- How to do without pumping

- Video: about bacteria in the cesspool

- Video: how to extend the life of a cesspool

- Cesspool device options in a private house

- The sequence of the construction of a cesspool of concrete rings

- Expert advice

- Do-it-yourself cesspool equipment without pumping

- Characteristics and types

- Before starting the construction of a drain pit in the country, you should pay attention to the following factors

- To determine the required volume of the drain pit, it is taken into account

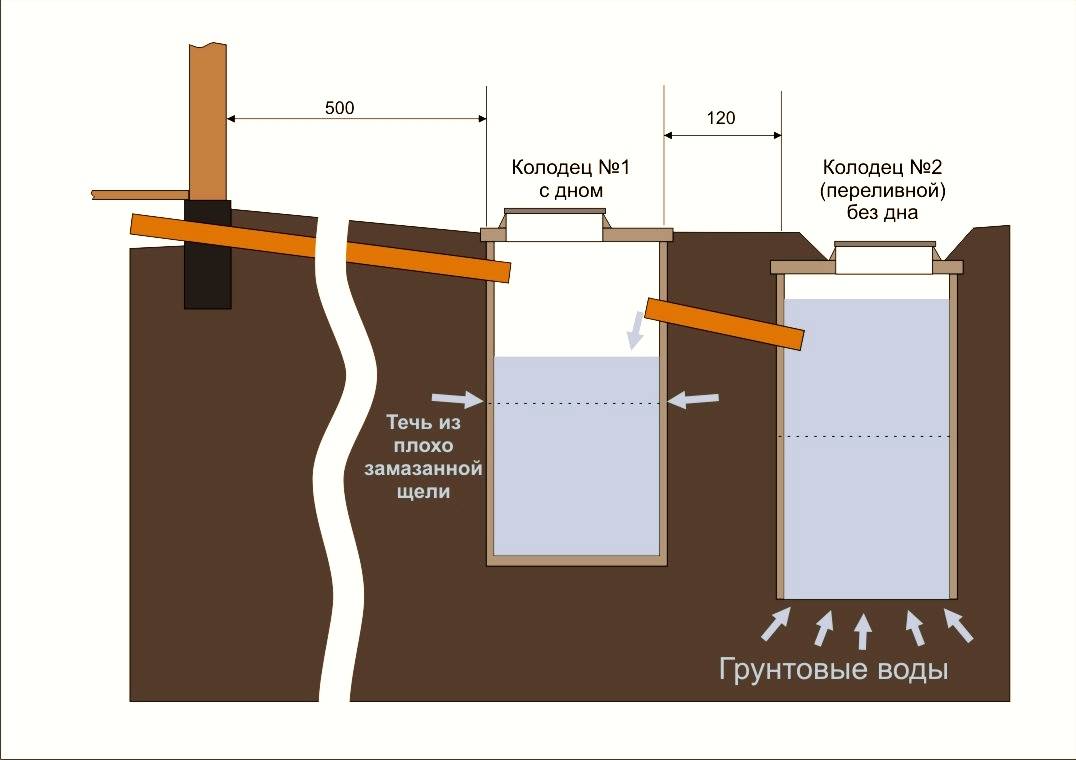

- Pit for drains without a bottom

- Sealed pits

- Installation technology of plastic containers for sewerage

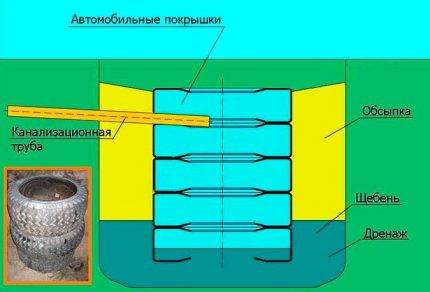

- Tire tank construction

- Features of local sewerage

How to do without pumping

A properly calculated, arranged and filled with bacteria cesspool without pumping out can work for more than 10 years if the daily flow is relatively uniform. In places with cold winters and complex geology that does not allow deepening the cesspool to the horizon with a more or less stable temperature favorable for bacteria, heating the cesspool can stabilize their community.

The launch of the bioseptic after filling with bacteria lasts quite a long time. At a weekend cottage, this may be unacceptable - you already have to leave, but they have not yet swayed. "Cheer up" and sour or overflowing house cesspool.A typical recommendation for this is a complete pumping, cleaning and refilling. But, if you give a “horse dose” of a biological product with the addition of highly valuable nutrition for bacteria, then most likely they will cope with the “hands-on”, and there is no need to call a sanbochka, see next. video:

Video: about bacteria in the cesspool

In the same way, it is possible to eliminate dense plaque that clogs the filters. A sign of its formation - from a normal drain, the pit begins to overflow, but if you let it rest, the level of the contents slowly decreases without a strong smell and foam formation. Activated bacteria will loosen the plaque, and its microparticles will go to the disposal of their soil counterparts. The process will take several days, during which the flow to the cesspool should be limited as much as possible. To quickly remove plaque, baker's yeast or calcium carbide is sometimes used, see for example:

Video: how to extend the life of a cesspool

But this is a very dangerous procedure, because. combustible gases are released that form an explosive mixture with air - methane, acetylene. In addition, cleaning the cesspool in this way does not eliminate the need for pumping, it only delays its duration.

The formation of solid deposits in the cesspool is accelerated and enhanced by improperly arranged sewage systems that require frequent cleaning: pipe cleaners kill bacteria, and the microflora does not process the suspension of solid contaminants from pipes

Therefore, for a long operation of the cesspool without pumping and cleaning, it is important not to make mistakes when installing the sewer system, see the video guide on how to avoid them:

Cesspool device options in a private house

When building a new house, you need to think about where and how to make a cesspool.Of course, a city dweller does not even think about the organization of a wastewater system, another thing is the owner of a private house, this problem is from the category of “pressing” for him. It is clear that for a comfortable stay, the sewer structure must function properly and clearly.

Cesspool depth device.

The cesspool system, with the proper approach and using high-quality building materials, will last a long time.

Before proceeding to construction, consider how it will be cleaned and how much volume you need.

