- 4. Styrofoam

- 1. Ways to protect pipes from freezing

- Use of high pressure and air insulation

- Why is it sometimes necessary to insulate some parts of the plumbing?

- Thermal insulation for water supply pipes

- Rigid insulation

- Roll insulation

- Segment (casing) heaters

- Sprayed insulation (PPU)

- Requirements and regulations

- Mistakes made when laying pipes

- Warming methods

- Types of heat-insulating materials for pipes

- Styrofoam

- Foamed polyethylene

- Alternative materials

- Thermal insulation paint

- Sewer pipe heating

- Other insulation methods

- Heating cable

- High pressure

- Warming with air

- How to perform thermal insulation of polypropylene pipes

- Types of insulation for water pipes in the ground and on the street

4. Styrofoam

This material is a fairly effective insulation, which has a small weight. This greatly simplifies the installation process. Due to sufficient rigidity and strength, the foam does not deform under soil pressure. The main form of release of pipe insulation made of foam plastic are cylinders. They consist of two halves, which are interconnected by means of a thorn-groove.

varieties of foam

- Penoizol;

- Extruded polystyrene foam;

- Expanded polystyrene foam.

The above materials differ in their density. Depending on this, the thickness of the heat-insulating layer also changes, which can range from 20 to 100 mm or more. The inner diameters of the foam cylinders are equal to the standard outer diameters of water pipes, which allows them to be insulated, provided that they fall within the diameter range from 15 to 144 mm. The coefficient of operating temperatures of the material is also sufficient - from -188 to +95°C. Styrofoam shells are often used for noise and heat insulation not only for plumbing, but also for ventilation and air conditioning systems, sewerage and gas pipelines. By choosing one of the varieties of foam as a heater, you can count on the following advantages:

- Minimum heat loss;

- Protection of pipes against corrosion;

- Tightness of the heat-insulating layer;

- Possibility of reusable connection;

- The ability to use the shell as additional insulation when insulated with a heating cable. Since there are varieties of cylinders with a special groove for cable laying;

- Resistance to the chemical effects of salts, lime and acids that may be in the soil, as well as to the vital processes of various microorganisms;

- Durability;

- Resistant to sudden changes in temperature;

- Possibility to choose a protective shell even for fitting connections due to the presence of shaped parts.

Among the shortcomings can be noted increased sensitivity to solvents such as gasoline, acetone, nitro paint. Under their action, the material simply melts.

1. Ways to protect pipes from freezing

From the preface to the article, you have already been able to imagine in all colors what the consequences of freezing sewer pipes are fraught with. Therefore, we will no longer return to the question of whether this is really necessary, but will immediately consider directly the methods of insulation. In practice, really usable methods are:

Laying sewer pipes to a depth that exceeds the level of soil freezing by at least 10 cm. If this condition is met, then insulation as such may not be required. This method seems simple in execution only at first glance. But let's see. Let's say the freezing level in your area is at a depth of 1.5 meters. This means that the pipes must be buried at least 1.6 meters into the ground. Given that for normal operation, sewer pipes must have at least a minimum slope, the depth can increase to 2-2.5 meters. This means that the septic tank (if any) will need to be deepened by 2.5-3 meters. Agree, doing it yourself will be very hard physically and for a long time. Just imagine how much earthwork you have to do. In addition, if the pipeline runs at such a depth, its repair will be complicated. Summarize. This method of insulation can be implemented if you have special equipment that will greatly simplify and speed up the work, and the septic tank model provides for the possibility of placement at such a great depth;

Warming with heat-insulating materials. This method is one of the most optimal. Fortunately, a variety of insulating materials allows you to choose the option that suits you, both in terms of cost and depending on the material of execution of sewer pipes.In addition, it is quite possible to isolate pipes in this way on your own, because installation is extremely simple and does not require special knowledge.

