- How to choose a voltage stabilizer for a gas boiler

- Types of voltage stabilizers for gas boilers

- Stabilizer Selection Criteria

- Determination of the required power of the stabilizer

- Conclusion

- Why do you need a stabilizer

- Main types

- Why do you need a stabilizer in the heating system?

- Stabilizer Power

- Types of stabilizers

- How to choose a stabilizer

- Manufacturers of electronic and mechanical stabilizers

- Rating of the best stabilizing devices

- Conclusion: which stabilizer for a gas boiler to choose

- Voltage stabilizers for gas boilers - how to choose the type and power

How to choose a voltage stabilizer for a gas boiler

We have already decided that the optimal voltage stabilizers for heating boilers are electronic units. Now we will teach you how to choose these appliances correctly. There is nothing complicated about this, you do not need special education.

The pump is a reactive load, so at the time of start it consumes much more than when it enters the operating mode. That is why we need such a large stock.

The most important parameter is the power of the voltage stabilizer for the gas boiler.It is calculated very easily - we look into the passports for the boiler and the circulation pump, calculate the power consumption, multiply it by 5 and add another 10-15% of the figure obtained for reliability.

Stabilization accuracy is an equally important parameter when choosing a stabilizer for a gas boiler. The maximum rate is 5%, the lower the better. It makes no sense to take models with an indicator above 5%, since this does not look like normal voltage stabilization in any way.

We also pay attention to other parameters:

- The presence of a voltmeter - it is convenient to evaluate the current voltage at the input and output;

- Stabilization speed - the higher this parameter, the faster the correct output voltage is reached;

- Input range - here you need to focus on the differences in your own electrical network. Most stabilizers for gas boilers successfully operate in the range from 140 to 260 volts.

The brand is no less important - it can be domestic or foreign, it does not matter much. We advise you to purchase stabilizers for gas boilers of the brands Resant, Shtil, Ruself, Energia, Suntek, Sven, Bastion.

An interesting fact is that some manufacturers produce stabilizers with a stabilization accuracy of more than 5% and at the same time recommend them for use.

Types of voltage stabilizers for gas boilers

Commercially available stabilizers can be classified according to the principle of operation.

Electromechanical (servo). The principle of its operation is based on the movement of a current-collecting brush by a servo drive along the contacts of a booster transformer. This design is able to regulate the voltage in a wide range of values. However, in this case, operation is possible only in warm rooms.In addition, the electromechanical regulator requires periodic replacement of brushes and is sensitive to dust.

Relay (electronic) stabilizers for a heating boiler. In such models, switching between the windings of the transformer is carried out using a relay. Thanks to this feature, there are no moving parts in the device, which increases its reliability. At the same time, the characteristics largely depend on the number of steps of the autotransformer. Therefore, before buying such a stabilizer, you must make sure that the declared sensitivity and range of adjustments comply with the requirements of the boiler manufacturer.

Triac (thyristor). Current parameters are adjusted by semiconductor devices - thyristors. This results in a very high response speed. In addition, thyristor devices are distinguished by their reliability, noiselessness and insensitivity to operating conditions. The disadvantage is the relatively high cost.

Double conversion stabilizers (inverter). Their feature is the absence of a massive transformer. The current supplied from the network is rectified in them, regulated to the required values, after which the inverter performs a reverse conversion to alternating. Additionally, energy is stored in the capacitor, which improves the performance of the stabilizer.

PWM stabilizers. Pulse-width modulation (PWM) involves voltage stabilization using a pulse generator

Thus, it is possible to obtain optimal frequency characteristics of the output current, which is extremely important when operating with gas boilers. In addition, the stabilizing equipment of this type is able to maintain operability with significant drawdowns in the power grid.

Ferro-resonance stabilizers

This is the oldest type of stabilizing device, which appeared on sale in the middle of the last century. They are based on the principles of saturation of magnetic transformer cores. To date, domestic use of such devices practically does not find the form of design complexity and high cost. They are mainly used in industry, where they are valued for their high accuracy of output parameters and fast response time.

