- Types of tanks

- Characteristic features of an open tank

- Design features of the container

- Form and material of manufacture

- Types (closed and open type)

- Expansion tank connection

- Calculation of the volume of the heating expansion tank

- Method # 1 - calculation by formulas

- Method # 2 - online calculator for calculation

- Tank types

- Types of closed expansion tanks of membrane type

- Tanks for heating systems

- How to choose

- What is an expansion tank for?

- Do-it-yourself open tank

- The principle of operation and features of the expansion tank

- Is it necessary to install an additional expansion tank

- How to put the tank

Types of tanks

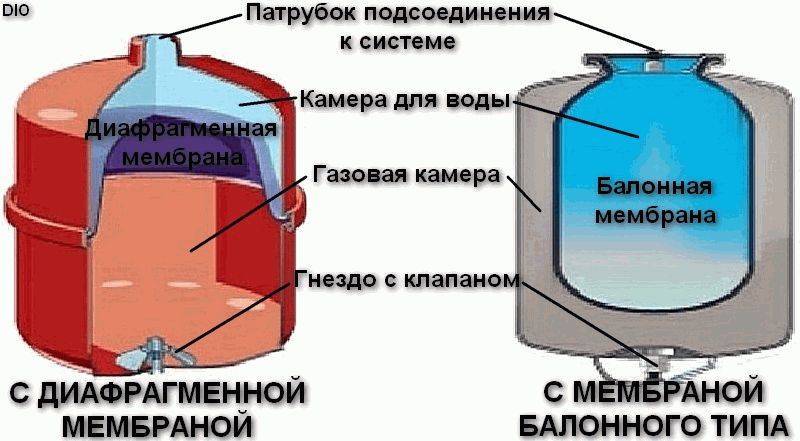

Expansion tanks are of two types - closed and open. They differ from each other in design features.

Table. Types of expansion tanks.

| Type of | Description |

|---|---|

| Closed or membrane | This is a tank that has just a membrane separation between the compartments - water and air. The diaphragm in it is heat-resistant and avoids corrosive activity. Such a tank is airtight, outwardly it looks like a small cylinder or a ball of metal. This element of the system serves for a long time, and if the membrane is damaged, it is easy to replace it with a new one.Also, in addition to this type of expansion tank, a pressure gauge and a safety valve must be installed - together they form a security system. |

| Open | Such a tank is a container at the bottom of which there is a threaded connector, which allows you to combine the device with the system. It is necessary to install this design in the highest part of the heating system. It is used extremely rarely, as it has a lot of drawbacks - this is an increase in the risk of corrosion in pipes, and fairly decent dimensions, and a quick failure at critical pressure indicators. The liquid level indicators in such a container also directly depend on how much water is in the heating circuit. |

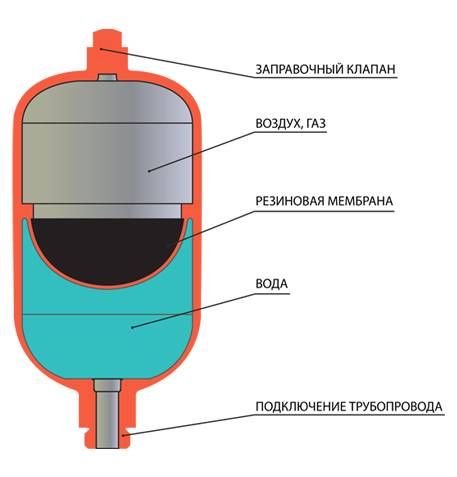

The principle of operation of a closed expansion tank

Membrane tanks, in turn, are divided into two types - with a replaceable diaphragm and with a stationary one. The replaceable membrane speaks for itself - if necessary, it can be easily changed by removing it through a flange fixed with a few bolts. An expansion tank of this type serves as long as possible, and the shape of the body can be both vertical and horizontal, which makes it possible to select a container for a specific room.

