- Overview of fittings for the metal-plastic system

- Option #1: collet

- Option #2: compression

- Option #3: push fittings

- Option #4: press fittings

- Installation of pipes from different types of materials

- Assortment of fittings in different shapes

- More about manual models

- Buyer Tips

- Installation of a heating system from metal-plastic pipes

- Types of fittings and options for their use

- Features of the installation of pipes made of metal-plastic

- How threaded fittings for metal-plastic pipes are connected

- Compression fittings

- Laying of water metal-plastic pipes

- Press tongs for metal-plastic pipes

- The secrets of competent installation of such parts

- How to choose a press tongs?

- Mounting secrets from experts

Overview of fittings for the metal-plastic system

To prepare for work, it is important to cut the pipes into sections of the required length, while all cuts must be made strictly at right angles. If the pipe is deformed during the cutting process, it must be leveled with a gauge (it will also help to remove the internal chamfer)

To connect metal-plastic pipes of different categories into a single structure, connecting elements are used - fittings that differ in design, size and fastening methods

For the installation of the structure, various types of fasteners are used, we will dwell on them separately.

Option #1: collet

Collet fittings, consisting of a body, a ferrule, a rubber gasket, have a split design, so they can be used several times. The carving of details allows to combine them with household appliances.

To connect the connecting elements to the pipe, put on a nut and a ring in series. Insert the resulting structure into the fitting, tighten the nut. To make the pipe easier to pass into the connecting element, it is desirable to moisten it.

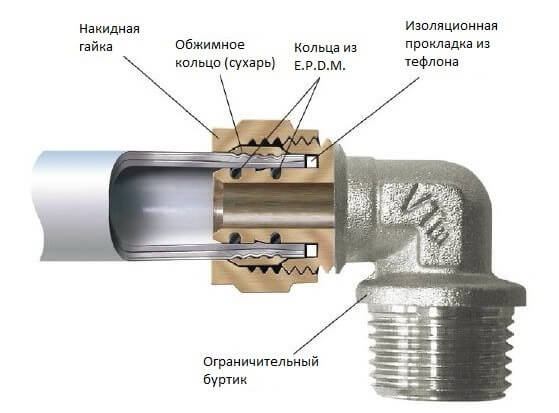

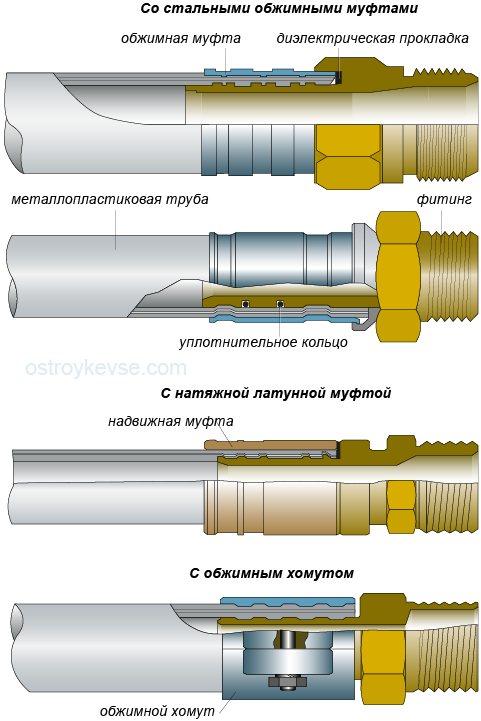

Option #2: compression

Parts widely used for connecting pipes, which can be called conditionally detachable

Before installation, it is important to make sure that the sealing rings and dielectric gaskets are present, which must be located on the shank of the part.

Compression fittings are widely used in the construction of metal-plastic structures. They allow you to easily create connections without the use of special tools.

To connect, a nut and a compression ring are put on the end of the pipe (if it has the shape of a cone, then the process is carried out from the narrower side of the part). After that, the shank is inserted into the pipe (for this you need to make some effort), while in order to seal the part is covered with tow, flax, sealant.

