- Why do you need a clay castle for a well and is it needed at all?

- The correct clay castle for a well made of concrete rings on

- Features of waterproofing with a soft blind area

- Laying technology

- How to lay a soft blind area around the well + video

- Disadvantages of a clay castle

- Conclusion + useful video

- What it is

- Advantages and disadvantages

- How to do it yourself?

- Soft

- hard

- Operating tips

- The process of making a clay castle

- Safety basics

- Performing a blind area

- How to make a solution

- Advantages and disadvantages

- How to equip a soft blind area?

- Clay castle: what is it, how to make it and why

- What is a clay castle

- How the right clay castle works

- Why do you need a clay castle for a well and is it needed at all

- When to make a blind area and whether to do it at all

- Types of blind area

- Solid types of blind area

- Soft blind area

- Benefits of soft blind area

Why do you need a clay castle for a well and is it needed at all?

A waterproof layer around the well is necessary if there is swampiness and an abundance of moisture in the off-season on the site. A lock is needed if surface water spoils the quality of the spring.

This is evidenced by the following signs:

- After prolonged precipitation, reinforced concrete rings located below the ground surface get wet.

- After rains, the water level in the well rises, it becomes cloudy.

- During heat treatment, an unpleasant odor emanates from the water.

Pawning of the lock is not performed in the following cases:

- On wells operated less than one year. The natural shrinkage of the soil near the walls takes from 1 to 2 years. Only after that you can start building.

- It is postponed when planning the pipeline from the well. The castle is being built after the organization of communications.

- Do not build on soils prone to heaving due to the risk of shaft deformation and displacement of joints.

There is no need to build a castle near the wells, in which peat, stone and sand are exposed behind the fertile layer.

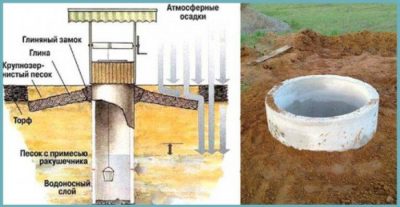

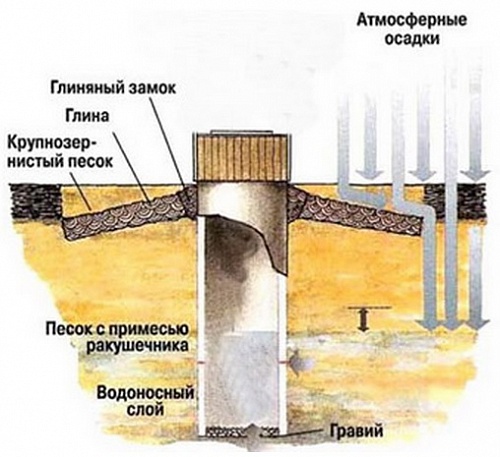

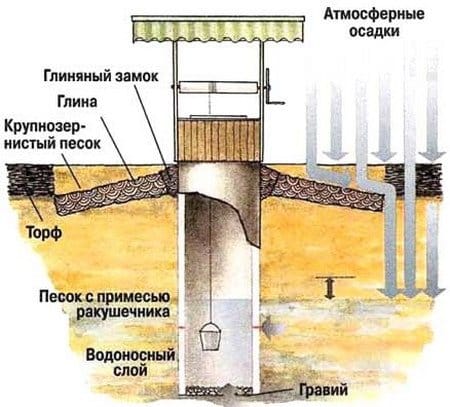

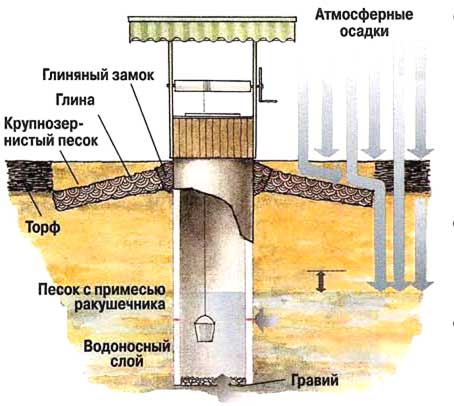

How it works clay castle for a well.