Diaphragm type expansion tank

In containers with a stationary membrane, this part cannot be replaced - it is tightly attached to the walls of the housing. In case of failure of the unit, it is completely changed. By the way, water in such an installation, unlike the previous type, is in contact with the metal of the tank, as a result of which a corrosion process occurs on its inner surface. Installation can also be both vertically and horizontally oriented.

Expansion tank dimensions

Expansion tanks are not only mounted, but also floor. They can also have a flat shape, differ in color: blue are for cold water, red for hot water.

Characteristic features of an open tank

Such tanks are extremely simple - an ordinary bucket, a specially made container from improvised materials, a canister, or something like that can always be used as an expansion tank.

Design features of the container

The main design requirements are:

- the presence of sufficient volume;

- lack of tightness.

That is, even the absence of a cover is allowed, although it is desirable - it protects against dirt particles entering the heating system.

The tank, which is planned to be used as an expansion tank, must be equipped with a pipe to which a pipe is connected from the heating system. This is the only required fixture.

The design of any expansion tank is extremely simple - it is a conventional container equipped with one or more inlets / outlets. This allows excess fluid to accumulate and drain. The most technologically advanced tanks are equipped with a water supply, a drain valve, which is needed to transport water to the sewer in case of too large volumes of its surplus

The design of any expansion tank is extremely simple - it is a conventional container equipped with one or more inlets / outlets. This allows excess fluid to accumulate and drain. The most technologically advanced tanks are equipped with a water supply, a drain valve, which is needed to transport water to the sewer in case of too large volumes of its surplus

But for comfort and to avoid minor troubles, it is advisable to use the following accessories:

- Overflow hose or pipe - such a structural element is necessary in case of overflow of the expansion tank. That is, this structural element, diverting liquid into the sewer or simply outside the building, excludes the possibility of flooding.

- Water supply pipe - it is necessary to replenish the heating system with water.It is quite possible to do without it, but it should be understood that this procedure will have to be done with a bucket in hand. Although in the latter case, the design will be cheaper.

Since expansion tanks are often installed in attics, you should take care of its thermal insulation. That will exclude freezing of the liquid and the failure of the entire system.

Only ordinary water can be used as a heat carrier. Because modern effective antifreezes in open tanks evaporate quickly. Which leads to a significant increase in the cost of the entire procedure for heating the room.

In addition, antifreeze fumes are almost always toxic, which affects the health of the occupants. More about types of heat transfer fluids for heating systems and their features we have discussed in this article.

Form and material of manufacture

The shape of the tank is not of fundamental importance, so it can be any:

- round;

- rectangular;

- trapezoidal, etc.

The material of manufacture can be any metal or even plastic, but since the coolant can be heated to significant temperatures, it must be heat-resistant.

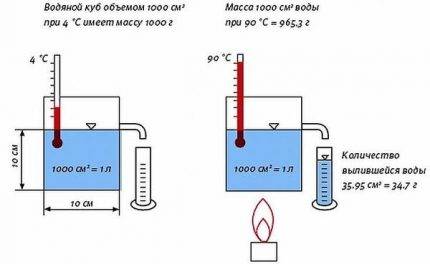

This figure helps to understand the principle of operation of the expansion tank. The image on the left shows the coolant in a cold state. He has more than enough space. But, when heating begins (figure on the right), an excess of water soon appears. In fact, there is not much excess liquid, but this is quite enough to find a weak point in the system and form a leak or cause equipment failure.

This figure helps to understand the principle of operation of the expansion tank. The image on the left shows the coolant in a cold state. He has more than enough space. But, when heating begins (figure on the right), an excess of water soon appears. In fact, there is not much excess liquid, but this is quite enough to find a weak point in the system and form a leak or cause equipment failure.

There are various options for open expansion tanks on sale, among which it is easy to choose the most suitable one.Or make a homemade tank from improvised materials, which will play the role of an expansion tank.