The next step is to put on the fitting body and tighten the union nut. It is convenient to do this with the help of two keys: one of them fixes the part, the other tightens the nut.

This method is quite easy and does not require the use of special equipment, however, it is undesirable to use it for hidden wiring, since it requires a connection check.

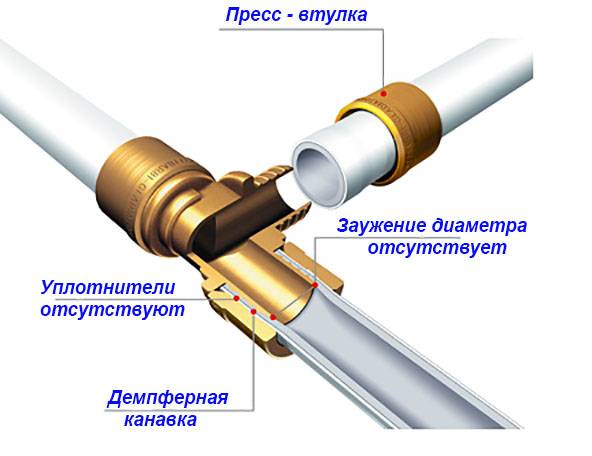

Option #3: push fittings

Convenient connecting elements for fastening of which special tools are not required. For installation, it is enough to insert the product into the connecting part, while the end of the pipe should be visible in the viewing window.

Immediately upon completion of installation, thanks to the included water jet, the wedge of the fitting is pushed forward, forming a clamp that prevents leakage.

This method allows you to quickly and easily create the necessary design, providing high-quality durable connections. Almost the only drawback of push fittings is their high cost.

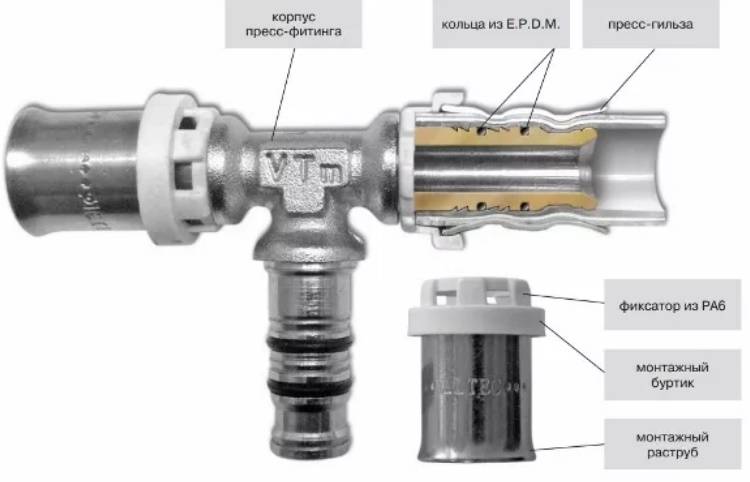

Option #4: press fittings

These elements are used to create one-piece connections using press tongs or similar devices.

Press fittings create tight, durable connections, but they can only be used once. In addition, pressing tongs are required to work with similar elements.

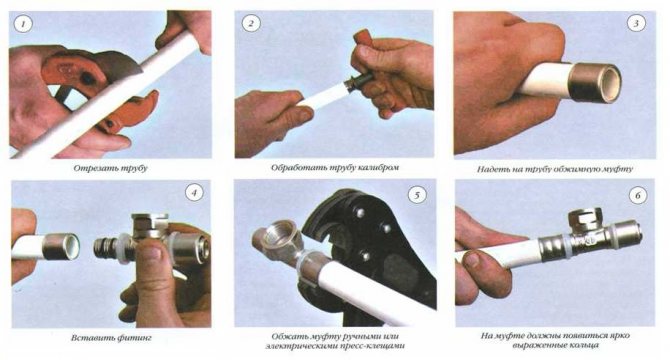

To connect, you need to calibrate the part by removing the fez from it, after which the sleeve is put on it and the fitting is inserted. The sleeve is captured by press tongs, after which, by bringing the handle together, the part is firmly clamped.