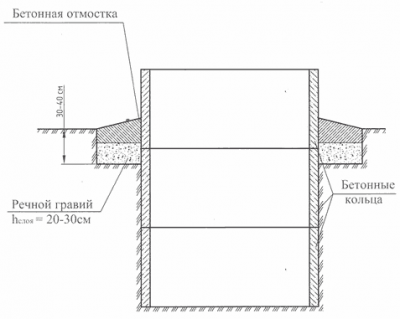

The correct clay castle for a well made of concrete rings on

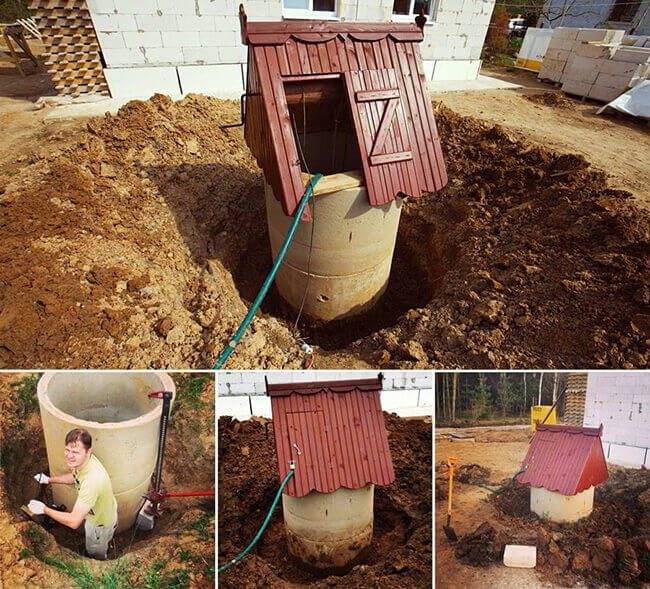

After the well is dug, so that the walls do not burst, it is necessary to complete the arrangement. Masters recommend using for concrete wells rings - clay castle. This technology is popular due to the high degree of protection of the reinforced concrete structure in the ground.

Features of waterproofing with a soft blind area

The use of temporary waterproofing in the soft blind area around the well has a variety of technological aspects that must be taken into account during the installation process:

- The entire structure is laid at the level of the second ring.

- The materials used are waterproofing film and sand.

- The edges of the film strips are thrown over the well rings.

- Decorative material is laid on top of the film and sand.

At the same time, all technological requirements must be met.

Laying technology

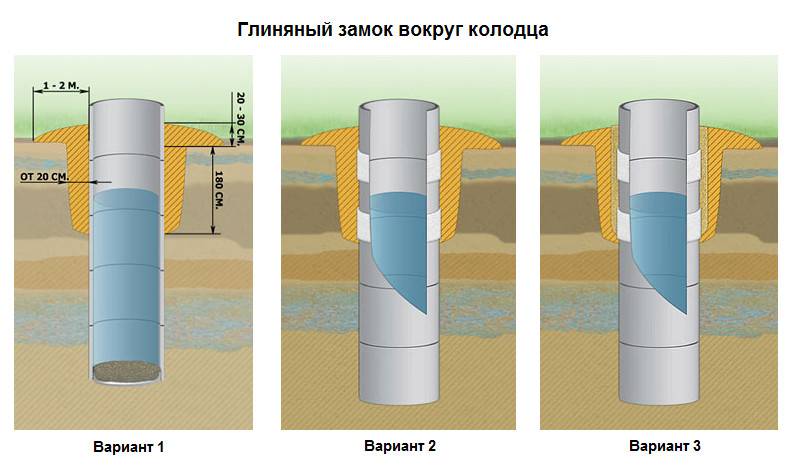

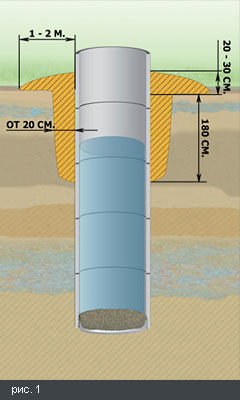

Before you make a clay castle, you need to dig the soil to the level of the 2nd ring. The selected soil is no longer used and must be removed and disposed of. A film is laid on the bottom.The size of the site to be closed is at least a meter from the outer wall of the reinforced concrete ring.

