- Features of tapping into a water pipe

- Manhole construction

- How to connect to a common water main

- Detailed description of the main stages of work: tie-in to the water supply

- Materials: cast iron and others

- Do-it-yourself installation in 7 steps: clamp, saddle, sewerage scheme, coupling

- Photo tie-in to the pipe

- Features of inserting bends into pipes

- Tapping into a pipe under water pressure

- Insertion into the gas pipeline

- Punch methods

Features of tapping into a water pipe

Before starting any work, it is imperative to obtain the appropriate permission for this. When performing an illegal installation process, there is a high probability of being held administratively liable.

Before starting any work, it is imperative to obtain the appropriate permission for this. When performing an illegal installation process, there is a high probability of being held administratively liable.

According to the rules, for the tie-in, you should take a permit signed by the management of the local water utility and a plan of the site where the work will be carried out. In addition, technical conditions will be required, for which you will have to visit the central department of the water utility. Specifications usually contain information about the connection point, data for the tie-in, as well as the diameter of the pipeline of the underlying pipeline.

In addition to the employees of the water utility, other companies specializing in such work with the appropriate license can develop design estimates.The price for services related to the preparation of documentation for tapping into a pressure water supply may be slightly lower for such organizations.

However, in the future there is a possibility of a conflict situation with representatives of the water utility, who do not always give approval to such design developments.

Having received the necessary papers, you should contact the SES department, where to register the project. Here you will also need to write an application to obtain the necessary permission to connect to the water supply system.

In accordance with generally accepted standards, only specialists with the appropriate approval can perform work on tapping into a water pipe. The person who ordered the implementation of this service can save money only on digging and filling the trench with his own hands, as well as on auxiliary work that does not require permits.

There are some situations in which inserting a pipe into a water supply system is prohibited:

- connection to the highway without installing a meter;

- lack of connection to a centralized sewerage system;

- a larger diameter branch branch than that of the main pipeline.

Manhole construction

To simplify the tie-in process, you can build a manhole about seventy centimeters wide.

To simplify the tie-in process, you can build a manhole about seventy centimeters wide.

Such a well will be enough to place shut-off valves in it and perform the necessary manipulations for connecting to the water supply. Such a construction will make it easier in the future to carry out possible repairs to the home system.

To make a well, they dig a pit of the required parameters, the bottom of which is covered with a ten-centimeter layer of gravel. To form a reliable foundation, the resulting “pillow” is covered with a sheet of roofing material.A concrete screed is poured on top.

After at least three weeks, the walls of the shaft are laid out above the hardened slab. For this purpose, brick, reinforced concrete rings or cement blocks can be used. The mouth of the pit is raised flush with the surface.

When building a well in a site with frequently rising groundwater, it should be watertight. It is most convenient in this regard to use a ready-made plastic container, which is attached to a concrete base. The upper part is covered with a plate with a hole for installing a hatch.

Water pipes are made of several types of materials: plastic, cast iron or steel

It is worth paying attention to each of them.

This is interesting: Devices and tools for expanding copper pipes - we explain in detail

How to connect to a common water main

Before crashing into a water pipe under high fluid pressure, familiarize yourself with three technology options that vary depending on the material of which the pipes are made (they can be polymer (PP), cast iron, galvanized steel).

For a polymer central route, a tie-in into a pressurized water pipe looks like this:

- A trench no less than one and a half meters in size is excavated, the area where the work will be done is exposed, and a trench is being dug from it to the house;

- At the end of the earthmoving work, a saddle is prepared for tapping into the water supply system - this is a collapsible crimp collar that looks like a tee. The straight outlets of the saddle are divided in half, and a valve is installed on the vertical outlet to shut off the pressure. A pipe is drilled through the tap with a special nozzle for tie-in. The most reliable saddle scheme is collapsible welded.It is easy to divide such a clamp into two halves, assemble it over the tie-in section, and weld it to the main route. Thus, the clamp for tapping into the water supply is welded into the body, providing a reliable and absolutely hermetic water supply to the dwelling;