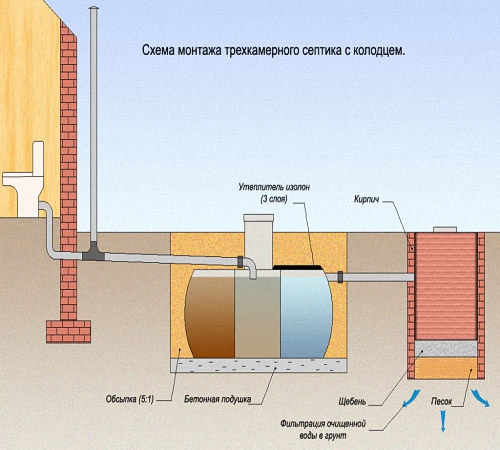

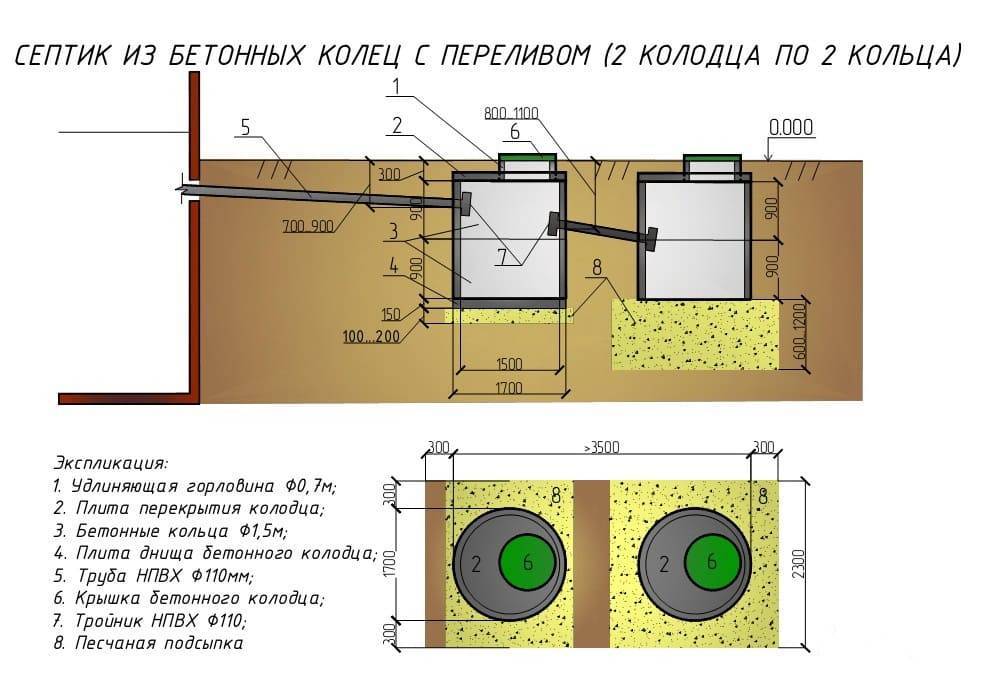

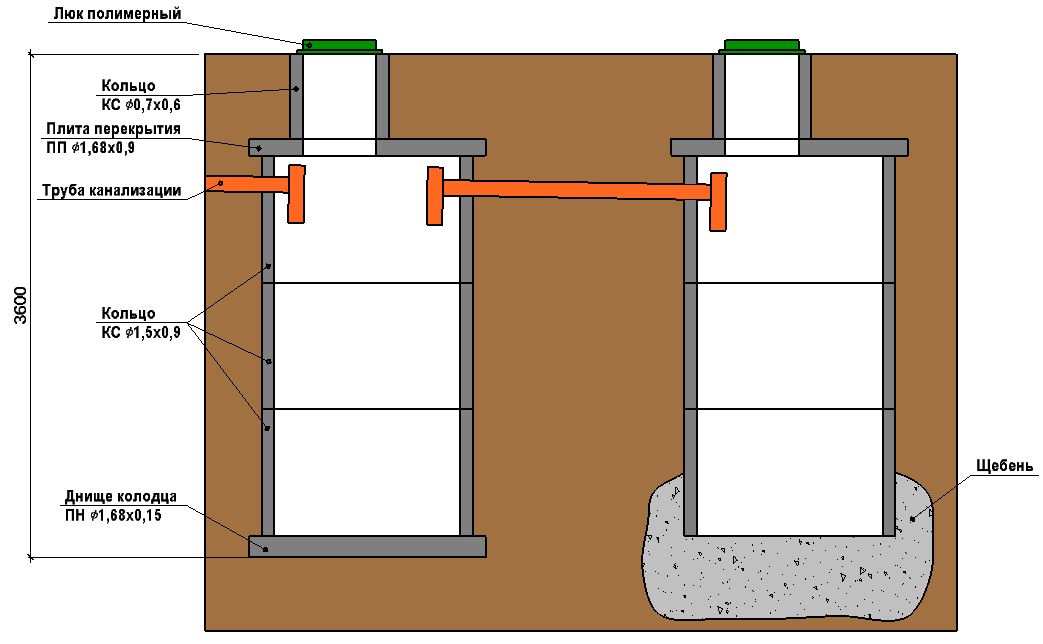

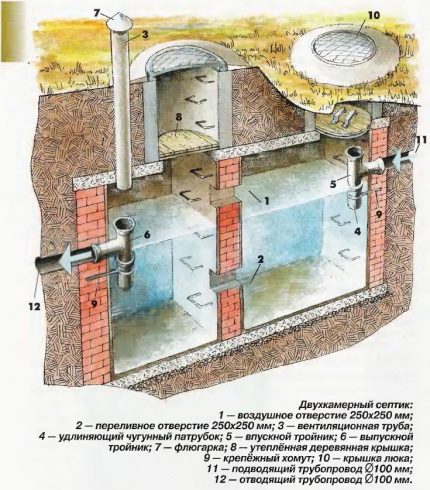

The sequence of the construction of a cesspool of concrete rings

First of all, it is necessary to draw up a detailed drawing, which will indicate the overflow system, the depth of the "well", the inlets and outlets of the pipes. Then prepare all the necessary tools and materials for work. When all the preparation is over, they begin to dig a pit. When digging a hole, you must remember all the requirements of the sanitary instructions.