One end of the film is thrown over the well over the seam. It needs to be fixed, for which a metal belt, adhesive tape or self-tapping screws are used, which are screwed directly into the concrete. In the case when adhesive tape is used, it is necessary that several turns be wound. After that, the cavity is filled with sand over the film.

Backfilling is not carried out to the very top if FEM or rubble natural stone is used as a decorative coating. When laying, it is checked that there is a slope away from the well of at least 1.0-1.5 degrees. But this is a temporary method, and in order to ensure the tightness of the well, a clay castle is a must. But not every type of clay can be the material.

How to lay a soft blind area around the well + video

Some "specialists" argue that this type of protection against water pollution is an atavism and a relic of the past. In fact, such claims are justified by two tricks:

- Few people say that you need to wait two years, and then proceed to the improvement of the well. This is to put the source into operation as early as possible.

- It is beneficial for them that the client turns to them every year. After all, as a rule, the same people are engaged in cleaning the wells from dirt, and it is beneficial for them that the garbage in the water appears as early as possible.

The technology involves laying a film that covers the soil for a meter around the walls of the well. The overlap that fits over the seam between the first and second ring should cover it. The cavity obtained after the excavation of the soil is filled with clay. It cannot be simply filled and compacted mechanically. The laying technology is better to see.

Disadvantages of a clay castle

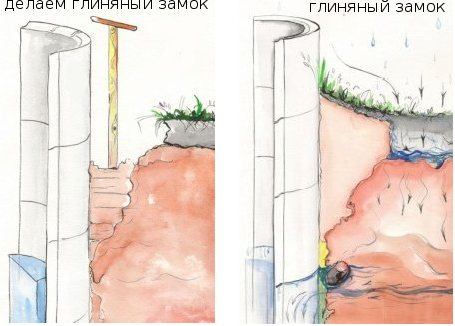

The poor quality of the work performed is due to the fact that people who decide to lay the clay castle on their own do not adhere to the technology.

If the clay is not sufficiently matured, not properly mixed, dry or inhomogeneous, it is impossible to achieve the desired plasticity. People do the backfill as is and just compact it with a mechanical rammer.

As a result, the top water, which lies in the upper layers of the soil, freezes in winter. The resulting ice, when expanding, exerts excessive pressure on the rings and the seam and leads to a violation of the integrity of the structure. Another drawback is the two-year wait for natural soil settlement. But this problem is solved by a temporary castle of compacted sand.

Conclusion + useful video

Summing up all of the above, we determine that all work related to the installation of a clay castle can be done independently. Brigades who claim that this is not necessary cannot be considered professional, or they are cunning in front of the customer. The described procedure is one of the mandatory measures for the improvement of sources of natural drinking water.

The only thing to consider is that the clay castle is installed two years later, after the well is put into operation.

This means that in some cases, the decoration will have to be postponed. And during the biennium, sand will be laid instead of clay. Otherwise, there are no difficulties, and the water in the well will remain clean and transparent for years.

