- Steel pipe installation

- Required materials when connecting to the central pipeline

- The final stage of the tie-in

- The cost of tapping into the water supply

- How to connect to a common water main

- Options for inserting into a plastic pipe

- Mounting the crimp collar of the lining

- Clamp or manifold device

- Electric welding saddle attachment

- Insertion by means of a branch pipe

- Choosing the Best Solution

- Detailed description of the main stages of work: tie-in to the water supply

- Materials: cast iron and others

- Do-it-yourself installation in 7 steps: clamp, saddle, sewerage scheme, coupling

- Tapping into a pipe under water pressure

- Methods

- Insert technology

- When should you hit the pipe?

- Punch methods without welding

- Construction of a well for arranging a node

- What documents need to be collected and prepared

- Insertion into the water supply from metal pipes

Steel pipe installation

Pipes made of steel are characterized by their rigidity with simultaneous plasticity. Their installation can be carried out in a manner similar to the insertion of polymer analogues. When working with them, you must follow a certain sequence of actions:

- the surface of the tie-in area is cleaned of corrosive deposits;

- a pipe is mounted on it;

- welding of seams is carried out with their subsequent check for tightness;

- the branch pipe is connected to a threaded or flanged valve, through which a main pipe is drilled under pressure;

- install a new branch pipeline.

The upper layers of the highway are drilled with a puncher, and the remaining few millimeters are worked out manually.

Required materials when connecting to the central pipeline

Depending on the material of the water pipe, it may be necessary to use certain additional pieces of equipment.

Depending on the material of the water pipe, it may be necessary to use certain additional pieces of equipment.

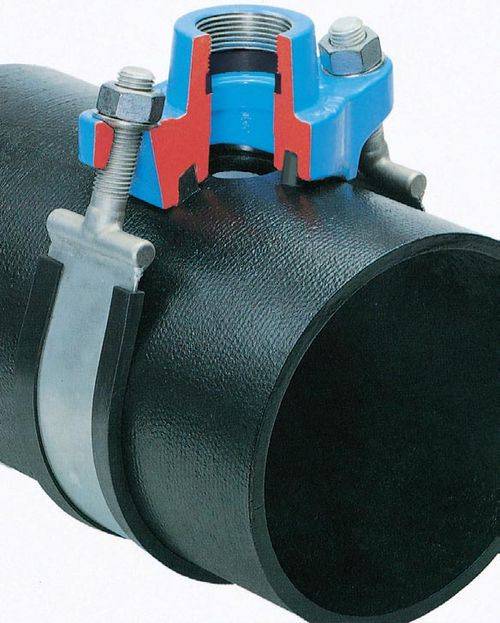

To cut into a plastic pipe with a pressure of about 1.6 MPa, it is necessary to use an annular saddle clamp. This device has a spiral with a cutter used in the formation of holes

When buying a saddle for tapping into the water supply, you should pay attention to the barcode marked on its body. It ensures the accuracy of the parameters of the created hole

For tapping into a cast-iron or steel pipe, you need to buy a saddle clamp. This fixture is divided into two parts, which are pulled together by bolts during operation. The metal seat is equipped with a locking plate.

It is mounted to the pipeline with a bracket. A tie-in into a steel water supply system can also be carried out without the use of a saddle by welding a branch pipe, however, with this method, the diameter of the main pipe, which must be with a large cross section, matters.

Today, due to an affordable price and excellent quality, saddles with built-in valves and a cutter have gained great popularity among specialists. They are usually used when tapping into a pipeline under a pressure of not more than sixteen bar.

They are equipped with a coupling, which allows installation by a welding machine.The most attractive feature of these saddles is their good resistance to corrosion processes, extending the service life up to fifty years.

The final stage of the tie-in

The final step in any pipeline connection process is the testing of the connected system components.

For this purpose, pressurized water is supplied to the created new branch, and the accumulated air is bled from the other end of the pipe using a tap located on it.

