- Rules for choosing a heating boiler

- Varieties of water heaters

- 3 Correcting the calculations - additional points

- How to choose a heat source - recommendations

- Power calculation

- What power should the boiler be?

- Induction boilers

- Heating electrical installations

- The best solid fuel boilers for direct combustion

- Viadrus Hercules U22

- Zota Topol-M

- Bosch Solid 2000 B-2 SFU

- Protherm Beaver

- Types of boilers according to the principle of operation

- How to choose the right boiler?

- Combined devices

- What are the advantages of liquid fuel boilers?

Rules for choosing a heating boiler

Before proceeding with the selection of a specific model of a heating boiler, it is necessary to study the criteria that should be guided by. Understanding the features of operation and the main parameters of the equipment, you can choose a device that can satisfy all your needs.

First of all, consider the following nuances:

- boiler type and efficiency;

- camera design;

- the power of the device and the area of the room;

- combustion time and supported fuels;

- heat exchanger material;

- additional functions and protection systems.

Boilers are single-circuit and double-circuit. The first option is connected to an autonomous heating system and is intended exclusively for heating. Some models work in conjunction with a boiler.

The second option replaces the water heater and boiler, providing not only heating, but also hot water supply.

The efficiency indicator of the boiler, expressed in the efficiency parameter, shows how productive the device is. The higher it is, the less fuel materials will be needed to heat the room.

The efficiency indicator of the boiler, expressed in the efficiency parameter, shows how productive the device is. The higher it is, the less fuel materials will be needed to heat the room.

One of the main indicators of the equipment is the output thermal power. This parameter must be selected based on the area that is supposed to be heated.

It is highly desirable that the model has the ability to adjust the power, allowing you to achieve the optimal comfortable temperature.

Boilers with an open type of chamber design take oxygen from the room and remove combustion products through the chimney. They should be installed in places with good ventilation. Units with a closed chamber type can be placed in almost any room

Boilers with an open type of chamber design take oxygen from the room and remove combustion products through the chimney. They should be installed in places with good ventilation. Units with a closed chamber type can be placed in almost any room

The frequency of bookmarking depends on the time of fuel combustion in the boiler. Pyrolysis boilers, long-burning devices, retain heat the longest. The best option would be units that work not only on wood, but also on alternative fuels.

Also, when choosing, it is important to pay special attention to the heat exchanger:

Operational safety and equipment efficiency are enhanced by additional built-in mechanisms and functions. It is good if the selected model has overheating protection, devices for regulating traction, measuring current pressure and temperature indicators.

Varieties of water heaters

All modern heating boilers used in private houses and apartments are divided into groups according to the following criteria:

- consumed energy carrier - natural gas, electricity, solid fuel, and so on;

- according to the method of installation - floor and wall;

- in terms of functionality - single-circuit and double-circuit, the latter additionally heat water for hot water supply;

- the need for electrical connection - dependent and non-volatile.

We propose to consider boiler plants, dividing according to the main criterion - the energy carriers used. Existing types of devices:

- gas;

- solid fuel;

- electrical;

- diesel;

- combined, otherwise - multi-fuel.

Now we will analyze each group separately, detailing all the disadvantages and advantages of boilers.

3 Correcting the calculations - additional points

In practice, housing with average indicators is not so common, so additional parameters are taken into account when calculating the system. One determining factor - the climatic zone, the region where the boiler will be used, has already been discussed. We give the values of the coefficient Woud for all areas:

- the middle band serves as a standard, the specific power is 1–1.1;

- Moscow and Moscow region - we multiply the result by 1.2–1.5;

- for the southern regions - from 0.7 to 0.9;

- for the northern regions, it rises to 1.5–2.0.

In each zone, we observe a certain scatter of values. We act simply - the further south the area in the climatic zone, the lower the coefficient; the further north, the higher.

Here is an example of adjustment by region. Suppose that the house for which the calculations were made earlier is located in Siberia with frosts up to 35 °. We take Woud equal to 1.8. Then we multiply the resulting number 12 by 1.8, we get 21.6. We round off towards a larger value, it turns out 22 kilowatts. The difference with the initial result is almost twice, and after all, only one amendment was taken into account. So the calculations need to be corrected.