Types (closed and open type)

Depending on the intended purpose and design, there are:

• Expansion tanks of open type, which have a direct connection with the atmosphere and are installed mainly in heating systems with natural circulation at the top point, after the coolant acceleration section. Most often they are made of sheet steel and equipped with inspection hatches and two or more branch pipes for inlet or outlet of water, connection with control or discharge devices. With all the advantages (cheapness, unlimited volume, simplicity), the installation of an open tank adversely affects the operation of the system due to evaporation and the need for periodic topping up of the coolant.

• Closed expansion tanks, mandatory installed in systems with pumps. This group is represented by both conventional closed large-volume tanks (hydraulic accumulators) and devices with flexible balloon and disc-type separating membranes that are displaced towards the air chamber at excessive pressure in the system and return to the opposite position at normal parameters. Due to a number of advantages, tanks with membranes are gradually replacing other varieties and are installed in all modern heating and hot water systems.

In particular, closed expansion tanks with membranes can be installed at any point of the heating system (preference is given to reverse sections with laminar movement, but this condition is not critical, there is no need to move the device to the upper point after acceleration), operate at an excess pressure of the coolant and respond to changes its pressure with high precision.

It is not necessary to add coolant to systems with such tanks, which has a positive effect on the stability of their operation and protection against corrosion. Closed membrane tanks do not need additional insulation and are operated at minimal cost.

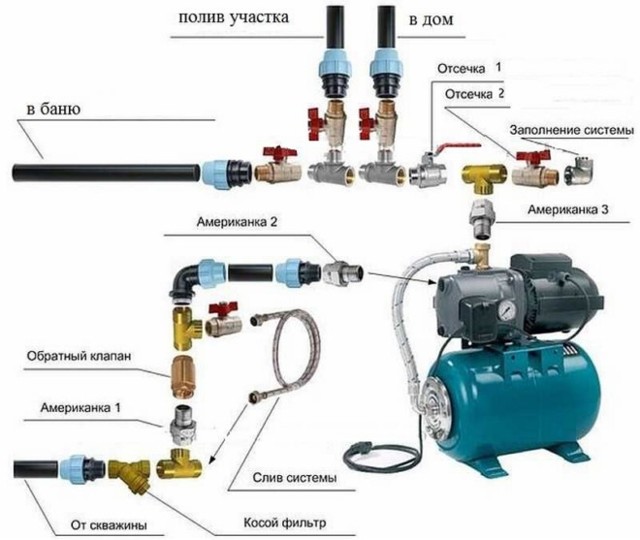

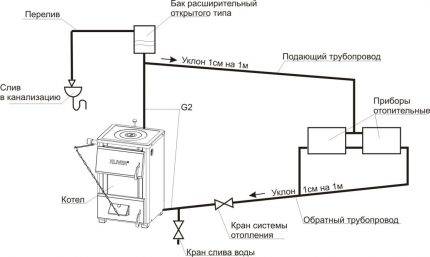

Expansion tank connection

The place for mounting such a tank is chosen where the intake of excess coolant will be most effective.

When figuring out how to properly install an expansion tank in an open heating system, you need to pay attention to three important points:

- select the highest point of the contour;

- place the tank directly above the heating boiler so that they can be connected by a vertical pipe;

- provide overflow in case of an accident.

The requirements are explained by the features of the functioning of gravity heating systems. The hot coolant moves from the boiler through the pipes and reaches the expansion tank, having lost a significant part of the thermal energy.

An open expansion tank must be installed at the highest point of the heating circuit, as well as directly above the heating boiler

An open expansion tank must be installed at the highest point of the heating circuit, as well as directly above the heating boiler

The cooled water naturally flows through the pipes to the heat exchanger for new heating.The location of the tank at the highest point allows you to remove air bubbles that have entered the system from the coolant.

Calculating tank capacity for an open system is simple. The total volume of coolant in the circuit is measured, 10% of this indicator will be the desired figure. Most often, the expansion tank is installed in the attic.

This is especially convenient if you need a large capacity, because a significant amount of coolant may be needed for the normal operation of a gravity-flow system. And a small expansion tank can even be placed in the kitchen under the ceiling, if this allows you to properly connect it to the heating boiler.

