- Comparison of wells made of plastic and concrete rings

- Types of plastic wells

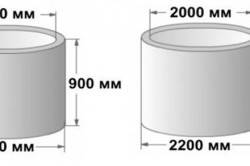

- Selection of reinforced concrete rings

- Application of bituminous materials

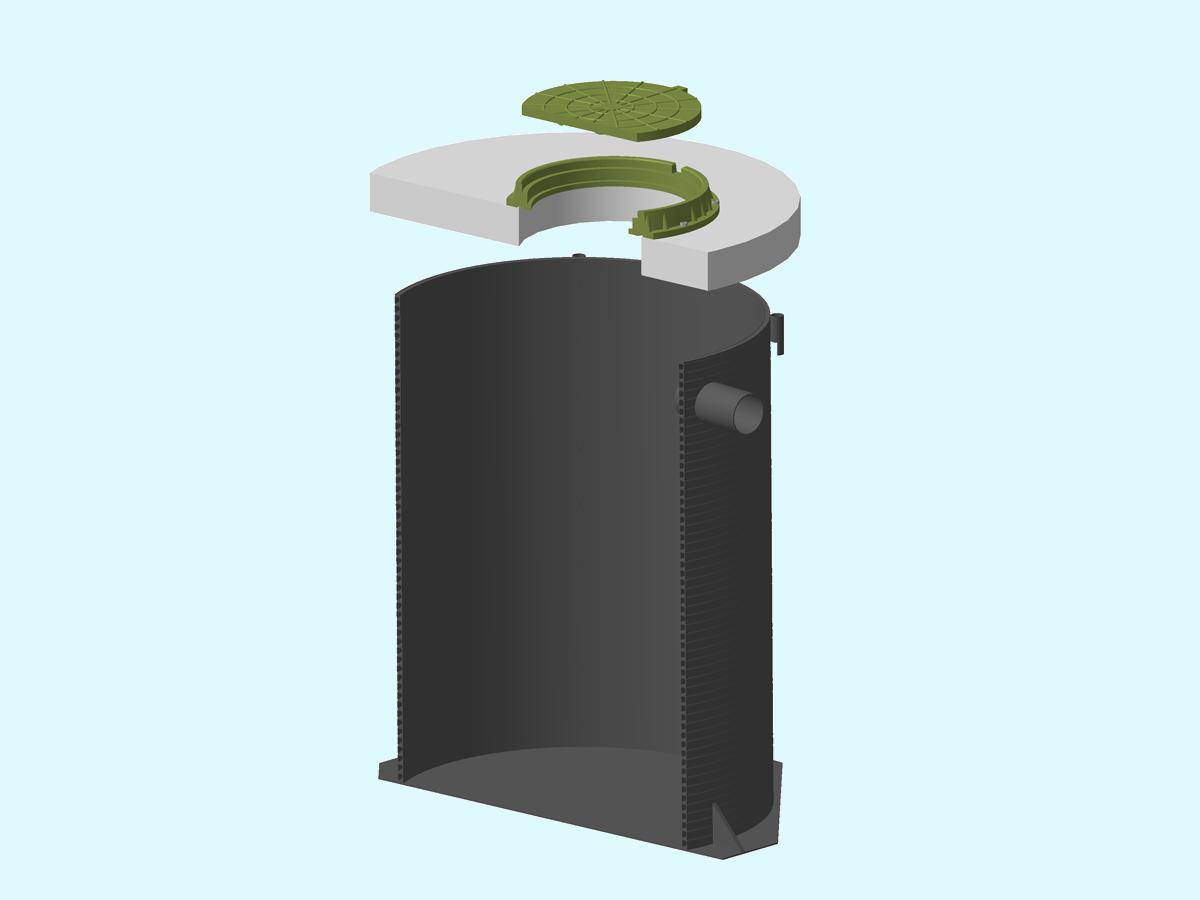

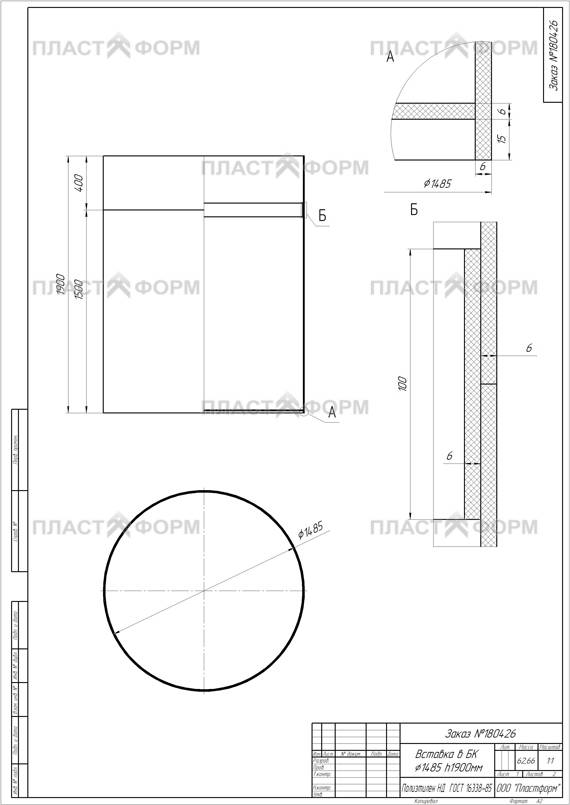

- What is an insert in a concrete septic tank

- Traditional bituminous way

- External and internal sealing

- Alternative to plastic insert

- Waterproofing the seams of a concrete septic tank

- Roll waterproofing installation

- Types of sealing

- Concrete well waterproofing technology

- Seam cleaning

- Surface preparation

- Applying waterproofing to joints

- Applying insulation to the surface of concrete rings

Comparison of wells made of plastic and concrete rings

Concrete as a material for wells has both advantages and disadvantages. The main advantage is that concrete and reinforced concrete rings for the well have a lower cost compared to analogues made of polypropylene, polyvinyl chloride and polyethylene.

The disadvantages that significantly limit the use of concrete rings include the complexity of installation. There is no way to do without a crane and heavy special equipment. In addition, concrete rings are produced in standard sizes, which significantly limits their use. Here you can see the weight of the concrete ring for the well.

And now we list the advantages of plastic rings:

- Their main advantage is their low weight.Put in place a ring weighing 40 kg under the force of two normal men. Therefore, if the construction of a well in your country house or in your yard is on the agenda without involving a large number of people and equipment, then plastic rings are the only right decision.