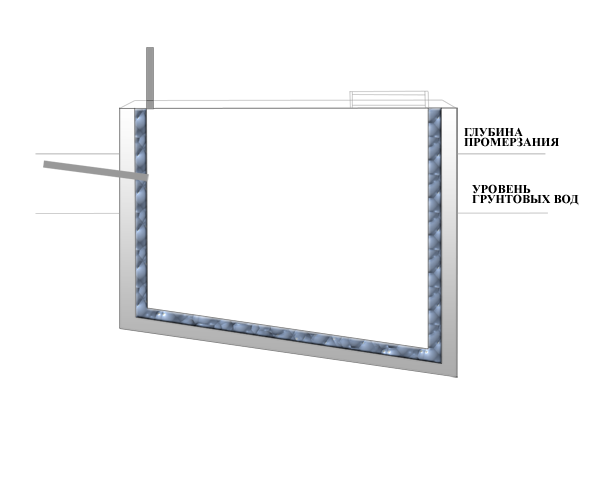

The dimensions of the pit depend on the rings and based on safety requirements. So in close contact with groundwater, good waterproofing is taken care of. When using special equipment, they immediately dig a volumetric pit into two chambers. If do-it-yourself work is done, then a separate pit is provided for each container.

The sequence of installation of concrete rings:

- The bottom must be well tamped and leveled. Next, the plate is mounted on the bottom.

- To concrete the bottom on your own, first a sand cushion is poured. Enough 30 cm of material, after which everything is compacted. Then the formwork, armored belt is installed and everything is poured with concrete.

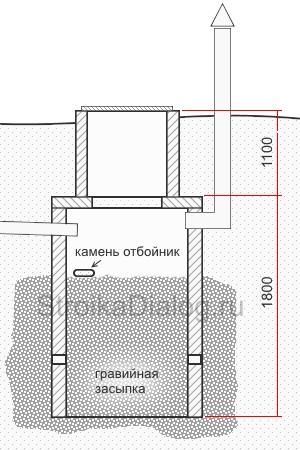

- In the absence of a bottom, another preparation of the base occurs. No need to compact the soil. For filtration, a layer of crushed stone is poured.

- A cement-sand mortar is applied along the edges of the tiled base, on which the first ring lies. Then the rest of the rings are laid according to the same principle.

- When sewerage requires better strength, the rings are additionally fastened together with bolts or metal plates.

- Cut holes for pipes with overflow. Sewer pipes lead into a receiving tank.

The entire structure must be well sealed. All joints, cracks and gaps must be sealed. To do this, use cement or other sealants. These works are carried out on both sides of the rings. Outside the ring, you will also need to additionally lay a layer of waterproofing.

It remains only to install the floors. Channels or corners are mounted on the rings, formwork with a cutout for hatches is placed on them. Next comes the installation of a layer of waterproofing, armored belts and ventilation. The flooded sewer pit is covered with polyethylene. After drying, the film is removed, and the floor is covered with earth.

Expert advice

If you are going to build a cesspool, you need to choose the right place for the building and the material for the structure. It is best to use stone or bricks. If possible, you should choose ready-made containers made of plastic

This material is durable, tight, which is important if there is clay soil on the site

Attention! A tank without a bottom will cost less than hermetic factory-made tanks. Cesspool standard arrangement will cope with its functions if it is not possible to connect to the main sewer line

It is necessary to correctly calculate the parameters and location of the pit, during operation, service it in time

A cesspool of a standard arrangement will cope with its functions if it is not possible to connect to the main sewer line. It is necessary to correctly calculate the parameters and location of the pit, during operation, service it in time.