The only thing I would like to focus your attention on is that such work should be carried out immediately at the time of laying the pipeline. We will tell you more about the types of insulation materials in the following paragraphs;

Insulation with a heating cable

This method and this invention of mankind is gaining more and more popularity. This is not surprising, because having once invested a certain (most often considerable) amount of money, you will receive a system that, with proper operation, can serve you for decades and pay for itself in full. About what types of heating cable there are, and you can find recommendations for choosing it in our article by clicking on this link. The heater can be installed both externally and internally, depending on the diameter of the pipes and the condition of the pipeline. Even a pipe filled with concrete can be insulated with a heating cable, so pay attention to this method;

Combined method. To heighten the effect, or if abnormally low temperatures are characteristic of your climatic zone, it is rational to combine several protection methods in order to really achieve the desired result and not waste your energy and money. Alternatively, pipes deepened to a sufficient size are additionally covered with expanded clay, or enclosed in a foam or other shell. With a small depth of pipeline laying, it is rational to use a heating cable and additional external insulation, etc.

the need for insulation

Use of high pressure and air insulation

It turns out that in order to protect the home plumbing system from freezing, it is not necessary to cover communications with a heat-insulating layer. There is one interesting way of warming, based on the physical laws of thermodynamics familiar to everyone from a school physics textbook. It is known that an increase in liquid pressure significantly reduces the crystallization temperature.

And if you maintain a high pressure in the system, the water will not turn into ice and will retain its liquid state. For example, creating a working pressure in the plumbing system of 3 atm. reliably protect the water supply of the cottage from freezing. True, for this you need to install an additional device - the receiver.

The second unusual way of insulating "without insulation" water pipes - with warm air, is based on the use of air flow emanating from the ventilation duct of the basement. To do this, the water pipe is placed in a plastic sleeve of a larger diameter. The outer pipe is connected to the basement ventilation, in which warm air comes directly from the ground, and at the other end it vents to the outside.

Important: in order to create good circulation, it is necessary to equip the air channel with a suction deflector. Warm air flow will circulate faster, and the water in the pipes will be constantly heated.

Why is it sometimes necessary to insulate some parts of the plumbing?

In places (described above) where the water supply is at risk of being frozen, it is necessary to protect polypropylene pipes from the cold.Polymers have significant elasticity and resistance to stretching, therefore, water expanding during freezing does not lead to rupture of products. However, this does not mean that such parts of the water supply system do not need to be insulated. The reasons:

- The resulting ice plugs block the water flow, and the water supply system ceases to function.

- Repeated mechanical impact on the material leads to its accelerated wear.

- With the constant freezing of water in the system, the pipes can still burst.

The outer parts of the water supply can be buried deeper into the ground, and for the inner sections, thermal insulation is used for polypropylene or any other pipes. It can be mineral wool, polyurethane foam shell, polyethylene foam and other varieties.

Thermal insulation for water supply pipes

It is not difficult to get confused in a wide range of thermal insulation materials. To choose the best option, you need, at a minimum, to know the main types and types, key characteristics and features.

Thermal insulation of water pipes is carried out by various heaters, which are grouped below (in the form of classification) according to the principle of unity of insulation technology.

Rigid insulation

This category includes polystyrene, expanded polystyrene (2560-3200 rubles / cubic meter) and Penoplex (3500-5000 rubles / cubic meter), thermal insulation properties and price depend on density.

Laying water pipes in a foam box

Roll insulation

This segment includes: polyethylene (as an additional material), foil foam (50-56 rubles / sq.m.), cotton wool (mineral (70-75 rubles / sq.m.) and glass wool (110-125 rubles / sq.m.) ), furniture foam rubber (250-850 rubles / sq.m., depending on the thickness).

Insulation of water supply pipes with roll insulation is also fraught with difficulties, which lie in the hygroscopicity of the material. Those. the insulation loses its properties under the influence of moisture, which means it has a narrower scope, or needs additional protection. Plus, it is necessary to think over the method of attaching the insulation to the pipe.