Such an element can only be used once, however, the fasteners mounted with it are quite tight and reliable, making them suitable for hidden wiring.

Installation of pipes from different types of materials

To connect elements, one of which is made of metal, and the second is made of metal-plastic, special fittings are designed, one end of which is equipped with a thread, and the other with a socket.

For installation, a metal pipe must be cut into threads, wrapped with tow, lubricated with soap or silicone, and then put on the fitting by hand.After its second end is connected to the plastic element, the thread is completely tightened with a key.

Assortment of fittings in different shapes

For ease of installation, the connecting elements can have a different shape. The most common are:

- adapters for connecting pipes with different diameters;

- tees providing branches from the central pipe;

- corners for changing the direction of flow;

- water outlets (installation elbows);

- crosses, allowing you to organize different directions of flow for 4 pipes.

Press fittings can have a special configuration (couplings, triangles, tees).

More about manual models

Considering that electric-hydraulic pressing tongs are practically not used in the household, below we will consider issues related to only manual models.

Equipment

Additional tool kit

Press tongs are available complete with a set of interchangeable inserts for and a metal or plastic case (can be replaced with a special case or bag).

Connected pipes diameter

Most manual models are designed for the installation of pipes with a diameter of up to 26 mm. Some mechanical models of reinforced type and manual hydraulic pliers allow you to mount pipes with a diameter of up to 32 mm.

Availability of additional functions

Additional functionality is provided by several options:

- OPS system - provides optimization of the applied forces due to the built-in step-type clamps.

- APS system - provides a uniform load on the fitting sleeve, depending on its diameter.

- The APC system - automatically controls the completeness of the crimping of the sleeve by blocking the opening of the press head until it is fully compressed.

Manufacturer

The most expensive models are produced by a number of European manufacturers (Belgium, Germany), and their cost to a greater extent depends not on the technical parameters of the equipment, but on the popularity of the brand. Nevertheless, you can find quite decent functional Italian and Turkish models at fairly affordable prices.

Chinese press tongs are traditionally in the lower price category, but at the same time they do a good job with small amounts of work.

Specifications manual press tongs, which can be bought in Russia

ModelREMS Eco-PressVALTEC VTm-293FORApressSTC 500

| Country | Germany | Italy | Turkey | China |

| Max diameter | up to 26 mm | up to 32 mm | up to 32 mm | up to 26 mm |

| approximate cost | 19.800 rub. | 7.700 rub. | 9.500 rub. | 3.300 rub. |

Additional equipment:

- REMS Eco-Press - steel case with a set of inserts 16, 20, 26.

- VALTEC VTm-293 - bag with a set of liners 16, 20, 26, 32.

- FORApress — plastic case with a set of inserts 16, 20, 26, 32.

- STC 500 - plastic case with a set of inserts 16, 20, 26.

Buyer Tips

Despite the large selection of crimping tools, its purchase by a home craftsman for personal use in most cases does not seem to be optimal.

Even the cheapness of manual Chinese models does not save the situation, because after laying the pipeline, the tool may not be useful at all. It turns out that its purchase for a small one-time amount of installation or repair work is clearly inappropriate.

In this situation, the best option would be to rent for a few days at a rental company, which in any case will cost less than the actual purchase of ticks.At the same time, you have the opportunity to select high-quality press tongs for metal-plastic pipes with suitable parameters for little money.

Another option would be to buy the mites in exchange with neighbors or acquaintances who may also need a tool in the future. In this case, you can use them alternately as needed.

When selecting pressing tongs, it is necessary to take into account their main specifications and maximum dimensions used in the installation of MP pipes. To do this, you should carefully study the passport of the device and check the availability of a quality certificate for the product.

It should be remembered that the use of an unreliable tool can lead to poor quality connections and cause further serious problems in the operation of pipelines.

The main source of heating in the heating systems of apartments and private houses are radiators that give off heat from their outer surface to the surrounding air space. How to connect a heating radiator to the system without resorting to the help of third-party specialists.