- Due to the low weight, the second plus follows - the possibility of delivering the rings with your own transport to any place in your personal plot.

- Polymers are plastic materials. If, for example, water constantly freezes and melts in a concrete well, then, in the end, this will make it unusable. Plastic wells are not sensitive to rapid temperature changes, as well as increased soil vibration. So in some places (near the highway, working mechanisms) plastic rings are an alternative that will allow the well to do without repair for a long time.

- Installation of plastic in terms of ease cannot be compared with the installation of concrete rings. Polymers can be cut, sawn, sanded and bent. Therefore, each well made of plastic rings is customized to the specific needs of the customer.

- Thanks to the threaded connections, the plastic rings are tightly screwed onto each other. Special impregnations and mastics complete the 100% tightness.

The variety of wells made of polymers knows no bounds. In addition, you can always order an individual project, which will cost not much more than a typical one. The ease of working with plastic and the relative cheapness of its manufacture allows us to talk about a new era in building materials.

Prefabricated plastic rings have a guarantee of 50 years.But even if something happened and one of the rings of the sewer, drainage or drinking well turned out to be damaged, it can always be replaced. Screw connections facilitate the dismantling and installation of new elements at times.

Types of plastic wells

Sewer. If there is no centralized sewage system in the country house or there is no desire to install a storage septic tank, then a plastic sewer well will always help out. Install special kinets at the bottom, through which the liquid will go into the soil.