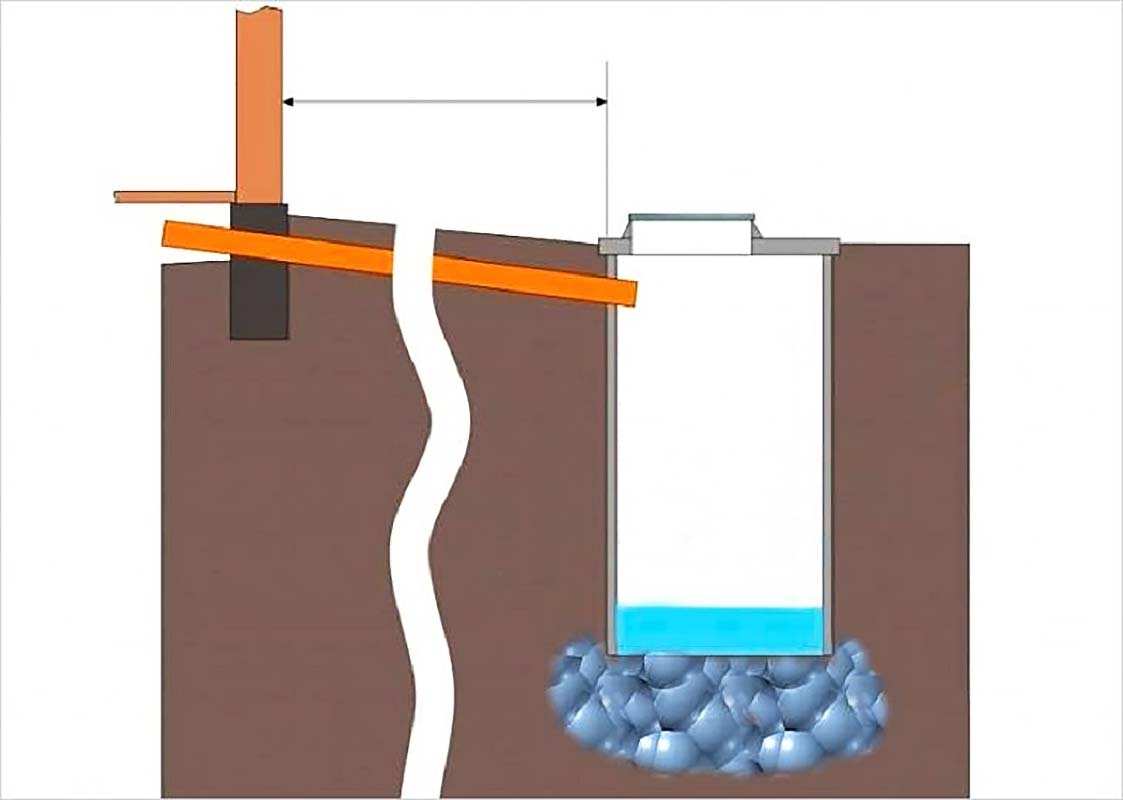

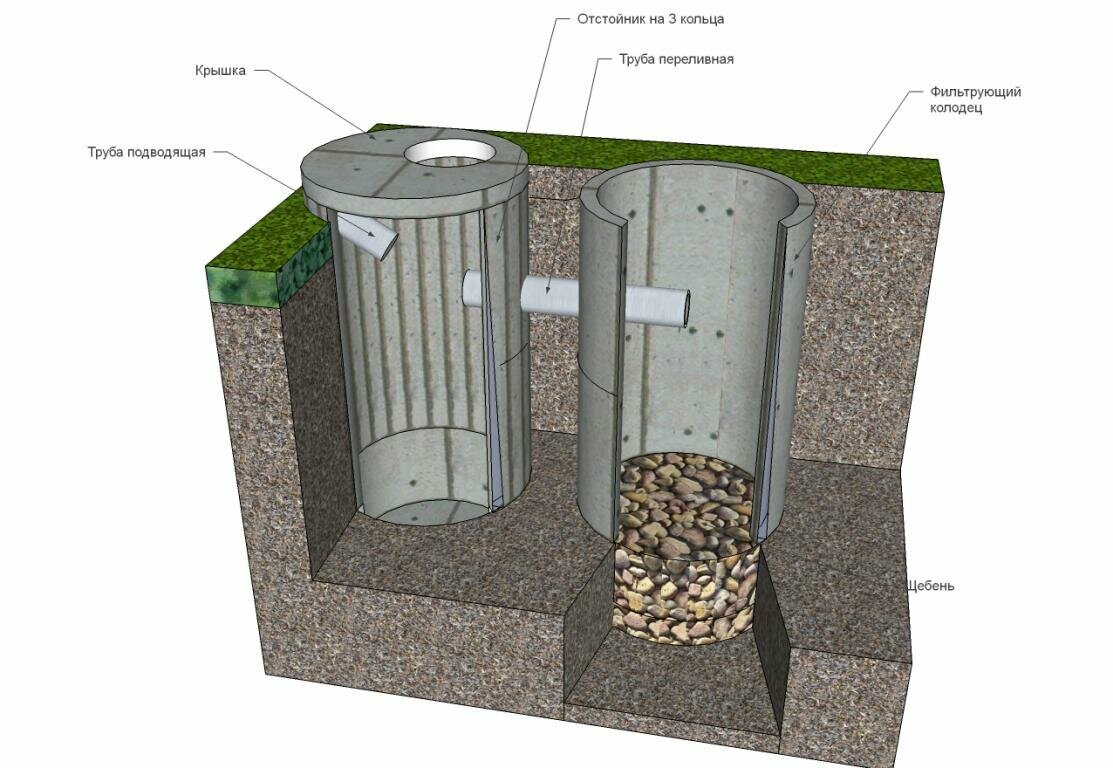

Do-it-yourself cesspool equipment without pumping

The absorption pit provides a self-contained sewer that you can lay out with your own hands. The waste pit has an open bottom, on which a layer of rubble is laid. Liquid drains seep through the stones, while the solid remains in the pit.

Bacteria from the soil feed on organic matter, processing it. The depth of the pit depends on the number of family members and the intensity of the waste. On average, 120-200 liters per day are taken per person. Liquid with water seeps through the gravel after 3 days.

Advantages of a drain pit without pumping:

- Simple arrangement;

- All materials are freely available;

- Quick installation.

But there are also drawbacks to this design. There is always an unpleasant smell from drains. It is also worth noting that an open sewage pit threatens nature.

Characteristics and types

Flexible hose for plumbing is a hose of different lengths, made of non-toxic synthetic rubber. Due to the elasticity and softness of the material, it easily takes the desired position and allows installation in hard-to-reach places. To protect the flexible hose, the upper reinforcing layer is designed in the form of a braid, which is made of the following materials:

- aluminum. Such models withstand no more than +80 ° C and retain functionality for 3 years.In high humidity, aluminum braid is prone to rust.

- Of stainless steel. Thanks to this reinforcing layer, the service life of the flexible water supply is at least 10 years, and the maximum temperature of the transported medium is +95 °C.

- Nylon. Such a braid is used for the manufacture of reinforced models that can withstand temperatures up to +110 ° C and are designed for intensive use for 15 years.

Nut-nut and nut-nipple pairs are used as fasteners, which are made of brass or stainless steel. Devices with different indicators of permissible temperature differ in the color of the braid. The blue ones are used for cold water connections, and the red ones for hot water.

When choosing a water supply, you need to pay attention to its elasticity, reliability of fasteners and purpose. It is also mandatory to have a certificate that excludes the release of toxic components by rubber during operation.

Before starting the construction of a drain pit in the country, you should pay attention to the following factors

-

Place. It is selected taking into account the distance from housing, from the source of water, neighbors and terrain.

- Volume. In the event that the services of vacuum trucks are required, leave a place for the entrance of equipment.

- Determine what material the hole will be made of.

- Consider the stages of installation of the structure

- Decide how to design the appearance of the structure so as not to disturb the aesthetic appearance of the site.

To determine the required volume of the drain pit, it is taken into account

- The number of people living in the house. Average consumption 200l/day per person.

- Accommodation. Permanent or temporary

Pit for drains without a bottom

The simplest type of construction.Drains go into the ground on their own, waste and garbage are pressed. After operation, the pit is dug in and settled in a new place, or vacuum trucks are called, and pumping is performed.

The main disadvantage of such pits is the mass of restrictions during construction. 50 meters from all water intakes, location level, groundwater accounting, distance from home, etc. for non-compliance with standards and pollution of groundwater, a large fine is charged.

- A pit is being prepared with a depth of not more than 0.8 m.

- The bottom is covered with large gravel, the layer thickness is 0.4 m

- Tires are being prepared. The sides are aligned for a snug fit. On the last part of the wheel, a hole is made for the drain pipe.

- Tires are installed one on top of the other, extremely evenly.

- The pit is filled with soil and covered with a lid.

Pit from a plastic barrel:

-

Barrel preparation. A 200 liter tank is perfect. A pipe is mounted at the bottom. It is treated with sealant and covered with geotextile. Sealing is done from the outside and inside of the bottom. Drainage holes are drilled around the entire circumference of the barrel at a distance of 15-20 cm.

- A pit is dug out so that 0.3-0.4 m remains from the barrel to the ground on the sides.

- The bottom of the pit is covered with a mixture of crushed stone and gravel. Layer thickness 0.3m

- The barrel is installed

- Filled with rubble and gravel.