If the expansion tank is installed in an unheated attic, it should be insulated in order to save heat energy in the house as much as possible.

If the expansion tank is installed in an unheated attic, it should be insulated in order to save heat energy in the house as much as possible.

If the device had to be placed in the attic, you need to take care of its insulation.

This is especially important if the attic is not heated. Although the coolant enters the tank already cooled down, you should not neglect the opportunity to save some of the thermal energy

In the future, it will take less time and fuel to heat up, which will significantly reduce heating costs.

To connect the expansion tank and overflow, two pipes must be drawn into the boiler room. The overflow is usually connected to the sewer, but sometimes the owners of the house decide to simply bring the pipe outside, an emergency discharge is made to the outside.

The configuration of the expansion tank can be any, such devices are made of sheet iron, plastic tanks and other materials that tolerate heat well.

The configuration of the expansion tank can be any, such devices are made of sheet iron, plastic tanks and other materials that tolerate heat well.

After the place for installing the expansion tank is selected and its volume is calculated, you need to find and install a suitable container.Small tanks are mounted on the wall with brackets or clamps.

Capacious containers must be installed on the floor. It is not necessary to hermetically close such a tank, but a lid is still needed. It is necessary to protect the coolant from debris.

Part of the water from an open system evaporates, the lost volume must be replenished. The coolant is usually added to the open circuit through the expansion tank.

This point must be taken into account when choosing a place to mount the device. It is not always convenient to carry water in a bucket to the attic. It is easier to foresee the installation of a supply pipe that leads to an expansion tank.

Calculation of the volume of the heating expansion tank

There are several ways to determine the volume of an expansion tank. Firstly, numerous design bureaus and individual specialists offer their services. They use special software for calculations, which allows you to take into account all the factors that affect the stable operation of the heating system. It's all wonderful, of course, but expensive.

Secondly, you can independently calculate the expansion tank using the formulas. Here you need to be especially careful, since the slightest mistake can significantly distort the final values. Everything is taken into account: the volume of the heating system, the type of coolant and its physical characteristics, pressure.

Thirdly, you can use online calculators to perform calculations. True, in this case, it is better to double-check the results on several resources in order to exclude the possibility of incorrect page operation.

Fourthly, you can estimate by eye - equate the specific capacity of the heating system to 15 l / kW. These are indicative figures.This method is suitable only at the stage of a feasibility study. Already immediately before the purchase, more accurate calculations are necessarily carried out.

Method # 1 - calculation by formulas

The basic formula for calculating is as follows:

where C is the total volume of the coolant in the heating system, l; Pa min is the setting (initial) absolute pressure in the expansion tank, bar; Pa max is the maximum (limiting) absolute pressure that is possible in the expansion tank, bar.

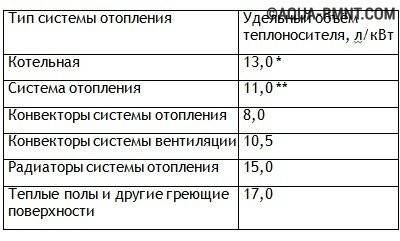

When calculating the total volume of the heating system, all pipes and radiators, underfloor heating and a boiler, as well as other elements are taken into account. Approximate values are shown in the table:

Note: * without taking into account the volume of storage liquids; ** average value.

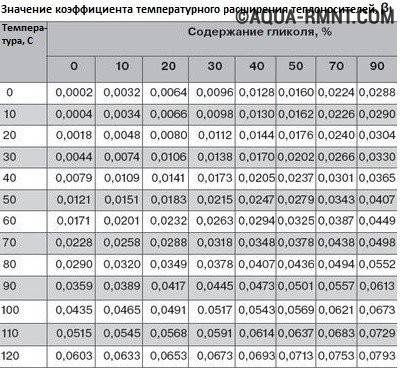

The table shows the values of the coefficient βt - an indicator of the thermal expansion of the coolant, which correspond to the maximum temperature difference in the working and non-working system.

