- Features of tapping into a water pipe

- Manhole construction

- Insertion into the gas pipeline

- Features of tie-in into a metal gas pipeline

- Gas pipe connection options

- Option number 1 - weld

- Option number 2 - soldering pipes

- Option number 3 - tie-in to the pipe

- Option number 4 - use a threaded connection

- Option number 5 - flange connections

- Use of clamps

- Docking pipes without welding: general information

- Options for solving the problem

- Insert tee, manifold

- Using overlays

- The principle of insertion into the system

- How to crash into a metal plumbing system?

- Methods for connecting metal pipes without welding

- Docking pipes without welding: general information

- How to connect asbestos-cement pipes?

- How to cut a pipe into a heating pipe

- How to connect pipes without welding?

- Articulation of profile pipes

- Application of clamps

Features of tapping into a water pipe

Before starting any work, it is imperative to obtain the appropriate permission for this. When performing an illegal installation process, there is a high probability of being held administratively liable.

According to the rules, for the tie-in, you should take a permit signed by the management of the local water utility and a plan of the site where the work will be carried out.In addition, technical conditions will be required, for which you will have to visit the central department of the water utility. Specifications usually contain information about the connection point, data for the tie-in, as well as the diameter of the pipeline of the underlying pipeline.

In addition to the employees of the water utility, other companies specializing in such work with the appropriate license can develop design estimates. The price for services related to the preparation of documentation for tapping into a pressure water supply may be slightly lower for such organizations.

However, in the future there is a possibility of a conflict situation with representatives of the water utility, who do not always give approval to such design developments.

Having received the necessary papers, you should contact the SES department, where to register the project. Here you will also need to write an application to obtain the necessary permission to connect to the water supply system.

In accordance with generally accepted standards, only specialists with the appropriate approval can perform work on tapping into a water pipe. The person who ordered the implementation of this service can save money only on digging and filling the trench with his own hands, as well as on auxiliary work that does not require permits.

There are some situations in which inserting a pipe into a water supply system is prohibited:

- connection to the highway without installing a meter;

- lack of connection to a centralized sewerage system;

- a larger diameter branch branch than that of the main pipeline.

Manhole construction

To simplify the tie-in process, you can build a manhole about seventy centimeters wide.

Such a well will be enough to place shut-off valves in it and perform the necessary manipulations for connecting to the water supply. Such a construction will make it easier in the future to carry out possible repairs to the home system.

To make a well, they dig a pit of the required parameters, the bottom of which is covered with a ten-centimeter layer of gravel. To form a reliable foundation, the resulting “pillow” is covered with a sheet of roofing material. A concrete screed is poured on top.

After at least three weeks, the walls of the shaft are laid out above the hardened slab. For this purpose, brick, reinforced concrete rings or cement blocks can be used. The mouth of the pit is raised flush with the surface.

When building a well in a site with frequently rising groundwater, it should be watertight. It is most convenient in this regard to use a ready-made plastic container, which is attached to a concrete base. The upper part is covered with a plate with a hole for installing a hatch.

Water pipes are made of several types of materials: plastic, cast iron or steel

It is worth paying attention to each of them.

This is interesting: Devices and tools for expanding copper pipes - we explain in detail

Insertion into the gas pipeline

A gas pipeline is a structure through which gas is transported. Depending on the purpose, it can be supplied under different pressure. For example, if we are talking about main pipelines, then the pressure in them is quite high, while in distribution systems it can change.

Tapping into the gas pipeline without stopping work can be carried out during the repair and connection of individual consumers.The system will work without interruption and the pressure will not be reduced. This technology is also called cold tapping and is sometimes replaced by a more traditional method, which involves welding the pipe and is considered labor intensive.

Tapping into the gas pipeline when using plastic pipes is carried out using fittings or fittings. For this, metal elements are used, and the method provides for a socket connection, which is glued with special compounds after installation is completed. The steel insert is treated with compounds that can protect the surface from rust, because water ingress can cause corrosion processes.