In addition to the climatic conditions of the regions, other corrections are taken into account for accurate calculations: the height of the ceiling and the heat loss of the building. The average ceiling height is 2.6 m. If the height is significantly different, we calculate the coefficient value - we divide the actual height by the average. Suppose the ceiling height in the building from the example considered earlier is 3.2 m. We consider: 3.2 / 2.6 \u003d 1.23, round it up, it turns out 1.3. It turns out that to heat a house in Siberia with an area of 120 m2 with ceilings of 3.2 m, a boiler of 22 kW × 1.3 = 28.6 is required, i.e. 29 kilowatts.

It is also very important for correct calculations to take into account the heat loss of the building. Heat is lost in any home, regardless of its design and type of fuel. Through poorly insulated walls, 35% of warm air can escape, through windows - 10% or more

An uninsulated floor will take 15%, and a roof - all 25%. Even one of these factors, if present, should be taken into account. Use a special value by which the received power is multiplied. It has the following stats:

Through poorly insulated walls, 35% of warm air can escape, through windows - 10% or more. An uninsulated floor will take 15%, and a roof - all 25%. Even one of these factors, if present, should be taken into account. Use a special value by which the received power is multiplied. It has the following stats:

- for a brick, wooden or foam block house, which is more than 15 years old, with good insulation, K = 1;

- for other houses with non-insulated walls K=1.5;

- if the house, in addition to non-insulated walls, does not have an insulated roof K = 1.8;

- for a modern insulated house K=0.6.

Let's return to our example for calculations - a house in Siberia, for which, according to our calculations, a heating device with a capacity of 29 kilowatts is needed. Suppose that this is a modern house with insulation, then K = 0.6. We calculate: 29 × 0.6 \u003d 17.4. We add 15-20% to have a reserve in case of extreme frosts.

So, we calculated the required power of the heat generator using the following algorithm:

- 1. We find out the total area of the heated room and divide by 10. The number of specific power is ignored, we need average initial data.

- 2. We take into account the climatic zone where the house is located. We multiply the previously obtained result by the coefficient index of the region.

- 3. If the ceiling height differs from 2.6 m, take this into account as well. We find out the coefficient number by dividing the actual height by the standard one. The power of the boiler, obtained taking into account the climatic zone, is multiplied by this number.

- 4. We make a correction for heat loss. We multiply the previous result by the coefficient of heat loss.

Placement of boilers for heating in the house

Above, it was only about boilers that are used exclusively for heating. If the appliance is used to heat water, the rated power should be increased by 25%

Please note that the reserve for heating is calculated after adjusting for climatic conditions. The result obtained after all calculations is quite accurate, it can be used to select any boiler: gas, liquid fuel, solid fuel, electric

How to choose a heat source - recommendations

If you have carefully studied the previous material, many questions have probably disappeared.Let's summarize our review of heat sources with general recommendations and tell you which boiler to choose in certain conditions:

Always start with energy availability. The best option for residents of the Russian Federation is gas heaters, wood-burning ones are in second place. In countries where the price of blue fuel is high, priority remains with TT boilers.

Count on 2 types of fuel. For example, liquefied gas and electricity at a nightly rate or firewood and electricity.

To provide a family of 2 people with hot water, a double-circuit heat generator is enough. If there are more residents, buy a single-circuit unit and an indirect heating boiler. An alternative option is to install a separate water heater.

Do not rush to purchase an expensive condensing boiler. Take a "aspirated" or a turbo unit - you will not lose in efficiency, but you will win in terms of initial and operating costs.

From solid fuel devices, we want to single out boilers of direct and long-term combustion. Pyrolysis plants are capricious, and pellet plants are too expensive. If you plan to fire with coal, be sure to choose a model sharpened for a high combustion temperature.

We do not recommend purchasing steel TT-boilers with upper combustion of firewood of the Stropuva type

The units are not bad, but "famous" for significant shortcomings - freezing of fuel, the inability to load "on the go" and similar troubles.

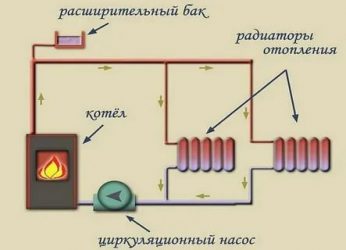

It is important to properly tie solid fuel installations - to organize a small circulation ring through a three-way valve. Electric and gas heaters are easier to connect - they are not afraid of condensate in the furnace.