What it is

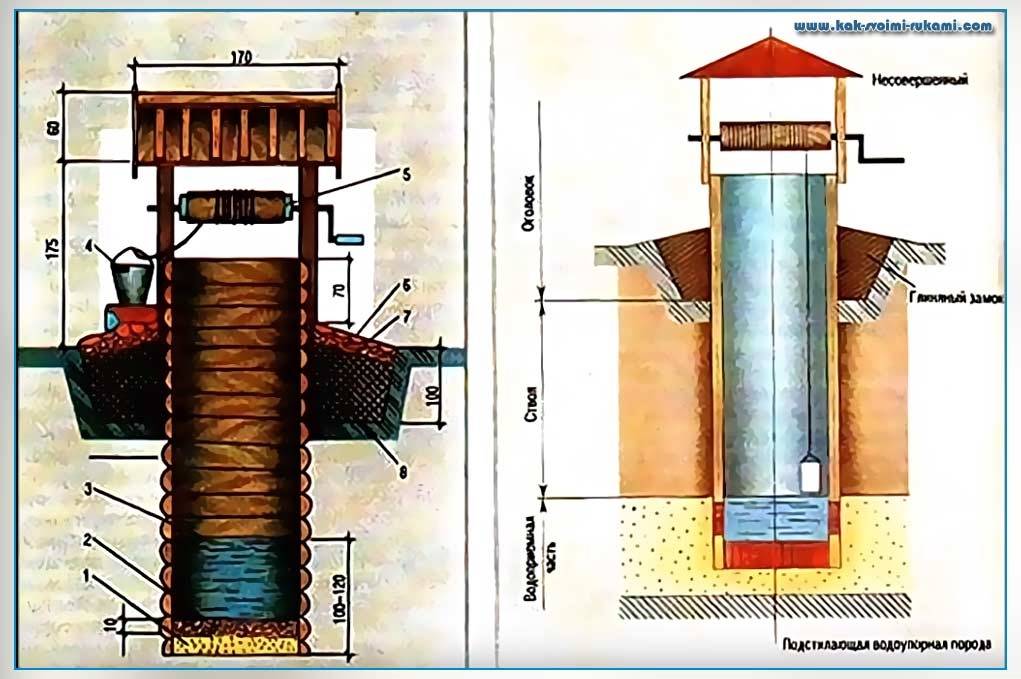

A mud lock for a well is a layer of compacted clay that is laid along the concrete rings of a water shaft and prevents rain or sewage from entering.It is actually a water seal.

Advantages and disadvantages

The advantages include:

- Reliable and effective waterproofing material. It is not for nothing that at the depth where the clay layer lies, there is practically no groundwater.

- Very low cost.

- You can build yourself.

- Simplicity of design.

- With the right device, the structure will last a long time, it will not have to be repaired and monitored.

However, there are also some disadvantages:

- The installation process is quite laborious and long.

- Not every clay is suitable for a shutter.

- If it has not dried out properly, then during frosts it will swell and cracks will form.

- With poor compaction, the material tends to sit down, this will lead to the formation of a hole around the shaft.

How to do it yourself?

All types of protective structures - soft and hard - are built according to one algorithm:

- Pause exposure per year.

- Cleaning up the workspace.

- Digging a trench around the perimeter.

- Bulk cushion equipment.

In this case, any blind area is arranged at an angle of 2-5 degrees for hard, 5-10 degrees for soft.

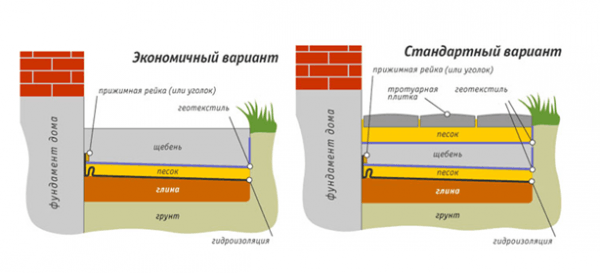

Soft

Excavation is carried out to a width of up to 1.5 m on all sides around the mine, it is desirable to select the entire fertile layer and reach the parent rock. The bottom is carefully compacted and sprinkled with fine sand.

The finished trench is overlapped and with folds (avoiding tension) covered with the selected material for waterproofing, the corner of the film should reach the upper ring of the well. The ends of the film are fixed with construction adhesive tape or metal staples, it is also possible to use screws. The folds on the film are designed to smooth out the processes of soil displacement.

Building sand is laid out on top of the insulating layer for better drainage, followed by paving stones (paving slabs, crushed stone, large river pebbles or other decorative materials can be used), sometimes a lawn is sown at the request of the owners of the site.

hard

For the construction of a concrete blind area of the well, it is necessary to remove the top layer of soil. At the bottom of a trench up to one meter wide, a herbicide is poured to prevent grass growth, followed by a 15 cm layer of sand cushion, then 10 cm of crushed stone.

For the construction of a concrete blind area of the well, it is necessary to remove the top layer of soil. At the bottom of a trench up to one meter wide, a herbicide is poured to prevent grass growth, followed by a 15 cm layer of sand cushion, then 10 cm of crushed stone.

All materials are heavily compacted. If you plan to use the well for a long time, it is advisable to reinforce it with a metal mesh.