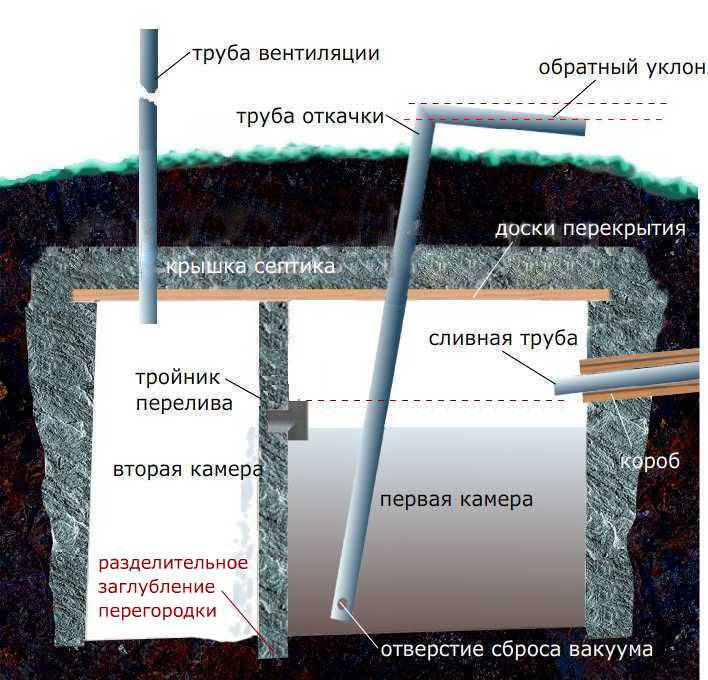

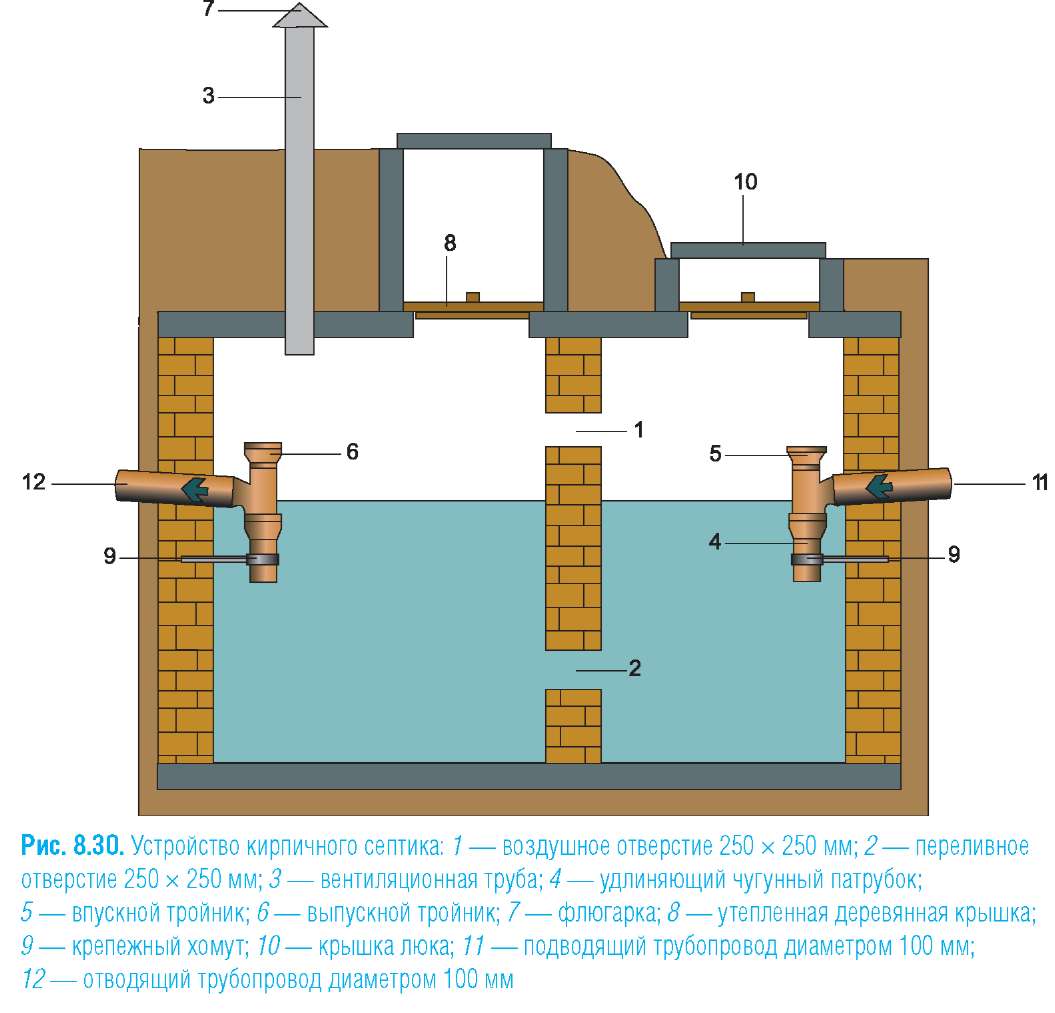

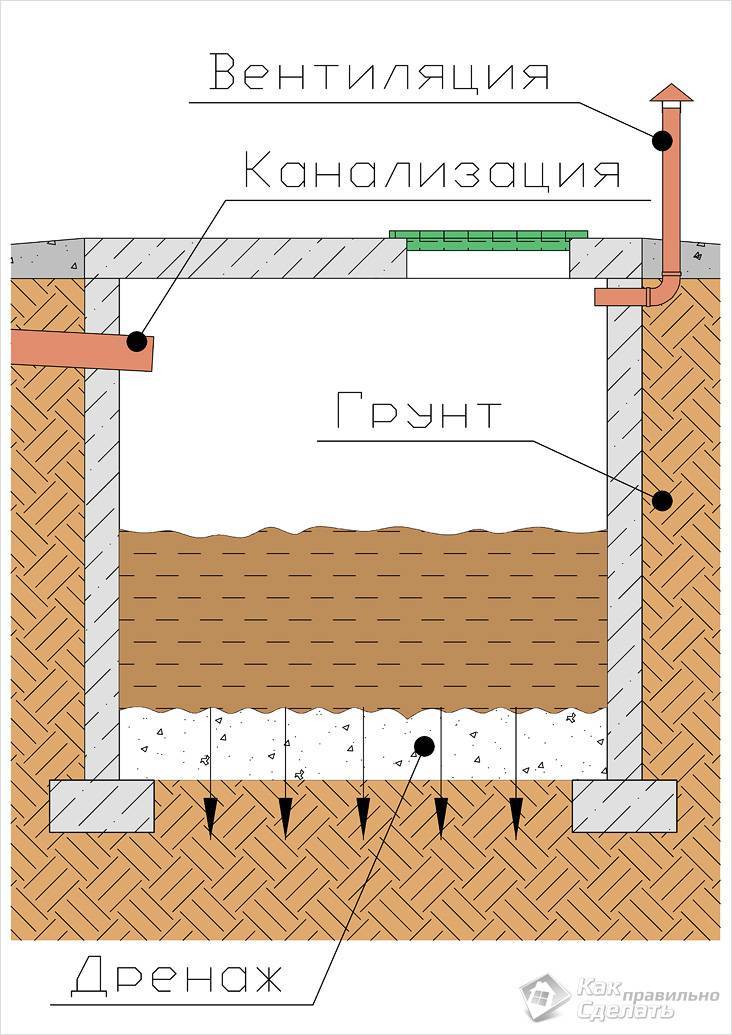

Sealed pits

Such structures are much more reliable than the previous ones. Their installation does not depend on the occurrence of groundwater, they do not harm the environment. A pit is assembled from materials such as wood, concrete and concrete rings, brick.When the structure is ready, waterproofing is performed. Such a hole can be of any size.

Brick pit:

- A pit breaks out

- The bottom is covered with sand and gravel, well compacted and poured with cement mortar.

- After solidification of the bottom. The walls are lined with bricks. You can use any brick, even second-hand or make laying of stone.

- The outer side of the brick structure is waterproofed with roofing material.

- The space between the roofing material and the ground is filled with concrete mortar.

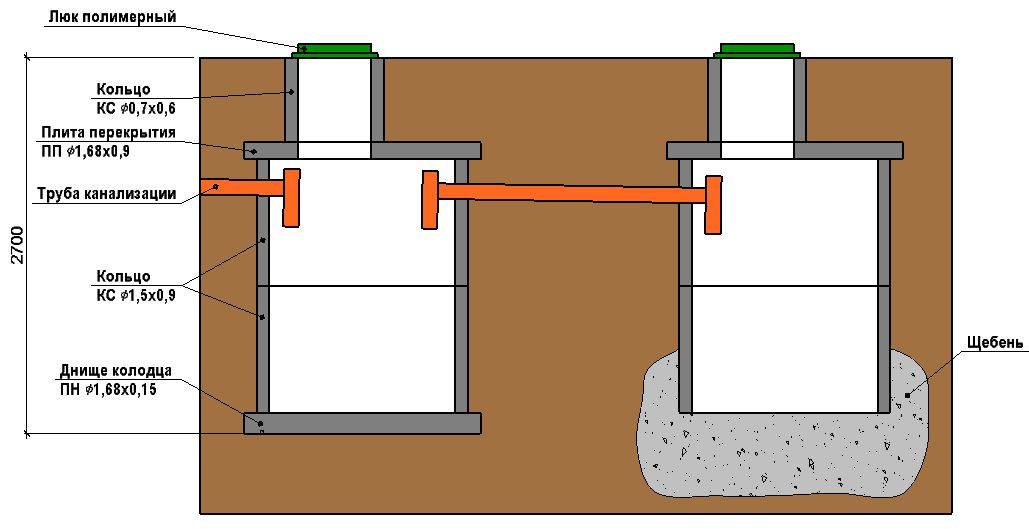

Pit from reinforced concrete rings:

- The pit is being prepared

- The rings are lowered and connected by grooves. The number of rings depends on the depth of the hole. The standard ring height is 1 m.

- Joints are sealed with cement mortar.

- The bottom is being equipped (the technology is the same for sealed pits)

- The void between the rings and the ground is filled with soil.

The design has clear advantages - reliability and long service life.

plastic pit:

The structure is sold ready-made. Installed in a pit. Fall asleep with soil. Plastic is the most durable and reliable material.

Wood pit:

Installation is difficult. And wood is not a cheap material.

-

Pit, larger than the intended design

- The frame is laid.

- The seams are sealed with tow, linen, rope made of natural material.

- The bottom is equipped with wood or a mixture of sand, cement, gravel and water.

- Sealing is carried out with resin, tar or a special sealant. It is advisable to protect the tree from early decay and process it, then paint it with acrylic paint.

- The auxiliary structure is removed from the outside of the pit and covered with soil.

Concrete pit:

- A pit of the desired size and depth breaks out

- Assembling formwork

- Poured with concrete

- After the walls harden, the auxiliary structure is removed and the bottom is made.

- After complete drying, the pit is ready.

