- The device and principle of operation of expansion tanks for heating

- The device of a closed membrane expansion tank

- Causes of breakdowns and ways to eliminate them

- How to install?

- Types of expansion tanks

- Selection Guide

- Popular tank manufacturers

- Why do you need an expansion tank

- Ways to connect storage tanks

- top location

- bottom location

- Design features

- Equipment selection rules

- Classification of accumulators for water supply systems: selection criteria and basic nuances when buying, scope

- Storage tank for water supply: instructions, installation and optimal pressure

- Do-it-yourself installation steps for a hydroaccumulator for water supply systems

- Choosing a hydraulic tank connection scheme

- Connecting the accumulator to the water supply system

- What pressure should be in the accumulator: we check the system for operability

- Rating of high-quality accumulators, according to buyers, from various manufacturers for 2020

- Model "WAO 80" from the company "Wester"

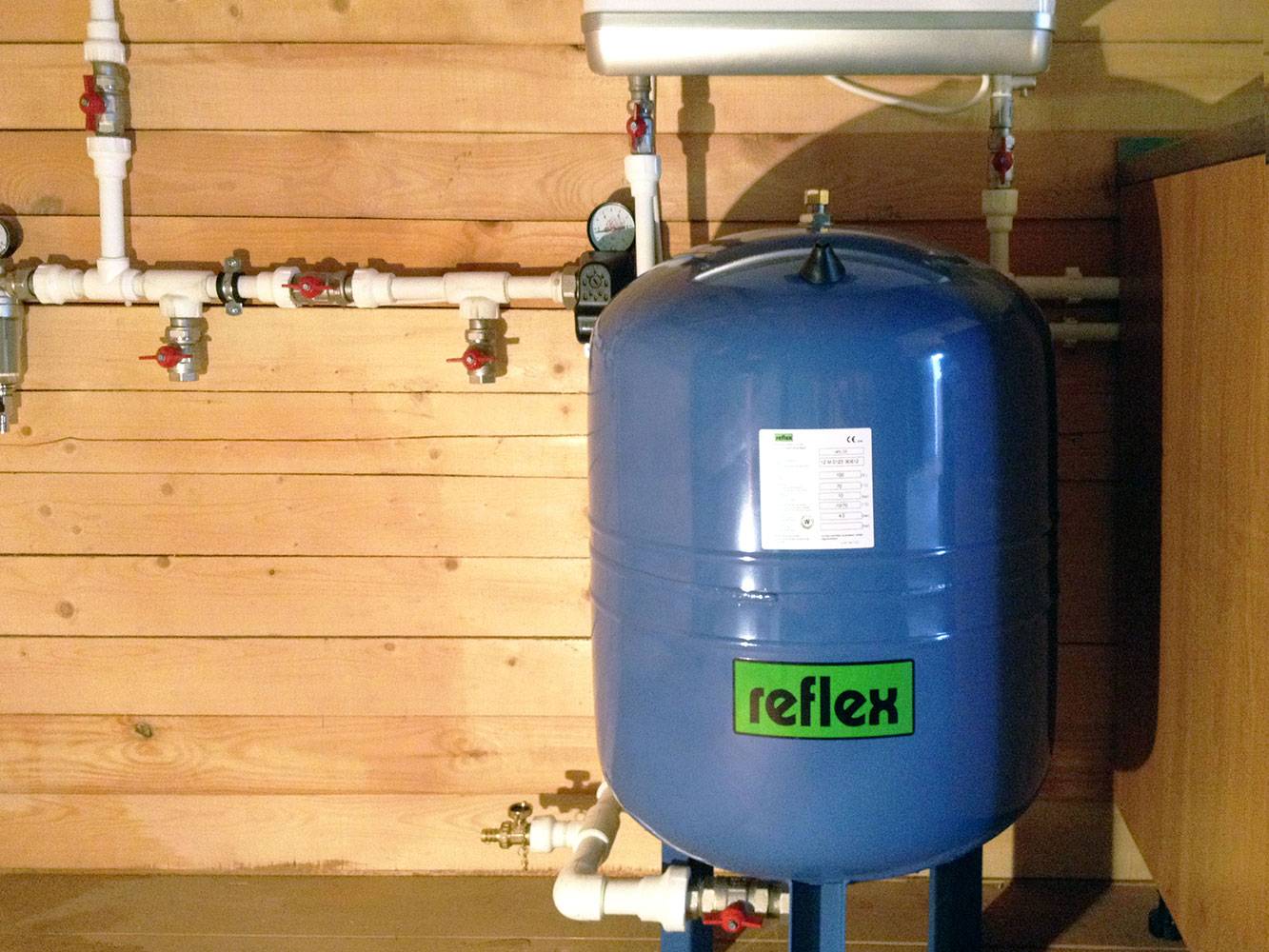

- Model "DE 100" from the company "Reflex"

- Model "Crab 50" from the company "Dzhileks"

- Model "GA-50" from the company "Whirlwind"

- Types of tanks

The device and principle of operation of expansion tanks for heating

Expansion tanks, like heating systems, are:

- closed type

- open type.