A layer of waterproofing is attached to the outer walls of the well shaft (where there will be contact with concrete), this is done to prevent the solution from attaching to the walls of the well and further cracking.

Wooden slats, lubricated with bituminous resin, are laid out in a circle around the well at regular intervals - they are needed to level the poured concrete.

The laid out concrete mixture is carefully leveled and the surface is sprinkled with fine cement dust (smoothed with a construction trowel), and so on several times. The completed blind area is kept for about a week in a constantly wet state (it is supported with wet rags).

Like other types of blind areas, concrete protection is also placed on a slope to drain water, sometimes even drain channels are laid.

Operating tips

- It is not advisable to equip them immediately after the installation of the well. It is better to let the soil sink for a year or more.

- When installing a soft blind area, it is better to use special waterproofing films.

- It is better to make a castle and a blind area in late spring, when there are no more frosts, and the soil is still filled with water. In addition, in the spring and summer it will be seen whether the work has been carried out correctly and whether it copes with water.

- The slope angle for a solid blind area is 2-5 degrees. For soft - 5-10.

- For the installation of a concrete blind area, it is better to assemble a wooden or metal formwork, and not just pour raw materials into a dug ditch. This will help to give shape and accuracy to the final version.

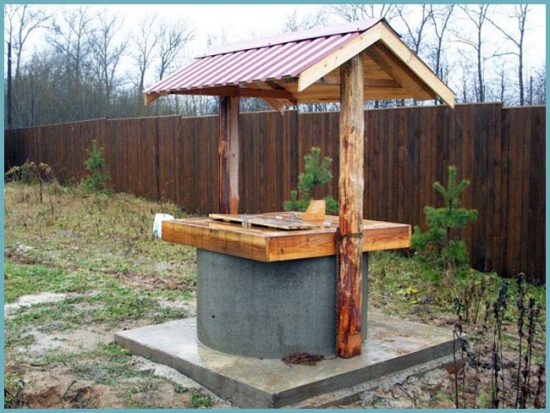

- After arranging the concrete blind area on the surface, you can build any decorative structure, for example, a gazebo with a roof.

The process of making a clay castle

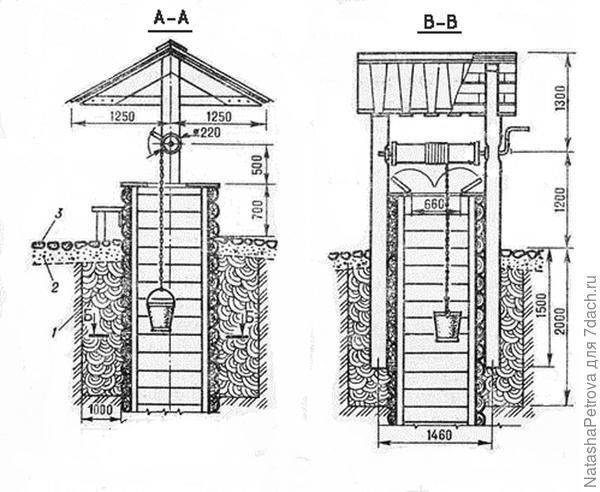

Since the foundation is the foundation of the house, it must be completely isolated from the influence of groundwater and rainwater. The device of the clay castle and its width depends on the depth of the base of the house in the ground. If the depth of the foundation is two meters, then the width at the bottom of the clay castle is 40-50 centimeters, and at the top - 25-30 centimeters. A clay castle around the foundation is not often installed.

Before starting the entire installation, a pit of the required width is dug. Crumpled clay should be laid in layers in the pit.

If you did not have time to do all the work in just one day, then the entire structure must be covered with a membrane that will protect the structure from moisture. In order to make a waterproof coating around the building, it is necessary to wait about half a month after the construction of the clay castle.

In order to provide complete protection from any moisture, a waterproofing membrane can be placed between our structure and the base of the house.

Safety basics

Inexperienced homeowners often neglect elementary rules and endanger not only themselves, but also their partners. To avoid ridiculous injuries, you need to follow at least some elementary rules.

- A person in the mine must protect his head with a helmet. Anything can happen, a bucket falling down or a fallen tool is not uncommon.

- Ropes, ropes, cables, rings - everything related to lifting is carefully checked before starting work.