Stabilizer Selection Criteria

Voltage stabilizers, in addition to the advantages and disadvantages inherent in each type, have common technical characteristics:

Voltage stabilizers, in addition to the advantages and disadvantages inherent in each type, have common technical characteristics:

- Number of phases;

- Permissible load power;

- Voltage normalization rate;

- Installation accuracy;

- Input voltage range;

- Output voltage shape;

- Operating temperature range.

Individual heating systems are usually designed to be powered by a single-phase network. Load power is the most important characteristic of any stabilizer. This parameter determines what load power can be connected to the stabilization unit.

Determination of the required power of the stabilizer

To determine the required power of the stabilizer, it is necessary to separately calculate the active and reactive loads. In this case, the control circuit is an active load, and the fan and circulation pump are reactive. The power of a compact heating boiler usually varies from 50 to 200 watts, and the circulation pump can have a power of 100-150 watts. Often the documentation indicates the thermal power of the pump.

To find out the total power, you need to divide the thermal power by cosine phi, and if it is not specified, then by a factor of 0.7 (P thermal / Cos ϕ or 0.7).At the moment the pump is turned on, the current consumption increases by about three times. This lasts no more than five seconds, but it is necessary to take into account the starting current, so the result is multiplied by three.

After calculating all the capacities, the data are summed up and multiplied by a correction factor of 1.3. As a result, the formula will look like this:

Stabilizer power \u003d Power of the automation unit + (pump power * 3 + fan power * 3) * 1.3.

The fastest stabilizer is an electronic device based on thyristors, and the slowest is an electromechanical device with a servomotor. The servo-driven stabilizer will not have time to work out the instantaneous change in mains voltage, and the boiler control unit will fail.

The fastest stabilizer is an electronic device based on thyristors, and the slowest is an electromechanical device with a servomotor. The servo-driven stabilizer will not have time to work out the instantaneous change in mains voltage, and the boiler control unit will fail.

The voltage setting accuracy is not an important parameter, since even a cheap stabilizer for a gas boiler provides an accuracy of ± 10%, and this value corresponds to the domestic standard.

The most unpretentious stabilizer in relation to temperature is an electronic device with thyristor control. It can be operated in the range from -40 to +50 degrees.

Conclusion

Summing up, we can make an unambiguous conclusion - the best stabilizer for a gas boiler is a microprocessor-controlled thyristor device that provides a smooth sinusoid at the output.

In a large house with a complex heating system, there are usually several pumps to move the coolant, so experts recommend in such cases to install two stabilizers, one of which will provide high-quality voltage to the automation of the heating boiler, and the other will work only for circulation pumps.This will greatly increase the reliability of the system.

Why do you need a stabilizer

Domestic electrical networks should provide electric current with a voltage of 220 V. But there is a significant difference between “should” and “give” - if you put the multimeter probes into the outlet, it turns out that the voltage is 180, 200, 230, or even 165 Volts, depending on network congestion. Moreover, the readings constantly fluctuate both smoothly and abruptly. And it's impossible to do anything about it.

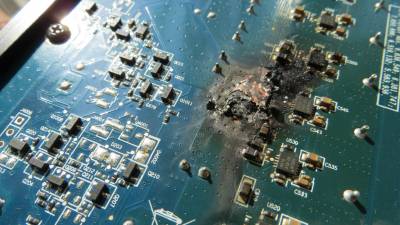

Due to power surges, all household appliances suffer. Some endure the jumps more or less calmly, while the other, in need of stable nutrition, begins to fail. Most of all, heating boilers need stability - this is confirmed by specialists who often encounter burnt electronics. Moreover, for boilers and their electronic filling, both power drawdowns and increased voltage are equally dangerous.

In some cases, a burnt board can cause significant damage to the gas boiler itself, but this does not happen so often.