The tie-in is carried out by creating inserts from alloys perpendicular to the pipe. The insert has a length ranging from 70 to 100 mm and is built up by the method of socket contact connection. This method implies that plastic pipes are placed on a heated steel insert. The method is used to create branches from gas pipelines with low pressure. If the pressure is medium, then before building up, it is necessary to apply powdered polyethylene to the place of the future connection, which will ensure tight adhesion of the two materials.

Features of tie-in into a metal gas pipeline

An insert into the central branch of metal pipes is carried out after drawing up a sketch of future work and preparing all the materials that will be useful in the process based on the chosen connection method.

The first step is to clean the work surface. At the same time, absolutely everything superfluous is removed from the place chosen for connection to the gas pipeline: garbage, paint, rust. Next, mark the place of the tie-in, making marks.Make the necessary holes.

After that, the wells are well treated. During the dissection of the surface of the pipe, the cracks are carefully coated with clay. This is required to minimize the risk of ignition of the escaping gas during the incision.

The holes made are sealed as soon as possible with an asbestos-clay plug, and the treated area is quickly cooled.

The connection of pipes should be carried out in such a way as to achieve the most accurate intersection of the axes of the pipelines.

The next stage of work will be the installation of a disconnecting device. After the metal has cooled, the plug is removed in order to be able to remove the section of the cut pipe from the gas pipeline.

Now, a disconnecting device is installed in the gap formed. It consists of a set of rubber and wooden discs and bags filled with viscous clay.

Next, install the pipe. Having closed the hole with a disconnecting device, they begin to make the main hole, designed to connect a new pipe. First of all, it is necessary to check the conformity of the diameter, since sometimes the markings have to be adjusted.

Next, make a hole and mount the pipe. Its butt joints are welded by welding from two sides and the valve on it is closed. After close up the holes.

After completing the installation of the pipe, proceed to welding a new pipe. Before this, the metal slag formed after making the main hole is removed. After cleaning the surface of the pipeline, a new pipe is installed in the holes and, coated with clay, welds are made.

Next, they take an aqueous solution of soap and carefully coat the new seams with it, making sure that they are tight and that there is no leakage of blue fuel.

Pipe joints should be carefully checked for the absence of blue fuel leakage by lubricating them with a solution of soap and water

If no gas leakage is observed, proceed to the final stage of work, that is, fill up the trench. However, this is not such a simple operation as it seems at first glance.

Backfilling of the trench must also be carried out in accordance with the standards given below:

- around the circumference of the insertion point of the ball valve and the connecting pipe, it is necessary to backfill soft soil with a layer more than 20 cm thick and compact it;

- it is strictly forbidden to fill the trench with soil with a bulldozer or other heavy construction equipment.

Hitting the mentioned equipment on the soil layer covering the insertion point, and the pipes coming from it, as well as on the ball valve protruding above the soil surface, is strictly prohibited.

Gas pipe connection options

Today, masters distinguish 5 types of connections when installing a gas pipeline. These are welding used for metal pipes, soldering used for copper and PVC, tapping, threaded and flanged connections.

Option number 1 - weld

Steel pipes are processed using an inverter apparatus or gas welding equipment. The ends to be connected are placed at a distance of 1.5-2 mm from each other, thoroughly fixed.

In the process of melting the metal, the welder applies two seams: the main and additional insuring.

Experienced craftsmen cool the heated metal and only after that they get rid of scale. This makes it possible to avoid the appearance of cracks.

Experienced craftsmen cool the heated metal and only after that they get rid of scale. This makes it possible to avoid the appearance of cracks.

Polyethylene elements are joined by an apparatus that controls the temperature reached during heating. For connection, a fitting with a consumable element is used. By heating the surrounding material, it turns the mixture into a homogeneous mass. The result is a tight, durable seam.

Option number 2 - soldering pipes

Butt soldering is suitable for both metal pipes and thermoplastic polymer products. The work is carried out on a modular unit, including a hydraulic unit, a centralizer, a soldering iron and a built-in cutter.

The algorithm is:

- The ends of the elements to be soldered are cleaned from chips, dust, foreign particles. Degrease.

- Using a soldering iron for polypropylene pipes, the parts are heated and approached until a 1 mm thick influx appears on the joint surface.

At the end of work, the connection is left in the unit until it cools completely. Any movement during the period of temperature decrease can cause fistulas.