Basalt heat-insulating mats and foam rubber for insulation of water pipes

Segment (casing) heaters

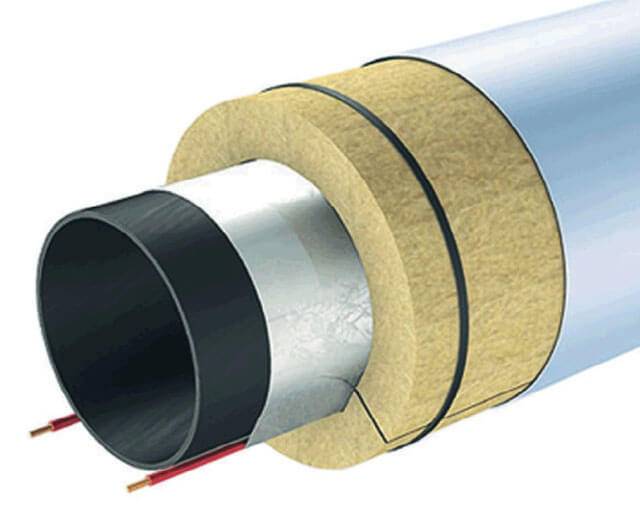

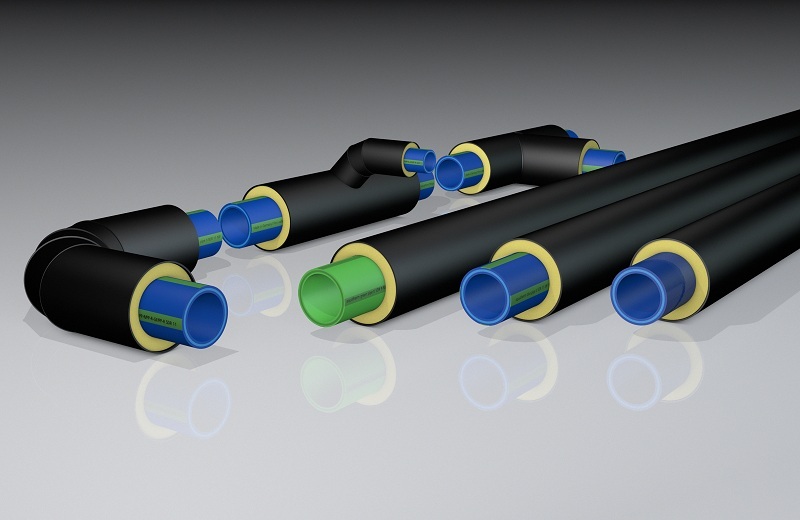

The casing-insulation for pipes is the most progressive variant of thermal insulation of the pipeline. The water pipe insulation shell provides maximum tightness and, as a result, creates a reliable heat-insulating layer.

There are varieties of segment heaters:

Styrofoam shells rigid for insulating water pipes (heat-insulating casing for pipes - shell made of expanded polystyrene (PPU) or foamed polystyrene. Price from 190 rubles / m.p., depends on the thickness and diameter of the cylinder);

Sprayed insulation (PPU)

The peculiarity of insulation by spraying polyurethane foam is that thermal insulation is applied to the surface of the pipe, providing 100% tightness (the cost of components for polyurethane foam filling is from 3.5 euros per kg).

The number of components is determined by the thickness of the fill, the work is paid extra). On average, the cost of insulation by spraying polyurethane foam is 15-20 dollars / m.p.

Sprayed insulation also includes heat-insulating paint for pipes. You can apply it yourself, because. thermal paint is sold in cans in the form of an aerosol.

20 mm paint layer. replaces 50 mm basalt wool insulation. In addition, it is the only material that is not susceptible to damage from rodents.

Insulation of water pipes by spraying polyurethane foam (PUF) Water pipe insulated with polyurethane foam (PUF)

When choosing a heat-insulating material for insulating water pipes, you need to take into account the following factors:

pipeline installation site

Insulation of pipes laid on the ground and located underground is carried out in different ways, even when using the same materials (it is also important to take into account pipes laid to or below the freezing level);

pipeline operation frequency. For example, in a country house that is not intended for permanent residence, it is enough just to avoid a pipe rupture

To do this, a receiver is installed or the water pipe is insulated with a cable. But in a private house it is necessary to ensure the supply of water all year round. Here, the choice of insulation should be approached more carefully;

indicator of thermal conductivity of pipes (plastic, metal);

resistance to moisture, burning, biological activity, ultraviolet, etc. determines the need to protect the insulation from these factors;

ease of installation;

price;

life time.

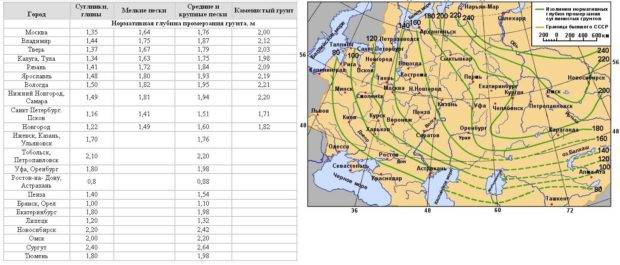

Requirements and regulations

It is not necessary to involve craftsmen to carry out calculations and measurements; instead, you can be guided by the base of standards, compiled taking into account the area on which the installation work will be performed. Documents will be provided in the appropriate authority. Data for the database is obtained during scientific research.