Now we calculate Pa min and Pa max using the formulas:

The first formula calculates the absolute set pressure (h2 is substituted with a minus sign when the tank is located below the tie-in point). The second formula determines the absolute maximum possible pressure in the expansion tank.

Method # 2 - online calculator for calculation

To calculate the volume of the expansion tank, you can use the online calculator. There are many of them. Let's analyze the mechanism of work using the example of a calculator offered on the site

* - it is better to take the most accurate figure. If there is no data, then 1 kW of power is equal to 15 liters; ** - should be equal to the static pressure of the heating system (0.5 bar = 5 m); *** - this is the pressure at which the safety valve operates.

This technique is greatly simplified and is suitable only for the calculation of individual heating systems. Let's take a look at the diagram step by step on a concrete example:

- determine the type of coolant: in this case it is water. The coefficient of its thermal expansion is 0.034 at a temperature of 85C;

- calculate the volume of coolant in the system. For example, for a 40 kW boiler, the volume of water will be 600 liters (15 liters per 1 kW of power). It is possible, and this will be a more accurate figure, to summarize the volume of coolant in the boiler, pipes and radiators (if such data is available);

- the maximum allowable pressure in the system is set by the threshold value at which the safety valve operates;

- the charging pressure (initial) of the expansion tank can be greater than or equal to (but in no case less than) the hydrostatic pressure of the heating system at the tie-in point of the membrane;

- expansion volume (V) is calculated by the formula V = (C* βt)/(1-(Pmin/Pmax));

- the calculated volume is rounded up (this will not affect the operation of the system in any way).

The expansion tank is selected so as to compensate for this very estimated volume (see table):

The filling factor of the expansion tank with coolant is determined from the table based on a combination of maximum and initial pressure values. Further, the calculated volume is multiplied by the coefficient and the resulting figure is the recommended volume of the membrane

Tank types

- Tanks of open type. Are established on attics, roofs of buildings. The water pressure in the system is determined only by the installation height.

- Tanks of closed type - with an elastic partition (membrane), which divides the capacity of the device into two parts: for filling with water and for air.

Types of closed expansion tanks of membrane type

With fixed membrane:

- as a rule, these are containers of small capacity;

- if the diaphragm fails, it will be impossible to replace it;

- are mainly used in heating systems.

With a replaceable diaphragm - a balloon type (a balloon is also called a "pear"). Optimal for plumbing for the following reasons:

- water enters directly into the pear membrane and does not come into contact with the metal walls of the tank; accordingly, there is no corrosion and the quality of water does not change;

- the pressure necessary for the operation of the system is easily pumped;

- the membrane is easily replaceable;

- devices of this type can have a high capacity, which is very important for private households.

This is interesting: Making a homemade pump for do-it-yourself water

Tanks for heating systems

In a situation where the documentation for the tank does not prescribe how to properly orient it in space, we advise you to always place the tank with the inlet pipe down. This will allow for some time to extend his work in the heating system in the event that a crack appears in the diaphragm. Then the air at the top will not rush to penetrate the coolant. But when the tank is turned upside down, the lighter gas will quickly flow through the crack and enter the system.

It does not matter where to connect the cistern supply - to the supply or return, especially if the heat source is a gas or diesel boiler. For solid fuel heaters, the installation of a compensating vessel on the supply is undesirable; it is better to connect it to the return.Well, at the end, adjustment is required, for which the device of the expansion membrane tank provides a special spool on top.

The fully assembled system must be filled with water and vented. Then measure the pressure near the boiler and compare it with the pressure in the air chamber of the tank. In the latter, it should be 0.2 bar less than in the network. If this is not the case, it must be ensured by lowering or pumping air into the membrane water tank through the spool.

How to choose

The main working body of the hydraulic tank is the membrane. Its service life depends on the quality of the material. The best for today are membranes made of food rubber (vulcanized rubber plates). The body material matters only in membrane type tanks. In those in which a “pear” is installed, water is in contact only with rubber and the material of the case does not matter.

The flange should be made of thick galvanized steel, but stainless steel is better

What is really important in tanks with "pears" is the flange. It is usually made from galvanized steel.