When choosing an electric boiler, give preference to products that heat the coolant with heating elements - the devices are reliable in operation, maintainable and undemanding to water.

Choose a diesel, combined or pellet heating boiler as needed. Example: during the day you want to heat with coal, at night you want to use electricity at a cheap rate. Another option: the budget allows you to buy an automatic TT boiler, pellets are inexpensive, and there are no other energy sources.

Instead of a combined wood-electricity boiler, it is better to purchase 2 separate units and connect them in parallel with check valves

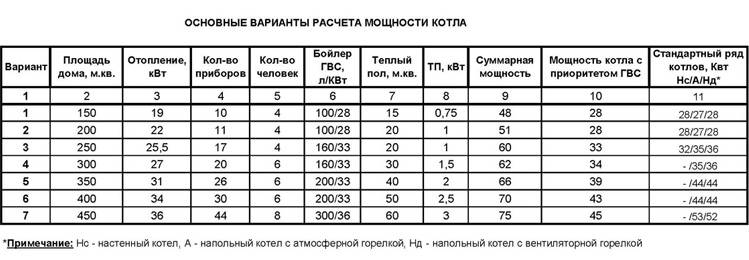

Power calculation

When choosing a gas boiler for a private house, you should pay attention to the power of the equipment. It is generally accepted that for heating 10 sq.

m. of living space in the Russian climate requires 1 kW of thermal energy. In the northern and Far Eastern regions, it rises to 1.2-1.5 kW, and in the southern regions it drops from 0.8 kW. But even in the south, it is customary to stick to the average, in case of a cold winter.

Following the formula, we get that for heating a private house with an area of 200 sq. m. we need a gas boiler with a capacity of 20 kW. But we forgot about the necessary reserve - it is needed in case of heat losses and excessively cold winters. As a rule, the margin is 10-20%. Based on this recommended capacity of equipment for heating private houses with an area of 200 sq. m. is 24 kW.

Table for calculating the power of a gas heating boiler for a private house.

Heat loss is affected by:

- window construction;

- The presence of attic insulation (or a heated second floor);

- The presence of insulated walls;

- The ratio of window area to floor area;

- The number of external walls in a particular room.

Also, the average temperature in the coldest period in the area is taken into account.

What power should the boiler be?

The technical documentation for the gas heater necessarily contains information about the rated power. Before buying equipment, it is advisable to calculate the need for heat in the room. Often, the manufacturer there also indicates the quadrature of the room that this equipment will be able to heat.

But all this is rather arbitrary, without competent heat engineering calculations for a particular house, you should not choose a gas boiler.

The calculation of the required power is made taking into account the quadrature of the building, the configuration and type of the heating system, the climate zone and many other factors

Recommendations of 1 kW for every 10 m2 of a cottage are very average figures. They rarely reflect reality.

An experienced heating engineer in the calculations should take into account:

- area and cubic capacity of each room;

- climatic conditions of the region of residence;

- quality of insulation of external walls;

- the size and number of windows, as well as the type of double-glazed windows in them;

- the presence of balconies and street doors;

- characteristics of the heating system, etc.

In addition, the quality of the fuel and the gas pressure in the line are taken into account. A separate calculation is made for the DHW system. And only then both figures are summed up and increased by 15-20% in reserve, so that the boiler can cope with both constant and peak loads without problems.

Induction boilers

The principle of operation by which induction boilers work is similar to the operation of a transformer. The metal labyrinth transfers energy to the coolant, practically without loss, which in turn heats up due to magnetization reversal in an alternating magnetic field created by an inductive coil.Induction boilers work with any coolant, it can be water, antifreeze, oil. They do not need additional automation, protection or a special ventilation system.

Small-sized induction boilers allow you to efficiently use the space of the room, they are easy to install, start and maintain. They are also used as a backup system or in mobile installations in case of emergency. Induction boilers are considered the most economical, but their installation is possible only if the heating system is of a closed type, with excess pressure and forced circulation.

induction boiler

induction boiler

Compact and quiet electric boilers do not require special installation conditions. They are simple and safe, do not smoke, do not need maintenance or cleaning. But they are not the most economical option, and in the event of a power outage, the room will remain without heat.

Heating electrical installations

To work together with water heating, manufacturers produce 3 types of electric boilers:

- TENovye. The device heats the coolant with the help of tubular elements that are used everywhere - in boilers, heat accumulators, heat pumps and so on.

