does not flow after application, the hardened material does not crack.

Some sealants from certain manufacturers are most used in car repairs.

Some sealants from certain manufacturers are most used in car repairs.

Widely used for processing various areas:

- connection of the roof to the chimney;

- joints of ventilation ducts;

- areas exposed to direct fire or high temperatures;

- car repair.

Producer Renosil

Another Estonian manufacturer that produces wide-spectrum sealants. Various compositions of this brand are made on the basis of silicone or liquid glass. For example, a product called Renosil +1500 Premium Sealant is used to protect joints and gaps from exposure to high temperatures and moisture.

Refractory sealant Makroflex HA 147:

The main characteristics of the composition:

- high adhesion with tiles, metal, artificial or natural stone, concrete, brick;

- durable seams that do not crack or crumble;

- contains no asbestos.

Seams and cracks in furnaces or chimneys, which are affected by high temperatures, are sealed with a sealant. In addition, with the help of the mixture, boiler and furnace appliances are repaired. It is not recommended to use the material in structures subject to deformation.

Brick structures, of course, are not eternal. With constant exposure to temperatures, cracks and cracks appear in stoves or fireplaces, which can be repaired with modern high-temperature silicone sealants. The compositions are used in case of violation of the integrity of the system, external and internal sections of chimneys.

Scopes of sealants on the basis of silicate:

- to create tightness of combustion chambers, joints of linings and treatment of those surfaces and elements that have direct contact with the flame and hot flue gases

- for sealing gaps and cracks between brick surfaces and adjoining metal or cast iron parts

- for sealing chimneys designed to remove high-temperature combustion products (for example, for sauna stoves and boilers)

- for processing and preparation of furnace casting mounting areas

- to eliminate leaks in water tanks and heating boilers

- for mounting chimneys and connecting (joining) modules of sandwich pipes with each other

Types of sealants and materials

The main component of sealants is polymers. In this case, different polymers are used and give different characteristics to the main composition. They are packaged in tubes of different sizes and configurations. Some resemble tubes of toothpaste and squeeze out the same way. There is tubes for mounting gun. In this case, the spout is cut off on the cone of the lid, the tube is installed in the device, squeezing out the required amount using the trigger lever.

Heat resistant sealant in a tube

There are two-component compositions that need to be mixed before work. They are more often used by professionals because of the stringent requirements: when mixing, it is required to measure parts with high accuracy (the permissible error is only 0.5-1 gram). In addition, if even a small part of one component accidentally gets into another, a reaction occurs, and the suitability of the mixture is only a few hours. In general, ready-made paste sealants are easier to use.

For chimneys and stoves, special high-temperature compounds are used. Sealants that withstand high temperatures come in two categories:

- Heat resistant.Used for places that heat up to 350 ° C. The area of their use is the outer surfaces of stoves and fireplaces - gaps between masonry bricks (but not between stove casting and masonry), sealing joints of brick chimneys, sandwiches and roofs (but not simple metal chimneys), parts of the heating system and hot water, etc. d.

- Heat resistant or heat resistant. Withstand very high temperatures - up to 1500oC. Scope: if we talk about stoves and fireplaces - the junction of casting and masonry, in boilers - in combustion chambers or furnaces, in chimneys - joints and seams, including immediately after the chimney outlet. These compounds can be used in places of direct contact with the flame, but then there must be one more characteristic: fire-resistant or fire-resistant.

One of these sealants is used depending on the temperature and required characteristics. So the oven sealant, depending on the area of application, can be either heat-resistant silicone or heat-resistant silicate. To understand what is the difference between them, what they are, how to use them, consider the properties and characteristics.

Peculiarities

The main active ingredient in the composition of the sealant is a polymer material. Depending on the purpose of the application, it can be silicone, silicate, rubber, bitumen. Sealant is produced in tubes intended for manual use or using a special feeder - an assembly gun.

Depending on its composition, heat-resistant sealant is produced in three types - one-, two- or three-component.

A one-component sealant is a product that can be used in finished form, and the polymerization process of the composition occurs at room temperature for several hours. At the same time, it is not required to apply a sealant in a thick layer - a layer with a thickness of 2 to 10 millimeters will completely cope with the task assigned to it. Each manufacturer indicates more specific parameters on the packaging of their products and they may differ for different brands.

- Two-component sealant consists of a base and a catalyst. The polymerization process occurs when these two components interact. The resulting mixture should be used immediately, as it is not subject to storage.

- Three-component sealant consists of a main component, a curing compound and a catalyst that accelerates the curing process.

Sealants used in high temperature conditions are divided into two categories.

- Heat-resistant sealants withstand a temperature load within 1300 degrees. The components of such a sealant are capable of contact with an open flame. The product contains sodium silicate in its composition. In turn, heat-resistant sealants are fire-resistant or fire-resistant. The difference between them lies in the temperature conditions and a number of characteristics.

- Heat-resistant sealants can be used in those areas of the structure that do not exceed a temperature of more than 350 degrees by heating. As a rule, these are elements of joints, joints and slots on the outer surfaces of the structure.

According to the composition of the polymeric substance, sealing products are of several types.

- Acidic - sealants that form acetaldehyde during polymerization.This substance can destroy or deform the surface that will react with it. Therefore, acid sealants can only be used to a limited extent. So, for example, metal surfaces will quickly corrode, and concrete or cement will give powdered oxidation.

- Neutral - a type of sealant that consists of heat-resistant silicone and releases water and ethanol during polymerization. Their use is safe for all types of surfaces, and therefore these sealants have a fairly wide range of uses. The silicone seam is perfectly restored after any deforming effects, and its service life is at least 15 years.