The most unpleasant thing in this whole situation is that the repair and replacement of gas boiler electronics results in a fortune - the cost of some boards reaches 10 thousand rubles, or even more. Not surprisingly, experts recommend the use of stabilizers. At a low cost, they are able to protect sensitive equipment and extend its uninterrupted service life.

Main types

There are different types of stabilizers supply for gas boiler:

- servo-driven. They are otherwise called electromechanical. This is the simplest design that came from the times of the USSR. The principle of operation of such a device is to use an autotransformer, along the windings of which carbon brushes move.When the input voltage changes, the position of the brushes is changed by a servo drive, which creates a predetermined voltage of 240 V 50 Hz at the output. Such designs are simple and cheap, but their speed does not allow solving the problem in the desired mode. The difference in time between the change and the reaction of the device to it allows the boiler electronics to work in a dangerous mode for moments. Because of this, control boards often burn out, despite the connected stabilizer;

- relay. The device of these devices resembles the operation of an autotransformer. Its coils are divided into several sections giving different values. When changing the power supply parameters in the network, a special relay switches sections, correcting the output value of the device. These stabilizers are relatively inexpensive, but have a large margin of error (typically 8%) associated with the stepped type of adjustment. In addition, the speed of relay stabilizers is low, which endangers the delicate electronics of the gas boiler. The advantages of relay devices are reliability and low maintenance requirements;

- thyristor. These are modified versions of relay stabilizers. The difference is that instead of a relay, the switching of the windings occurs at the command of the thyristors. This greatly increases the speed, as well as the service life of the device. Such designs can withstand up to a billion switching operations without loss of performance. The disadvantages of thyristor devices include the discrete (stepped) nature of switching, which sets a high error at the output (the same 8%);

- inverter stabilizers. These are the most accurate and high speed devices. Otherwise they are called double conversion stabilizers. They have a different design.There is no autotransformer, which makes the devices light and compact. The principle of operation has also been changed - the input alternating current is passed through the filter and becomes constant. A certain amount of energy is stored in the capacitor in order to give a charge at the right time to maintain the flow parameters. Then the inverse conversion into alternating current with a given value is performed. All actions are performed at lightning speed, in continuous mode. The output values are continuously adjustable with high precision. The only drawback of the devices is the high cost.

The most effective models are inverter stabilizers, however, all other devices are in demand and are used to work with various equipment.

Why do you need a stabilizer in the heating system?

In private houses, foreign-made heating boilers are usually installed, which can very easily fail if the mains voltage differs significantly from the nominal value. In the countryside, such deviations happen all the time, but even if the house is located within the city, no equipment is immune from strong network deviations. Most often, power surges occur in the evening, when most institutions and enterprises that do not have a night shift are closed.

The control unit of an imported gas boiler is very sensitive to even small voltage changes. There is an automation system that, in case of power surges, can block the operation of the heating boiler, and only the masters from the service center can unlock and restart it.