- Induction installations heat water with a metal core placed inside an electromagnetic field.

- Electrode boilers use the conductivity of ordinary water. The current passes between two electrodes immersed in a coolant.

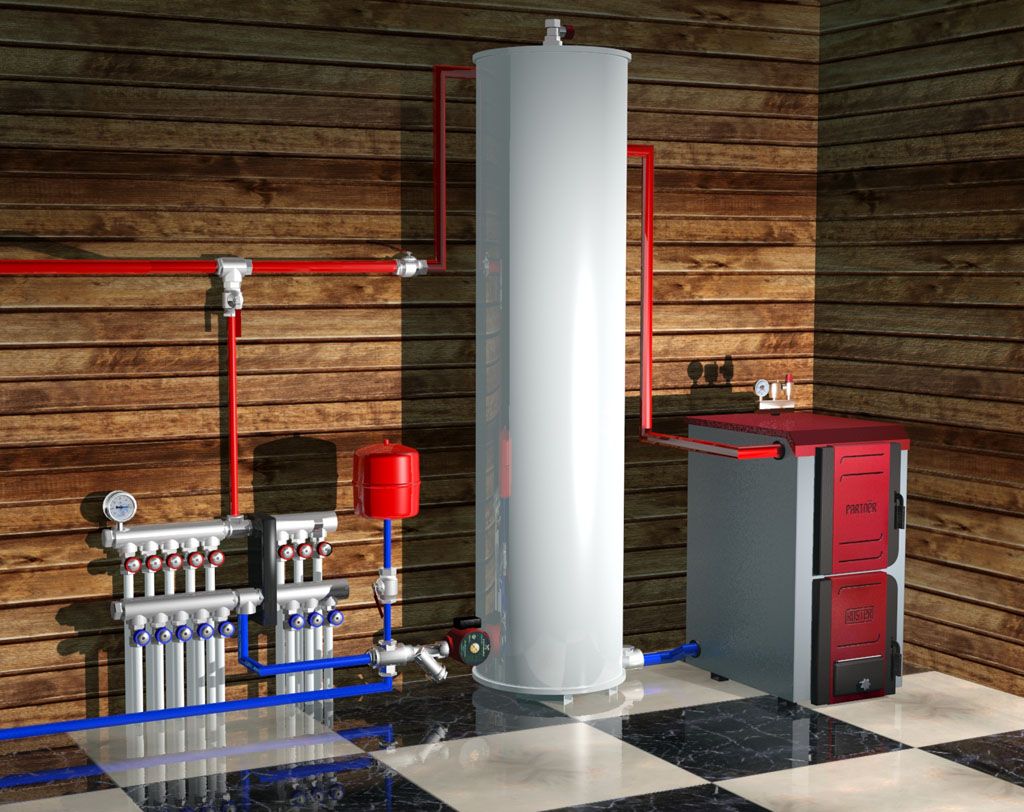

Mini-boiler room with tubular electric heaters placed inside a tank with a coolant

Heaters with heating elements externally and internally resemble hinged gas units. A circulation pump, a safety group and an expansion tank are usually hidden under the case.Induction and electrode boilers need to be understaffed - buy pumps and other piping parts.

Advantages of electric water heaters:

- the best efficiency among all heat sources;

- noiselessness (excluding old models equipped with electromagnetic starters and contactors);

- small weight and dimensions;

- low price of equipment;

- relatively simple installation;

- full autonomy in work, maintenance - annually at the beginning of the season.

The heating block of the electrode apparatus can be controlled remotely using room thermostats

Heat generators really do not require attention from the homeowner, except when setting the temperature. There are nuances in the operation of the electrode apparatus - the coolant must be salted, otherwise the heating intensity will drop.

Cons of heating electric boilers:

The best solid fuel boilers for direct combustion

Viadrus Hercules U22

The lineup

The model range of this series of Vidarus boilers is represented by seven solid fuel boilers with power from 20 to 49 kW. The most productive of them is able to heat a building up to 370 sq.m. All equipment is designed for a maximum pressure in the heating circuit of 4 atm. The operating temperature range in the coolant circulation system is from 60 to 90 ° C. The manufacturer claims the efficiency of each product at the level of 78%.

Watch product video

Design features

All models of the presented line are designed for floor installation. They have an open combustion chamber with air supply due to natural draft.The large square-shaped doors easily open wide, which is convenient when loading fuel, removing ash and inspecting the condition of internal elements.