An open expansion tank is a parallelepiped-shaped, stainless steel tank that is installed at the highest point of the system, most often in the attic.

Several pipes are connected to the tank:

- main;

- circulation;

- signal.

In open systems, the coolant moves under the influence of natural gravity without installing pumps.

Despite the relatively low set-up costs and ease of maintenance, open systems are rapidly losing their popularity due to too many weaknesses:

- the need for mandatory monitoring of the water level in the tank due to the intensive evaporation of the coolant in open vessels;

- the need to add water as needed;

- the impossibility of using antifreeze due to the openness of the tank, which evaporates even faster than water;

- the need for drainage or sewage supply, as sometimes there is an overflow of water in the expansion tank;

- the presence of effective thermal insulation in order to prevent freezing of the coolant in an open expansion tank;

- the need to additionally purchase connecting parts and pipes for installing a membrane-type expansion tank in the attic;

- the appearance of rust on radiators and pipes, the formation of a plug associated with air entering the heating network from the expansion vessel.

Scope of application: systems with open tanks are installed mainly for heating buildings of a small area of one floor. In large houses, it is advisable to install a closed system.

The device of a closed membrane expansion tank

The closed membrane expansion tank is divided by a flexible membrane into compartments for:

- liquids, where the excess coolant formed during heating enters;

- gases, where air is under pressure, and in some cases - an inert gas or nitrogen.

The principle of operation of the membrane expansion tank:

- an increase in the temperature of the coolant leads to the fact that an increasing volume of it is fed into the compartment;

- the volume of the gas compartment is reduced, and the pressure in it increases;

- critical pressure causes the safety valve to turn on and excess pressure to be released.

With a cooling heating system, the opposite process is observed: a membrane expansion tank returns water back to the pipeline.

Causes of breakdowns and ways to eliminate them

Despite a fairly strong and durable design, it happens that the accumulator for water supply fails. There are several reasons for this. Very often there is airing of the water line. An air lock is formed in the pipeline, which prevents the normal circulation of water. The cause of airing the water supply is the accumulation of air inside the membrane. It gets there along with the flow of water, and gradually accumulates, spreading through the pipeline.

In hydraulic tanks with a vertical installation method, a special drain nipple is installed in their upper part to bleed the air accumulated in the membrane. Small drives, with a volume of less than 100 liters, are usually carried out in a horizontal pattern. Blowing air into them can be a little more difficult.

The procedure here is carried out in several stages:

- The hydraulic accumulator is disconnected from the power supply.

- All water is drained from the system until the storage tank is completely empty.

- Then all valves in the pipeline system are closed.

- The hydraulic tank is connected to electricity and refilled with water.

The air accumulated inside the accumulator will leave together with the discharged water.

How to install?

When installing expansion water tank it's important to know:

- the tank is mounted so that it is easy to maintain it, it is easy to change pipes;

- the diameter of the pipes connected to the tank is selected not less than the diameter of the tank nozzles;

- equipment must be grounded;

- between the pump and the connection point, no obstacles or elements that violate the standard pressure must be allowed.

The liquid to the boiler goes through the valve, which prevents the release of hot water into the cold water supply system. The tank is installed between the boiler and the valve. So hot water will flow immediately from the tap. Sometimes the tank is mounted after the boiler, but then cold liquid from the tank will go into the hot water supply at first.

Types of expansion tanks

Used expansion tanks are the main component of water supply devices, heating systems and fire extinguishing devices. There are only a few varieties:

- Membrane tank (closed type). It is a metal capsule-capacity, which has the shape of a ball or capsule. Inside it, the space is divided by a membrane, for the production of which thermal rubber is used. As a result, two chambers are formed - air and liquid. The air valve should be installed in the air chamber. It will allow you to remove some air at a time when the pressure level will be significantly increased. So the liquid fills the entire tank.

- Tank of open type. It looks like a container, at the bottom of which there is a special device that is directly connected to the heating device (its pipe).The characteristic features include the ratio of the total volume of fluid in the heating system and that which is in the expansion tank. The volume will directly depend on the temperature regime inside the system. It is recommended to install the tank at the top of the heating device (attic space). To reduce heat losses, it is possible to use a heat insulator. An open-type tank cannot be called airtight, which makes it not very attractive, rather bulky, which does not allow installation in residential areas.