- The pipe is drilled with a conventional drill and an electric drill. Instead of a drill, you can use a crown, but the result is important, not the tool;

- A through hole is drilled until a jet of water comes out of it, after which the drill is removed and the valve is closed. For safety reasons, at the end of the drilling process, the electric tool is replaced with a hand drill or a brace. If you drill a hole not with a drill, but with a crown, then it will automatically ensure the tightness of the drilling site. In addition to these options, there is a solution using a special cutter, which is rotated by an adjustable wrench or an external brace;

- The last stage of the tie-in to the central water supply is the establishment of your own water supply, laid in a trench in advance, and connecting it to the central route with an American compression coupling.

For complete control of the insertion point, it is advisable to equip a revision above it - a well with a hatch. The well is equipped as standard: a gravel-sand cushion is made at the bottom, reinforced concrete rings are lowered into the trench, or the walls are laid out with bricks. Thus, even in winter it will be possible to shut off the water supply if it is necessary to repair it in the house.

For a central water supply pipe made of cast iron, a saddle tie-in looks like this:

- To tap into a cast-iron pipe, it must first be thoroughly cleaned of corrosion. At the very place of drilling, the top layer of cast iron is removed by a grinder by 1-1.5 mm;

- The saddle is built into the pipeline in the same way as in the first paragraph, but to completely seal the joint between the pipe and the crimp, a rubber seal is laid;

- At a further stage, a shut-off valve is attached to the clamp nozzle - a valve through which the cutting tool is inserted.

- Next, the body of the cast iron pipe is drilled, and do not forget about the need to cool the cut site, as well as change the crowns in a timely manner.

- A hole is drilled for tapping into the main water supply with a hard-alloy victorious or diamond crown;

- The last step is the same: the crown is removed, the valve is closed, the insertion point is scalded with special electrodes.

A steel pipe is slightly more ductile than a cast-iron pipe, so the tie-in of the pipes is carried out according to a technique similar to the solution with a polymer line, but the saddle is not used, and before making a tie-in into a galvanized steel water pipeline, the following steps are implemented:

- The pipe is exposed and cleaned;

- A branch pipe of the same material as the main pipe is immediately welded onto the pipe;

- A shut-off valve is welded or screwed onto the pipe;

- The body of the main pipe is drilled through the valve - first with an electric drill, the last millimeters - with a hand tool;

- Connect your water supply to the valve and the pressurized tie-in is ready.

Detailed description of the main stages of work: tie-in to the water supply

When deciding how to make a tie-in to the water supply without turning off the pressure in the central system, you must carefully familiarize yourself with each stage of the work. In the beginning, it is necessary to calculate the route of the pipes. The optimal depth for them is 1.2 m.Pipes should go straight from the central highway to the house.

Materials: cast iron and others

They can be made from the following materials:

- polyethylene;

- cast iron;

- Cink Steel.

Artificial material is preferable, since the tie-in to the water supply does not require welding in this case.

To simplify work on the tie-in place, a well (caisson) is built. For this, the pit is deepened by 500-700 mm. A gravel cushion is filled up at 200 mm. Roofing material is rolled out on it, and concrete 100 mm thick with a reinforcing grid of 4 mm is poured.

A cast plate with a hole for a hatch is installed on the neck. Vertical walls are coated with a waterproofing substance. The pit at this stage is covered with previously selected soil.

The channel breaks through manually or with the help of an excavator. The main thing is that the depth meets the requirements of the project. It is below the border of soil freezing in this climatic zone. But the minimum depth is 1 m.