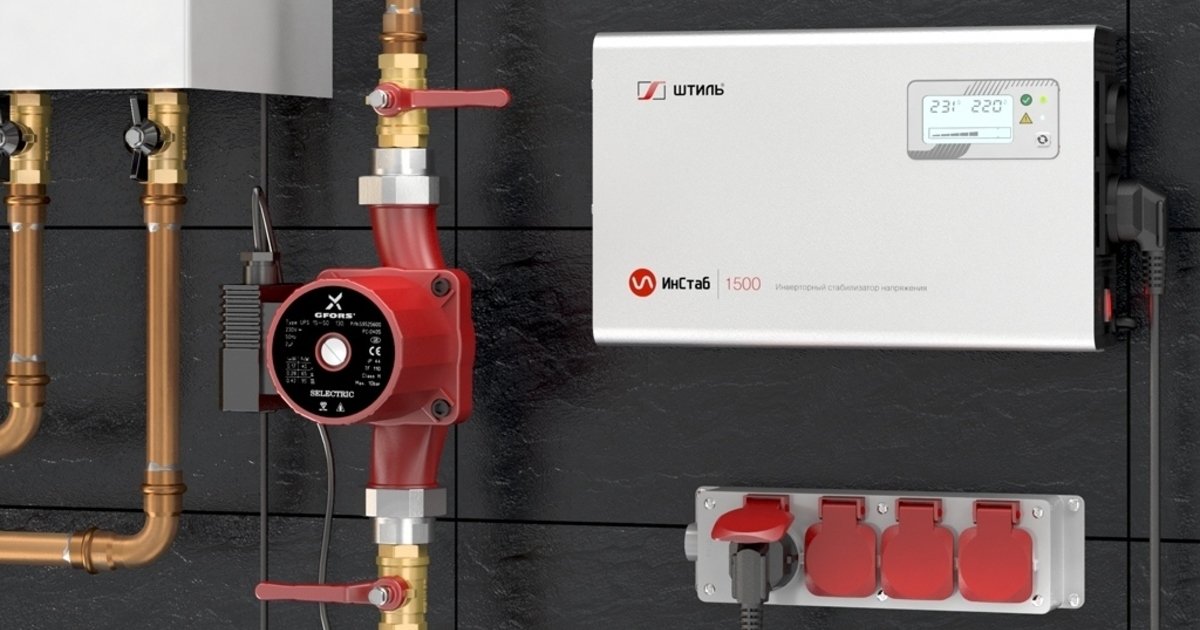

The circulation pump, which is an integral part of heating systems, also needs a stable mains voltage, so the use of an autonomous heating system without a voltage stabilizer is generally unacceptable in principle. To understand which voltage regulator is best for a gas boiler, you need to familiarize yourself with the characteristics of different types of devices.

Stabilizer Power

It is necessary to calculate the maximum load that your boiler equipment will set. The power consumption of the boiler itself and the built-in pump, an external pump, as well as additionally installed equipment are taken into account. In this case, starting currents must be taken into account.

Due to the difference in power factors, the actual consumption will differ from the nominal. And this discrepancy can be 1.3-1.5 times.

The transformation ratio also has an effect. Taking into account the current-voltage characteristics and calculate the required power according to the most characteristic value of the voltage before stabilization.

Types of stabilizers

The period of maintenance-free operation of gas a boiler with a pump and ignition from the mains depends on a stable and constantly the same voltage. Therefore, the inclusion of a stabilizer in the boiler operation scheme, if not necessary, is highly desirable. Modern stabilizers are divided into three types:

- Relay type - the cheapest, but not the most durable devices. Burning contacts forces the owner to change the device every 3-4 years. The stabilization amplitude accuracy also leaves much to be desired.

- Servomotor-based stabilizers can smoothly equalize the output voltage, but they operate more slowly, which increases the risk of an accident.

- Electronic circuits based on controlled thyristors (triacs) and microprocessors are durable, have high stabilization accuracy, are silent in operation and instantly respond to power surges in the network.

According to other parameters, stabilizers are divided into direct or alternating current devices, floor or wall structures, single-phase or three-phase devices. The table shows the technical characteristics of the most popular stabilizer models in 2014. The analysis shows that the electronic device can work in any conditions, with any voltage drops. The electronic stabilizer does not distort the shape of the voltage, which means that the gas boiler will work stably and reliably.

A mechanical or servo stabilizer has a longer response time for input voltage and current fluctuations. That is, during amplitude jumps, the mechanical device does not have time to equalize the amplitude and voltage fluctuations enter the electronic and electrical devices of the boiler. Fluctuations are rare, but often cause damage to the load electronics.

Therefore, only the owner of the unit can answer the question of which voltage stabilizer for a gas boiler is better. The cost of the device, and the requirements for it, and even the dimensions of the stabilizer play a role. Since a gas boiler is expensive, it makes sense to put a more expensive, but high-quality stabilizer for its maintenance, and not save on trifles.