After checking all the elements of the water supply for tightness, it is possible to dig in a trench laid from the main to the connection point with the home network.

The cost of tapping into the water supply

The price tag for a polymer clamp is 100–250 rubles. In this case, a fitting installed on a pipe with a diameter of 32 mm will cost 100 rubles, and for 75 mm fittings - 250 rubles.

The cost of a stainless steel clamp, supplemented with a flange outlet, is 9–10.5 thousand rubles. The scope of delivery of this equipment includes a rubber gasket and 6 studs that provide the ability to fix the staples.

Electrowelded saddles manufactured by the Italian company Eurostandard Spa, having a diameter of 40–250 mm, can be purchased for 25–80 euros. As for the cost of work, the average price tag for services of this type ranges from 2 thousand to 2.5 thousand rubles.

How to connect to a common water main

Before crashing into a water pipe under high fluid pressure, familiarize yourself with three technology options that vary depending on the material of which the pipes are made (they can be polymer (PP), cast iron, galvanized steel).

For polymer central route tie-in into the pipe pressure plumbing looks like that:

- A trench no less than one and a half meters in size is excavated, the area where the work will be done is exposed, and a trench is being dug from it to the house;

- At the end of the earthmoving work, a saddle is prepared for tapping into the water supply system - this is a collapsible crimp collar that looks like a tee. The straight outlets of the saddle are divided in half, and a valve is installed on the vertical outlet to shut off the pressure. A pipe is drilled through the tap with a special nozzle for tie-in. The most reliable saddle scheme is collapsible welded. It is easy to divide such a clamp into two halves, assemble it over the tie-in section, and weld it to the main route. Thus, the clamp for tapping into the water supply is welded into the body, providing a reliable and absolutely hermetic water supply to the dwelling;

- The pipe is drilled with a conventional drill and an electric drill. Instead of a drill, you can use a crown, but the result is important, not the tool;

- A through hole is drilled until a jet of water comes out of it, after which the drill is removed and the valve is closed. For safety reasons, at the end of the drilling process, the electric tool is replaced with a hand drill or a brace. If you drill a hole not with a drill, but with a crown, then it will automatically ensure the tightness of the drilling site. In addition to these options, there is a solution using a special cutter, which is rotated by an adjustable wrench or an external brace;

- The last stage of the tie-in to the central water supply is the establishment of your own water supply, laid in a trench in advance, and connecting it to the central route with an American compression coupling.

For complete control of the insertion point, it is advisable to equip a revision above it - a well with a hatch.The well is equipped as standard: a gravel-sand cushion is made at the bottom, reinforced concrete rings are lowered into the trench, or the walls are laid out with bricks. Thus, even in winter it will be possible to shut off the water supply if it is necessary to repair it in the house.

For cast iron central plumbing pipes saddle method tie-in looks like this:

- To tap into a cast-iron pipe, it must first be thoroughly cleaned of corrosion. At the very place of drilling, the top layer of cast iron is removed by a grinder by 1-1.5 mm;

- The saddle is built into the pipeline in the same way as in the first paragraph, but to completely seal the joint between the pipe and the crimp, a rubber seal is laid;

- At a further stage, a shut-off valve is attached to the clamp nozzle - a valve through which the cutting tool is inserted.

- Next, the body of the cast iron pipe is drilled, and do not forget about the need to cool the cut site, as well as change the crowns in a timely manner.

- A hole is drilled for tapping into the main water supply with a hard-alloy victorious or diamond crown;

- The last step is the same: the crown is removed, the valve is closed, the insertion point is scalded with special electrodes.

A steel pipe is slightly more ductile than a cast-iron pipe, so the tie-in of the pipes is carried out according to a technique similar to the solution with a polymer line, but the saddle is not used, and before making a tie-in into a galvanized steel water pipeline, the following steps are implemented:

- The pipe is exposed and cleaned;

- A branch pipe of the same material as the main pipe is immediately welded onto the pipe;

- A shut-off valve is welded or screwed onto the pipe;

- The body of the main pipe is drilled through the valve - first with an electric drill, the last millimeters - with a hand tool;

- Connect your water supply to the valve and the pressurized tie-in is ready.