Drainage or absorption. This is a type of sewer well. You can do without throws in it, but you need to put a pillow of gravel and sand on the bottom.

Classic drinking. Here, plastic can be used not only at the initial stage of building your own water source. With the help of prefabricated plastic rings, you can "reanimate" the old concrete structure. Leaks at the joints of reinforced concrete rings, unpleasant smells from the depths of the well, clogging of the aquifer and other problems can be solved by restoration. This process is also called “rehabilitation.” For this, plastic rings of a smaller diameter than the former well are taken and sequentially screwed one onto the other. Between concrete walls and plastic rings, a pillow of sand and cement is poured. A filter of fine-grained gravel and sand is poured at the bottom. As a result, you do not need to dig a new well, which saves more than tens of thousands of rubles.

Cumulative. This type of well is adapted to collect rainwater and use it for irrigation.

It is important to ensure the tightness and reliability of the butt joints, because the water here will be above the aquifer.The strength characteristics of plastic rings for wells make it possible to withstand significant pressures and mechanical loads in any direction. Lookouts

They are designed to control and repair sewer systems. Ladders, handrails and other devices are mounted in them for the convenience of the maintenance personnel.

Lookouts. They are designed to control and repair sewer systems. Ladders, handrails and other devices are mounted in them for the convenience of the staff.

Selection of reinforced concrete rings

The issue related to the choice of reinforced concrete rings should be resolved responsibly. It is recommended to purchase material after a thorough study of all the characteristics of these products and the necessary calculations.

It is important that there is no damage on their surface, including cracks or shells. Otherwise, the rings will be subjected to rapid destruction during operation. Rust on mounting loops sticking out on the surface of concrete products is unacceptable

If it is present, then this is evidence of a corrosion process. As a result, lifting the product without breaking the loop will be impossible. When purchasing a quality blank, it is necessary to check the availability of a passport containing information about the constituent materials

Rust on mounting loops sticking out on the surface of concrete products is unacceptable. If it is present, then this is evidence of a corrosion process. As a result, lifting the product without breaking the loop will be impossible. When purchasing a quality blank, it is necessary to check the availability of a passport containing information about the constituent materials.

The lining of reinforced concrete rings is a reliable protection of products from rust.It allows for a high-quality reconstruction of reinforced concrete wells from the inside. If the sewer begins to collapse, starting from the tank, then this process can only be prevented with the help of a lining. It is a modern polymer protection that ensures a long service life of concrete rings.

The use of polyethylene sheets for lining helps prevent the formation of all kinds of growths on the walls of the well from the inside. The sealed surface can be easily cleaned if necessary. This improves the performance of the structures.

Application of bituminous materials

Giving waterproofing properties to various structural materials by treating them with heated petroleum bitumen is one of the methods most used in the recent past. The advent of modern waterproofing materials has left this method with only one advantage - its low cost. Bituminous coatings have low resistance to variable temperature changes. Low adhesive interaction with concrete surfaces provokes delamination and cracking of the waterproofing bituminous layer.

Another type of material that has a bituminous component as a base is specialized mastic. Additives with special properties are integrated into its composition, which are designed to increase the resistance of the waterproofing layer and significantly increase its service life. The advantage of using mastics over bitumen is also the cold method of applying them to the insulated surface, which greatly simplifies and speeds up the work.

What is an insert in a concrete septic tank

What is the role of a plastic insert in a concrete septic tank? The use of a concrete septic tank in an autonomous sewage system is quite common. However, the tightness of the treatment structure is broken already 1 year after installation.

This is due to the banal temperature difference, when, due to partial freezing of the soil, the concrete rings are displaced, i.e. gaps are formed at the joints of structural elements.

As a result, wastewater seeps through cracks in the concrete structure, the joints of the bottom and walls of the septic tank, the places where communications are supplied and enters the soil. Further, there are 2 possible scenarios for the development of the situation.

- If the groundwater is below the bottom of the septic tank, then gradually the sewage will sink down and reach their level. At what point this will happen is difficult to predict, and in most cases it is impossible to notice on your own if waste products in small doses fall into a well with drinking water. The real degree of pollution and the danger of drinking water can only be identified in laboratory conditions.