Mayevsky crane for cast-iron radiators: an overview of a device for bleeding air pockets from heating systems.

Installation of a heating system from metal-plastic pipes

The main convenience of work in the absence of welding, all elements are assembled on fittings. If the section of the elements for the contour is correctly selected, the linen winding, the grinder is prepared, then the formation of the system will not cause trouble.

Features of the arrangement of heating circuits:

- So that the winding of linen thread at the threaded joints does not burn, does not get wet, it must be impregnated with quick-drying paint.

- Pieces of pipes are cut only with a grinder or a hacksaw.You can’t use a regular knife, it leaves bumps and burrs.

- The edges of the parts must be cleaned, calibrated and then chamfered - better with a shaver, it turns out smoother, the joints will not leak.

- In order not to regulate the entire heating riser in a high-rise building, you need to put jumpers in front of ball valves, chokes to cut off radiators. But you can do without jumpers if the heating system is formed in a private house - in this case, you can quickly adjust the intensity of the coolant supply.

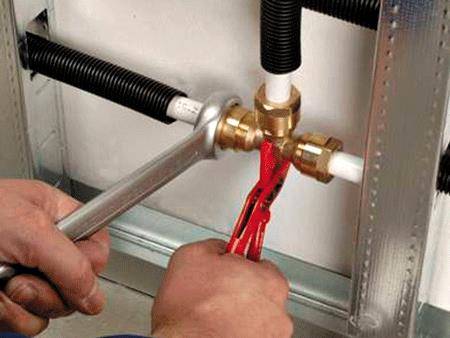

- In the process of tightening the nut of the compression fitting, the body of the unit must be held with a second wrench. If you do not hold the housing, you can break the tightness of the connections.

- You cannot bend the pipe, so special corners are used for turns and bends. If the bending radius is large, the pipe takes up a lot of space, a small radius threatens to break the core.

- For arranging the liner and radiator, American women with a union nut are used. Details will help to quickly dismantle the elements in case of need for replacement or repair.

When choosing fittings for combining structures, you need to know which fittings are suitable for each individual case. Therefore, we will consider all fittings for metal-plastic circuits.

Types of fittings and options for their use

Fittings can be collet (collapsible), compression (conditionally collapsible) and there are non-collapsible press fittings.

How to choose and where to install elements:

- Collets can be assembled and disassembled, there are collapsible threaded fittings. The body is brass, fastening on a pipe on a gasket with a ferrule. To assemble the fitting, screw the nut onto the calibrated end of the pipe, put on the ring and tighten the fitting until it stops.Then again the ring and nut - first tighten it with your fingers, and then tighten it with a wrench. The service life of collapsible fittings is up to 3 years, then they leak. You can tighten the nut, but it is better to replace the element with a new one.

- Conditionally collapsible compression fittings are a fitting with a union nut, fastened to the pipe with a compression ring. For installation, you will need 2 keys, you can take adjustable ones, the service life of products is up to 2-3 years.

- Non-separable press fittings are considered the best, provide the proper level of tightness of the joints. If all nodes are assembled with press fittings, then there will be no leakage in the system - the line will withstand pressure and temperature drops. Installation of a non-separable fitting requires the use of a press machine, the equipment is expensive, but can be rented. The sealed circuit can be hidden in walls or floor screed - with press fittings, a leak will not appear for a very long time.

Features of the installation of pipes made of metal-plastic

Knowing the technical characteristics of metal-plastic pipes for heating, you must familiarize yourself with the installation rules:

- The coolant heating indicator of +70 C is considered working and does not require adjustment. Permissible peak short-term loads up to +110 С.

- To quickly adjust the heating, it is recommended to equip the system with thermostats.

- The pipes do not have a large linear expansion, so when the temperature drops to minus values, the line will break. This imposes certain restrictions - in open areas, the system must be insulated with high quality or a transition to metal pipes must be made.