For tie-in, it is better to use artificial material

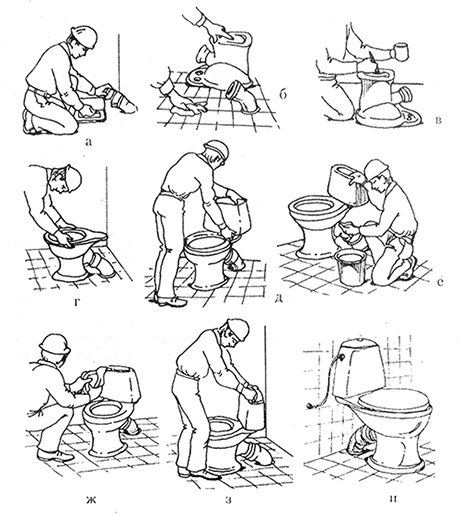

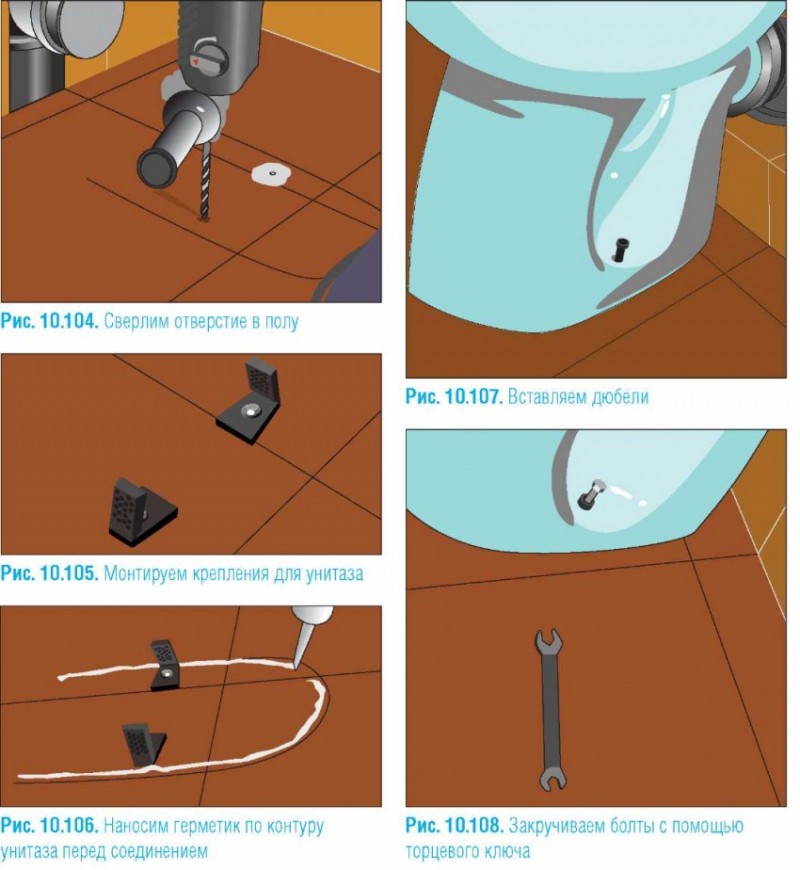

Do-it-yourself installation in 7 steps: clamp, saddle, sewerage scheme, coupling

The installation process takes place according to the following technology.

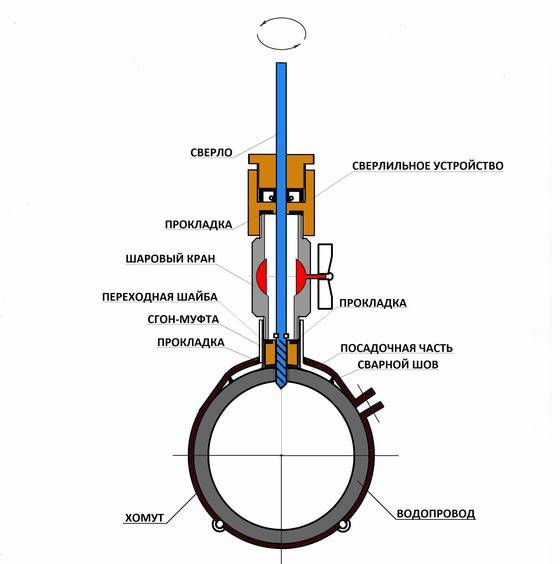

- The device for tapping under pressure is located in a special collar pad. This element is installed on a pipe previously cleaned from thermal insulation. The metal is rubbed with sandpaper. This will remove rust. The cross-sectional diameter of the outgoing pipe will be narrower than that of the central one.