Options for inserting into a plastic pipe

Consider how to embed into a plastic water pipe in different ways: by crimping a clamp with an overlay, connecting a manifold or a tee, installing an electric welding saddle, providing a tie-in through a pipe.

Mounting the crimp collar of the lining

This assembly consists of two parts with bolts tightened with clamps. The upper part is attached to the pipe through a sealing gasket that prevents water leakage. For good clamping, both parts of the lining must be matched to the appropriate size according to the marking.

In the first upper part there is a technological hole for connecting a new water supply line.

Possible connection via:

- stopcock element,

- the presence of a built-in cutter and a protective valve,

- metal end in the form of a flange,

- the possibility of a plastic end for gluing.

After placing the clamp with overlays, I direct the upper part towards the planned branch of the new line. The assembly is fixed with bolts, which are pre-selected in size, taking into account the diameter of the assembly. With a special device, a hole is drilled in the line through the pipe of the mounted fitting.

This method also allows you to connect to a plastic pipe under pressure with water. For this, a built-in valve is installed in the assembly, by turning which a hole is drilled. After obtaining the desired result, the valve closes and the cutter rises.

This is a very profitable way to solve the problems of connecting to water in cases where it is not possible to stop the water supply or it is extremely inconvenient. This solution simplifies the procedure and makes it possible to carry it out online.

Clamp or manifold device

Installing a tee can be called a classic solution to the problem. Instead of the installation, prepared by removing part of the pipe from both sides, a separate part is mounted in the form of a tee or manifold. Next is soldering.

Electric welding saddle attachment

This mechanism resembles the above described method of attaching the lining, but with differences. It, like a tee, provides a tight and reliable fastening by soldering at the molecular level of the material.

This is achieved due to the device in plastic overlays of electric heating coils, which are a special welding device that has a program configured for each node to prevent overheating. After that, the plastic, warming up to a certain temperature, not exceeding the critical one, sticks to the plastic and provides a tight and strong contact.

Insertion by means of a branch pipe

A good way on low pressure pipes. The principle of fastening is that with the help of a branch pipe and a girth, without welding, it is installed on pipes. The elements of the device of the required diameter are selected, otherwise the assembly may leak water. The fastener allows you to quickly and easily install the outlet.

Choosing the Best Solution

Without a doubt, it is possible that the most versatile and effective way, given the complexity of mounting the assembly, is lining. Compared to other methods, it provides reliability and flexibility in installation.

Detailed description of the main stages of work: tie-in to the water supply

When deciding how to make a tie-in to the water supply without turning off the pressure in the central system, you must carefully familiarize yourself with each stage of the work. In the beginning, it is necessary to calculate the route of the pipes. A depth of 1.2 m is considered optimal for them. Pipes should go straight from the central highway to the house.

Materials: cast iron and others

They can be made from the following materials:

- polyethylene;

- cast iron;

- Cink Steel.

Artificial material is preferable, since the tie-in to the water supply does not require welding in this case.

To simplify work on the tie-in place, a well (caisson) is built. For this, the pit is deepened by 500-700 mm. A gravel cushion is filled up at 200 mm. Roofing material is rolled out on it, and concrete 100 mm thick with a reinforcing grid of 4 mm is poured.

A cast plate with a hole for a hatch is installed on the neck. Vertical walls are coated with a waterproofing substance. The pit at this stage is covered with previously selected soil.

The channel breaks through manually or with the help of an excavator. The main thing is that the depth meets the requirements of the project. It is below the border of soil freezing in this climatic zone. But the minimum depth is 1 m.

