- Types of seals

- Ways of cutting into the pipeline

- Consider the simplest method

- Built-in cutters

- Using drill collars

- Other tie-in methods

- Variants of mechanisms for organizing a branch

- Types of pipe cutting machines for flameless cutting

- Pressure pipe welding

- Photo tie-in to the pipe

- Insert technology

- Tapping using a tee

- Insertion into PVC pipes

- Cutting into a metal pipe

- Work Permit

- Application of clamps

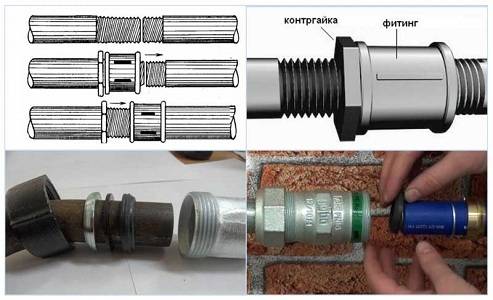

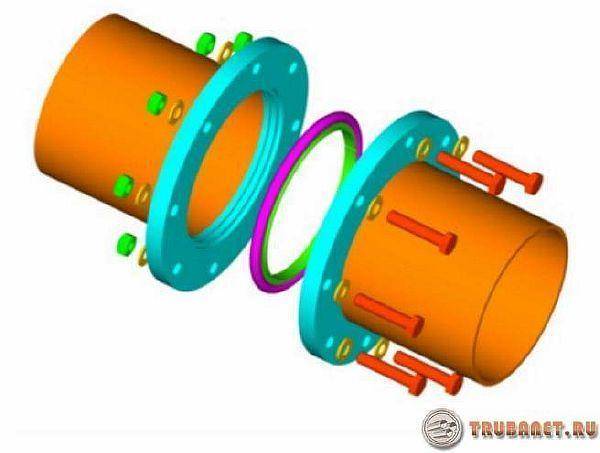

- How to connect without threading and welding

- How to crash into a plastic water pipe

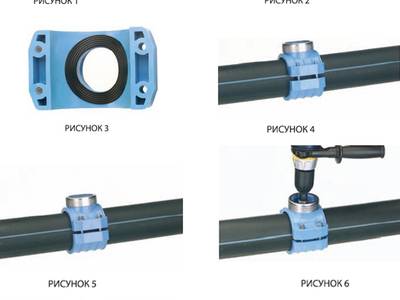

- Method # 3 - crimp collar (pad)

- The nuances of work on the water supply under pressure

- Conclusions and useful video on the topic

- How to embed your knee in plastic plumbing

Types of seals

Previously, there was no such variety of seals as today. Some plumbers use the full range of materials in their work, and there are conservatives who still recognize only linen. Are they right? Let's figure it out. How to seal the thread on the heating pipe:

- fum tape;

- flax with paste;

- anaerobic adhesive sealant;

- sealing thread.

Flax dries in systems with a hot coolant, and rots in cold water. In the first and second cases, the result of the process will be the appearance of a leak.Thanks to the paste, the fitting can be released a little after twisting, making a turn back no more than 45 degrees. Universal material, suitable for connecting metal heating pipes, as well as for polymers.

Flax is suitable for all types of threads on heating pipes, regardless of diameter. It is the cheapest of seals.

It is important to wind it correctly:

- with the help of a cloth for metal or a file, notches are made on the thread;

- a strand of flax is rolled into something like a thread;

- winding is carried out in the course of fitting tightening (usually clockwise);

- protective paste is evenly applied.

Linen seal

When winding flax, it is important not to overdo it. First you need to make the first turn, which will secure the seal on the thread. It leaves a tail

On the second turn, the remaining tail is picked up and wound together with a common fiber. Make sure there are no twists. It is necessary to distribute the material along the thread evenly from the end to the body of the fitting. When working with flax, when connecting heating pipes, you need to watch your hands, as they are constantly smeared with paste. If you take hold of a polypropylene pipe with such hands, an imprint will remain

This leaves a tail. On the second turn, the remaining tail is picked up and wound together with a common fiber. Make sure there are no twists. It is necessary to distribute the material along the thread evenly from the end to the body of the fitting. When working with flax, when connecting heating pipes, you need to watch your hands, as they are constantly smeared with paste. If you take hold of a polypropylene pipe with such hands, an imprint will remain.