According to the rules, when digging a trench, workers determine the place of laying, adding half a meter to the freezing depth of the soil.If you have the initial data (it is enough to know the area on the map), then you can use Internet services to determine the required distance.

Information on how to lay a water pipe underground is also published in the SNiP tables. Due to the structure of the soil, digging a ditch of the right size can be difficult. In this situation, the masters recommend digging it as deep as possible. However, to protect water pipes from frost and heat, they are well insulated.

In regions that are located in the North, pipeline systems are laid in the ground in special ways. Here, soils can freeze by 3-4 m. To dig such a deep trench, powerful equipment is used.

AT temperate regions indicators vary, it depends on the soil:

- soft and loose sandy loamy soils - 1.6 m;

- soil of medium looseness with gravel - 1.7 m;

- viscous clay soil - 1.3 m;

- coarse-grained, stony soils - 1.9 m.

In the south, pipes are led into the house at a shallower, meter depth. If the system is dripped higher, the plumbing may be damaged. The thicker the layer of earth, the better the pipes will be protected from external loads (vehicle traffic, etc.).

Mistakes made when laying pipes

The laying of communication systems from a well is largely determined by the composition of the earth in a particular area. And often there are difficulties with this when performing installation work, since the composition of the soil does not allow deepening the ditch to the indicator specified in the SNiP. For example, the ground may be dense or swampy, so the worker will not be able to complete the task.

In such cases, the craftsmen choose trenchless laying of water supply. It can also be very difficult to carry out work during the winter months. But even in this situation, there is a solution - you can dig a ditch as deep as you can, and then insulate the system in many ways.

If the winters in your area are mild enough, don't make the mistake of laying the pipeline near the surface, as the risk of damaging the system increases dramatically. And excessive deepening is fraught with the fact that cracks will appear on the structure under the pressure of the soil. In this case, the plumbing may break.

Warming methods

Insulation of water pipes is necessary under any circumstances, even when it is possible to fix the system at maximum depth. One way is to lay a heating cable along the pipeline. And although this method will require significant material costs from you, it is considered very reliable. You can learn about the methods and methods of isolation from the videos that are on the Internet.

Insulation of pipes will ensure a more correct operation of the water supply system. High-quality thermal insulation materials will keep the temperature, extend the life of the pipeline and save you from unnecessary expenses for repairs. The type of thermal insulation is selected depending on the operating conditions and the raw materials from which the pipes are made.

All these properties affect the choice of insulation. To insulate pipes, materials such as rubber, mineral wool or expanded polystyrene are used. There are not many types of them on sale, so it's easy to find something suitable.

If a metal-plastic construction is installed, then opt for a material such as thermal fiber. It is not very dense, and this is its main advantage.But this raw material requires additional insulation. However, the work in this case will take more time and require high costs.

Insulation of low-pressure polyethylene structures is performed differently. Usually construction tape is wrapped around the pipe.

Types of heat-insulating materials for pipes

Styrofoam

This is a very popular material for warming plumbing systems.

Let's take a look at some of its benefits:

- much more often used as a heater for water pipes and is produced in the form of finished parts (shells) of different diameters;

- can be used both independently and in conjunction with other materials (for example, waterproofing);

- for its installation, the manufacture of mounting trays is not required;

- It is used both in houses and for outdoor laying of engineering networks.

The installation instructions for this heater are extremely simple:

- the required number of foam shells is purchased to insulate pipes of a certain diameter;

- two halves are put on the water supply section and secured with a special lock;

- for additional strength, the insulation can be sealed with adhesive tape;

- at the docking points, the insulator must be overlapped in order to avoid the occurrence of cold bridges.

Foamed polyethylene

Such material is less common, but more convenient for arranging thermal insulation. It is used as a heater for sewer pipes and other similar networks.

Foamed polyethylene has the following undeniable advantages:

- flexibility;

- long term of work;

- elasticity;

- good thermal insulation features;

- high sound absorption coefficient;

- environmental friendliness;

- affordable price.