For tie-in, it is better to use artificial material

Do-it-yourself installation in 7 steps: clamp, saddle, sewerage scheme, coupling

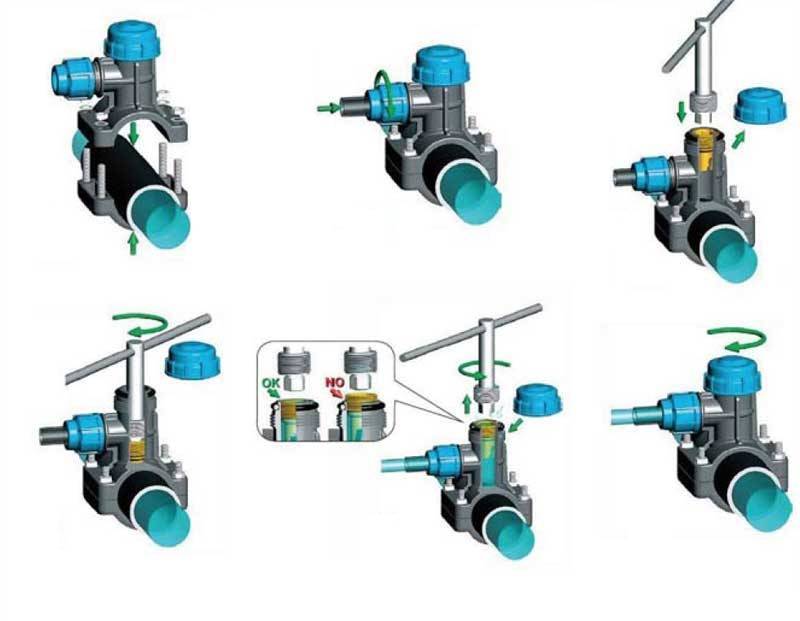

The installation process takes place according to the following technology.

- The device for tapping under pressure is located in a special collar pad. This element is installed on a pipe previously cleaned from thermal insulation. The metal is rubbed with sandpaper. This will remove rust.The cross-sectional diameter of the outgoing pipe will be narrower than that of the central one.

- A clamp with a flange and a branch pipe is installed on the cleaned surface. On the other side, a gate valve with a sleeve is mounted. A device is attached here in which the cutter is located. With her participation, an insertion into the general system is carried out.

- A drill is inserted into the pipe through an open valve and a gland of a blind flange. It must match the size of the hole. Drilling in progress.

- After that, the sleeve and cutter are removed, and the water valve closes in parallel.

- The inlet pipe at this stage must be connected to the flange of the pipeline valve. The protective coating of the surface and insulating materials are restored.

- Along the route from the foundation to the main canal, it is necessary to provide a slope of 2% from the tie-in to the inlet outlet pipe.

- Then a water meter is installed. A shut-off coupling valve is mounted on both sides. The meter may be in the well or in the house. To calibrate it, the shut-off flange valve is closed and the meter is removed.

This is a common tapping technique. The puncture is carried out in accordance with the type of material and design of the reinforcement. For cast iron, grinding is performed before work, which allows you to remove the compacted outer layer. A flanged cast-iron gate valve with a rubberized wedge is installed at the tie-in point. The body of the pipe is drilled with a carbide crown. It matters what material the cutting element is made of. A cast iron flanged valve requires only strong crowns, which will have to be changed about 4 times during the tapping process.Tapping under pressure into a water pipe is carried out only by competent specialists.

For steel pipes, it is not necessary to use a clamp. The pipe must be welded to it. And already a valve and a milling device are attached to it. The quality of the weld is assessed. If necessary, it is additionally strengthened.

The polymer pipe is not ground before a pressure tapping tool is put on the puncture site. The crown for such material can be both strong and soft. This is another reason why polymer pipes are considered beneficial.

The next step involves testing. Stop valves (flanged valve, gate valve) and joints are checked for leaks. When pressure is applied through the valve, air is bled. When water begins to flow, the system is inspected with the channel not yet buried.

If the test is successful, they bury the trench and the pit above the tie-in. Works are carried out in compliance with safety regulations and in accordance with the instructions.

This is a reliable, productive method that does not disturb the comfort of other consumers. Work can be done in any weather

Therefore, the presented method is so popular today. Connecting to the water supply is a very important technical event.