In this case, the thickness of the metal is important. If it is only 1 mm, after about a year and a half of operation, a hole will appear in the metal of the flange, the tank will lose its tightness and the system will stop working. Moreover, the guarantee is only a year, although the declared service life is 10-15 years. The flange usually rots after the end of the warranty period. There is no way to weld it - a very thin metal. You have to look for a new flange in service centers or buy a new tank.

So, if you want the accumulator to serve for a long time, look for a flange made of thick galvanized steel or thin, but made of stainless steel.

What is an expansion tank for?

As we know, water tends to expand when heated.Yes, just like any other liquid. The coolant in the heating system is no exception. When the liquid expands, its excess needs to be put somewhere. For these purposes, in heating, they came up with expansion tanks.

First of all, let's remember the basic law of physics: when heated, bodies increase, and when cooled, they decrease. The circulating coolant (water) in the system, when heated, increases in volume by an average of 3-5%. To prevent accidents and maintain the efficiency of heating equipment, a container is needed, which will smooth out the temperature difference and, as a result, the pressure and volume of water. That is, when heated, the tank will take on excess liquid, and when cooled, it will drain it back into the system. Thus, the pressure in the boiler remains within acceptable limits. Otherwise, the automatic protection is activated and the system stops. Which can be unsafe in severe frosts.

Do-it-yourself open tank

open tank

Another thing is the expansion tank for heating an open house. Previously, when only the opening of the system was assembled in private homes, there was even no question of buying a tank. As a rule, an expansion tank in the heating system, the scheme of which consists of five main elements, was made right at the installation site. It is not known whether it was possible, in general, to buy it at that time. Today it is easier, as you can do it in a specialized store. Now in the predominant majority of housing is heated by sealed systems, although there are still many houses where there are opening circuits. And as you know, tanks tend to rot and it may be necessary to replace it.

A store-bought heating expansion tank device may not meet the requirements of your circuit. There is a possibility that it won't fit. You may have to make it yourself. For this you will need:

- tape measure, pencil;

- Bulgarian;

- welding machine and skills to work with it.

Remember safety, wear gloves and work with welding only in a special mask. Having everything you need, you can do everything in a couple of hours. Let's start with what metal to choose. Since the first tank is rotten, then you need to make sure that this does not happen to the second. Therefore it is better to use stainless steel. It is not necessary to take a thick one, but also too thin. Such metal is more expensive than usual. In principle, you can do with what is.

Now let's take a look at how make the tank yours hands:

action first.

Metal sheet marking. Already at this stage, you should know the dimensions, since the volume of the tank also depends on them. A heating system without an expansion tank of the required size will not work correctly. Measure the old one or count it yourself, the main thing is that it has enough space for the expansion of water;

Cutting blanks. The design of the heating expansion tank consists of five rectangles. This is if it is without a lid. If you want to make a roof, then cut out another piece and divide it in a convenient proportion. One part will be welded to the body, and the second will be able to open. To do this, it must be welded onto the curtains to the second, immovable, part;

third act.

Welding blanks in one design. Make a hole in the bottom and weld a pipe there through which the coolant from the system will enter.The branch pipe must be connected to the entire circuit;

action four.

Expansion tank insulation. Not always, but often enough, the tank is in the attic, since the peak point is located there. The attic is an unheated room, respectively, it is cold there in winter. The water in the tank may freeze. To prevent this from happening, cover it with basalt wool, or some other heat-resistant insulation.

As you can see, there is nothing difficult in making a tank with your own hands. The simplest design is described above. At the same time, in addition to the branch pipe through which the tank is connected to the heating system, the following holes can be additionally provided in the scheme of the expansion tank for heating:

- through which the system is fed;

- through which the excess coolant is drained into the sewer.

Scheme of a tank with make-up and drain

If you decide to make a tank with your own hands with a drain pipe, then place it so that it is above the maximum fill line of the tank. The withdrawal of water through the drain is called an emergency release, and the main task of this pipe is to prevent the coolant from overflowing through the top. Make-up can be inserted anywhere:

- so that the water is above the level of the nozzle;

- so that the water is below the level of the nozzle.