- A person dripping a mine must be insured with a rope, and if the depth of the well is more than 6 m, then with two: working and safety.

The construction of the well must be carried out by several people

There are so-called gas pockets in the soils, and since the air exchange in the mine is not fast, as it descends, a candle is periodically set on fire. Its flame should burn evenly, which indicates sufficient oxygen, if the fire goes out, the pit needs to be checked.

Advice! There are several ways to ventilate a mine. The easiest way to do this is with a thick blanket, which is lowered to the bottom several times and raised back on the ropes. Also, a fan lowered to the bottom of the mine will help speed up gas exchange.

Performing a blind area

When the clay castle is ready, proceed to create a blind area. Why is she needed? The fact is that after heavy rains or the melting of large volumes of snow, even the most compacted castle can begin to become limp - its top layer will either get wet, turning into mud, or dry out in lumps. This will gradually lead to depressurization of the protective structure. Some well owners do not want to mess with the blind area and simply close the clay castle with crushed stone and sand, but, as practice shows, this is not always enough.So, if you are interested in the durability of a clay castle, you cannot do without a blind area.

It is recommended to use either paving slabs or stone as a coating - these materials are quite strong and durable. The technology for performing the blind area is quite simple:

- Cover the clay castle with geotextile or any other insulating material with similar functional properties.

- Lay the selected finishing material on the insulating screed. Be sure to make a slight slope to ensure the removal of excess moisture from the area of \u200b\u200bthe well and the castle.

Installation of the blind area

Installation of the blind area

If you want to make the blind area even more reliable, you can proceed as follows: after laying the insulating material, install a low formwork on it, and then fill the clay castle with concrete mortar - after it dries, lay tiles or stone.

As you can see, the clay castle has every reason to claim the title of one of the most effective protection options for wells. If done correctly, it will successfully cope with its functions for more than one year, so if you want to get a high-quality design, follow the proven technology and do not deviate from the rules - this is the only way you will provide reliable protection to your water source.

How to make a solution

To prepare the solution, it is necessary to observe the proportion: 1 part of cement, 3 parts of pure sand and 4 parts of crushed stone. The gravel to be used must be fine. Less is better. The solution is mixed in a special trough or in a concrete mixer. First, cement is mixed with sand and a little water is gradually added.The denser the solution, the better the rings will be.

To prepare the solution you will need cement, crushed stone and sand

Make sure that the edges of the ring are uniform. Formwork can be dismantled after 10 days. The ring has not completely hardened yet, so you need to be extremely careful with it. It is placed on 2 rails or other parallel strong boards and left for another 10 days.

Advantages and disadvantages

The advantage of a clay castle is the low cost of its arrangement. During installation, mainly natural materials are used - clay, a small amount of sand, pebbles. Another advantage of such a waterproofing structure is durability.

The disadvantage is the complexity of arranging the castle. The soil must be laid in layers of small thickness and carefully compacted. High quality material should be used, free of impurities, and it can be difficult to find clay with the desired characteristics in nature or to purchase it.

Disadvantages and advantages of clay locks on a well.

How to equip a soft blind area?

The construction of the blind area begins after the installation of the rings is completed.

To form it, you will need the following consumables:

- Sand - 2-3 cubic meters. It can be obtained while digging a well shaft.

- Polyethylene film or polymer coating for waterproofing pools 150 cm wide and up to 500 cm long.

- Metal tape - width 5 cm, length 300-350 cm.

- Self-tapping screws and dowels.

Soft sand pavement

The process of forming a blind area is as follows:

- We remove a layer of soil around the upper ring. The width of the pit is up to 1.5 meters. Depth - to the level of the junction of the first and second rings.

- We lay out the plastic film along the bottom of the trench, raising the edge closest to the well above the level of the junction of the first and second rings (overlap - 10-15 centimeters).

- We fix the film to the well with a steel tape, forming a belt. We fix the tape with self-tapping screws and dowels.

- We fill the trench with sand.

- We form a decorative finish. In this case, it is best to use gravel or paving slabs laid at an angle from the well to the edge of the trench.

As you can see: nothing complicated. Moreover, the quality of insulation in this case is much higher than when arranging a clay castle.