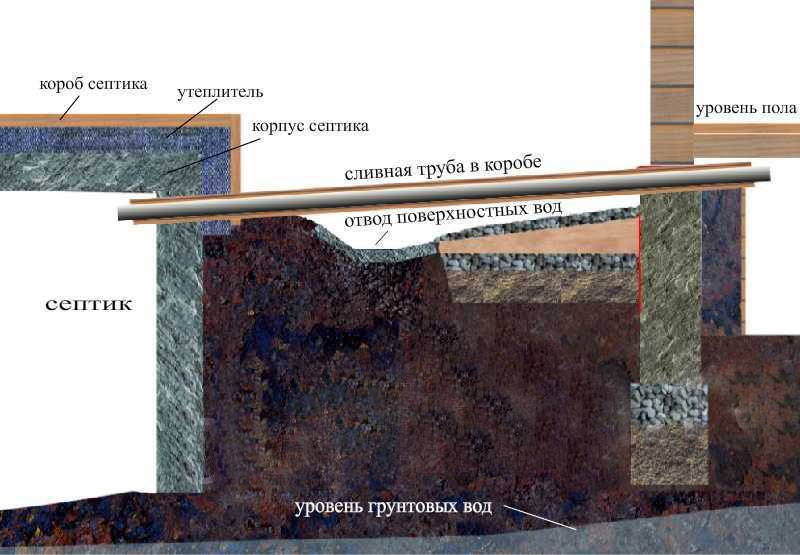

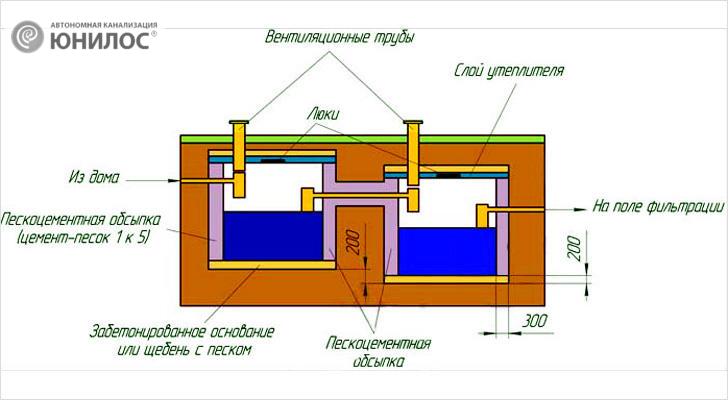

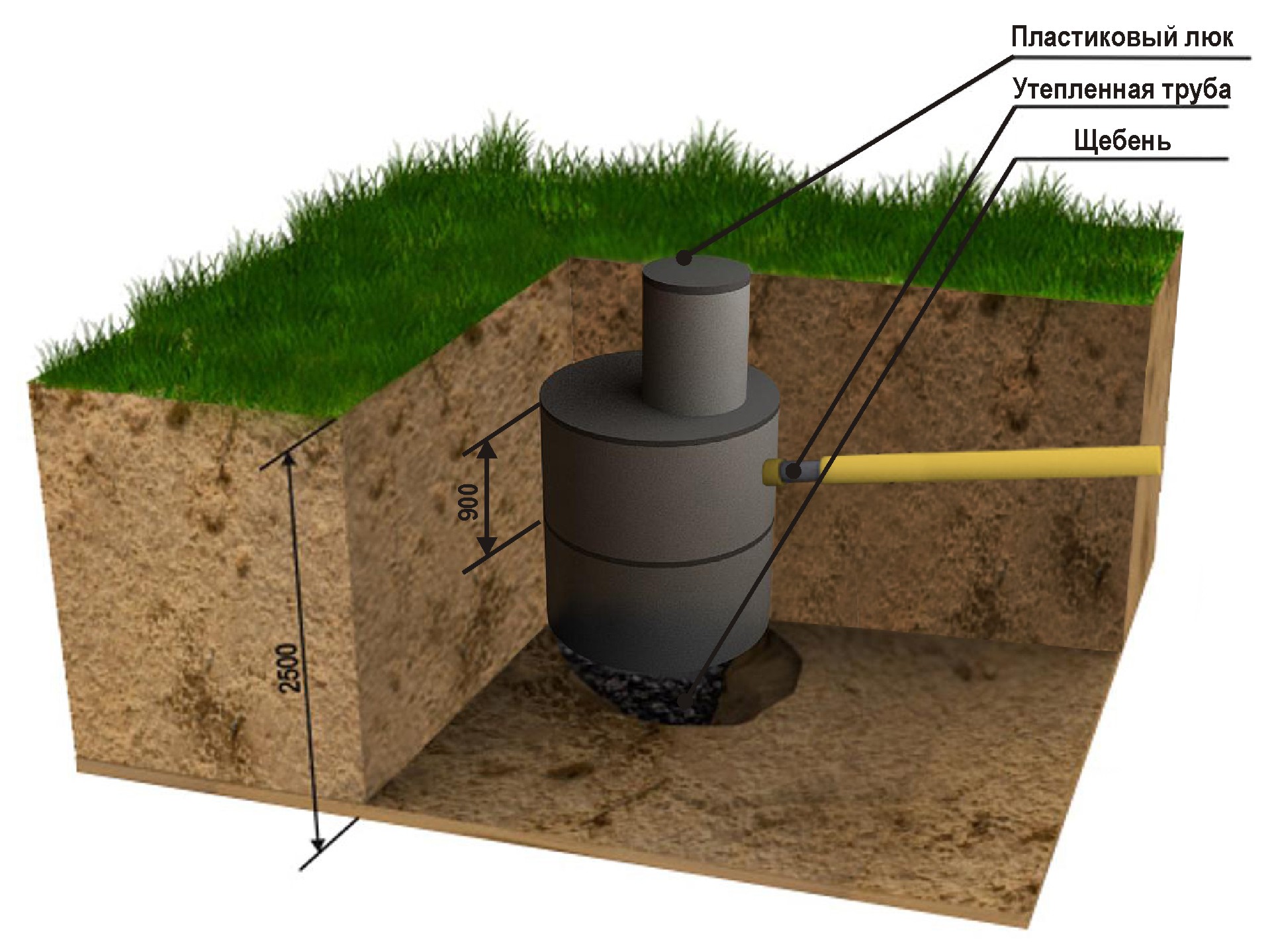

Installation technology of plastic containers for sewerage

With the seeming simplicity of the ongoing construction operations, it is not so easy to install a plastic tank:

- A pit is dug to fit the size and shape of the container. The dimensions of the pit are 50 cm larger on each side. Digging is carried out manually with shovels or an excavator.

- The bottom is leveled and covered with sand, which is compacted.

- A trench is dug from the house to the pit.

- The barrel is being installed inside the pit.

- The gaps between the tank and the walls are filled with sand. At the same time, as the filling is carried out, water is poured into the barrel. This is done so that the walls of the tank do not bend inwards under the action of the sand backfill, thereby reducing the volume of the drain pit. After completion of work, the water is pumped out, releasing it into the garden or outside the site.

- Sewer pipes are being installed from the house to the pit.

- The pipe is connected to the tank by means of a two-way coupling or a socket method.

- Bury the trench with soil.

- The upper part of the sewer plastic container is also covered with soil, leaving only a hatch with a lid on the surface.

- Install the ventilation pipe.

Installation of a plastic container under the cesspool

Often, the upper part of the tank is insulated using one of the modern thermal insulation materials. For example, polystyrene boards. This is in case that in severe winters the water inside the barrel does not freeze. If the groundwater level is high at the site, then the plastic container must be fixed so that it does not float in the spring with an increase in water under the ground. They do it like this:

- below the bottom of the pit, at least two holes are dug on opposite sides with dimensions of 40x40x40 cm;

- a concrete solution is poured into them, into which a rod is inserted, bent into hooks on both sides;

- after the cabinets have dried, the tank is mounted, which is attached to the hooks with chains, steel cables or any other materials that do not rot in the ground, that is, they are thrown over the barrel from one to the other, which is why the cabinets are built on opposite sides of the pit.