Fum tape is used for thin-walled fittings and connectors with fine threads.It is easy to work with the material, hands are always clean. At the same time, fum tape is quite expensive and is mainly used for small diameters. A significant drawback of this seal is the impossibility of adjustment. That is, if the joint of the heating pipes is twisted and needs to be released a little to center it, then the connection loses its tightness.

The sealing thread, like the fum tape, does not need lubrication and the use of a special paste. It can be wound on dirty or wet threads, suitable for plastic.

Sealants are applied to clean and degreased threads (usually new). They are:

- dismantled;

- difficult to dismantle.

And in fact they are not dismantled. Before connecting the heating pipes using a sealant, you must be prepared for the fact that the connection can be disassembled only after heating. And only then, perhaps, it will be possible to unscrew it. But during installation, the joints do not even need to be tightened with keys.

Ways of cutting into the pipeline

Connection to the pipeline is made in different ways. The simplest of them is as follows.

Watch the video

Consider the simplest method

It consists in installing a transitional locking element before drilling the wall on the pipe. For this purpose, a ball valve mounted on a saddle is used. In the open position, it passes a drill through the through hole.

To protect against the release of water onto it, the upper trim of a plastic bottle is put on through the hole on the lid. After passing through the pipe wall, the drill is removed from the hole and the ball valve is closed.

Built-in cutters

Such tools are equipped with a core drill for making a hole and a protective valve to contain the back pressure of water.

The rotation of the tool is done manually by acting on the handles. A professional tool works using a drive from an electric drill. The end of the pipe is equipped with a locking device through which the tool is brought in.

The rotation of the tool is done manually by acting on the handles. A professional tool works using a drive from an electric drill. The end of the pipe is equipped with a locking device through which the tool is brought in.

In the non-working position, the pipe is closed by a valve that opens when pressed. A rubber seal in the form of a ring is installed around the circumference of the pipe.

Devices of this design are most often used for tapping into polyethylene pipelines.

After drilling is completed, there may be a small amount of water seeping through the nozzle. The cutter is withdrawn in the opposite direction until it touches the valve, it closes and blocks the leak.

The side outlet must be in the closed position and opens only after the installation of the water supply in the house and on the site.

Using drill collars

Quite often, drilling clamps are used for tapping into a pipeline under pressure. The sales kit of such products, as a rule, includes nozzles and swivel connectors.

Structurally, such products can be made in several versions, they are used to connect pipes with a diameter of 80 mm or more. When drilling, a deep punching of the pipe is required to avoid slipping of the drill on an inclined surface.

Other tie-in methods

You need to pay attention to a typical tie-in device, popular with water utility workers. It looks like a pipe with multilayer seals.

It is put on the main pipe and fastened with long studs.

Watch the video

The tightness of the device is so perfect that no leakage occurs when the drill passes through the wall. A pressure gauge is installed in this device, a change in the indicators of which indicates the end of drilling.

Variants of mechanisms for organizing a branch

For tapping into a pipeline, the material of which is polyethylene, there are such devices:

- saddle coupling for cold tie-in;

- valve for tapping under pressure;

- spigot pad (or overhead care);

- flange saddle;

- electrowelded polyethylene saddle coupling for soldering.

Saddles with a threaded outlet (or tie-in clamps) are designed to organize the removal of a secondary channel from the main pipeline in systems transporting drinking or process water. They are widely used in irrigation and irrigation networks in the private sector.

The pressure tapping valve is a special part that can perform the following functions:

- a branch with which a pipe branch is mounted;

- shutoff valves capable of blocking or opening the flow of fluid through the pipeline.