- If the septic tank is at the groundwater level, then sewage waste enters the well very quickly. In such a situation, drinking water will become unusable in the shortest possible time due to excessive pollution by sewage. This fact is easy to determine by the changed color and smell of water. Drinking water in this case is dangerous to health.

That is why it is important to pay attention to the waterproofing of the treatment plant.And in order not to waste time from year to year pumping out sewage, the unpleasant procedure for cleaning the walls and bottom of the septic tank, sealing the seams with a solution, you can use a special plastic liner. Unlike resins and mortars, which can provide tightness for 1-2 years, plastic containers serve as waterproofing guards for decades.

Unlike resins and mortars, which can provide tightness for 1-2 years, plastic containers serve as waterproofing guards for decades.

And in order to protect your well from groundwater contaminated by other neighbors, it is recommended to use plastic liners not only for sewage, but also for drinking water wells.

Traditional bituminous way

External and internal sealing

Scheme of applying penetrating waterproofing to concrete rings.

By itself, hot bitumen, although it is a good insulating material, is rather short-lived, subject to detachment and destruction during temperature changes. Therefore, for the processing of concrete rings, a bitumen-gasoline mixture is used in combination with bituminous mastics, supplemented with special additives.

The outer and inner surfaces of the concrete rings must be cleaned. Next, with the help of a compressor, the first layer of a mixture of bitumen with gasoline is applied in a ratio of 1: 3. Subsequent layers have a ratio of 1:1. The mixture is brought to dryness. The second layer is applied with hot bitumen using a brush or kwach, allowed to cool and covered with a third layer of hot bitumen.

After the bitumen has completely cooled, a mastic layer of at least 2-3 mm is applied.

On the outer surface of the concrete ring, on top of the mastic, a roofing material or other sealing material is glued.

Advantages of the bituminous method of waterproofing a septic tank from concrete rings are low cost and ease of operation. There are also disadvantages: doubts about 100% reliability and the impossibility of being used as internal waterproofing in wells with drinking water.

The use of traditional materials and methods for waterproofing concrete rings is justified by time. You can not discount the relatively low cost of these works. But there are modern materials, the use of which, although more expensive than traditional ones, will nevertheless provide a much higher degree of reliability.

Alternative to plastic insert

First, it is necessary to empty the storage tank or septic tank to be repaired by pumping out the contents with the involvement of a team of vacuum trucks. The service for pumping out a septic tank, the removal of its contents is provided by public utilities and private companies. It is cheaper to negotiate directly with the sewer of municipal services.

Cessation vehicles will need an access platform to the work site. Moreover, the distance of the entrance will be the smaller, the shorter the transport sleeve of the car. Its permissible length is up to 180 meters and even more - up to 500 m, if it is a high-pressure polyethylene hose.

The pumping of the septic tank must be carried out by trained specialists, amateurs will not be able to cope. Work on cleaning the septic tank is carried out by a special pump - sewer (fecal).