Tapping into a pipe under water pressure

To crash into a pipe under pressure, you need one

compression connection - saddle. This connection can be purchased at

plumbing stores, but before buying, check what diameter your pipe is,

in which to crash.

Install pipe clamp and tighten the bolts connecting its halves. When tightening the bolts, distortions between the halves of the saddle must be avoided.It is desirable to tighten the bolts crosswise.

Installation of a compression joint on a pipe under water pressure.

Installation of a compression joint on a pipe under water pressure.

After that, an ordinary ball valve of suitable diameter must be screwed into the thread of the saddle. How to choose a high-quality ball valve and open it if it is jammed can be found in this article.

It remains only to drill a hole in the pipe through the open

ball valve.

First, we determine the diameter of the drill. For getting

good water flow, it is desirable to drill a hole as large as possible

diameter. But in this case, the ball valve has its own hole. it

the hole is smaller than the inside diameter of the faucet thread. Therefore, the drill will have to

pick up this hole.

During drilling, it is important not to hook the fluoroplastic

seals inside the ball valve. If they damage the crane will stop holding

water pressure

For drilling plastic pipes, it is best to use

pen drills for wood or crowns. With these drills, PTFE seals

cranes will remain intact and such drills will not slip off the pipe in the very

start of drilling.

During drilling, you do not need to worry about the chips, it will be washed

water flow when the hole is drilled.

To drill holes safely and easily, there are several

tricks.

Since in the process of making a hole there is a high probability of pouring water over it, it is not advisable to use a power tool. You can of course use a mechanical drill or a brace. But they will be difficult to drill metal pipes. You can use a cordless screwdriver, even if it is flooded with water, then the electric shock will be insignificant. But a screwdriver at one important point may not have enough power.When the hole is almost drilled and the drill bit has almost passed the pipe wall, it can get stuck in the metal pipe wall. And then the situation will turn out that water is already flowing under pressure on the tool, and the hole has not yet been drilled to the end. This may not necessarily happen, but it is worth remembering.

Particularly desperate people use an electric drill, but the work is done with a partner who turns off the drill from the outlet when water appears.

To protect the instrument from the flow of water, you can put it in a plastic bag.

A plastic bag wrapped around a screwdriver.

A plastic bag wrapped around a screwdriver.

Drilling a hole in a pipe through a ball valve.

Drilling a hole in a pipe through a ball valve.

Or put a circle with a diameter of 200-300 mm of thick rubber directly on the drill, which will act as a reflector. You can even use thick cardboard instead of rubber.

Cardboard-reflector, dressed on an electric drill drill.

Cardboard-reflector, dressed on an electric drill drill.

There is another simple and affordable way. Plastic is taken

1.5 liter bottle. A part with a bottom of about 10-15 cm is cut off from it, and in

a hole is drilled in the bottom. We dress this bottom on the drill with the cut off part

from a drill and with such a device we drill a pipe. The bottle should cover

a crane. The flow of water will be reflected by a semicircular bottom.

Methods

Often the material of the water supply pipeline determines both the material of the branch line pipe and the method of tie-in. If the central or secondary pipe is steel, then it is also better to use a steel layer. In extreme cases, make a transition section in the form of a fitting from a steel pipe with a valve, to which then connect a pipeline from another material.

Insertion of steel pipes is carried out in two ways, such as:

- using a welding machine by welding the fitting to the water supply;

- by means of a steel collar without welding.

Both methods are used both for tapping into a pipeline that is under pressure and without pressure. But on high-pressure pipelines, welding is recommended only in emergency, emergency cases, as well as when organizing additional safety equipment. In the normal mode of work, actions are needed to completely turn off the section of the water supply system where the tie-in is made using welding.