- When using solid fuel boilers in the house, a metal-plastic system is used only if there is a heat accumulator.The coolant in such boilers warms up to +110 C, and this is the peak load for a metal-plastic pipe; the system will not work in this mode for a long time.

In all other cases, the materials can be used without restrictions in heating systems, distribution of hot water, cold water. Installation is standard, the number of fasteners, valves and fittings depends on the scheme and type of circuits.

How threaded fittings for metal-plastic pipes are connected

Pipes can be installed with brass compression fittings. Their device includes a fitting, a nut, a split ring. With the use of an open-end wrench and threaded fittings, you can create reliable connections. The procedure is as follows: when tightening the nut, the press sleeve (split ring) is compressed, which forms a hermetic pressing of the fitting to the inner cavity of the pipe.

One of the advantages of compression fittings is that they can be installed without expensive special tools. In addition, the threaded fitting allows quick disassembly of the connections. At the same time, practice shows that reassembling a node with such a fitting may be less airtight, therefore, to repair the network, it is better to cut out the damaged section and install a new pipe section in its place using threaded fittings. To reinstall the used connecting element, it is necessary to replace its sealing elements.

For connecting individual pipes the end must be cut at a right angle. This can be done with pipe cutter or hacksaw for metal.For bending pipes, it is better to use a spring pipe bender, but you can also perform this operation manually. When bending by hand, the minimum radius is five outer diameters of the tubular product, and when using a pipe bender, three and a half diameters.

You can buy any kind of compression fittings from domestic firms. When choosing such fittings, it is necessary to purchase products in strict accordance with the parameters of metal-plastic pipes (diameter and size of pipe walls). Ideally, it is better to choose pipes and connections from the same brand.

Pipes made of metal-plastic perfectly hold their shape, therefore, when arranging networks, a minimum number of clamps is required. Connection using compression fittings can be made according to the tee (comb) or manifold principle. If the installation is carried out in the form of a comb, then it is necessary to first install the main pipeline, and then cut the fittings into it in the right places (or carry out the installation in a different order).

Example of connecting a compression fitting:

Mark the connection points.

Perform pipe cutting.

Put a corrugation of insulation on the metal-plastic pipe (optional step).

Perform pipe calibration.

Put a nut with a sealing ring on the pipe.

Connect pipe and fitting.

The photo shows the installation of compression fittings of a tee design. In the catalogs you can find many other options for such connections, which makes it possible to assemble pipelines according to any scheme.

The assembly process is carried out in the following sequence:

-

Align the pipe so as to obtain a flat section 100 mm long before the cut and 10 mm after it.

-

In the right place, you need to cut the pipe at a right angle.

-

Finish the face with a reamer with millimetric chamfering. It is necessary to ensure the correct round shape of the end face.

-

A nut with a split ring must be put on the pipe.

-

Wet the fitting.

-

You need to put a fitting on the pipe. In this case, the end of the cut should rest firmly against the edge of the fitting. We screw the fitting nut by hand until it stops. If the nut does not turn well, then the threaded connection may be broken or the nut does not go along the thread, which will reduce the tightness of the connection.

-

You will need two wrenches to tighten the fitting. One needs to fix the fitting, and the other needs to perform up to two turns of the nut so that up to two threads of the threaded connection are visible. Do not use wrenches with reinforced levers, as tightening the nut can lead to loss of tightness of the connection.

To prevent the metal-plastic pipe from fogging during temperature changes of the transported medium, a special insulating casing made of polyethylene foam or other similar materials is put on top of it. Such insulation can also be put on after installation is completed during the operation of the pipeline. To do this, the polyethylene foam sleeve must be cut lengthwise, and after installation, fix it on the pipe with adhesive tape.

Fittings are marked according to two indicators:

-

according to the outer diameter of the pipe;

-

according to the parameters of the threaded connection, with which pipe fittings are mounted.

For example, the presence of symbols 16 × 1/2 for internal thread indicates that the fitting can be connected at one end to a pipe of 16 mm in outer diameter, and the other end to a fitting that has a half-inch threaded connection.