Selection Guide

When choosing a tank, special attention should be paid to its design. If critical pressure drops are not expected, then it is better to prefer an inexpensive fixed tank. Otherwise, it will be necessary to install an expansion collapsible tank, since replacing the membrane will cost much less than replacing the entire structure completely.

Otherwise, it will be necessary to install an expansion collapsible tank, since replacing the membrane will cost much less than replacing the entire structure.

Additional factors to consider when choosing:

- wall thickness: must be at least 1 mm;

- type of external and internal coating: the case made of metal should not be subject to corrosion;

- volume of the liquid compartment: should not be too large in order to avoid a decrease in the temperature of the coolant in the pipes;

- container design: it can be horizontal or vertical, in other positions its installation is prohibited.

Despite the apparent simplicity of such an element of the heating system as a water tank, its selection and installation require a lot of attention and scrupulousness, even in small things.A serious attitude will avoid any troubles and make heating a private house efficient and safe.

Related video:

Popular tank manufacturers

1. Wester heating tanks are recognized as one of the best in Russia for home use. The domestic manufacturer produces vertical and horizontal models based on a volume of 8 to 500 liters. Their rubber is made of a particularly durable heat-resistant material that can withstand heating up to 100 ° C. Plus, the expansion tank is equipped with a replaceable membrane, which increases the service life.

The body is made of durable steel. The heaviest barrels are equipped with supports. The warranty covers 3 years. The price of Wester WRV 80, the most popular model, is about 2,500 rubles.

2. The next interesting brand is Reflex from a German manufacturer. Differs in the high durability and long term of operation - till 12 years. The Reflex expansion tank for heating of any model is made according to the famous technology of the Krupp dynasty, famous for high-quality steel.

Volumes are very different: from 8 to 1,000 liters. The tank is equipped with a replaceable membrane designed for temperatures up to 70 °C. The cost of this line is from 1,520 rubles.

3. Very often found in the sale of a series of Chinese manufacturer Zilmet CAL-PRO. The market offers tanks with a capacity of 4 to 900 liters. Their body, made of carbon steel, is either ringed or welded together. The membrane is made of synthetic rubber. The device can operate at temperatures from -10 to 100 °C.

The cost of a membrane expansion tank of the CAL-PRO series for heating starts from 1,170.

How to choose for home

When heated to 70-90 ° C, all water increases in volume by 4-5%. Without a buffer, it creates high pressure in the pipes, which can cause them to burst. Therefore, the correct choice of a membrane tank for a heating system is very important. It should be done on the basis that the expander should take on all the excess volume of liquid. Therefore, before buying, you must correctly calculate this amount, and even better, consult with the designers.

It is also desirable to ensure that the tank is made of high quality materials, otherwise it simply will not withstand the loads.

Very often, inexperienced or unscrupulous sales assistants try to sell customers devices intended for water supply instead of the required ones, believing that there is practically no difference between them, except perhaps in color (blue and red). In fact, hydraulic accumulators are used in heating systems, except perhaps through an oversight. In this case, since their rubber is not designed to withstand heat, they quickly fail.

Brief instructions for DIY installation

- First you need to decide on the location of the device. According to the instructions, the expansion tank can be installed anywhere in the heating system, but in order to avoid sudden pressure surges, it is better to place it immediately after the circulation pump.

- It is necessary to place the device so that there is access to the air valve, drain cock, shut-off valves and other important details.

- During installation, the room must be at least 0 °C. The safety valve must be installed in the direction of the flow.

- There is nothing complicated in the installation itself, you just need to follow the instructions and use the proper tools, in particular the wrench for metal-plastic pipes and connectors. The nozzle must match the pipeline.

- Tanks with a large capacity must be mounted on additional brackets. To do this, first mark the place, then drill a hole and attach the hangers with anchor bolts.

- After the equipment is fixed, a pipe is brought to it so that it does not interfere and does not put pressure on the tank.

- Then a pressure reducer is mounted, it must be installed after the meter.

- If everything is done correctly, you can start setting up - pump in air and water, observing the pressure. When it is balanced, you can start turning on the heating.

- It is better to entrust the installation of a tank in a multi-boiler system to specialists who have been tested and received the appropriate license.