The algorithm of work using welding on an existing pipeline is as follows:

- a pit is dug out by an excavator to a level above the laid pipeline by about 50 cm;

- the section of the pipe into which the tie-in is planned is manually cleared of the soil;

- the tie-in place is freed from the anti-corrosion coating and other protective layers, and the specific area for connecting the fitting or branch pipeline is cleaned to a shiny metal;

- a fitting with a tap is welded;

- after the metal heated by welding has cooled, a drill is inserted through the tap into the fitting and a hole is drilled in the wall of the water pipe;

- when water flows through the fitting, the drill is removed and the tap is closed (the insert is made, further laying of the water supply line starts from the valve on the fitting).

The tie-in clamp is a regular part, consisting of two halves of semicircular shapes. These halves are put on the pipe and pulled together with bolts and nuts. They differ from ordinary clamps only in the presence of a threaded hole on one of the metal parts. A fitting is inserted into this hole, which serves as part of the bypass line.You can position the hole for the pipe anywhere in the water supply, and when screwing in the fitting, it will always be at right angles to the linear plane of the pipeline surface.

The rest of the process is similar to tie-in by welding: a drill is inserted into the fitting through a tap and a hole is drilled. If the outlet is of small diameter and the pressure in the water supply is within 3–4 kgf / cm², then the tap can be screwed on without problems even after drilling (if it is threaded and not welded). Connection of additional lines to the cast-iron line is also carried out using clamps.

Tapping into pipes made of plastic or polyethylene occurs with the help of plastic clamps or saddles (half-clamp with fasteners). Clamps and saddles are simple and welded. Working with simple devices is not much different from tie-in with a clamp into a steel pipe. And in welded saddles or clamps there is all the equipment necessary for welding. Such a saddle assembly is installed on the pipe in the intended place, the terminals are connected to electricity and after a few minutes the tie-in will be automatically performed.

Insert technology

Consider from a practical point of view how to make a hole in a pipe with water. There are two non-specialized rules when tapping into a pipeline:

- The pipe to be cut must be smaller in diameter than the pipe in which the hole is made.

- The diameter of the drill must correspond to the internal diameter of the pipe to be inserted, which, in turn, must be of a smaller diameter than the pipe of the main line.

If you need to cut into an iron water pipe, then you will need to use a saddle clamp for tapping with drilling.The saddle clamp is called due to the fact that its lower part is a semicircle that looks like a saddle. There are a couple of varieties of similar clamps. Before installing this device on a pipe, it must be scrupulously cleaned of dirt and rust (if any). The collar, apart from the “saddle”, has a shut-off valve with a hole for drilling and a drill in the upper part. Both parts on the pipe are bolted to each other. The clamp fits well to the surface of the pipe with the help of sealing rubber bands. After fixing it with a drill, a hole is made until water appears. After that, the drill is unscrewed and the plug is closed with a special screw so that water does not flow out of the pipe. In the future, such a clamp can be used as a shut-off valve. In addition, it is possible to use a clamp already with a valve screwed into it.

After the hole is ready, the drill is removed and the valve is closed. Now it is possible to do other work on the installation of water supply. It is also possible to attach a special machine to a simple iron clamp, the main elements of which are a ratchet handle, a locking bolt, a shaft with a drill at the end, and a flushing tap. All this is enclosed in an iron case and is attached to the clamp with the help of sealing rubber bands. The guide sleeve allows drilling in a given direction. With its help, iron and cast iron pipes are drilled.

For drilling a cast-iron pipeline under pressure, bimetallic crowns and clamps of a special design are used. The nuance of working with cast iron is that:

- work with light pressure. Cast iron is a brittle metal, does not "work" well in compression and tension;

- pre-clean the pipe surface from a special layer applied to the surface to prevent corrosion;

- overheating of the crown should not be allowed;

- work to be guided at low speeds.

If you want to cut into a plastic pipeline, then it is better to use an electrofusion saddle clamp. It is made of special plastic, equipped with a heating coil and a drilling mechanism. There is a bar code on the saddle body that allows you to accurately enter the desired parameters: welding and cooling times, etc. The clamp is bolted to the pre-cleaned pipe. With the help of a special welding machine, the spiral is heated and the branch is welded (terminals for welding are provided on the clamp). Then, an hour after the end of cooling, a hole is made with a special cutter and a shut-off valve is screwed on.