Each of the methods is correct, the only difference is that the incoming water from the pipe, which is above the water level, will murmur. This is more good than bad. Since make-up is carried out if there is not enough coolant in the circuit. Why is it missing there?

- evaporation;

- emergency release;

- depressurization.

If you hear that water from the water supply enters the expansion tank, then you already understand that there is a possibility of some kind of malfunction in the circuit.

As a result, to the question: “Do I need an expansion tank in the heating system?” - you can definitely answer that it is necessary and mandatory. It should also be noted that different tanks are suitable for each circuit, so the correct selection and correct setting of the expansion tank in the heating system is extremely important.

The principle of operation and features of the expansion tank

Today's tank design was not developed immediately. Now they use the designs of a new sample, and the old ones are practically not used. In the previous example, after the system warmed up, excess water entered the open tank, and when the system cooled, the water flowed back into the pipes. In such a system, there was a danger of hot water coming out of the tank, which could cause the house to flood. (See also: Do-it-yourself boiler installation)

The water from the well is under pressure, and the membrane at this time increases, the volume of air decreases, and some pressure is created. The pump turns off when the pressure reaches the required level. Water is consumed, the pressure drops accordingly, and the pump turns on to maintain pressure. The disadvantage of the expansion tank is an irrational method of temporary storage of water. The Dutch were the first to propose the use of expansion tanks with a membrane. Today, closed expansion tanks are very aesthetic and have a different design.

Figure 3: Expansion tank in action

The membrane expansion tank for water supply also has the disadvantage that the membrane cannot be replaced with such a design. If the heating system is working properly, then the liquid expands when the water starts, and otherwise the pressure fluctuations are smooth. The membrane of such a tank is made of high quality material and lasts a very long time.

Figure 4: Diaphragm expansion tank for water supply

Advice! Do not forget to check the air pressure before each heating season. For systems that have large volumes, it is best to use a stationary pressure gauge. (See also: Hydraulic accumulators for water supply)

With the help of a membrane expansion tank, hydrodynamic shock is compensated, which greatly reduces the frequency of pump operation. This design increases the service life and saves electricity. When the coolant is heated or cooled, the system remains intact. This compensates for the amount of change and it is for this that a membrane expansion tank is installed. Even during a power outage, the reserve tanks have a fire extinguishing function. It is possible to use membrane tanks not only in domestic systems, but also in industrial ones, since the working pressure is calculated up to 16 bar. Hydraulic accumulators can be horizontal and vertical, open and closed. In addition, they differ in terms of water volume and operating pressure.

Is it necessary to install an additional expansion tank

Good evening, the question is the installation of a bath, and specifically a double-circuit wall-mounted boiler gas

24 kW Wolf.I convince people that an additional expansion tank is needed for the heating system of liters, so for 12-14, in addition to the built-in 8l, we have 1 supply and return from the boiler to the collector group for 6 outlets for heated floors, the total square footage of the heated floor is 70 square meters and hot water and HVS say I'm right. Evgeniy

The required volume of the expansion tank is formed by calculation:

VL - full capacity of the heating system (volume of heat carrier in the boiler, heaters, pipes, boiler coil and heat accumulator), l;

E is the index of liquid increase, %;

D - performance diaphragm expansion tank.

For its part, D = (PV - PS) / (PV + 1)

PV - maximum working pressure (for a private house of medium size, in principle, 2.5 bar is enough);

PS - charging pressure of the expansion accumulator, m (0.5 bar = 5 meters, we use the value of static pressure, it is set by the difference between the upper mark of the heating system and the installation level of the tank).

Since we do not know the parameters of your heating system, nor the diameter of the heated floor pipes and their pitch, it is not possible to make an accurate calculation of the required volume of the expansion tank.