Fastening the barrel with straps

Tire tank construction

The main advantage of a cesspool from tires is a long service life and the use of practically free material. The building will serve properly for more than 30 years.

For work, you can use tires of any modification - both those that are installed on cars, and tires over a meter designed for trucks

The end parts of the tires can not be cut off. But untreated car tires will reduce the filter's plan dimensions. As a result: with frequent use of the structure, the bottom quickly silts up and stops filtering water quickly and efficiently.

Therefore, in order to simplify the laying of automobile tires and prevent the accumulation of solid waste in the protruding rims, it is advisable to cut the end parts of the tires with a jigsaw, forming a flat plane.

The construction of a pit from tires is carried out in several stages:

- Determining the diameter of a hole in the ground. The calculation is made based on the outer section of the selected tires.

- Digging a mine. It can take several days to carry out earthwork by hand.

- Bottom arrangement.At the central point of the bottom, using a garden drill, a drainage hole is drilled for the installation of a borehole pipe. The well will pass wastewater through itself, delaying sediment.

- Formation of a drainage "cushion". The bottom of the pit, equipped with a well, is sprinkled with a 15-centimeter layer of crushed stone with sand filler. A filter layer of at least 85 cm of sand is arranged on top of the gravel cushion.

- Tire installation. Tires are sequentially stacked on top of each other and fastened together with a bolted connection. A hole is made in the side surface of the upper tire for the introduction of a pipe to discharge wastewater.

- Seam sealing. Joints and seam contours are treated with sealant.

- Backfilling the pit. For the arrangement of additional waterproofing, it is better to seal the outer walls of the sewer structure from tires first with clay.

- Structure cover. The pit is covered with boards upholstered with roofing material.

- Protective cover installation. It is best to use a finished product made of polymeric materials.

If additional wastewater treatment is planned in the drainage sewer system, then drains are connected to the well. These are pipes laid with a slope towards the filtration fields with drainage holes along the entire length.

To equip an additional filter and improve the final quality of cleaning, a polypropylene mesh is pulled onto the pipe walls.

The number of tires depends on the depth of the structure; on average, it takes 5-7 tires to equip a pit that needs to be pumped out of sewage equipment (+)

The number of tires depends on the depth of the structure; on average, it takes 5-7 tires to equip a pit that needs to be pumped out of sewage equipment (+)

Ventilation is not a mandatory element of an absorption waste tank. But experts still recommend installing an outlet pipe.It should rise above ground level by about 60 cm.

In the future, with intensive use, such sewer structures require cleaning 1-2 times a season.

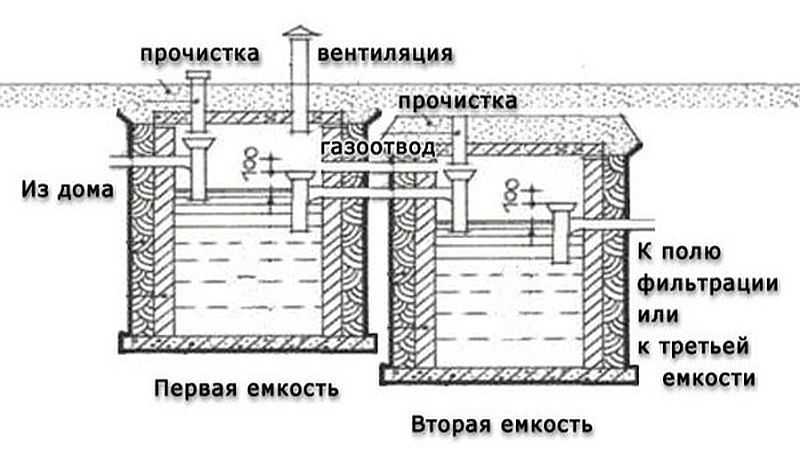

Features of local sewerage

The operation of a suburban household is associated with the generation of wastewater. Every homeowner is faced with the task of not so much accumulating domestic wastewater as cleaning it. Moreover, the solution common in rural areas - digging an old barrel or tank under the sewer cesspool - is ineffective.

If the daily volume of wastewater exceeds one cubic meter (1000 l), then the shortcomings of the "barrel" septic tanks will soon manifest themselves as unpleasant odors. Or worse - intestinal infections among households. Finally, a do-it-yourself drain pit from a worn-out keg is illegal in a number of situations.

RF regulations require private homeowners to comply with measures to protect groundwater from pollution by domestic sewage.

The Law “On the Sanitary and Epidemiological Welfare of the Population” (No. 52-FZ of March 30, 1999) and “Hygienic Requirements for the Protection of Groundwater from Pollution (SP 2.1.5.1059-01) oblige homeowners to solve the problem of wastewater.

The location of the drain pit in relation to the house and the source of drinking water must be observed. Otherwise there will be infections.

In turn, "Sanitary rules for the maintenance of the territory of populated areas" (SanPiN 42-128-4690-88), "Planning and development of gardening (country) associations of citizens, structures and buildings" (SNiP 30-02-97), as well as " Sewerage.

External networks and structures (SP 32.13330.2012) standardize the conditions for the organization and operation of "pit" sewage:

- distance from the house to the drain pit - from 8 m;

- distance from the well (spring trapping) - from 50 m;

- distance from a neighboring household (fence) - from 2 m;

- deepening of the cesspool capacity is carried out to the level of groundwater, but not more than 3 m;

- cleaning is carried out upon filling, but at least once a year.

Please note that the condition for the distance from sources of drinking water is valid regardless of where these sources are located. Those

Whoever the nearest well turns out to be - yours, neighborly or public - it is permissible to arrange a cesspool pit strictly 30 meters from it. Otherwise, there will be costs for fines, reconstruction of the cesspool to a two-three-chamber septic tank and restoration of the ecological balance in the soil layers

Those. Whoever the nearest well turns out to be - yours, neighborly or public - it is permissible to arrange a cesspool pit strictly 30 meters from it. Otherwise, there will be expenses for fines, reconstruction of the cesspool to a two- or three-chamber septic tank and restoration of the ecological balance in the soil layers.

In a drain pit of two chambers, sewage suspensions settle and sewage clarification occurs much better than in a single-chamber bunker (+)

In a drain pit of two chambers, sewage suspensions settle and sewage clarification occurs much better than in a single-chamber bunker (+)