How to choose a stabilizer

When buying, start from the main parameters:

- The power of the stabilizer is determined by the total power of the loads - a pump, a control panel, a gas burner and other automation elements. The standard stabilizer power is 150-350 watts.

- Instrument output voltage range.

- Mains voltage. To determine the voltage difference at different times of the day, measurements should be taken periodically, and then the arithmetic average should be taken.

Requirements for a quality stabilizer for a gas boiler:

- Aesthetic appearance.

- Small size and plenty of power.

- Possibility of wall or floor placement.

- Simplicity and reliability.

- Quiet operation and reliable thermal operation.

- Electronic execution.

- The price of the stabilizer should justify its technical characteristics.

If we talk about the price, then the miser pays twice. Choose a stabilizer with enhanced performance in relation to requirements - situations are different. If you have an expensive boiler installed, then the protection must match. Therefore, buy a stabilizer from a branded manufacturer, preferably with recommendations - from friends, from consultants or gas masters.

Manufacturers of electronic and mechanical stabilizers

Popular models of stabilizers of foreign and domestic production:

| Features \ Model | Snap-500 | VEGA-50-25 | RESANTA ASN-2000 | Shteel-1000 |

| Stabilizer | Mechanical | Electronic | ||

| Power | 500 W | 500 W | 2000 W | 1000 W |

| Adjustment speed, sec | 1,0 | 0,3 | 0,5-0,7 | 0,2 |

| Input voltage | 150-250V | 172-288 V | 140-260 V | 132-260 V |

| Voltage accuracy at the output of the stabilizer,% | 1 | 0,5 | 1,5 | 2,5 |

| Protection | Not | There is | There is | There is |

| Working temperature | -5/+40°C | -25/+45°C | 0/+45°C | +5/+40°C |

| Lifetime | 1-3 years | 7-15 years old | 5-10 years | 10-20 years |

| Dimensions | 175x190x140mm | 275x425x260mm | 100x183x240mm | 240x170x120mm |

| Weight | 4 kg | 16 kg | 4.2 kg | 6 kg |

| Service Warranty | 1 year | 5 years | 2 years | 5 years |

| Manufacturer | PRC | Italy | Russia | Ukraine |

| Price | 30 $ | 600 $ | 700 $ | 140 $ |

As you can see, the cheapest are Chinese mechanical devices. Russian stabilizers are the most expensive in their range of capacities and other technical characteristics. However, the cost is always justified. Therefore, advice from the pros: do not chase after savings - it can turn out to be expensive for you.

Rating of the best stabilizing devices

We bring to your attention our own TOP 7 of the best 220V stabilizers, which we compiled after studying numerous ratings of electrical appliance stores and customer reviews. Sorted model data in descending order of quality.