For the most part, water distribution around the house or apartment is made with metal-plastic. Therefore, the diameter of the pipes is small. If there is no inlet valve and there is no way to shut off the water through special work (housing office, water utility), then you will have to cut in under pressure to supply water to an additional point. The use of clamps in this case is not advisable due to the small diameter of the pipe. How to make such a cut? Quite simply. It is necessary to prepare a water tank, a floor cloth, a tool, a valve and special fasteners. The pipe is cut. The end from which water flows is lowered into a container of water. A nut, a clamp is put on it. After that, a valve is inserted into it in the open position, which is clamped with a nut. Later, by closing the tap, it is possible to continue the installation.

When should you hit the pipe?

Tapping into the plumbing system is performed in a wide variety of situations. We will not describe them all, we will note only the main directions.

By itself, the tie-in of the water supply should be performed in special cases. You can’t just crash into a pipe (especially someone else’s), you must have a special permit for this. It is still possible to operate with private water pipes without a huge pile of documents, but things are different with state affairs.

If the pipe is damaged during the tie-in of the water supply, then the fine will seriously increase. Provoking an emergency will raise the stakes even more. Well, if misfortune happens and it is proved that the pipe was damaged precisely due to the above actions, then the consequences for the defendant will be very sad.

The moral here is that if you are going to crash into the main or central channel, then you can act only after you have all the permissions, and act carefully.

Punch methods without welding

It is possible to cut into the main pipeline without using welding. This technology is used by many specialists, since welding work requires compliance with safety rules. In this case, special equipment is required for welding. Welding work is considered complex and time-consuming.

From non-welding tie-in technologies, there are:

- installing a collector is the best solution for a large private house. A compact collector system is also installed in the apartment. A water pipe is installed to the inlet of such a system. The collector has several outlets. Their number depends on the system model. The pipeline connects to any outlet. Adapters are used to fix the hoses;

- installation of a tee - this tie-in method is used if a single outlet is provided. The water supply connection is pre-untwisted, and then a tee is mounted in this place. The pipeline is expanded or shortened by threading;

- the process of cutting the pipe itself - the technique is optimal if there is no connection from the outside. To perform cutting, a grinder is used. A pre-threaded tee is installed;

- the use of a thin pipe - a hole is prepared in the system, on which a sealant, clamp is fixed. Lag screws are used to mount the outlet.

Construction of a well for arranging a node

To simplify the insertion into an existing water supply, it is convenient to use a manhole. The diameter of the structure should be about 70 cm. This space is enough to accommodate the shut-off valve (in the form of a valve or gate valve), as well as perform all the necessary manipulations for the tie-in.

In the future, during the period of operation, the presence of such a structure will facilitate the repair of home plumbing.

The tie-in unit used to turn off the input for the period of repair work will be located right inside the mine in the area of the connection point with the external water conduit

To build a well, they dig a new pit of the appropriate size. The bottom of the pit is covered with a gravel "cushion", forming a layer 10 cm high.

To make a reliable foundation, cuts of roofing material are spread over the leveled gravel dump and a concrete screed 10 cm thick is poured. When creating the fill, concrete grades M150 and M200 are used.

After three or four weeks, when the concrete has acquired the necessary strength, a shaft is erected above the slab.To do this, the walls of the pit are lined with bricks, cement blocks or reinforced concrete rings. The neck of the structure should reach the zero level.

If the well is supposed to be installed in a site where the groundwater level rises to one meter during the flood period, it is necessary to build a waterproof structure.

It is most convenient for this purpose to purchase a ready-made plastic container. From below it is anchored to a concrete slab, from above such a structure is covered with a cast slab equipped with a hole for installing a hatch.