Read the material on the topic: Replacing pipes in an apartment: professional advice

Compression fittings

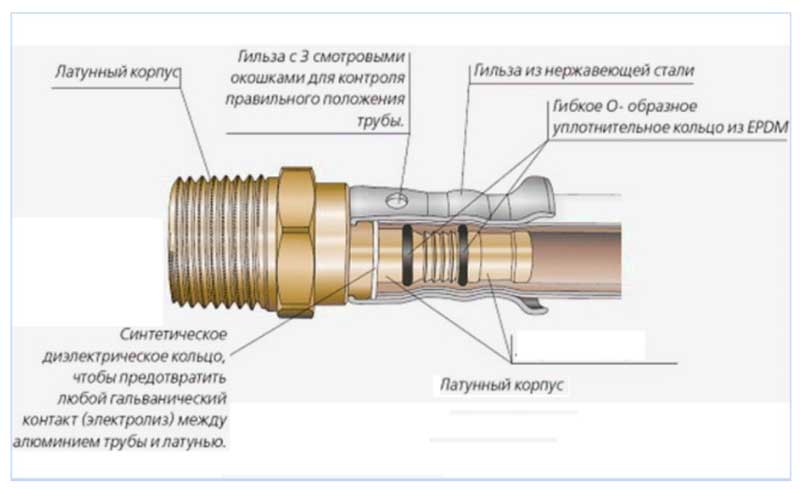

Compression fitting device: 1 - nickel-plated brass fitting; 2 - insulating Teflon ring; 3 - nickel-plated tightening nut; 4 - crimp ring with a slit; 5 - sealing rubber ring; 6 - pipe made of metal-plastic; 7 - shank

When connecting pipes made of metal-plastic using a compression fitting, you will need:

- Wrenches (2 pieces);

- Precision scissors;

- Calibrator;

Calibrator

- Sanitary linen.

Linen plumbing

The connection of metal-plastic pipes using compression fittings includes the following steps:

- The pipe is cut with precision scissors;

- They remove chamfers from the inside and outside of the pipe using a calibrator and a chamfer;

- A tightening nut and a compression ring are put on the end of the pipe;

- Insert the end of the fitting into the pipe;

- Insert the end fitting of the fitting into the pipe;

- The compression ring is pushed to the fitting, then the tightening nut is moved to it so that it closes the compression ring;

- Seal the thread of the fitting, for this you can use flax with paste or fum-tape;

- Using two wrenches, tighten the tightening nut to the stop, after which the connection with the compression fitting is completed.

Laying of water metal-plastic pipes

Adapters for metal-plastic pipes

Consider the main nuances of installing a water supply system from metal-plastic pipes:

- For fastening pipes made of metal-plastic to the walls, special clips-clamps are used;

- It is unacceptable to squeeze the pipes when fastening;

- Pipe fastenings should not have notches that can lead to a violation of the pipeline insulation;

- Before walling up pipes, you should check the entire plumbing system under maximum pressure. In addition, it is recommended to test the system at a pressure twice the working pressure;

- It is forbidden to wall up the water supply using compression fittings - cabinets and boxes can be used to hide metal-plastic pipes.

Press tongs for metal-plastic pipes

Crimping tools for multilayer pipes

For the installation of metal-plastic pipes in an apartment, special tools and fittings are used, and to obtain a one-piece connection, a steel compression coupling is often used, for which crimping pliers for metal-plastic pipes are used, which are sold in many stores and have a set of different inserts, the dimensions of which correspond to the diameters various pipes.

The crimping of metal-plastic pipes is considered to be performed correctly if two annular strips appear and the metal is bent into an arc. It should be remembered that the fluid pressure at the connection point must not exceed 10 bar.

A number of manufacturers produce compression couplings fixed on fittings, the process of mounting such fittings on pipes is slightly different: first, metal-plastic pipes are cut and calibrated, after which the pipe is immediately placed on the fitting, and it should be carefully controlled using the holes in the coupling, how tight it turned out nozzle.