Clay castle: what is it, how to make it and why

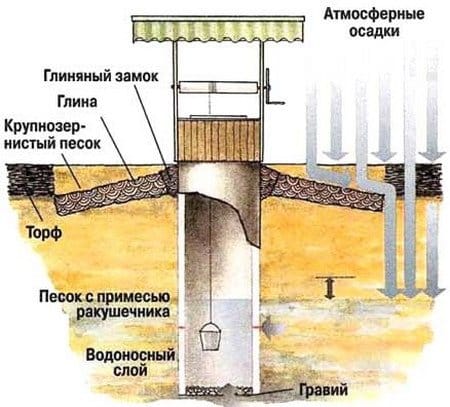

One of the final stages of creating a well is backfilling and compacting the soil around the top of the shaft. Often, customers require, and well builders, accordingly, offer a clay castle device.

Clay castle around the well shaft. Photo from the site

However, this element does not always function correctly and is generally necessary. Often, on the contrary, a clay castle is harmful.

What is a clay castle

A clay castle is a waterproofing structure made of clay of a certain quality around foundations, wells, cellars, pools, arranged where it is necessary to limit the flow of water. The characteristics of such structures were regulated by Building Codes and Rules (for example, SNiP II-53-73 "Dams from soil materials" is no longer valid).

Clay serves as a waterproofing agent because it consists of small particles (less than 0.002 mm in size) that are flake-shaped, like fish scales or lentils. The pores between the clay particles are also small, their size is about 0.005 mm.

Clay

When moistened, the clay particles swell and block the access of water, more precisely, water passes through the clay, but very slowly. And if she has another way, then the water will choose it instead of extremely slowly seeping through the clay.

How the right clay castle works

Structural features of clay (small flat particles-flakes) determine the functioning of the clay castle. SanPiN 2.1.4.1175-02 “Hygienic requirements for water quality of non-centralized water supply. Sanitary protection of springs” (instead of SanPiN 2.1.4.544-96) recommends its construction during the construction of wells. In particular, paragraph 3.3.4 of this document reads: "At the perimeter of the head of the well, a lock should be made of well-washed and carefully compacted clay or greasy loam, 2 meters deep and 1 meter wide."

Construction of a well and a clay castle. Photo from the site

If you are planning a clay castle, pay attention to these recommendations - depth and width. And most importantly, the fact that it is necessary to use clay or fatty loam, that is, rocks containing in their composition more than half of the clay particles or at least 40% (fatty loam)

And not just loam or even sandy loam, where clay particles are not more than 10%.

Clay for the castle should be well washed - only then it will become waterproof. Photo from the site iz-kirpicha.su

It is also important that the clay is well washed and then thoroughly compacted. When the clay is crumpled, its flat particles take a position parallel to each other: “lentils” are tightly nested one into the other

At the same time, the pores of the soil decrease, and the clay ceases to pass water - it becomes a clay castle.

Why do you need a clay castle for a well and is it needed at all

Why a clay castle to a well? To prevent water from running down the outer wall, seeping through the seams, and, in the end, from entering the moisture that has not been cleaned into the well.

As stated above, clay waterproofing will only work if the clay is properly prepared and laid. Therefore, just some kind of clay mixture, filled up and even rammed when laying with feet or with a hand tool, will not give a waterproofing effect. But it will be perfectly subjected to frost heaving - an increase in the volume of soil when water freezes in its pores. This is especially true for clay soils.

How the “wrong” clay castle harms. Photo from the site

In winter, the clay around the rings expands. And since it cannot expand in the horizontal direction, it does so in the vertical direction - along the shaft, while tearing off the upper rings. Cavities form under the clay layer: the soil around the rings continues to shrink for several years, and the castle has a different density and structure. Water and any debris, including the corpses of dead small animals, get into the formed caverns.

An improperly arranged clay castle does not prevent untreated surface water from entering the well, but exacerbates this process even more. Therefore, if you are not sure that the clay waterproofing layer will be laid correctly, it is better not to create unnecessary problems for yourself.

When to make a blind area and whether to do it at all

Let's start with the question - why do we need a blind area? Mainly so that polluted top water and melt water from the surface of the earth do not seep into the well with groundwater.