Alternative materials

In addition to the above, there are other materials that are used to isolate water transport systems and as a heater for chimney pipes.

| Material | hell |

| Fiberglass | A very good insulation for polymer pipes, which has a low density. But it requires additional waterproofing measures, which increases the price and installation time. |

| Basalt insulation | It has a low coefficient of thermal conductivity and an additional foil protective layer. Supplied as ready-made parts of a certain diameter (like foam), it is easy to install and does not require preparatory work before installation. The disadvantage is the high price. |

| Penofol | A fairly new insulation with an additional protective layer of iron foil. Represents polyethylene foam of different density. Sold in rolls, which facilitates its installation on pipes of different diameters, laid in hard-to-reach places. |

| polyurethane foam | This is a very effective insulation for pipes, which can significantly reduce heat loss in the heating system. It is mounted on a polymer pipe at the manufacturing stage. |

| Penoizol | It has characteristics similar to foam insulation. Sold in the form of a special mixture, which is applied to pipes using special devices. Has sealing properties. Great for processing outdoor pipes. |

Thermal insulation paint

This material is easy to apply and does not completely increase the size of the pipeline.

Despite this, heat-insulating paint has the following characteristics:

- has a low coefficient of thermal conductivity;

- protects iron parts from rust;

- prevents liquid condensation on the pipe surface;

- retains its properties at extreme temperatures;

- has a long service life;

- applied to the pipe with a brush or spray;

- it is possible to cover pipes in hard-to-reach places;

- enhances the appearance of the pipeline.

At the end of hardening, the composition provides the same level of thermal insulation as simple mineral wool.

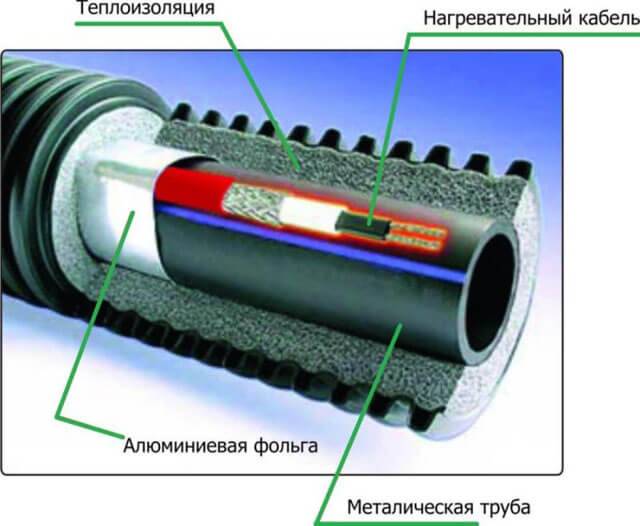

Sewer pipe heating

A good way to protect sewers from low temperatures is to equip the system with an electric cable. This method is considered the most effective, but also quite expensive. Installation involves not only installing the cable on pipes, but also connecting to a power source.

The heat-insulating cable must fit snugly against the walls of the pipeline so that it can be heated. Installation is carried out during the laying of the highway. If there is no insulating material, the heat generated as a result of heating will go to the environment.

For this reason, it is required to wrap the pipeline with a cable with insulation. This type of thermal insulation is suitable for individual sections of the sewer. The fact is that the cable may not be along the entire length of the pipeline. If necessary, it can be mounted on a problematic section of the sewer network, which is very convenient.

Other insulation methods

In addition to traditional methods of insulating underground water pipes, there are several alternative methods that avoid the need to lay pipes to great depths.

Heating cable

With this method, the pipeline is heated with a cable with a power of at least 20 W per 1 m of pipe.Insulation is carried out both from the outside and the inside of the pipes. This prevents them from freezing at the entrance to the house. Heating by this method is carried out only in frosts, so that in the warm season electricity can be saved.

The advantage of this method is that when pipe cable application it can be deepened by only 50 cm. Another positive side is the ability to defrost a pipe that has caught frost.

The main disadvantage of this method is its high cost. And in the absence of special skills for installing the cable inside the pipe, you will have to involve specialists, which will also affect the cost of heating. You can also run the cable over the pipe with your own hands, since such work is much easier to do. The work is carried out using a self-regulating insulation cable, which can be purchased already installed in the pipe.