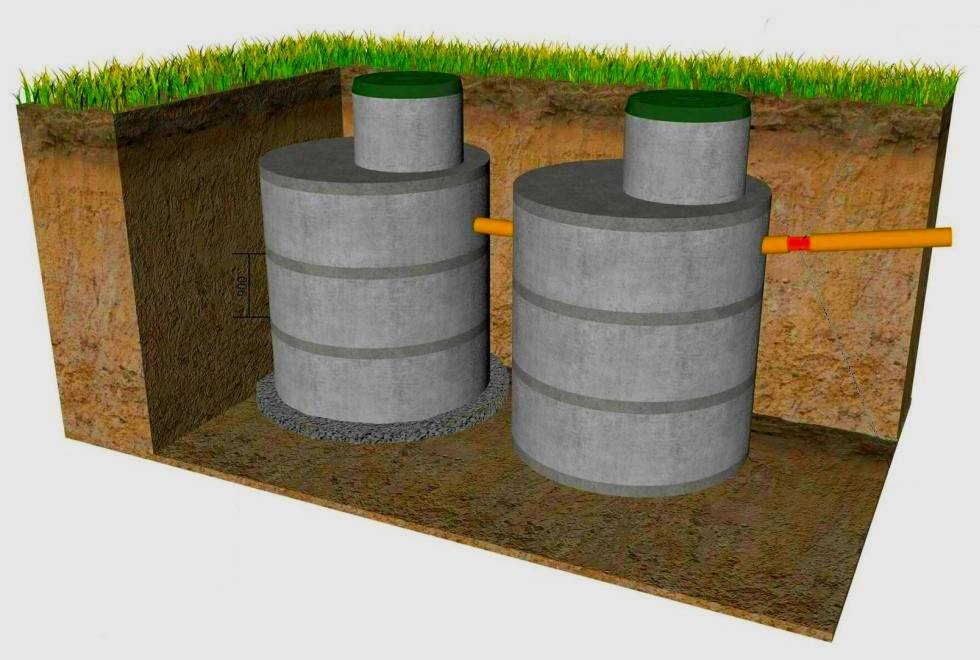

Waterproofing the seams of a concrete septic tank

To close up gaps between concrete rings well, you need to get to them outside the structure. It is necessary to dig a ditch around the septic tank to a depth that allows you to work with the joints between the reinforced concrete sections.

Accordingly, the more rings in the tank structure, the deeper the ditch will have to be dug. The width of the ditch is at least a meter. It will be difficult to work in a narrow ditch.

Having dug out the walls of the septic tank, you need to dry them. By the beginning of the waterproofing work, there should be no dark spots on the concrete walls. The seams must be cleaned of accumulated debris and soil, exposing the cavity to a minimum depth of 70 mm.

If rain is expected, cover the well and the ditch dug around it with moisture-proof material (plastic sheeting, tarpaulin, etc.).

If you dig a septic tank in a narrow trench, there will not be enough space for waterproofing work.

To fill the joints, well-washed clay and a plaster trowel are required. Clay should be kneaded with your feet in a basin or other similar container. Stuffing joints between concrete rings with unwashed clay is ineffective - its structure is uneven, including voids that let water through.

The sealing of external seams between the concrete sections of the septic tank can be done with a cement-sand mortar mixed with liquid glass. The composition of the mixture: liquid glass, cement and seeded fine sand in a ratio of 1:1:3.

The mixture should be prepared in small portions - when adding liquid glass, the solution quickly solidifies. The seams are filled with such a solution using a spatula.

The joint mortar is also prepared from a mixture of cement with PVA building glue. Proportion: 5 parts cement to 1 part PVA. After filling the joints with a solution, two or three layers of liquid glass can be applied on top. This will enhance the waterproofing.

Before filling the joints with cement mortar, it is necessary to treat them with a primer.For septic tanks, technical priming materials are used. For example, this is one part of bitumen to three parts of gasoline.

There are pores in the structure of concrete stone, therefore septic tanks assembled from reinforced concrete rings let water through, albeit in small quantities. When freezing, the water in the pores will crystallize, increase in volume and eventually destroy the monolithic connection.

To avoid the destruction of concrete with crystallizing water, it is necessary to impregnate the concrete from the outside with bituminous mastic at least 0.5 m below the seasonal freezing depth in the region

Roll waterproofing installation

Having completed the work on the seams of concrete rings, we proceed to the formation of the surface layer of protection of the tank from moisture. If clay was used for joints, then roll materials cannot be applied over them - clay plaster will be broken out when the adhesive mastic solidifies.

The outer surface of the concrete well must be completely covered with a primer, for example, bitumen-gasoline. This will improve the adhesion of the rolled waterproofing to the concrete rings. Then the walls are smeared with heated tar mastic, roll-bitumen material is glued in two or three layers.

Note that bituminous mastic for waterproofing the walls of a septic tank with rolled materials is not suitable - it cracks when it cools.