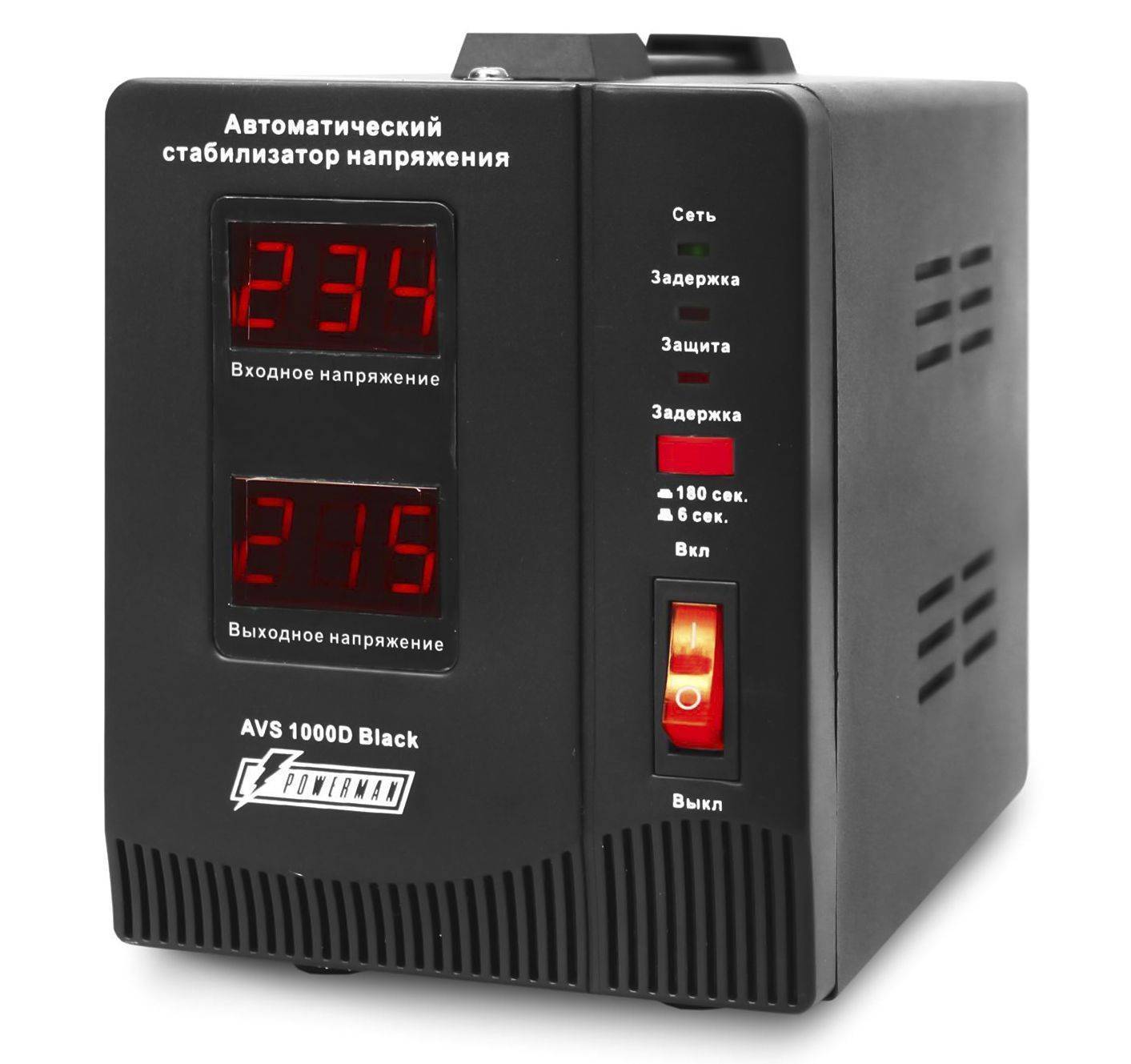

- Powerman AVS 1000D. Toroidal unit with high quality standards: low noise level, high efficiency, small dimensions and weight. The power of this model is 700W, the operating temperature is within 0...40°C, and the input voltage ranges from 140...260V. It has six adjustment levels and two outputs, and the reaction time is only 7 ms.

- Energy Ultra. One of the best electronic models for the buderus, baxi, viessman gas boiler. It has high technical parameters: load power 5000-20,000W, range 60V-265V, temporary overload up to 180%, accuracy within 3%, frost resistance from -30 to +40 °С, wall mounting type, absolute noiselessness of operation.

- Rucelf Boiler-600. An excellent device in a high-quality metal case, inside of which there is a well-insulated autotransformer.It has high technical parameters: power 600W, range 150V-250V, operation within 0 ... 45 ° C, four steps of adjustment, and the response time is 20 ms. There is one euro socket, which is located below. Wall mounting type.

- Resanta ACH-500/1-Ts. A relay-type device with a power of 500 W and an input voltage of 160 ... 240 V. Products of the Resanta brand have two design variations. The response time is 7 ms, it has four adjustment levels and built-in protection against overheating, short circuit, high voltage. Connects to a grounded outlet.