Installation of overhead care is possible only on a disabled channel. Unlike the escutcheon spigot, it has a positioning strap to hold the mechanism on the pipe.

The flange saddle is used in the construction and modernization of main sewerage and water supply systems for urban or industrial purposes. The electric welded saddle is suitable for installation on all types of gas and water HDPE pipes with pressure (working) up to 10 atm for gas and up to 16 atm for water.For gas pipelines, screw and other similar connections are not allowed.

Crash into polyethylene pipe can be without weldingwith a special clamp

Types of pipe cutting machines for flameless cutting

Pipe cutters are divided according to the scope of use:

- To cut pipes at the site of pipeline laying, manual or pipe cutters with hydraulic, electric or pneumatic drive are used.

- For cutting pipes in production conditions in a streaming mode, stationary pipe cutting units are used.

Split pipe cutters

Look

One-piece pipe cutters

Look

Types of manual machines: rotary pipe cutters of collapsible and non-collapsible type, pipe cutters, roller mechanisms. With their help, a pipeline is cut from steel, metal, iron, alloys. When using professional manual pipe cutters for cutting steel pipes with a wall thickness of up to 8 mm and a cross section of 10-900 mm, the effort of just one operator is required.

Pressure pipe welding

By following the tips below, you can greatly facilitate the work associated with the repair of water pipes under pressure:

- During pipe welding, when water comes out of it, the current strength on the welding machine should be increased. In this case, the electrode will not stick to the pipe all the time due to the fact that the metal cools too quickly.

- Before welding pipes under pressure, the electrodes should be annealed. In this case, a better and more stable arc can be achieved, which, in turn, will evaporate the seeping water from the fistula faster.

- The choice of direct or alternating current for welding water pipes depends not only on the pressure of the water layer, but also on the thickness of the metal to be welded.

So, for example, welding on alternating current makes it possible to form a more powerful arc. Therefore, even pipes under high pressure can be cooked with a “change”.

At the same time, the quality of the welding seam leaves much to be desired. In turn, DC welding allows you to deeply melt the metal and achieve greater strength of the welding joint.

Photo tie-in to the pipe

We also recommend viewing:

- Do-it-yourself headlight polishing

- Do-it-yourself scaffolding

- DIY knife sharpener

- Antenna amplifier

- Battery Recovery

- Mini soldering iron

- How to make an electric guitar

- Braid on the steering wheel

- DIY flashlight

- How to sharpen a meat grinder knife

- DIY electric generator

- DIY solar battery

- Flowing mixer

- How to remove a broken bolt

- DIY charger

- Metal detector scheme

- Drilling machine

- Cutting plastic bottles

- Aquarium in the wall

- Do-it-yourself shelving in the garage

- Triac power controller

- Low pass filter

- Eternal flashlight

- file knife

- DIY sound amplifier

- Braided cable

- DIY sandblaster

- Smoke generator

- DIY wind generator

- Acoustic switch

- DIY wax melter

- tourist ax

- Insoles heated

- solder paste

- Tool shelf

- Jack press

- Gold from radio components

- Do-it-yourself barbell

- How to install an outlet

- DIY night light

- Audio transmitter

- Soil moisture sensor

- Geiger counter

- Charcoal

- wifi antenna

- DIY electric bike

- Faucet repair

- induction heating

- Epoxy resin table

- Crack in the windshield

- Epoxy resin

- How to change a pressure tap

- Crystals at home

Help the project, share on social networks

Insert technology

There are several options to solve the problem

work.

Tapping using a tee

As noted earlier, this option in 90 percent of cases

used in a situation where a tee is mounted on a metal pipe. Everything

the fact is that in order to strengthen the junction of the two parts, you will have to

use welding. And at the initial stage of work, it is necessary to cut

pipe and cut off a piece that, in terms of its parameters, will be as accurate as possible

resemble the tee used for installation. It should be noted that the tee

considered method of tie-in will be mounted in the form of a coupling on a segment

pipes.