- A clamp with a flange and a branch pipe is installed on the cleaned surface. On the other side, a gate valve with a sleeve is mounted. A device is attached here in which the cutter is located. With her participation, an insertion into the general system is carried out.

- A drill is inserted into the pipe through an open valve and a gland of a blind flange. It must match the size of the hole. Drilling in progress.

- After that, the sleeve and cutter are removed, and the water valve closes in parallel.

- The inlet pipe at this stage must be connected to the flange of the pipeline valve. The protective coating of the surface and insulating materials are restored.

- Along the route from the foundation to the main canal, it is necessary to provide a slope of 2% from the tie-in to the inlet outlet pipe.

- Then a water meter is installed. A shut-off coupling valve is mounted on both sides. The meter may be in the well or in the house. To calibrate it, the shut-off flange valve is closed and the meter is removed.

This is a common tapping technique. The puncture is carried out in accordance with the type of material and design of the reinforcement. For cast iron, grinding is performed before work, which allows you to remove the compacted outer layer. A flanged cast-iron gate valve with a rubberized wedge is installed at the tie-in point. The body of the pipe is drilled with a carbide crown. It matters what material the cutting element is made of. A cast iron flanged valve requires only strong crowns, which will have to be changed about 4 times during the tapping process. Tapping under pressure into a water pipe is carried out only by competent specialists.

For steel pipes, it is not necessary to use a clamp. The pipe must be welded to it. And already a valve and a milling device are attached to it. The quality of the weld is assessed. If necessary, it is additionally strengthened.

The polymer pipe is not ground before a pressure tapping tool is put on the puncture site. The crown for such material can be both strong and soft. This is another reason why polymer pipes are considered beneficial.

The next step involves testing. Stop valves (flanged valve, gate valve) and joints are checked for leaks. When pressure is applied through the valve, air is bled. When water begins to flow, the system is inspected with the channel not yet buried.

If the test is successful, they bury the trench and the pit above the tie-in. Works are carried out in compliance with safety regulations and in accordance with the instructions.

This is a reliable, productive method that does not disturb the comfort of other consumers. Work can be done in any weather

Therefore, the presented method is so popular today. Connecting to the water supply is a very important technical event.

Photo tie-in to the pipe

We also recommend viewing:

- Do-it-yourself headlight polishing

- Do-it-yourself scaffolding

- DIY knife sharpener

- Antenna amplifier

- Battery Recovery

- Mini soldering iron

- How to make an electric guitar

- Braid on the steering wheel

- DIY flashlight

- How to sharpen a meat grinder knife

- DIY electric generator

- DIY solar battery

- Flowing mixer

- How to remove a broken bolt

- DIY charger

- Metal detector scheme

- Drilling machine

- Cutting plastic bottles

- Aquarium in the wall

- Do-it-yourself shelving in the garage

- Triac power controller

- Low pass filter

- Eternal flashlight

- file knife

- DIY sound amplifier

- Braided cable

- DIY sandblaster

- Smoke generator

- DIY wind generator

- Acoustic switch

- DIY wax melter

- tourist ax

- Insoles heated

- solder paste

- Tool shelf

- Jack press

- Gold from radio components

- Do-it-yourself barbell

- How to install an outlet

- DIY night light

- Audio transmitter

- Soil moisture sensor

- Geiger counter

- Charcoal

- wifi antenna

- DIY electric bike

- Faucet repair

- induction heating

- Epoxy resin table

- Crack in the windshield

- Epoxy resin

- How to change a pressure tap

- Crystals at home

Help the project, share on social networks

Features of inserting bends into pipes

Plastic pipelines are different. Some are used to supply water, others to divert it.

There are public highways, and there are personal intra-house and intra-apartment networks. And each option has its own nuances of work.