- Sven AVR Slim-500. Despite the Chinese origin, the relay device has decent mounting quality and technical characteristics: power 400W, four adjustment levels, input voltage in the range of 140 ... 260 V. Sven is able to operate at temperatures from 0 to 40 ° C. Equipped with a toroidal autotransformer with an overheating sensor. The response time is only 10ms.

- Calm R600ST. The only electronic stabilizer designed specifically for gas stakes. Thanks to triac switches, the operating voltage ranges from 150 to 275V. Device power - 480W, temperature range - 1 ... 40 ° C, four-stage adjustment, response time is 40 ms. There is a separate circuit for each of the two Euro sockets. Completely silent operation.

- Bastion Teplocom ST-555. Another model of the relay type, but whose power is an order of magnitude lower - 280 W, and the input voltage is 145 ... 260 V. Also, unlike the Resant brand, Bastion's reaction time is 20 ms, and the number of steps is only three. In addition, the device heats up during operation and there is no automatic fuse in it.

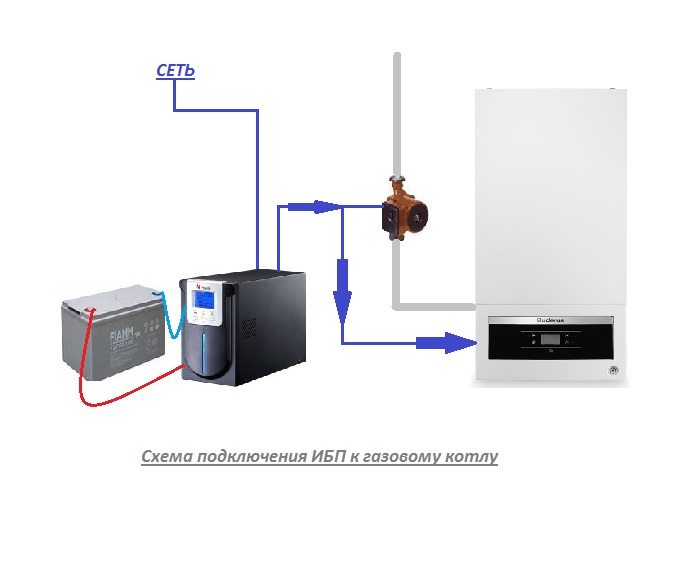

How to connect the device to the boiler?

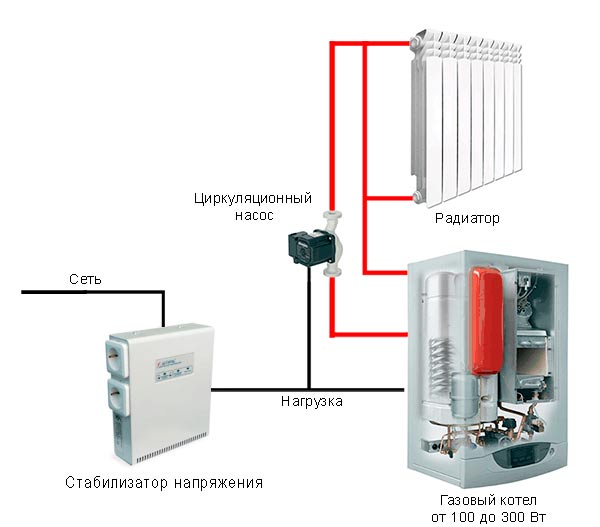

Now you need to study the correct connection diagram of the stabilizing device.

First of all, in order to protect your gas boiler, you need a surge protector directly in front of it, and immediately after the incoming automation, a voltage control relay.

As a rule, in places where heating boilers are used, the power supply is transmitted using a two-wire overhead line that is equipped with a TT earthing system. In such a situation, it is necessary to add an RCD with a setting current of up to 30 mA.

This results in the following diagram:

Attention! Both the stabilizer and the gas boiler must be equipped with grounding!