In addition to distinctive features, all types of heat-resistant sealants share common properties.

- Adhesiveness - the polymer components that are part of all heat-resistant sealing products have good adhesion to work surfaces. They can be used on brick, concrete, metal, glass, ceramic, wood or plastic structures.

- Plasticity - sealing joints after the end of the polymerization time have a certain plasticity. They do not crack, resistant to vibration and temperature extremes.

- Water resistance - polymeric materials have increased resistance when interacting with water and steam.

- UV resistance - polymer sealants are not affected by the damaging properties of ultraviolet rays.

According to the scope of application, heat-resistant sealants can be divided into three types.

- for use in construction and installation works;

- used for the repair of motor vehicles;

- sealants for narrow-profile special purposes.

Composition of refractory dyes

The main difference between heat-resistant paints for metal and conventional paints is that the composition of refractory dyes includes pigments based on substances that are resistant to elevated temperatures.

Most of these dyes contain up to 50% titanium dioxide. Which has a melting point of +1855 degrees and, when added to the paint, reliably binds its components into a homogeneous mass, preventing it from igniting.

Ferrous oxide is added to the mixture, which is not subject to decomposition at high temperatures, and, like titanium oxide, allows the components present in the composition to be more tightly bound. Heat-resistant paint contains chromium oxide, which increases its viscosity and color stability when exposed to high temperatures.

The listed elements are connected using a liquid base, which may consist of synthetic or organic non-flammable substances. Such a composition is used to treat a metal surface, which can be heated up to +1000 degrees.

Scope of application

High-temperature paint for metal is used for painting:

- heating radiators,

- internal combustion engine parts,

- stoves, boilers, fireplaces and various outdoor cooking appliances.

High temperature colors can be used both in production. For example, in the production of drying chambers, roofing materials or machine tools, and at home with the independent construction of fireplaces or stoves.

How to choose

Only the right paint will allow you to qualitatively paint a metal element that is operated at elevated temperatures.

For painting a solid fuel stove, it is also necessary to use refractory dyes. If you ignore this rule, then with significant heating, ordinary paint will not only lose its aesthetic appearance, but can also cause a fire.

Video:

This is interesting: Paint sprayer - description, characteristics, tips for choosing

Popular synthetic products

IRFIX +1500 High Temperature Sealant

An excellent sealant that is suitable for stoves and fireplaces. The maximum operating temperature is 1500 degrees. In this case, the composition will not lose its positive properties. Sold in a convenient 310 ml pack. The minimum temperature for application is 5 degrees.

The average price is 230 rubles.

IRFIX +1500 High Temperature Sealant

Advantages:

- Reliability;

- High-quality adhesion;

- Strength;

- Efficiency.

Flaws:

Mix "Pechnik"

The powder is produced by a popular company in Russia. Most often, this product is used for wall cladding. The manufacturer recommends using the product with the following materials: tiles, ceramics, natural or artificial stone. The solution can withstand temperatures up to 250 degrees without problems. Full drying time - 7 days.

Mix "Pechnik"

Advantages:

- Good adhesive function;

- Elasticity;

- High operational life;

- Long drying, which facilitates the masonry process.

Flaws:

Terracotta

Heat-resistant reinforced glue, which is sold in almost every store and in different volumes.This material is used only for one purpose - facing fireplaces, but the product is also suitable for underfloor heating systems. Using this mixture, a person will be able to work with almost all materials, including artificial stone.

The products of this manufacturer are distinguished by their high-quality composition, good resistance to humidity, and are also able to work with temperatures up to 400 degrees.

Heat-resistant reinforced adhesive Terracotta

Advantages:

- Excellent adhesion;

- Qualitative composition;

- Plastic;

- Price;

- Durability.

Flaws:

PalaTERMO 601

This substance is intended for exterior and interior decoration. The mixture is able to withstand various temperature fluctuations, in addition, it is suitable for working with many materials. In addition to finishing, the product is used for grouting, as well as putty. Therefore, if an unpleasant crack forms in the fireplace, then a person will be able to repair it by applying this material.

The average cost is 490 rubles per 25 kg.

PalaTERMO 601

Advantages:

- Good strength indicators;

- Price;

- Profitability;

- Elasticity;

- Eliminates deformation;

- Reliability.

Flaws:

How to accurately and correctly apply sealant

When working with both types of polymers, it is necessary to prepare the surface of the chimney: clean, remove dust and dirt, and degrease. It is desirable to sand the steel with fine sandpaper to improve the adhesion of the polymer.

The surface under the heat-resistant sealant must be completely dry. The tube is filled into the gun and a small amount of silicone is squeezed onto the sealed joint. Allow to harden (approximate time is indicated on the package).

The base for the heat-resistant silicate polymer is prepared and lightly moistened. Apply sealant and let dry.Excess heat-resistant mass is removed until the sealant has hardened. You can pre-glue the masking tape along the joint, and remove it after application.

It is desirable to perform work in warm weather.

Features of sealing sandwich chimneys

Sandwich pipes have a metal surface. Both silicate and silicone polymers are used for their sealing.

A characteristic feature of sealing sandwich pipes is the need to seal both the inner and outer pipes. In addition to the general safety considerations that were given at the beginning of the article, it is very dangerous for a sandwich to get atmospheric moisture from the outside or condensate from the inside into the insulation.

The outer layer should be coated with silicone - it has excellent hydrophobic properties. For an internal joint, a heat-resistant sealant is selected depending on the type of heater and smoke temperature.

The sealing process itself is not particularly difficult - a bead of sealant is applied to the joined surfaces of the outer and inner layers and gently smeared with a layer of 1-2 mm using a spatula or a steel flat plate, then the chimney modules are joined together.