Option number 3 - tie-in to the pipe

Punch is a technique that requires special skill. It can be performed hot, in which an arc welding unit is used, and cold, when drilling equipment is the main tool.

The meaning of the manipulation is to organize a sealed branch from a solid pipe.

Some owners of private houses, when connected to the central highway, carry out cold tie-in on their own, without notifying their neighbors or the supplier company. Doing so is prohibited. Only licensed organizations can connect a new site to gas

Some owners of private houses, when connected to the central highway, carry out cold tie-in on their own, without notifying their neighbors or the supplier company. Doing so is prohibited. Only licensed organizations can connect a new site to gas

Insertion by the first method is permissible only when the pressure in the gas pipeline is reduced to a value of 40-50 kg per square meter. see The second can be implemented without pressure reduction.In both cases, the permission of the supervisory authorities is required.

Read more about how to crash into a gas pipeline.

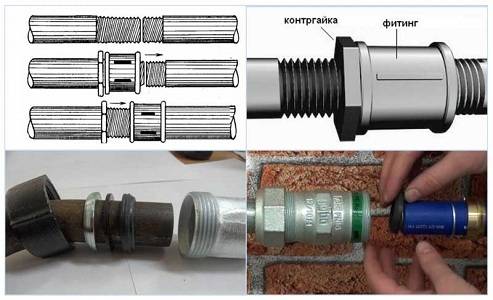

Option number 4 - use a threaded connection

Threaded connections are used along the entire length of the gas pipeline: from end elements to various types of branches. If flexible rubber hoses are already equipped with appropriate nozzles, then metal pipes often have to be cut.

It is carried out in the following way: the surface of the future thread is cleaned, processed with a file, lubricated with machine oil. Then, with the help of a pipe die, cutting is performed.

If it is intended to join two fixed sections of the gas pipeline, then the gas pipes are connected by means of a coupling. This is a separate metal element with an internal thread. Applying it to the external thread of the pipe ends makes it possible to ensure a snug fit.

Experienced craftsmen always monitor the position of the klupp: it must be located strictly perpendicular to the pipe. In addition, they perform cutting with alternating a full turn forward and half back. This is done to timely get rid of chips that prevent an even cut.

Experienced craftsmen always monitor the position of the klupp: it must be located strictly perpendicular to the pipe. In addition, they perform cutting with alternating a full turn forward and half back. This is done to timely get rid of chips that prevent an even cut.

Even a perfectly executed thread does not ensure the perfect integrity of the joint. Therefore, additional materials are always used to seal gas threaded connections.

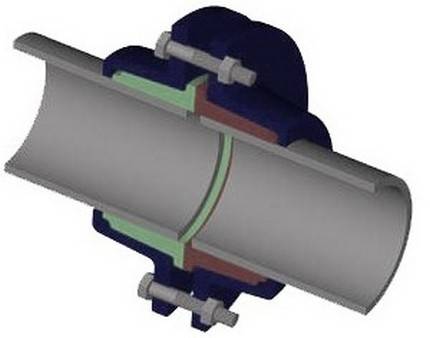

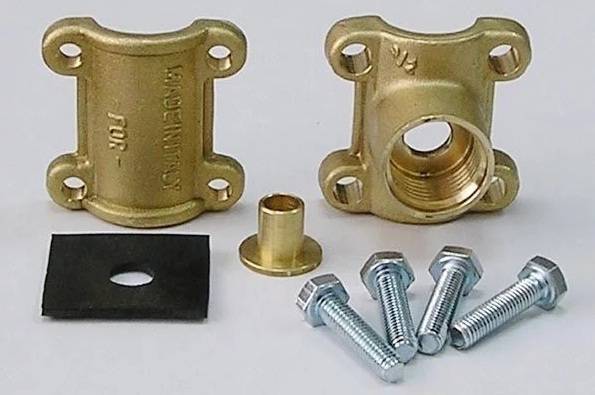

Option number 5 - flange connections

This method is suitable for pipes made of copper, steel, polyethylene. Used only in areas with low pressure.

A flange is a flat piece with holes drilled into it. The part itself serves as a connecting element. The holes in it are for studs and bolts.