If a high groundwater table is fixed in the region of the septic tank, then waterproofing is recommended to be carried out to the entire height of the sewer well shaft

To reduce or eliminate the likelihood of soil heaving around the concrete shaft, a sand-gravel backfill (40% sand, 60% crushed stone) is used. It fills a ditch previously dug around an underground reservoir to repair the seams between the well rings.

If sand without clay inclusions, gravel or gravel deposits lie under the soil layer on the site, then backfilling can be carried out with the soil of the dump formed during the development of the pit around the septic tank.

Types of sealing

There are other methods of sealing such structures. For example, injection and polymer sealing. However, due to the complexity of implementation and high cost, they have not found wide application.

Methods for waterproofing wells after their installation

- Concrete, cement insulation

. Joints can be sealed with concrete mixtures containing glass. Cement is also used in combination with liquid nails. - Penetrating waterproofing

. It is considered one of the most effective. If you apply such a composition from the inside and outside of the ring or the bottom of the well, then the solution will impregnate the concrete to its full thickness. Crystallizing, it will fill the existing voids and cracks. This increases the life of the well, preventing its destruction. The same type of insulation exists for seams. But applying it to the outside of the mounted structure requires an increased diameter of the well pit. The disadvantages of this processing method include the relative high cost and labor intensity. - bituminous insulation

. This is a classic, inexpensive type of insulation for a concrete ring and the joints between them. But in its pure form, bitumen is prone to cracking and is unstable to low temperatures. Therefore, manufacturers of such mastic use additives that increase their frost resistance and adhesion (adhesion to the surface). Such mastic is applied to concrete in a cold way. If necessary, it is liquefied with diesel fuel. The advantages of this method are: low cost and ease of implementation.

- Polymer-cement mixtures

. Waterproofing a septic tank from concrete rings with polymer-cement mixtures (for example, cement-coating) is cheaper than using bituminous materials. They also have a longer service life. This waterproofing of the septic tank is applied with a brush on the rings in two layers using the “wet on wet” method, i.e. application of the second layer does not require drying of the first.

Popular waterproofing brands include: Penetron, Penekrit, Lakhta, Hydrotex, Bastion RB 1, Tekmadray, Hydrostop, Aquastop. Insulation work is carried out in accordance with the instructions attached to them.

The current opinion about the uselessness of waterproofing concrete septic tanks can be easily refuted next spring. Therefore, do not rely on chance. Get the insulation done right and you won't have to redo the well any time soon.

Well waterproofing is one of the most difficult types of waterproofing work. No good waterproofing concrete rings of a structure made of they are unsuitable for the role of a source of drinking water. Special requirements for septic tanks and drinking wells allow the use of only a limited range of materials that do not pose a danger to humans and the environment. This article discusses the waterproofing of a well from concrete rings.

A well is an indispensable attribute of a suburban, rural, summer cottage. According to their purpose, wells are of three types:

- 1. Wells for drinking water. Over time, the walls of the well gradually lose their waterproofing properties and particles of soil and clay, products of agricultural and other activities, ground salts and much more get into clean water.That is why a very high quality external waterproofing is required for this type of wells.

- 2. Sewer well or septic tank. In this case, the hydroprotection should work differently - to prevent contamination of the soil surrounding the well.

- 3. Technological (dry) well for servicing the water supply and sanitation system. We can say that this is a kind of technical premises in which various systems are located, for example, water supply. There should be no moisture in such wells and high-quality waterproofing should be both inside and outside.

Each of the three types of wells must have completely sealed walls so that the external moisture of their upper soil layers does not get inside, or vice versa - contaminated water does not seep into the ground from the septic tank. To do this, it is imperative to perform such measures as waterproofing the well, especially if it is built of concrete rings. The fact is that, depending on the number of rings, there will be the same number of circular seams in the well through which water exchange will occur.

Figure #1. drinking well

Drinking well waterproofing excludes the most effective materials, such as bitumen-polymer mastics, as they give the water an unpleasant taste and are potentially hazardous to health.