For tapping into a street pipe of a central water supply system or a village sewer, permission from the owner of the networks is required; it is prohibited to carry out such installation work without permission

In order to crash into a common centralized system and not get into trouble with the law, it is necessary to go through preliminary approvals. It is best to sign all the necessary papers and entrust the tie-in work to a specialized organization. This will greatly simplify life.

But no one bothers to crash into a plastic pipeline inside an apartment or a private house. You can do this almost anywhere.It is only necessary to follow the elementary rules and not overload the system with an abundance of plumbing devices.

The water pressure in the water supply must be sufficient for all appliances and all users. And the sewer pipe is able to accept only the volume of wastewater for which it was originally designed.

There are several types of plastic pipes:

- "PP" - polypropylene;

- "PE" - polyethylene (most often it is HDPE);

- "PVC" - polyvinyl chloride;

- "PEX" - made of cross-linked polyethylene;

- "PEX-AL-PEX" - metal-plastic.

Some of them are recommended to be used for distributing hot water and heat supply systems, while others are only for supplying cold water or discharging it. Tapping technologies for all plastic pipes are largely similar.

The differences relate to the way they are connected to fittings and to each other in cases where an additional element is inserted into an existing pipeline.

The easiest way is to crash into a sewer pipe. Often it is enough to drill a hole of the required diameter and insert a pipe with a rubber cuff into it - there is no special pressure in the sewerage system, such a connection is quite enough

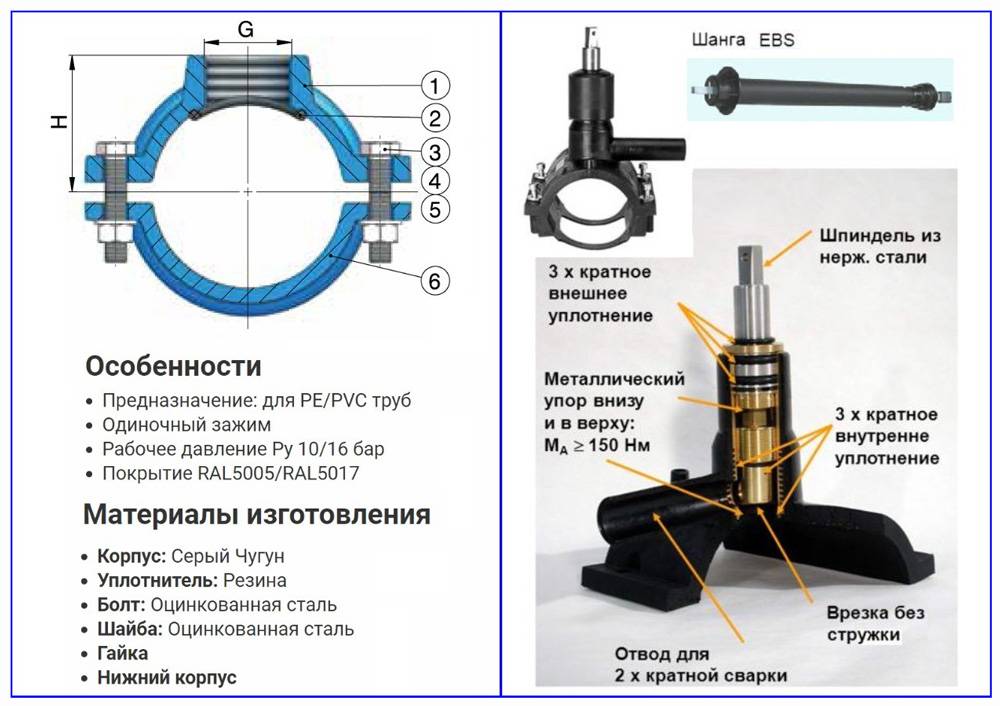

All techniques for inserting a branch into a plastic water pipe can be divided into two groups:

- Cutting a section of pipe and inserting a tee in its place.