In order to ground the boiler (as well as other electrical appliances), in the TT system it is required to equip a separate ground loop, which is completely isolated from the zero working conductor, as well as from the rest of the network. The resistance of the ground loop is calculated in accordance with the regulations of the Electrical Installation Rules.

Conclusion: which stabilizer for a gas boiler to choose

From all of the above, we can summarize which stabilizing device is best suited for a gas boiler:

- single-phase;

- with a power of 400 W or 30-40% more than the boiler power;

- any type, except for electromechanical, or install an electromechanical device in another room.

For consumers, the main criterion for choosing voltage stabilizers is the price of the product. One at the same cost, you can buy a device that is not suitable for gas equipment at all, or you can purchase a reliable model that will provide decent protection.Therefore, when choosing a stabilizing device, it is necessary to take into account the listed parameters, and not just the price.

Voltage stabilizers for gas boilers - how to choose the type and power

Calculating the required power of an electric stabilizer for one piece of equipment is much easier than for the whole house. It is enough to look into the attached passport or instructions, which indicate the electrical characteristics and find the active power value, usually between 90 and 180 watts.

photo from the site

It should be borne in mind that the built-in circulation pump is powered by an electric motor, the starting power of which can significantly exceed the active one. If the starting power is indicated in the passport, then further calculations are based on it. But if this figure could not be found, then you should know that the starting power exceeds the active power by 3-5 times, which means that on average it will be from 270 to 900 W, depending on the model.

The resulting figure is not the final result, since it must be multiplied by the power factor - cosφ, which for this type of device is usually 0.75-0.8. The result obtained will be equal to the total power for which the stabilizer should be designed. If you are too lazy to do calculations, then we can say that a performance of 0.8-1 kVA will more than cover the needs of any boiler.

Manufacturers recommend providing a 25-30% power reserve for the device, since working at the limit of technical capabilities will entail rapid wear of parts and, as a result, will shorten its service life.

The mechanism that ensures voltage stabilization largely determines the purpose of the device, its technical capabilities and cost.Based on this parameter, the electrostabilizers on the market can be classified into the following types:

- Relay;

- Electromechanical (servo);

- Electronic.

Despite the fact that the relay type is the simplest principle of operation, and the cost of such devices is the most affordable, such stabilizers are fully suitable for gas boilers. The output voltage accuracy rate for relay devices is 5-10%, although some manufacturers produce models with a 3-5% deviation. For sensitive equipment, this indicator is insufficient, and lighting or medical devices will work intermittently.

As we have already said, heaters allow 10% deviation from the standard values, and are more critical to sudden voltage surges. It follows from this that the speed of stabilization is much more important than its accuracy. The speed indicators of relay models are very decent - in 1 second, some of them are able to bring an oscillation of 100V to the norm.

The location of the boiler in an unheated room will also not affect its operation, since the relay mechanisms remain operational at low temperatures. Consumers also appreciate the fact that this type does not require regular service. For long-term operation, you only have to replace the relays as they wear out.

photo from 7.biz

Electromechanical devices are distinguished by high-precision stabilization with a deviation from the standard voltage values up to 1.5%. Compliance with such accuracy does not make sense in our case, and the combination with a rather modest stabilization rate of 10 V / s makes electromechanical units absolutely unsuitable for such a task.

At the top of the hierarchy are electronic regulators that provide instant equalization and flawless output voltage accuracy. In addition, such a mechanism makes it possible to use it with the widest possible spread of the supplied power supply, the values of which can range from 85 to 305 V. The structural elements of electronic devices are not subject to wear, which guarantees a 20-year service life. Actually, the only restriction to their installation can be a high cost, which, as you know, is a very subjective concept.

Summing up, we can say that the capabilities of relay and electronic stabilizers are sufficient to ensure the safety of heating equipment. It is this voltage stabilizer for a gas boiler that is the best. The electromechanical principle of operation in this case will be completely unsuitable.