If it is planned to place both a septic tank and a drinking well on your site, then please note that the distance from the well to the septic tank should be at least 15 meters. Most importantly, the septic tank should be located below the well along the terrain.

Concrete well waterproofing technology

When planning the repair of an underground structure, the nature of the damage is taken into account: the methods and means used depend on the degree of watering of the seams. Waterproofing is carried out in accordance with the requirements of building codes and regulations. Before applying the sealant, the contact surfaces are prepared with a primer.

Seam cleaning

Cleaning a well from concrete rings.

To get to the problematic place inside the well, the equipment is dismantled from its trunk and the head is exposed. If necessary, pump out water.

A ladder with a working platform is lowered into the underground working. To inspect and clean the joints of the rings from the outside, you need to dig a ditch around the well to the depth of the alleged leakage.

Surface diagnostics are carried out from top to bottom using a scraper, a metal brush and pressure water. Damage found should be carefully examined.

Unstable surfaces are removed in the following order:

- Chasing - the joint is deepened with the help of cuts around the grinder or chips with hammer blows on the chisel. You can use a hammer drill or impact drill.

- Cleaning the damaged area from destroyed concrete, dirt and dust. To do this, you need a scraper and a brush.

- Washing the cleaned joint with water.

The result is a rough surface that promotes adhesion of the repair compound. Depending on the material used, a primer or sealant is applied immediately.

Surface preparation

It consists in priming before applying the sealing composition. If the elements of the reinforcing frame are exposed during cleaning of the joints, the metal is treated with an anti-corrosion agent.

Preparation of surfaces in contact with waterproofing is carried out in the following sequence:

- Expansion of small cracks. It is carried out with an extension of 20-30 mm in any direction to a depth of 5-50 mm.

- Sealing of notches and chips. A mixture of cement and sand is used in a ratio of 1: 2. Water is added 0.5 parts. Factory-made compositions are also used.

- Surface priming. For preparation, bitumen-based compositions are applied - bituminous primers. The number of layers is one or 2, 0.1 mm each. Consumption - 150-300 g / m².

After drying, the primers proceed to the next stage of work. Before coating the surface with a protective layer, it is moistened.

Surface preparation.

Applying waterproofing to joints

Precast concrete manholes are vulnerable to water intrusion at structural junctions. At the construction stage, the joints on the outside are smeared with mastic and pasted over with a waterproofing tape that completely covers the joint. From the inside of the barrel, the seams are covered with a repair compound that is safe for humans.

When performing work on an existing well, seal connections located above the water level, if it is drinking water. The seams are sealed in sections of 10-20 cm, vertical cracks are puttied from the bottom up.

If a jet is knocked out of the gap, then you can avoid the removal of the sealant as follows:

- drill 25 cm below the joint 1-2 holes Ø20-25 mm to redirect the flow of groundwater;

- close the main hole with a waterproofing mixture, filling the gap by 70% so that the expanding composition does not destroy the structure;

- fix the hydraulic seal by hand for a period of 5 seconds to several minutes, depending on the properties of the sealant;

- clog the drainage holes with rubberized tow, a layer of filling solution or wooden plugs.

The bottom filter is cleaned after sealing all the cracks. If necessary, the crushed stone layer is replaced with a new one.

Applying waterproofing to joints.

Applying insulation to the surface of concrete rings

External waterproofing of wells is carried out during the construction period, when there is free access to the outer surface of the lining. It is produced after processing the joints on both sides of the concrete cylinder. In a multilayer protective structure, mastics and rolled waterproofing materials are used.

Work sequence:

- bituminous mastic is applied;

- the rolled material of the first layer is wrapped around the assembled structure in a horizontal direction with coating the edges of the tape with mastic;

- the strips of the second rolled layer are laid with the joints coated with a sealant.

The mechanized method of applying waterproofing consists in spraying or shotcrete: the cement mixture is fed under pressure through a nozzle onto the surface to be treated. Layer thickness 5-7 mm, dries 2-3 days. After that, the procedure is repeated. The third coating is applied with mastic or hot bitumen.