It is necessary to select a flange taking into account the parameters prescribed in GOST 12820-80. The document takes into account the correspondence between the nominal pressure of the gas pipeline and the size of the part

It is necessary to select a flange taking into account the parameters prescribed in GOST 12820-80. The document takes into account the correspondence between the nominal pressure of the gas pipeline and the size of the part

For PVC pipes, special fittings are used, which are connected by welding. In the case of metal elements, heating can be dispensed with. Bolts are used on them to fix the flanges.

Use of clamps

Reliable and practical, hose clamps are in high demand in a wide variety of industries. Due to the ease of installation, they are used in industrial and domestic purposes. When joining pipes, you can pre-plug them on both sides to ensure greater strength and reliability.

Pipe clamp is relatively inexpensive

Specialists use a variety of types of clamps:

- For hoses;

- With pivot bolt;

- Spring.

Metal clamp can be used in all types of fastening. For fixing, such products are made of galvanized or stainless steel, and for tightening, they are used bolts or screws. If they are used for plastic pipelines, rubberized seals can be used to avoid damage to the shells, reduce vibration and noise.

In case of increased mechanical loads, power clamps should be used. Their design allows to withstand very large loads along the clamp, which maintains integrity. Plastic clamps are used for fixing water and sewer pipes. Their design is similar to metal, but they have a much lower cost.

The connection of pipes can be performed in a variety of ways, it all depends on your own preferences.

Docking pipes without welding: general information

There are several ways of articulating pipe structures, tie-ins into the main line. Some of the communications after that are amenable to further installation if necessary (in the case of repair, emergency work), others are one-piece. They cannot be disassembled without destroying the entire structure or its individual section.

It is important from the very beginning to strictly follow the instructions for the correct insertion into the pipeline, to do everything as it is said, so that in the future you do not have to redo everything and buy new material. In principle, there is nothing complicated.

Before proceeding directly to the analysis of the rules for cutting into a pipe, debriefing and tips for a beginner, we will consider the types of pipes.

They are divided into 2 groups:

- Rigid (steel, copper, cast iron);

- Flexible (polypropylene, metal-plastic, polyethylene).

Accordingly, depending on the type of pipes, certain methods of articulation are used that are suitable in a given situation, corresponding to safety and quality standards. Also, for tapping into a pipe, you need an appropriate tool, which must be purchased in advance.

Options for solving the problem

If it’s quite simple to deal with a conventional connection, then the question of how to crash into a polypropylene pipe without soldering is asked quite often. In this case, there are also several options that can be used for other polymer products.

Tapping technologies are very similar, but they have their own areas of application. Some methods are ideal, they can even be used for distributing hot water and heating systems.Other methods are only suitable for cold water supply or sewage. The difference between technologies is the method of connection, if it becomes necessary to insert any element into an already existing pipeline.

There are “run-in” tie-in methods, but not all of them are possible if there is no suitable tool. There are only two main technologies that are successfully used for plastic water pipes: this is the insertion of tees or the use of clamps, saddles.

Insert tee, manifold

This method is recommended not to be used by those masters who do not have experience in such work. If a tie-in is necessary, but there are no skills yet, then a saddle overlay is much more preferable: it gives a chance to avoid unpleasant consequences. The first difficulty will arise if the water cannot be shut off. In this case, work with the power tool will become impossible. Working with a soldering iron also requires dry surfaces.

The role of insertion into the water supply can be "played" by an ordinary tee, a manifold, which makes it possible to connect several branches. Or a small piece of pipe to which a branch is soldered. In the latter case, two types of connections are considered - threaded or soldered. As a rule, choose the one that was used when installing the system. However, this option assumes the presence of a special soldering iron, so it does not make sense to consider it in detail. But there is an alternative - the use of pressure fittings.

Using overlays

This is the installation of a clamp (saddle) with a branch pipe. The first method is elementary: the saddle is put on the pipe, then fixed with bolts. The second option is suitable for HDPE pipes, it requires special products.The clamp is applied to the pipeline, and then welded using heating coils built into it.