Moscow prices

You can buy a membrane expansion tank at the estimated cost indicated in the table.

| brand | Cost, rubles | |||||||||||

| Volume, l | 8 | 12 | 18 | 24 | 35 | 50 | 80 | 100 | 150 | 200 | 300 | 500 |

| Wester | 790 | 860 | 900 | 1 000 | 1 650 | 1 900 | 2 500 | 3 500 | 5 200 | 9 500 | 11 500 | 18 100 |

| Volume, l | 8 | 12 | 18 | 25 | 33 | 60 | 80 | 100 | 140 | 200 | 300 | 500 |

| reflex | 1 520 | 1 600 | 1 980 | 2 300 | 3 070 | 4 900 | 5 900 | 6 700 | 9 060 | 10 860 | 15 000 | 23 000 |

| Volume, l | 8 | 12 | 18 | 25 | 35 | 50 | 80 | 105 | 150 | 200 | 250 | 500 |

| Zilmet CAL-PRO | 1 170 | 1 230 | 1 300 | 1 630 | 2 100 | 3 100 | 4 200 | 6 100 | 7 600 | 9 480 | 12 200 | 22 200 |

Why do you need an expansion tank

Installation of such a device allows you to simultaneously solve two bearing tasks of a technical nature, such as:

- contributes to a smaller number of cycles used (off and on) of the pump, which allows to increase its service life;

- allows you to protect the device from possible water hammer, which may indicate the airiness of the device or the presence of drops in the electrical network. These moments can make the device unstable;

- contributes to the creation of a reserve volume of liquid, which will be under a certain pressure inside the system, ensuring the optimal level of water supply anywhere in the house. On average, the volume of the tank is about 30 liters, which makes it possible to provide one point with liquid for several minutes.

Ways to connect storage tanks

The tank can be connected to the system in two different ways: by placing it at a high elevation or at or below ground level.

top location

Such a water supply scheme for a house from a storage tank is practiced mainly in cases where there are no appliances in the house that need good pressure, and the residents have a minimal need for water - to wash, wash dishes, etc.

And also with frequent power outages. Because water from a tank installed on a roof, attic or overpass flows to consumers by gravity, and such a system does not depend on the presence of voltage in the network.

Such pressure in the system will be insufficient for the operation of the washing machine, and even taking a shower will be problematic. You can increase it by connecting a booster pump at the outlet of the tank. The advantage of such an installation is its simplicity and ease of maintenance of the tank.

However, do not forget about the disadvantages:

- The storage tank takes up a lot of space, taking away useful space from the house;

- If you install it in the attic or on the street on a special overpass, then you can use water only in the warm season. Or you need to insulate and heat well both the tank itself and the pipes going to it and from it;

- If the instructions were not followed during installation or the system itself has worn out over time, leaks are possible that can cause a lot of trouble.

As you can see, each homeowner deals with these issues differently depending on the needs of the family.

- So that the water does not freeze, the tank is installed on a heated second floor or attic, sacrificing area.

- Or they use electric heating of a container standing in the attic. And they pay extra for electricity.

- Or they simply put it on the cabinet, content with the minimum pressure in the system.

bottom location

This is a more common and effective way of accommodation for houses with permanent residence and all the amenities familiar to a city dweller. Such a water supply system with a storage tank is necessarily equipped with an additional pump or pumping station. Without them, the water itself will not flow to consumers, and with it you can get any necessary pressure.

There are also several options for lower placement:

- Ground - when the tank is used only in the summer and does not need insulation;

- Underground - the tank is buried in the ground, and only the neck is brought to the surface, providing access to it for repair and maintenance;

Water supply at home - underground storage tank

Basement - when the house has a heated basement or technical room.

The last option is the most convenient, since the container does not need to be insulated, there is always access to it and it does not take up usable space.

The second most popular is the underground option. It also allows you not to use the area of \u200b\u200bthe house, but in this case, cleaning and repair will be fraught with certain difficulties. And the upper part, located above the freezing level, will also have to be insulated.

In addition, not every container can be buried in the ground.It must be strong, with thick walls, stiffeners or metal formwork. Otherwise, you need to build a rigid shell for it.

Installing a tank in a caisson made of waterproof boards

Design features

The device of the storage tank does not depend on the installation location. There are only a few nuances.

The container is supplied with the following structural elements:

float valve. It prevents it from overflowing and turns on the pump when the water level reaches the minimum mark.

float switch

- Overflow pipe in case of breakage of the float switch. It is located at the top of the tank and is connected to the sewer.

- Drain pipe at the bottom. Designed to remove sediment. They are equipped with storage tanks for water supply, located at the top or in the basement of the house. Underground tanks are cleaned by the upper hatch.

This photo shows both pipes connected to the sewer system

- The filter located at the inlet will retain some of the suspended particles. It can also be installed at the exit, equipped with a finer mesh.