- Overlay on a pipe of a collar (saddle) with a branch pipe.

The first method involves welding with a special soldering iron for plastic or using pressure fittings.

In the second case, the presence of a superimposed part is sufficient. It is simply put on the pipe and tightened mechanically with bolts or superimposed on a plastic surface and welded to it by means of built-in heating coils.

Tapping into a pipe under water pressure

To crash into a pipe under pressure, you need one

compression connection - saddle. This connection can be purchased at

plumbing stores, but before buying, check what diameter your pipe is,

in which to crash.

We install the clamp on the pipe and tighten the bolts connecting its halves. When tightening the bolts, distortions between the halves of the saddle must be avoided. It is desirable to tighten the bolts crosswise.

Installation of a compression joint on a pipe under water pressure.

After that, an ordinary ball valve of suitable diameter must be screwed into the thread of the saddle. How to choose a high-quality ball valve and open it if it is jammed can be found in this article.

It remains only to drill a hole in the pipe through the open

ball valve.

First, we determine the diameter of the drill. For getting

good water flow, it is desirable to drill a hole as large as possible

diameter. But in this case, the ball valve has its own hole. it

the hole is smaller than the inside diameter of the faucet thread. Therefore, the drill will have to

pick up this hole.

During drilling, it is important not to hook the fluoroplastic

seals inside the ball valve. If they damage the crane will stop holding

water pressure

For drilling plastic pipes, it is best to use

pen drills for wood or crowns. With these drills, PTFE seals

cranes will remain intact and such drills will not slip off the pipe in the very

start of drilling.

During drilling, you do not need to worry about the chips, it will be washed

water flow when the hole is drilled.

To drill holes safely and easily, there are several

tricks.

Since in the process of making a hole there is a high probability of pouring water over it, it is not advisable to use a power tool. You can of course use a mechanical drill or a brace. But they will be difficult to drill metal pipes. You can use a cordless screwdriver, even if it is flooded with water, then the electric shock will be insignificant. But a screwdriver at one important point may not have enough power. When the hole is almost drilled and the drill bit has almost passed the pipe wall, it can get stuck in the metal pipe wall. And then the situation will turn out that water is already flowing under pressure on the tool, and the hole has not yet been drilled to the end. This may not necessarily happen, but it is worth remembering.

Particularly desperate people use an electric drill, but the work is done with a partner who turns off the drill from the outlet when water appears.

To protect the instrument from the flow of water, you can put it in a plastic bag.

A plastic bag wrapped around a screwdriver.

Drilling a hole in a pipe through a ball valve.

Or put a circle with a diameter of 200-300 mm of thick rubber directly on the drill, which will act as a reflector. You can even use thick cardboard instead of rubber.

Cardboard-reflector, dressed on an electric drill drill.

There is another simple and affordable way. Plastic is taken

1.5 liter bottle. A part with a bottom of about 10-15 cm is cut off from it, and in

a hole is drilled in the bottom. We dress this bottom on the drill with the cut off part

from a drill and with such a device we drill a pipe. The bottle should cover

a crane.The flow of water will be reflected by a semicircular bottom.

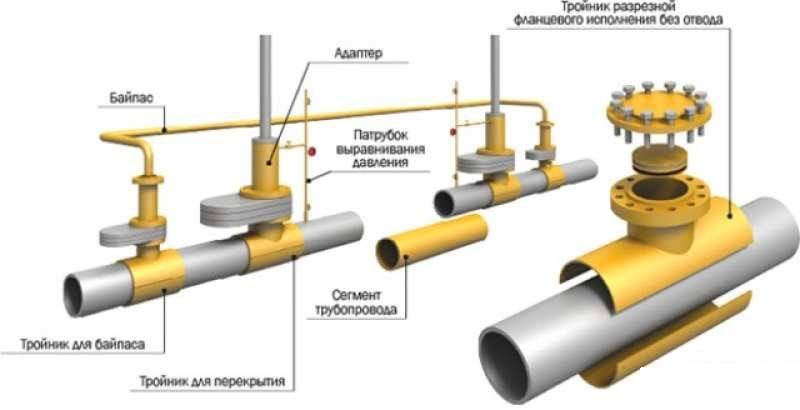

Insertion into the gas pipeline

A gas pipeline is a structure through which gas is transported. Depending on the purpose, it can be supplied under different pressure. For example, if we are talking about main pipelines, then the pressure in them is quite high, while in distribution systems it can change.