High pressure

It is possible to insulate water supply pipes by maintaining high pressure inside them, to create which you will need:

• Embed a receiver in the pipe, capable of creating pressure within 3-5 atmospheres.

• Pressure is maintained by submersible pumps. For this purpose, pumps are installed that pump pressure in the range of 5-7 atm.

• After that, you will need to install a non-return valve, while the valve must be closed in front of the receiver.

To start such a system, you just need to bring the pump into working condition. Air is bled from the system to bring the pipeline back into operation.

Warming with air

Freezing of the soil in winter occurs from its upper layers. At the same time, the lower layers of the earth, despite the severe frost outside, remain warm.This natural feature can also be used to heat the pipeline in private homes. To do this, you can put tubular thermal insulation on it, or make thermal insulation in the form of an umbrella. In the latter case, heat enters from below and is retained by an impromptu umbrella at the level of the pipeline.

Air insulation can also be done by laying one pipe inside another. For the outer layer, it is best to use a sewer pipe made of propylene. This method has the following advantages:

• In the event of an emergency, a polypropylene manifold can be used to route the emergency hose. To this end, it is recommended to equip the pipe with a cable or wire in advance.

• It will be possible to replace a damaged pipe without digging a trench.

• This method will guarantee heating of the pipeline under any conditions. If a high-pressure cable or system periodically requires repair, then the propylene manifold can serve uninterruptedly for a long time.

• In the event of a pipe freezing, warm air can be blown into the collector to melt the frozen water.

As you can see, different methods can be used to insulate water pipes. Properly carried out work will ensure the life of the pipeline even in the most severe frosts

It is important to remember that the issue of water supply insulation should be addressed in a timely manner, without waiting for the pipes to burst from frozen water.

How to perform thermal insulation of polypropylene pipes

The sequence of actions practically coincides with the insulation of metal pipes. If glass wool is used as a heater, then work cannot be started without protective gloves.Auxiliary tools in this case will not be useful if you use ready-made sleeves made of glass wool or glass wool (Germany). Today, such a heater for polypropylene pipes is practically not in demand, it has been replaced by other materials in the form of liquid ceramics, synthetics and ceramic fiber sleeves. FUM tape is often used on seals and butt joints.

Also, as a heat insulator, you can use a special anti-condensate material, which must be applied several times to all bends, connections and pipe turns. Thus, all elements of the pipeline will be isolated from outside influences and completely sealed. Your polypropylene pipes for heating will be guaranteed to be protected from delamination and temperature fluctuations in the walls.

If the heating system is immured into the wall, and it warms up the entire space around it, is it necessary to insulate the polypropylene pipes additionally? It turns out yes.

And there are several reasons for this:

- Thanks to additional sealing, it is possible to delay the process of heat leakage due to a pipe rupture.

- With a significant temperature range outside and inside the tubular product, the process of its cooling is accelerated, etc.

That is, it has been proven in practice that the benefits of insulating and sealing polypropylene pipes are enormous. It is better, of course, to use the highest quality materials, among which polyethylene foam occupies a leading position (for more details: “How to choose a heater for polyethylene foam pipes - characteristics of an insulating material”). With its help, the thermal insulation of the pipe is carried out quite quickly, one has only to press the balloon piston.

Types of insulation for water pipes in the ground and on the street

A wide range is what is characteristic of this segment of the building materials market. Based on this, you will surely be able to decide how to insulate a water pipe on the street or in the ground. Intense competition plays into the hands of consumers: manufacturers are forced to expand their product range.

The following materials are used as thermal insulation for water pipes in the ground and on the street:

- glass wool. With its help, you can insulate surfaces of any type;

- heat-insulating basalt shells (cylinders). To insulate water pipes in a private house, you can choose such products of various designs, including those coated with aluminum foil, which increases the wear resistance of the insulation;

- polystyrene (polystyrene foam) shells. The use of these products is the best solution to the problem than to insulate the water pipe on the street with your own hands;

- synthetic rubber. This material is non-toxic and suitable for insulating water pipes in a country house or a private house. After wrapping the elements of the water supply system with it, the seams are glued together.

As for glass wool, this material is considered harmful, and therefore it is now used much less often than before.

But if you decide to save money, then do not forget about the precautions when working with it.