- Ventilation pipe or breathing valve. If they are not installed in the lid of the tank, when the water is drained, the walls of the tank may flatten under the influence of atmospheric pressure.

Lid with breather valve

Equipment selection rules

It is important to choose the right tank volume in order to adjust the pressure in the system

The main characteristics of the membrane tank, which are guided by when buying:

- volume;

- maximum pressure;

- membrane and housing material;

- working temperature.

These criteria will ensure the reliability of the heating operation. Insufficient or excessive volume of the reservoir will not allow normal pressure to be established in the circuit.The type and material of the diaphragm and housing affect the life of the equipment. High-quality rubber withstands a large number of expansion and contraction cycles. In order for the body to not corrode, it must have a protective coating. It is worth considering the dimensions of the product and consider the installation location. Experts advise buying products from well-known manufacturers. The low cost of production is often an indicator of the use of low-grade materials.

Classification of accumulators for water supply systems: selection criteria and basic nuances when buying, scope

How to choose a high-quality hydraulic accumulator in all respects? First of all, it is worth understanding what devices are. The table shows the main types of water batteries.

Table - "Classification hydraulic accumulators for systems water supply"

| Type of: | Due to which the accumulation and return of the energy of the hydraulic fluid is carried out in the system (principle of operation): | Peculiarities: |

|---|---|---|

| Cargo: | potential energy, which is at a certain height of the load | ensuring constant pressure; |

| great working potential; | ||

| inexpensive. | ||

| Spring loaded: | mechanical energy of a compressed spring | high energy intensity; |

| budgetary | ||

| Pneumohydraulic: | compressed gas energy | reliability and simplicity of designs; |

| minimum inertia; | ||

| high energy capacity with minimal dimensions. |

Selection Tips:

- For domestic purposes and in industry, it is better to use pneumohydraulic accumulators for water. They are equipped with durable tanks for preset pressure values and have an elastic element (internal piston, cylinder, membrane) that maintains the "pressure" of the working fluid in the system.

- Hydroaccumulators with mechanical accumulation are not recommended. They are very rarely used due to a number of disadvantages: unreliable designs, small working volume, dependence of pressure on filling volume and spring characteristics.

Basically, the scope of hydraulic accumulators is a system of autonomous water supply for country houses, villages or small enterprises.

We are talking about accumulators of pneumohydraulic type. They are classified into several categories, depending on the assembly of the structure:

- piston;

- Membrane;

- Balloon;

- Bellows.

What is the best battery to buy? Buying advice:

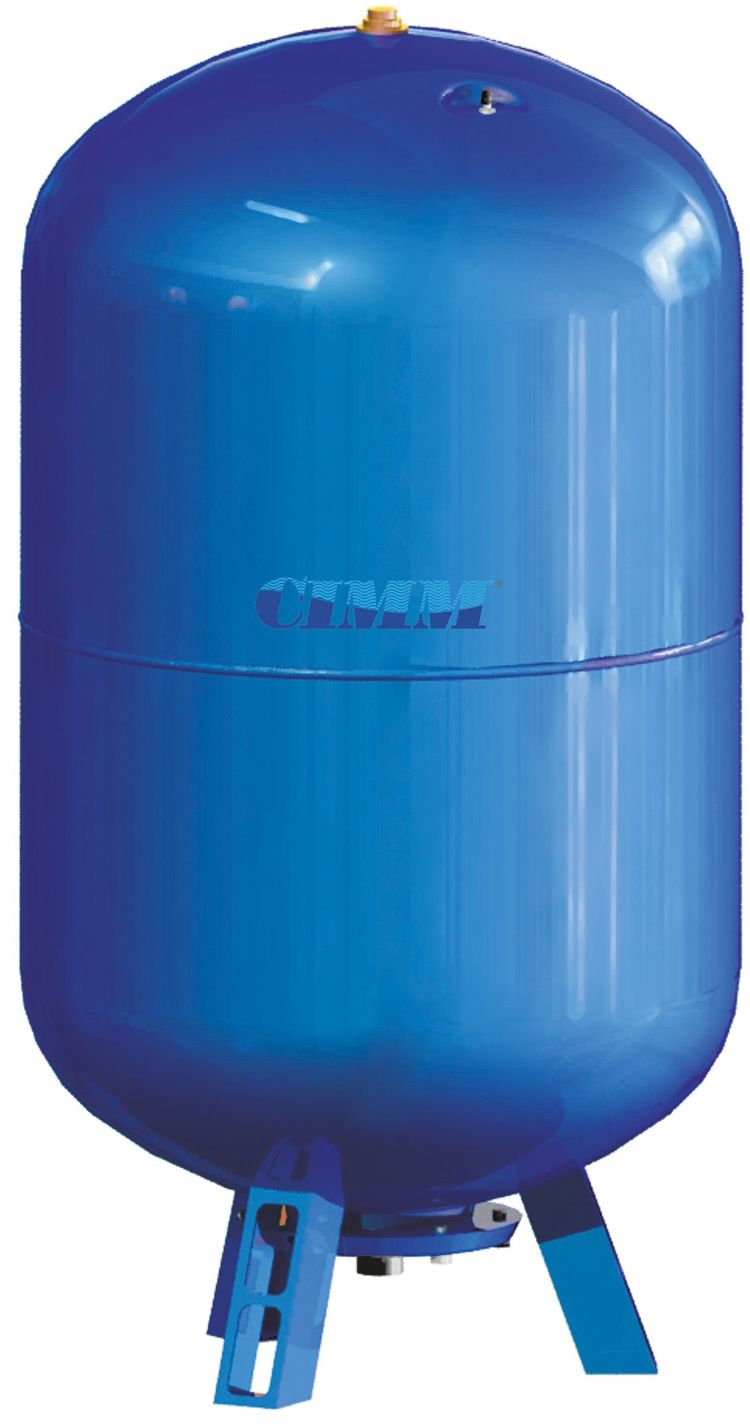

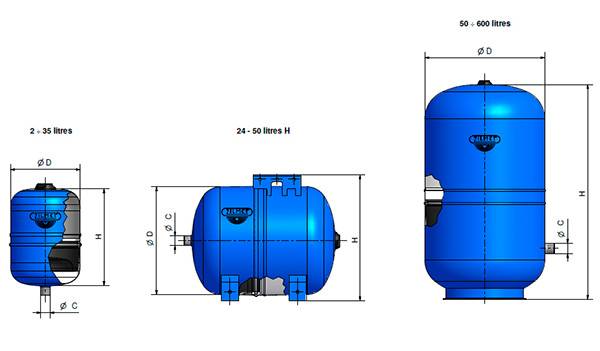

Depending on the method of installation, the buyer must decide what design he needs: horizontal, vertical or universal. The last installation is used, in most cases, for large-scale purposes (it can be attached in one of two ways). If the area allows, you can buy a horizontal battery. For those who want to save space, vertical appliances are suitable.

Storage tank for water supply: instructions, installation and optimal pressure

Other containers are also used to regulate pressure. In particular, expansion tanks are used in the hot water supply system. Their purpose is to compensate for pressure changes when the temperature of hot water changes. There are two types of expansion tanks: open and closed. Open systems communicate with the atmosphere, and in closed systems a constant pressure is maintained in the water supply expansion tank.

Many summer residents prefer not to install an expensive accumulator, but are limited to a simpler and cheaper water supply system with a storage tank.Its advantage is ease of installation and operation. If desired, such a system can be created independently, using a water pump, a container of a suitable volume, pipes or hoses, and a simple control system for this.

The principle of operation of such a system is the same as that of a water tower. The storage tank for water supply is installed at the calculated height. As a rule, the installation height is determined by the height of the building. To create a pressure of 0.5 - 0.7 bar, the container must be at a height of 5 - 7 meters, respectively. If this requirement cannot be met, then the installation is carried out in a separate building, or additional pumps are used to maintain the working pressure in the system.

Do-it-yourself installation steps for a hydroaccumulator for water supply systems

Work on the installation of the purchased accumulator is carried out in several stages. The first thing to do is check the pressure in the air chamber. This is done simply, using a car pump or compressor equipped with a pressure gauge. The pressure is made slightly greater than the rate at which the pump turns on. The upper level is set from the relay and is set one atmosphere above the primary level.

Next, you should decide on the installation scheme.

Choosing a hydraulic tank connection scheme

The most convenient is the connection diagram of a hydraulic accumulator with a five-pin collector. Installation is carried out according to the scheme, which is in the technical documentation. A collector with five outlets is screwed to the fitting of the accumulator. The remaining 4 outputs from the collector are occupied by a pipe from the pump, water supply to the dwelling, a control relay and a pressure gauge. If it is not planned to install a measuring device, then the fifth output is muted.

Connecting the accumulator to the water supply system

After assembling all the nodes, the pump (if the system is equipped with a submersible pump) or the hose (if the pump is surface) is first lowered into the well or well. The pump is powered. That, in fact, is all.

Important! All connections are made with winding FUM tape or flax. It should be understood that the pressure in the system will be quite high. However, you should not be too zealous either, everything is good in moderation.

Otherwise, there is a risk of breaking the nuts on the fittings.