The built-in heat exchanger made of high-quality cast iron is adapted to work in a single-circuit heating system. The boilers do not have devices powered by an external electrical network and are operated in a completely autonomous mode. All settings are mechanical.

Fuel used. The design of a spacious firebox is designed to use firewood as the main fuel, but coal, peat and briquettes can be used.

Zota Topol-M

The lineup

The line of six Zota Topol-M solid fuel boilers starts with a compact 14 kW model designed to heat a house for an average family, and ends with an 80 kW unit capable of heating a large cottage or production workshop. The boilers are designed for operation in systems with pressure up to 3 bar. Efficiency of thermal energy use is 75%.

Watch product video

Design features

Their distinctive feature is a slightly raised design, which makes it more convenient to open the ash pan door and empty it. Open type combustion chamber with chimney connection from the rear wall. There is a built-in temperature sensor. All adjustments are made manually.

A heat exchanger for a single-circuit heating system is mounted inside, connected to 1.5 or 2” pipelines. Boilers work offline. Products of this brand are easy to install and reliable in operation.

Fuel used. Firewood or coal is used as fuel, for which a special grate is provided.

Bosch Solid 2000 B-2 SFU

The lineup

Solid fuel boilers Bosch Solid 2000 B-2 SFU are represented by a number of models with a capacity of 13.5 to 32 kW. They are able to heat buildings with a usable area of up to 240 sq.m. Parameters of the circuit operation: pressure up to 2 bar, heating temperature from 65 to 95 ° C. Efficiency according to the passport is 76%.

Watch product video

Design features

The units have a built-in single-section heat exchanger made of cast iron. It is connected to a single-circuit heating system through standard 1 ½” fittings. The boilers are equipped with an open type combustion chamber with a 145 mm chimney. For normal operation, a connection to the electrical network with a voltage of 220 volts is required.

The temperature regulator and protection against an overheat of water is provided. The ash pan has a small volume, so it requires regular cleaning. Manufacturer's warranty 2 years. The design is simple, safe and highly reliable.

Fuel used. The boiler is designed to use hard coal. On this type of fuel, it demonstrates high efficiency. When working on wood or briquettes, the efficiency is noticeably reduced.

Protherm Beaver

The lineup

A series of solid fuel boilers Protherm Bober is represented by five models with power from 18 to 45 kW. This range completely covers any private house. The unit is designed to work as part of a single-circuit heating circuit with a maximum pressure of 3 bar and a coolant temperature of up to 90 ° C. For the correct operation of the control system and actuation of the circulation pump, connection to the household electrical network is required.

Watch product video

Design features

Boilers of this series are equipped with reliable cast-iron heat exchangers.The original design of the combustion chamber increases the efficiency of heat transfer. Exhaust gases are discharged through a chimney with a diameter of 150 mm. For connection to the heating circuit, there are branch pipes for 2”. Such boilers are designed for long-term operation.

Fuel used. The declared power is designed for burning firewood with a moisture content of up to 20%. The manufacturer has provided for the possibility of using coal. In this case, the efficiency of work increases by several percent.