Due to the greater reliability of connections using press fittings compared to conventional compression fittings, press fittings are more often used in hidden communications equipment, which are usually laid in floors and walls.

However, not every home builder will have a special tool for crimping pipes, especially since it may be needed only once when replacing a water pipe.

In this regard, many plumbing stores offer services for customers to crimp pipes using fittings, or rent pliers for crimping metal-plastic pipes, which is very convenient - using pliers does not require special skills, and on the second or third attempt a person is usually already able to perform the assigned task correctly.

That's all I wanted to tell about the connection of water and sewer pipes made of metal-plastic, fittings for making connections and a tool for crimping metal-plastic pipes. This article is intended to significantly help those who have set themselves the task of equipping a high-quality and reliable pipeline with their own hands.

The secrets of competent installation of such parts

Installation of parts is very fast and quite simple. For its implementation, you will need a special tool, without which it is impossible to compress the fitting.

How to choose a press tongs?

Press tongs for fittings - a device designed to install a part on a pipe. Manual models and more complex hydraulic models are available. For independent work, the first option is quite suitable, since it is the easiest to use and cheapest. And in terms of the quality of the connections made with its help, they are not inferior to those in the process of which a professional hydraulic tool was used.

When purchasing equipment, it must be borne in mind that it is designed to work with a certain pipe diameter. There are models equipped with special inserts that make it possible to work alternately with pipes of several diameters. In addition, on sale you can find improved variations of the tool. They are marked with:

-

- OPS - the device increases the forces applied to it by using step-type clamps.

- APC - during the process, automatic control over its quality is carried out. The press will not open until the crimp is successfully completed.

APS - the device independently distributes the force that is applied to it, depending on the size of the fitting.

Crimping press pliers are a necessary tool for installing fittings. Manual and hydraulic models of special equipment are available

What to look for when buying connectors

The reliability of the connection largely depends on the quality of the parts.

When buying press fittings, experts advise paying attention to the following points:

- The quality of the markings on the case. Companies that produce quality parts do not use cheap molds. All symbols on the body of the fittings are printed very clearly.

- Part weight.For the production of high-quality products, brass is used, which has a fairly large weight. It is better to refuse a fitting that is too light.

- The appearance of the element. Low-quality parts are made of thin metal that looks like aluminum. It is not able to provide a quality connection.

You should not save on fittings and try to buy them "cheaply" at a dubious outlet. In this case, there is a high probability of subsequent alteration of the entire pipeline.

Mounting secrets from experts

Let's start by cutting pipes. We measure the required length and cut the element strictly perpendicular. It is best to use a special tool for this purpose - a pipe cutter. The next stage is the processing of the end of the pipe. We insert a caliber inside the part, straightening a small ovality that inevitably forms during cutting. We remove the inner chamfer using a chamfer for this. In its absence, you can do this operation with an ordinary sharp knife, and then clean the surface with an emery cloth.

At the end of the work, we put the press fitting on the pipe, controlling the tightness of its fit through a special hole. There are models in which the ferrule is not fixed to the fitting. For their installation, such operations are performed. We put the crimp sleeve on the pipe. We insert a fitting inside the element, on which the sealing rings are fixed. To protect the structure from electrocorrosion, we install a dielectric gasket at the contact area of the metal connecting part and the metal-plastic pipe.

For crimping any models of press fittings, we use a tool that is suitable in diameter. We grab the sleeve with a clamp press tongs and reduce their handles to the stop.After removing the tool, two uniform ring strips should remain on the fitting, and the metal should be bent in an arcuate manner. Compression can be performed only once, there should not be any repeated operations. This leads to a broken connection.

The installation of press fittings for metal-plastic pipes takes place in four main stages, which are shown in the figure

Press fittings for metal-plastic provide a very strong, durable connection. Their wide range allows the implementation of pipelines of various configurations. In addition, they are very easy to install. Even a beginner can install press fittings. This requires patience, accuracy and, of course, a careful study of the instructions. The result of the efforts will surely please you with a hand-made pipeline that is reliable in operation.