Tapping into the gas pipeline without stopping work can be carried out during the repair and connection of individual consumers. The system will work without interruption and the pressure will not be reduced. This technology is also called cold tapping and is sometimes replaced by a more traditional method, which involves welding the pipe and is considered labor intensive.

Tapping into the gas pipeline when using plastic pipes is carried out using fittings or fittings. For this, metal elements are used, and the method provides for a socket connection, which is glued with special compounds after installation is completed. The steel insert is treated with compounds that can protect the surface from rust, because water ingress can cause corrosion processes.

The tie-in is carried out by creating inserts from alloys perpendicular to the pipe. The insert has a length ranging from 70 to 100 mm and is built up by the method of socket contact connection. This method implies that plastic pipes are placed on a heated steel insert. The method is used to create branches from gas pipelines with low pressure. If the pressure is medium, then before building up, it is necessary to apply powdered polyethylene to the place of the future connection, which will ensure tight adhesion of the two materials.

Punch methods

Often the material of the water supply pipeline determines both the material of the branch line pipe and the method of tie-in. If the central or secondary pipe is steel, then it is also better to use a steel layer. In extreme cases, make a transition section in the form of a fitting from a steel pipe with a valve, to which then connect a pipeline from another material.

Insertion of steel pipes is carried out in two ways, such as:

- using a welding machine by welding the fitting to the water supply;

- by means of a steel collar without welding.

Both methods are used as when tapping into a pipeline, which is under pressure, and without pressure. But on high-pressure pipelines, welding is recommended only in emergency, emergency cases, as well as when organizing additional safety equipment. In the normal mode of work, actions are needed to completely turn off the section of the water supply system where the tie-in is made using welding.

The algorithm of work using welding on an existing pipeline is as follows:

- a pit is dug out by an excavator to a level above the laid pipeline by about 50 cm;

- the section of the pipe into which the tie-in is planned is manually cleared of the soil;

- the tie-in place is freed from the anti-corrosion coating and other protective layers, and the specific area for connecting the fitting or branch pipeline is cleaned to a shiny metal;

- a fitting with a tap is welded;

- after the metal heated by welding has cooled, a drill is inserted through the tap into the fitting and a hole is drilled in the wall of the water pipe;

- when water flows through the fitting, the drill is removed and the tap is closed (the insert is made, further laying of the water supply line starts from the valve on the fitting).

The tie-in clamp is a regular part, consisting of two halves of semicircular shapes. These halves are put on the pipe and pulled together with bolts and nuts. They differ from ordinary clamps only in the presence of a threaded hole on one of the metal parts. A fitting is inserted into this hole, which serves as part of the bypass line. You can position the hole for the pipe anywhere in the water supply, and when screwing in the fitting, it will always be at right angles to the linear plane of the pipeline surface.

The rest of the process is similar to tie-in by welding: a drill is inserted into the fitting through a tap and a hole is drilled. If the outlet is of small diameter and the pressure in the water supply is within 3–4 kgf / cm², then the tap can be screwed on without problems even after drilling (if it is threaded and not welded). Connection of additional lines to the cast-iron line is also carried out using clamps.

Tapping into pipes made of plastic or polyethylene occurs with the help of plastic clamps or saddles (half-clamp with fasteners). Clamps and saddles are simple and welded. Working with simple devices is not much different from tie-in with a clamp into a steel pipe. And in welded saddles or clamps there is all the equipment necessary for welding. Such a saddle assembly is installed on the pipe in the intended place, the terminals are connected to electricity and after a few minutes the tie-in will be automatically performed.