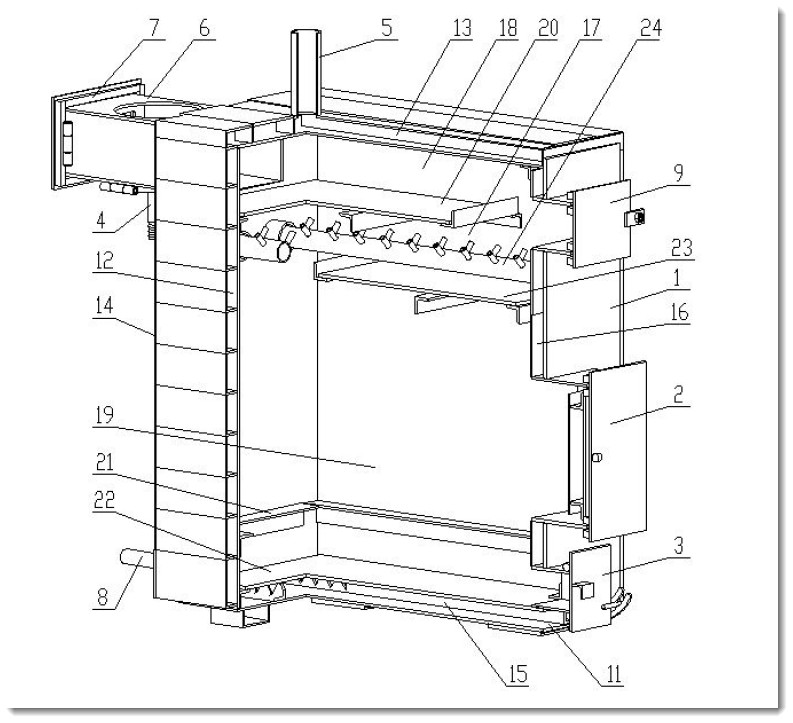

Types of boilers according to the principle of operation

Depending on the method of combustion of fuel, four types of boilers are distinguished:

Classic direct combustion boiler (or natural draft). This is the traditional and most common design. Main advantages: simple device, affordable price, ability to work on any type of fuel, energy independence. The last factor is very important for rural areas with poor quality of electrical networks - as a rule, electricity is not needed for the operation of the boiler, and thermoregulation is carried out using a damper and a mechanical drive. There is only one fundamental drawback - incomplete combustion of fuel. And the rest follow from this: low compared to other types of efficiency, a large percentage of the solid residue of combustion products, labor-intensive maintenance and care. Based on this. this type is difficult to categorize as "the best solid fuel boilers for home heating."

Direct combustion scheme with bottom air supply and mechanical draft "on a chain" for damper control

Classic boiler with additional draft. There are two device options. In the first case, air is "blown" into the furnace, which ensures more complete combustion of the fuel.In the second, the boiler is equipped with a smoke exhauster (exhaust fan in front of the chimney), which creates a vacuum in the combustion chamber and increases natural draft. The advantages are the same as those of a direct combustion boiler, except for energy independence. But the “dependence” on electricity is compensated by increased efficiency and higher power rates with the same furnace size and type of fuel.

Boiler with additional

Pyrolysis (or gas generating) boiler. To some extent, this is the next stage in the development of a boiler with additional thrust, but the very principle of fuel combustion is changing. Functionally, the boiler is divided into two chambers. In the first, with an artificial lack of air, firewood smolders, generating not only heat, but also pyrolysis gases that enter the second chamber, where they are completely burned out under conditions of additional air supply. In terms of efficiency, these boilers are the most efficient, but also “capricious”. The main disadvantage is the strict requirements for stable fuel quality. If this is firewood (and most types of pyrolysis boiler models are “tuned” specifically for them), then the standard requirement is that the moisture content of the wood should be no higher than 20%. Otherwise, the generation of pyrolysis gases is reduced, turning the boiler into a conventional discharge with forced air supply, which, given the high cost of equipment, is unprofitable. In addition to efficiency, the duration of the combustion of one tab - up to 12 hours - is an advantage.

An example of the practical implementation of a gas-generating boiler

The burn time of one bookmark depends on the type of fuel

Separately, it must be said about boilers with automatic feeding fuel into the combustion chamber.According to the principle of operation, these are traditional boilers with natural or forced draft, but thanks to a separate bunker for fuel, the operating time at one “gas station” can reach from several days to several weeks (depending on the volume of the bunker and the area of \u200b\u200bthe heated room).

Pellet boilers with a tray burner in fact also support the "top" combustion of fuel with high heat transfer efficiency

Boilers with a bunker operate either on pellets or on coal, crushed to a certain fraction (usually no larger than 25 mm). There are models with automatic ash removal, which, combined with automatic maintenance of the operating mode, makes the heating scheme of a private house with a solid fuel boiler as convenient to use as a gas one.

How to choose the right boiler?

The only objective criterion for choosing a combined boiler for your home is the required power to ensure the functioning of the heating system. Moreover, this indicator should not be affected by the number of connected circuits.

It makes no sense to pay more for a powerful boiler in the hope of adjusting its operation with automation. This approach contributes to the "idle" operation of the device, which leads to a faster failure. In addition, this mode of operation contributes to the acceleration of the condensation process.

As for the calculation of power, theoretically, to heat an area of 10 m2, it will be necessary to use 1 kW of heat energy.

But this is a rather conditional indicator, which is adjusted based on the following parameters:

- ceiling heights in the house;

- the number of floors;

- degree of building insulation.