What documents need to be collected and prepared

The basis for drawing up a contract for the supply of cold water is an application on behalf of the customer or his representative, acting under a power of attorney, or an offer from the water supply service chosen by the customer.

The application must include the following information:

- Subscriber details:

- For individuals - postal address of registration or place of residence, full name, passport details or other identity document, contact information.

- For legal entities and individual entrepreneurs - registration number in the State Register and the date of its entry, location with an indication of the postal and registration address at the place of residence, individual taxpayer number (TIN), bank details and documents confirming the subscriber's right to sign business documentation.

- The name and location of the object in respect of which the contract is being drawn up.

- Information about other sources of water intake, indicating the volume and owners through whose networks water is supplied.

- If standards are established for the customer for the disposal of sewage water in cases where there are no septic tanks for summer cottages and country houses on the site, their composition and properties are indicated in the dynamics of changes over the year.

- The area of the individual site of the customer with the objects located on it and its characteristics.

- Data on the type of activity in the case of normalized spillways.

The list of papers submitted with the application includes the following documents:

- A photocopy of the certificate of property rights to the object or device connected to the water supply line, which is necessary for connecting to the system.

- A copy of the passport or other document confirming the identity of the subscriber. Power of attorney for the preparation of business papers, if the customer acts as his authorized representative.

- Standard documents established by law for organizations, partnerships, housing cooperatives when drawing up contracts with resource-giving bodies.

- The information needed to calculate the consumed volumes is the area of irrigated land, housing and auxiliary premises, the number of storeys of houses, the number of residents.

- Photocopies of documents and previously concluded agreements for connecting the subscriber to the water supply line.

- Photocopies of acts on connection, washing and disinfection of the line and equipment at the customer's territory inside the house and in an individual area when tie-in to the water supply line.

- Photocopies of papers for water meters to verify their compliance with legal requirements, installation diagram and information about their readings at the time of drawing up the contract. The norm does not apply to consumers with a intake volume of less than 0.1 cubic meters per hour and when the installation of meters is optional.

- Diagram of the sampling site.

- Photocopies of papers confirming the ownership of an individual land plot.

- Balance of maximum consumption indicating the intended use and load according to needs (for household needs, fire protection, filling pools, periodic water consumption for irrigation).

- A positive expert decision of federal or private expertise in cases where it is required by law.

- Documentary photocopies of papers on other sources of water supply, contracts with water supply services and their licenses for the use of subsoil, indicating the volumes of supply.

Rice. 3 Plumbing scheme in a private house - an example

Insertion into the water supply from metal pipes

- the flange is made independently from a pipe, the inner diameter of which coincides with the diameter of the laid line. Compliance with this condition will provide the necessary tightness for the entire system;

- you can use a tee with the desired diameter. To do this, a part of the pipeline without a branch pipe is removed from the part. Then the consumable is cut, a hole is made. To fix the pipeline, welding or a branch pipe is used;

- experts advise welding the flange to the pipeline. Welding work is carried out around the entire perimeter of the product. The welding technique can be replaced with a sealant and a clamp.

Using a special device, holes are made in consumables under pressure. The principle of the method under consideration:

- removal of insulation;

- pipe surface cleaning.

- installation of a flange on the supply pipeline with its subsequent fixation with a clamp;

- connecting the valve to the flange;

- installation of a drilling device;

- cutter insertion through the valve;

- hole cutting;

- removal of drilling equipment;

- blocking the water supply from the pipe.

Using the above technology, you can make a tie-in without welding into steel pipe. This technique is somewhat different from the technology of tapping into a polypropylene product without using welding. Therefore, before starting installation work, it is recommended to determine the type of consumable used. Its calculation is made with a margin. Upon completion of the work, the system is checked for leaks. In case of violation, additional repair work is carried out. They can be done independently or with the help of specialists. If the system is sealed, the line is ready for operation.

![[instruction] do-it-yourself toilet installation | video](https://fix.housecope.com/wp-content/uploads/e/0/5/e05c3aaa569c15a65a76abf551b1139c.jpg)