If we talk about the reliability of both methods, then the option with the insertion of a tee will be the leader here. This is a common job where fittings are used. However, the method is not without one significant drawback: such a "surgical" operation is not always possible. An example is a pipe located almost right next to a wall. In this case, problems may arise with the implementation of the idea by any method. The need for special equipment is also a disadvantage.

Using comfortable pads is the best answer to the question of how to cut into a polypropylene pipe without soldering. The technology is simple, and if the water supply is under pressure, then the master simply has no other options. If the system has to be freed from water before installing the tee, then when using some models of clamps (saddle branches for tie-ins), this stage of preparation is not needed.

The principle of insertion into the system

Before starting installation work, it is recommended to coordinate them with the water utility and the local administration. If there is no central sewerage on the land plot, tapping may be prohibited. But in the presence of a septic tank and all established sanitary standards, it is possible to obtain such a permit. To join the pipes, a special well is equipped.

If the water utility prohibits tapping into an existing water supply, then the object is connected to a nearby well.But it must be in working condition. The process of tapping into an external line is carried out according to the following technologies: using fittings that are installed on the pipe during installation; fixing the outlet branch of the system if there is no pressure in the system; using a fitting that is fixed on the pipe. Such a connection does not require prior shutdown of the water supply in the system.

How to crash into a metal plumbing system?

- The flange must be done by hand. In this case, a pipe segment with an inner diameter similar to the diameter of an already installed pipeline is used, into which it is required to crash. Only in this case, the required degree of tightness is ensured by reducing the mounting gap;

- It is acceptable to use a magazine tee with a sufficient diameter. In this case, a part of the pipe without a branch pipe is removed from the tee. For further work, the pipeline is cut, a hole is made in its working part, then a branch pipe is fixed by welding;

- It is optimal if the flange is welded to the pipeline. To do this, it is necessary to boil it around its entire perimeter. If welding is not possible, sealant and clamps, epoxy can be used. The latter is used in cases where liquids are transported for technical needs.

A training video will help you correctly crash into the plumbing system, which shows in detail how this work is done by professionals. The video will allow you to visualize all the information on this topic, which contributes to the quality of doing the work with your own hands.

Methods for connecting metal pipes without welding

Not all metals weld well, sometimes the quality of the seams is poor.Threaded joints are not tight enough, the screw thread on the metal collapses over time.

Weldless connections are technological. Devices are used for high pressure gas pipelines, when transporting heated media. For the installation of seals, no preliminary preparation of joints or cutting of edges is required. It is enough to clean the ends of dirt, dust.

Methods for connecting metal pipes without welding:

- Clamp tie. A sealed, tight-fitting pad is used to seal leaks. Repairs can be done quickly.

- Flanged. The tightness of the plates is regulated by bolt fasteners, the tightness is ensured by a rubber gasket.

- Installation of the repair and assembly clip. The joint is securely fixed in a small metal case.

- Use of the Gebo coupling. The compression fitting is suitable for repeated use.

- Fastening fittings without thread. An inseparable hermetic connection of high strength is formed.

- Crab systems. Are used for profile hire.

For threadless connections, no special electrical or gas equipment is required, a mounting tool is sufficient. Installation of the device does not require technical training of specialists.

Docking pipes without welding: general information

There are several ways of articulating pipe structures, tie-ins into the main line. Some of the communications after that are amenable to further installation if necessary (in the case of repair, emergency work), others are one-piece. They cannot be disassembled without destroying the entire structure or its individual section.

It is important from the very beginning to strictly follow the instructions for the correct insertion into the pipeline, to do everything as it is said, so that in the future you do not have to redo everything and buy new material. In principle, there is nothing complicated.

Before proceeding directly to the analysis of the rules for cutting into a pipe, debriefing and tips for a beginner, we will consider the types of pipes.

They are divided into 2 groups:

- Rigid (steel, copper, cast iron);

- Flexible (polypropylene, metal-plastic, polyethylene).

Accordingly, depending on the type of pipes, certain methods of articulation are used that are suitable in a given situation, corresponding to safety and quality standards. Also, for tapping into a pipe, you need an appropriate tool, which must be purchased in advance.

How to connect asbestos-cement pipes?