Therefore, it is advisable to use a one-and-a-half coefficient in your calculations, i.e. in calculations, increase the margin by 0.5 kW.The power of a multi-circuit heating system is calculated with a surcharge of 25-30%.

So, in order to heat a building with an area of 100 m2, a power of 10-15 kW is required for single-circuit heating of the coolant and 15-20 kW for double-circuit heating.

To select a gas burner for a solid fuel boiler, you need to accurately measure the dimensions of the combustion chamber. It is these proportions that will correspond to the size of the gas burner

An equally important criterion when choosing a combined heating boiler is the price category. The price of the device depends on the power, the number of functions and the manufacturer.

For users, other characteristics are no less important:

- DHW;

- material of manufacture;

- ease of management;

- dimensions;

- accessories;

- weight and installation features;

- other.

The issue with hot water supply will immediately have to be resolved: a boiler will provide hot water or there is an electric boiler for this.

In the case of determining the first option, the preferred method is chosen - storage or flow, as well as the parameters of the water reservoir according to needs (calculated based on the number of residents).

As for the dimensions of the equipment, they only matter in the case of installation in a room with a small area.

According to the material of manufacture, a wide range of boilers is presented. But the most popular options are steel or cast iron. Also, such a boiler is able to withstand a high and prolonged temperature load, has a longer service life.

Judging by the intensity of sales and relying on consumer reviews, the following models are actively in demand:

Automation of control affects the usability, and the security system depends on how automated the process of combustion of energy carriers is. Most models can be controlled using convenient remote controls or panels.

Most models are optional. This includes the presence of a hob for cooking, injectors, draft regulators, burners, a soundproof casing, etc.

The choice of a boiler according to this parameter should be based on personal preferences and the allocated amount for the purchase.

When choosing a heating boiler with a combination of wood / electricity, it is necessary to calculate the required power of the heating element. It is recommended to choose models with an indicator of at least 60% of the required coefficient for home heating

But the weight of the equipment and the complexity of its installation should immediately pay attention. Installation in a residential building of most floor models of combined boilers for heating, equipped with several combustion chambers, requires an additional concrete pedestal device, because a standard floor covering cannot withstand such a load

The best solution is to equip a separate boiler room

Installation in a residential building of most floor models of combined boilers for heating, equipped with several combustion chambers, requires an additional concrete pedestal device, because a standard floor covering cannot withstand such a load. The best solution is to equip a separate boiler room.

Knowing the main parameters that affect the choice of a combined boiler, you can choose the most suitable model.

Additional selection recommendations, as well as a comparative overview of different heating units for a private house, are given in.

Combined devices

Before you choose the power of the boiler for your home, you should pay attention to another type of boiler - combined. This refers to devices that can work with several fuel options.

Most often, consumers purchase solid fuel boilers with built-in heating elements. At the moment of burning coal or firewood, the system warms up in the same way as when using a conventional solid fuel boiler. When the fuel burns out and the boiler starts to cool down, electric heating elements are turned on to maintain the temperature in the house. By themselves, they are not able to fully heat the house, but they can maintain the temperature and prevent the system from freezing.

Combined boilers with burners for liquid fuel are in rather high demand. Such devices are equipped with two separate combustion chambers - for solid fuel and for liquid.

What are the advantages of liquid fuel boilers?

The main advantage of boilers that burn diesel fuel, mining and heavy heating oil is autonomy. The unit is indispensable when there are no other energy sources - firewood, gas and electricity in the required volumes.

There is no need to monitor the combustion process, the device operates in automatic mode until the diesel fuel runs out. Installation does not require any permissions, but the initial start-up and adjustment of the burner should be done by an intelligent master.

This is where the pluses of diesel units end, then there are solid minuses:

- high cost of equipment and fuel;

- constant smell of diesel fuel in the boiler room;

- maintenance - as needed, which occurs quite often due to the quality of the fuel;

- for the same reason, it is necessary to constantly clean the chimney;

- you need to monitor the level of diesel in the tank;

- in terms of weight and dimensions, the unit is comparable to a floor cast-iron boiler.

An example of a diesel boiler house with two heat sources. Fuel tanks and fuel pumps are installed at the end of the room.

If it comes to your mind to heat the house with used engine oil, add to the list of shortcomings the dirt in the furnace and an additional 2-4 squares of area for barrels - sumps.