The length of each heating circuit can be set according to the designations on the inlet and outlet pipes connected to the combs. During production, they are marked in meters. By subtracting the smaller value from the larger value, you can find out the length of the loop. Knowing the total length of all pipes and their diameter, it is possible to determine the volume of liquid in them. The amount of heat carrier that the boiler can hold is noted in its technical data sheet. If there is a heat accumulator, a water heater, the data must also be taken from the instructions for the equipment.You do not mention heating batteries, however, if they are, it is also necessary to calculate the volume of liquid both in heat supply devices and in supply pipes. Add up the resulting numbers, this will be the total capacity of the system. Knowing it, you will be able to calculate the volume of the expansion tank on your own.

Whether an additional expansion tank is needed and what its volume should be, one can think very, very approximately, based on the power of the boiler. In the absence of an additional heat accumulator, in the circulating heating system, on average, there is:

- for convector wiring - 7 liters per 1 kW of boiler power;

- for radiator - 10.5 l / kW;

- for heated floors - 17 l / kW.

In our case, based on your description, the approximate volume of the system is 17 l / kW x 24 kW = 408 liters.

For an approximate calculation, figuratively speaking, we will take the values of the following indicators: PV = 2.5 bar; PS = 0.5 bar (height from the top point to the tank 5 m); E = 0.029 (water, 70°C).

We count according to the formulas:

D \u003d (2.5 - 0.5) / (2.5 + 1) \u003d 0.285

V = (408 x 0.029) / 0.285 = 41.5 liters

Purchase: additional expansion tank

must have a volume of 41.5 - 8 = 33.5 liters. When choosing between a smaller and a larger option, it is better to take a larger one - 40 liters, and not 30 liters.

You, Eugene, are, of course, right: an additional expansion accumulator is required in this case. The estimate, carried out "by eye", eloquently speaks of this. However, the volume of the expansion tank, as well as other system parameters, require a fairly accurate calculation, otherwise the heat supply will work unstably and not economically enough.

Describe your question in as much detail as possible and our specialist will answer it

hello, I'm worth it gas

the wall-mounted boiler has its own expander in the middle is it possible to install an additional expansion tank

How to put the tank

When installing an open tank in the attic, a number of rules should be observed:

- The container must stand directly above the boiler and be connected to it by a vertical riser of the supply line.

- The body of the vessel must be carefully insulated so as not to waste heat on heating a cold attic.

- It is imperative to organize an emergency overflow so that in an emergency situation hot water does not flood the ceiling.

- To simplify level control and make-up, it is recommended to bring 2 additional pipelines into the boiler room, as shown in the tank connection diagram:

Installation of a membrane-type expansion tank is carried out vertically or horizontally in any position. It is customary to fasten small containers to the wall with a clamp or hang them from a special bracket, while large ones are simply placed on the floor. There is one point: the performance of a membrane tank does not depend on its orientation in space, which cannot be said about the service life.

A vessel with a closed type will last longer if it is mounted vertically with the air chamber up. Sooner or later, the membrane will exhaust its resource, cracks will appear. With a horizontal location of the tank, air from the chamber will quickly penetrate into the coolant, and that one will take its place. You will have to urgently install a new expansion tank for heating. If the container hangs upside down on the bracket, the effect will appear faster.

In a normal vertical position, air from the upper chamber will slowly penetrate through the cracks into the lower one, as well as the coolant will reluctantly go up.Until the size and number of cracks increase to a critical level, the heating will work properly. The process takes a long time, you will not notice the problem immediately.

But no matter how you place the vessel, you should adhere to the following recommendations:

- The product must be placed in the boiler room in such a way that it is convenient to service it. Do not install floor-standing units close to a wall.

- When wall-mounting the expansion tank of the heating system, do not place it too high, so that when servicing it is not necessary to reach the shut-off valve or air spool.

- The load from the supply pipelines and shut-off valves should not fall on the tank branch pipe. Fasten the pipes together with the taps separately, this will facilitate the replacement of the tank in case of breakage.

- It is not allowed to lay the supply pipe on the floor through the passage or hang it at head height.

Option for placing equipment in the boiler room - a large tank is placed directly on the floor