Asbestos cement is a building material for pipes, consisting of Portland cement and asbestos fibers. The components are mixed in a ratio of 4 to 1, and after some additions they harden, forming the desired shape for the workpiece. I choose the tie-in method based on the type of execution and the pressure inside the system.

| System type | What do I use |

|---|---|

| gravity channel | I use thick-walled couplings made from chrysotile cement. |

| channel under pressure | when transporting gas or liquid under pressure, I advise you to use cast iron flanges of the “Jabot” type. |

| Communication cables | The diameters of such pipes are from 80 to 400 mm. The lack of pressure inside allows the use of polyethylene sleeves. |

The main problem for beginners when working with asbestos cement is the fragility of the material. When making holes for the outlet, you should be extremely careful not to crumble the wall in the area of the pipe insert.

Insertion of pipes by hot welding using a "saddle":

How to cut a pipe into a heating pipe

At one time, pipelines in houses and apartments were assembled by welding and, of course, no one provided for the installation of fittings for possible additional connection. Meanwhile, such a need periodically arises in connection with various redevelopments, and most often it concerns heating. The emergence of modern materials and the availability of tools and fixtures greatly facilitate the task and even allow you to choose the most preferred option. How to "crash" into a heating pipe with minimal financial and labor costs, read below.

How to connect pipes without welding?

There are several ways to connect pipes to the main line without welding. Some of them are classified as one-piece, which is almost impossible to disassemble without destroying the pipeline. Others are detachable joints that can be easily dismantled and, if necessary, reassembled.

The choice of option depends on what material the pipe is made of.

All pipe rolling is divided into two main groups:

- hard - pipes made of cast iron, copper and steel;

- flexible - products are made of polymeric materials (polypropylene, metal-plastic, polyethylene).

This separation is based on the need to use a larger engagement area at the moment of joining parts of polymer structures. For comparison: tie-in of metal pipes can be performed under limited conditions, using the minimum engagement area of the joined parts.

Articulation of profile pipes

The most affordable way to articulate profile pipes is by installing mounting clamps. With the help of these simple devices, it is convenient to assemble any type of small-sized metal structures, erecting sheds and racks, greenhouses and fences, canopies and modular partitions.

The indisputable advantage of using fasteners is the ease of installation and the ability to disassemble the assembled structure an unlimited number of times.

To implement this method, you need only three components:

- Rolled tubular cut to size.

- Required number of fasteners.

- Wrench.

Crab clamps can be "X", "G" and "T"-shaped elements, with the help of which it is convenient to dock straight sections of pipes, corner structures and simultaneously connect up to four segments within one node.

When assembled, they have the shape of a square or rectangle, the sides of which tightly wrap around the joined parts of metal pipes.

Fasteners with crabs should not cause any particular difficulties. Insert the cut pipes into the clamp and fix the pressure sticks by tightening the bolts on the system by anyone.

But this method can only be used for profile pipes with a cross section of not more than 20 x 20 mm, 20 x 40 mm and 40 x 40 mm. In addition, the docking of elements can only be done at right angles.

It is also possible to connect square pipes without welding by installing fittings of a given profile.

Fasteners in the form of fittings are of several types:

- Couplings - at the docking points on straight sections.

- Crosses and tees - for installation in places of branching;

- Elbows and turns - if necessary, change the direction of the pipeline.

With the help of fittings, you can get fixed fasteners, the only weak spot of which is only susceptibility to corrosion, which is typical for the ends of the joined elements inserted into it.

This situation occurs as a result of the accumulation of condensate inside the fastener. It will cause rust, provided that the metal pipes are not treated with an anti-corrosion compound.

Application of clamps

Universal pads are put on cracks to eliminate leaks. They can connect pipes without thread welding. Gaskets are used for tightness. Clamps are made of metal or dense sealed material. Clamps are comparable in strength to welding. Lining designs:

- wide and narrow in the form of split rings with holes for bolts;

- in the form of a metal bracket that fixes the hermetic gasket;

- complex geometry for fastening to a wall or two pipelines between themselves.

Clamps to eliminate leaks are made from improvised materials. Fix on the pipe with tape or wire.

There are many ways of mechanical connection. You can always choose something suitable for the situation. And the welding machine for the time of installation of the pipeline or metal structures can be left out.