However, you should not be too zealous either, everything is good in moderation. Otherwise, there is a risk of breaking the nuts on the fittings.

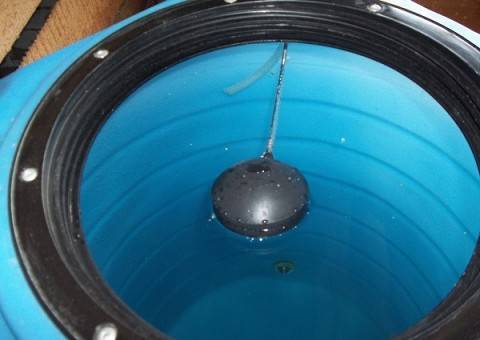

Having dealt with the installation, you can move on to the issue of replacing the membrane, which often fails in models with a vertical arrangement. Here we will make a step-by-step instruction with photo examples.

| Photo example | Action to take |

|---|---|

| First, we unscrew the bolts of the flange of the dismantled hydraulic tank. They are wrapped "in the body" or tightened with nuts - depending on the model. | |

| When the bolts are out, the flange can be easily removed. Let's put it aside for now - to pull out the failed pear, you need to unscrew one more nut. | |

| Expand the container. At the back is a purge nipple. The nut also needs to be removed. There may be two of them, one of which acts as a locknut. This is done with a key of 12. | |

| Now, with a little effort, the pear is pulled out through the large hole on the side of the flange. | |

| We lay out a new pear, we expel air from it. This is necessary to make it more convenient to install it in the tank. | |

| Having folded four times in length, we put it into the container completely, including the part that was outside during dismantling.This is done so that it is possible to get the nipple into the hole intended for it. | |

| The next stage is not for people with a full physique. Experienced craftsmen say that in order to install the nipple for the accumulator in place, sometimes you have to call your wife for help - they say, her hand is thinner. | |

| Once in the hole, it is imperative to make a nut so that during further assembly it does not go back. In this case, you will have to start all over again. | |

| We straighten the pear seat and tighten the nuts on the nipple. The matter remains small ... | |

| ... - put the flange in place and tighten the bolts. When tightening, do not be zealous over one screw. Having pulled everything up a little, we begin broach through the system of opposite units. This means with six bolts the order is as follows - 1,4,2,5,3,6. This method is used in tire shops when pulling wheels. |

Now it is worthwhile to deal with the necessary pressure in more detail.

What pressure should be in the accumulator: we check the system for operability

The factory settings of the hydraulic tanks imply a set pressure of 1.5 atm. It does not depend on the volume of the tank. In other words, the air pressure in a 50-liter accumulator will be the same as in a 150-liter tank. If the factory settings are not suitable, you can reset the indicators to values \u200b\u200bthat are convenient for the home master.

Very important! Do not overestimate the pressure in the accumulators (24 liters, 50 or 100 - it doesn’t matter). This is fraught with failure of faucets, household appliances, pump. 1.5 atm., installed from the factory, not taken from the ceiling

This parameter is calculated on the basis of numerous tests and experiments.

1.5 atm., installed from the factory, are not taken from the ceiling. This parameter is calculated on the basis of numerous tests and experiments.

Rating of high-quality accumulators, according to buyers, from various manufacturers for 2020

Popular models are devices of domestic and foreign production. Each product has a brief description, technical properties, pros and cons. These batteries are the most popular product, which, according to buyers, corresponds to the price and quality. The best manufacturers from this series:

- Wester;

- Reflex;

- "Jileks";

- "Vortex".

Model "WAO 80" from the company "Wester"

Russian-made installations are used for domestic needs. The body is made of durable metal, which prolongs the life of the device, the diaphragm is made of EPDM food grade rubber. All materials are environmentally friendly and do not affect the taste of drinking water. In the common people, this installation is called an expansion barrel.

The appearance of the accumulator "WAO 80" from the company "Wester"

Specifications:

Wester WAO 80

Advantages:

- Constant working pressure;

- Silences hydraulic shocks;

- Smoothes out the effects of water shocks that affect the operation of pumps and thermal boilers, thereby increasing their service life;

- Eliminates water loss in case of system leakage;

- Reliability of a design;

- Environmentally friendly product;

- Inexpensive device for the price.

Flaws:

Not identified.

Model "DE 100" from the company "Reflex"

This type of battery is used in booster installations, heating networks (floor water) or fire extinguishing systems. The frame is made of sheet steel, inside there is a special coating that, in contact with water, does not form corrosion.There are no fittings in the tank: shut-off, drain and flow. The membrane is replaceable, in the form of a pear.