Her task is not to let them through to the shaft, to take them aside. Do not neglect the fact that a well with a blind area looks more aesthetically pleasing, and it is much more convenient to use it, standing on a clean and dry base. However, the need for it may not arise if the following conditions are present:

- The well is located away from roads, industrial zones, in an ecologically clean place;

- It stands on a hill, which excludes the flow of surface water to it;

- Equipped with automatic water-lifting equipment that does not require your frequent presence at the well.

Now about when is the best time to make a blind area. The instruction says that not earlier than a year after the completion of construction, since during this time (and sometimes longer) self-compacting and sedimentation of the soil poured around the well shaft occurs, as a result of which voids and failures are formed.

Ground sinkholes around new well

Also during this period, a natural displacement of the upper rings of the well in a horizontal plane is possible, which can also violate the integrity of the blind area. Therefore, its device can be started only after the completion of these processes and the elimination of their consequences.

Types of blind area

The blind area at the well can be made of different materials: clay, concrete, reinforced concrete, as well as from a waterproofing film and sand.

The latter is called soft blind area. Let's look at the features of their device.

Solid types of blind area

They are made of clay or concrete with a thickness of 20-30 cm and a width of 1.2 to 2.5 meters around the entire perimeter of the structure:

The clay blind area is a layer of compacted clay laid in a recess of the specified dimensions.

Its main drawback is the formation of slippery and sticky dirt on the surface when water gets on it. This will require additional costs for the protective coating.

clay pavement

The concrete blind area of the well is carried out by pouring concrete into the formwork installed in the recess on a gravel pillow. To make it last longer, a reinforcing mesh is placed in the formwork before pouring the mortar.

A prerequisite for the manufacture of such a blind area is the waterproofing of the outer walls of the well in the place where they will come into contact with concrete. This is necessary to prevent rigid adhesion of the well ring to the frozen blind area slab.

Scheme of the concrete blind area

The disadvantage of this type is the frequent formation of chips and cracks on the surface. They not only allow surface water to pass through, but also give the concrete surface an untidy look.

However, this is not the biggest problem - if desired, the blind area for the well can be repaired. But she herself, if the manufacturing technology is not followed, can damage the well shaft, violate its integrity.

The fact is that frost heaving forces act on the blind area, and if it is rigidly connected to the upper ring of the well, it can be separated from the lower one. As a result, a gap is formed between them, through which contaminated water and soil particles enter directly into the mine with clean water.

The photo shows dirty streaks from the gap between the rings

Soft blind area

This design consists of a waterproofing film, which is covered with a layer of sand. From above, it is possible to install a decorative coating or lawn. Its production does not require large financial and physical costs and consists of the following steps:

- Before making a blind area around the well, fertile soil is removed around it to a width of 1.2-1.5 meters;

- A waterproofing film is laid at the bottom of the recess, the edge of which is wound onto the upper ring;

- The film is fixed on the ring using double-sided tape or a metal strip, through which it is attached to the walls with dowels or screws;

- In the place where the film passes from a vertical to a horizontal position, a fold is necessarily made. It is designed to compensate for the displacement and subsidence of the soil at the base, which will prevent damage and destruction of the upper decorative layer;

- Sand is poured onto the film, on top of which paving slabs, paving stones, bricks, crushed stone, etc. are laid. You can simply return the previously removed sod to its place or sow lawn grass.

Diagram of a soft blind area

Benefits of soft blind area

In addition to the fact that the manufacture of such a design in an economy version will require a minimum of effort, it has a lot of other advantages:

The most important thing is that there is no risk of a well shaft rupture along the seam between the rings;

The soil around the well can sink and compact without prejudice to both the well itself and the covering of the blind area;

Low price of materials used;

If it is necessary to repair the well, the soft blind area is easy to dismantle;

A waterproofing film will do a much better job of removing water from the walls of the well than clay or concrete;

The low labor intensity of the process - the blind area of \u200b\u200bthe well with one's own hands in this case is carried out without problems and the involvement of assistants;

Decent service life, reaching 80 years. Repair may be required only for the outer decorative layer;

Finally, you can use any decorative finish from wood flooring to stone cladding.