The appearance of the battery for the water supply system "DE 100" from the company "Reflex"

Specifications:

| Type of instalation: | vertical |

| Dimensions (centimeters): | 48/83,5 |

| Net weight: | 19 kg |

| Volume: | 100 liters |

| Maximum working pressure: | 10 bar |

| Tank pressure: | 4 bar |

| Flange: | metal |

| Execution: | on legs |

| Union: | 1 inch |

| Operating temperature (degrees): | 70-100 |

| Manufacturer: | Germany |

| Average price: | 7500 rubles |

DE 100 Reflex

Advantages:

- Easy installation;

- Reliability;

- The ability to change the membrane;

- Corrosion does not form;

- Attenuates noise impacts.

Flaws:

Not identified.

Model "Crab 50" from the company "Dzhileks"

Automatic station with a full set of elements necessary for installation. The body is made of plastic, equipped with a pressure gauge, filter change calendar. The pump turns on and off automatically, water is filtered before it enters the pipeline. Feature of the unit: installation can be carried out, regardless of the direction of water flow.

Model "Crab 50" from the company "Dzhileks" - appearance

Specifications:

| Type of instalation: | vertical |

| Tank: | 50 liters |

| Working pressure: | 1-5.5 bar |

| Relay: | 1.4-2.8 bar |

| Net weight: | 10 kg 900 g |

| Frame: | plastic |

| Connection socket: | inch |

| Maximum current: | 10 A |

| Working temperature: | 35 degrees |

| What is the price: | 5700 rubles |

Crab 50 Giles

Advantages:

- Design;

- Compact;

- Corrosion resistance;

- Functional;

- Easy and convenient installation: no additional settings required;

- Automation;

- Value for money.

Flaws:

Not identified.

Model "GA-50" from the company "Whirlwind"

An ideal hydroaccumulator for a private house. All characteristics correspond to consumer demand, the frame is made of durable and corrosion-resistant materials. The device copes with the main task. How to connect the unit is described in detail in the instruction manual.

Model "GA-50" from the company "Whirlwind" - the appearance of the accumulator

Specifications:

| Type of instalation: | horizontal |

| Tank Rating: | 50 l |

| Temperature: | up to 45 degrees |

| Membrane: | replaceable, food grade rubber |

| Working pressure (maximum): | 8 bar |

| Flange material: | steel |

| Net weight: | 7 kg |

| Dimensions (centimeters): | 37,5/54/35 |

| Air pressure: | 2 bar |

| Purpose: | for pumps up to 1 kW |

| Average cost: | 2000 rubles |

GA-50 Whirlwind

Advantages:

- Reliable;

- Membrane replacement is possible;

- Long service life;

- Easy installation;

- With autonomous on/off function;

- Inexpensive.

Flaws:

Not identified.

Types of tanks

Expansion tanks are of two types - closed and open. They differ from each other in design features.

Table. Types of expansion tanks.

| Type of | Description |

|---|---|

| Closed or membrane | This is a tank that has just a membrane separation between the compartments - water and air. The diaphragm in it is heat-resistant and avoids corrosive activity. Such a tank is airtight, outwardly it looks like a small cylinder or a ball of metal. This element of the system serves for a long time, and if the membrane is damaged, it is easy to replace it with a new one. Also, in addition to this type of expansion tank, a pressure gauge and a safety valve must be installed - together they form a security system. |

| Open | Such a tank is a container at the bottom of which there is a threaded connector, which allows you to combine the device with the system. It is necessary to install this design in the highest part of the heating system. It is used extremely rarely, as it has a lot of drawbacks - this is an increase in the risk of corrosion in pipes, and fairly decent dimensions, and a quick failure at critical pressure indicators. The liquid level indicators in such a container also directly depend on how much water is in the heating circuit. |

The principle of operation of a closed expansion tank

Membrane tanks, in turn, are divided into two types - with interchangeable diaphragm and from the stationary. The replaceable membrane speaks for itself - if necessary, it can be easily changed by removing it through a flange fixed with a few bolts. An expansion tank of this type serves as long as possible, and the shape of the body can be both vertical and horizontal, which makes it possible to select a container for a specific room.

Diaphragm type expansion tank

In containers with a stationary membrane, this part cannot be replaced - it is tightly attached to the walls of the housing. In case of failure of the unit, it is completely changed. By the way, water in such an installation, unlike the previous type, is in contact with the metal of the tank, as a result of which a corrosion process occurs on its inner surface. Installation can also be both vertically and horizontally oriented.

Expansion tank dimensions

Expansion tanks are not only mounted, but also floor. They can also have a flat shape, differ in color: blue are for cold water, red for hot water.