When work needs to be carried out with a system made using PVC pipes. One pipe should be replaced by several short sections, between which a piece of pipe equipped with a branch pipe will be placed. It is in this part that additional equipment will be connected. The problem in this installation is the connection using sockets, which are intended for inserting a pipe.

Insertion into PVC pipes

A tie-in is being carried out

into the sewer, during the installation of which plastic pipes were used, can

and on your own. For a job that will solve the problem of how to crash into a plastic sewer pipe,

would need:

- Prepare a piece of pipe together with a nozzle of the desired diameter.

- Prepare the workpiece. This stage of work involves leaving a part of the part and a pipe extending from it. The distance is calculated so that the tie-in place in the main part becomes securely blocked.

- A hole is drilled in the pipe, with a diameter identical to the width of the pipe.

- Sealant is applied to the inside of the flange. The outer side of the part near the hole is also smeared.

- The flange is superimposed on the pipe and tightly attracted along the edges with clamps. The fastening should be tightened gradually until the sealant begins to ooze from under the flange. Excess grease should be removed.

If sidebar

into the sewer pipe is carried out in places with a small pressure

liquid, then the use of clamps is not necessary. Enough is here

connect the flange to the pipe with ordinary electrical tape.

Cutting into a metal pipe

If you need a tie-in to the sewer riser made of metal

parts, it is best to use a ready-made tee that has several

larger diameter than a pipe. From the tee must first be separated

part without pipe.

However, there are often situations when it is necessary to prepare a flange

on their own. To do this, you need to purchase a pipe, the value of the internal

whose circle will match the value of the external parameter of the circle

connection pipes. Next, the part is cut longitudinally, it is drilled

hole and a pipe is welded. To fully answer the problem of how to crash into a cast iron

sewer pipe, it remains only to weld the prepared flange to

pipe. If the welding machine is not at hand, then you should

use any sealed mixture and clamps.

It is worth remembering that before starting the tie-in, it is necessary

make sure there is no fluid pressure in it.

Work Permit

Work on tapping into water mains, both by welding and without it, cannot be carried out without obtaining the appropriate permits.

Illegal tapping traditionally ends with bringing the owner to material and administrative responsibility.

Image gallery

Photo from

The pipeline is cut

Small diameter pipe insert

Insertion equipment

Insertion is performed by the master

Water connection

Connection to the water supply in the well

Surface water connection

Summer water connection

A site plan can be obtained from the Federal Center for Land Registration, and technical conditions from the central department of the water utility.

The technical conditions for connection will indicate:

- connection point;

- main pipeline diameter;

- data required for embedding.

In addition to the local structure of Vodokanal, the development of design estimates is carried out by specialized design organizations that have the appropriate license.

Then the documentation for the tie-in should be registered at the local branch of the SES. Simultaneously with the submission of the collected package of documents to the SES branch for registration, it is required to leave an application for issuing an opinion on the need to connect to the water supply.

To carry out the work, you should have a site plan in hand, as well as obtain technical conditions and permission to tie in the local water utility

According to generally accepted standards, the installation of a pipe under pressure and the installation of metering devices must be carried out by qualified specialists with the appropriate approval. It is prohibited to carry out such work on your own.

Save money by making your own efforts to connect, it will turn out only in the production of earthworks during the development and backfilling of the trench.

Conditions under which tapping is not allowed:

- if the main network pipeline has a large diameter;

- if the property is not connected to the central sewer system;

- if the tie-in is supposed to bypass metering devices.

Even in the presence of all permits, only qualified specialists should carry out the tie-in of the pipe to the existing network.

You can save only if you do some of the work on your own, the implementation of which does not require a license

These include: earthworks (digging and backfilling of trenches), delivery of material and other types of ancillary work that are not directly related to the tie-in procedure.

Of course, no one can forbid the owner to perform the sidebar on his own. Therefore, the article describes in detail the sequence of actions.

Interested in: Insulation outdoor plumbing in the ground: work technology + video

Application of clamps

Universal pads are put on cracks to eliminate leaks. They can connect pipes without thread welding. Gaskets are used for tightness. Clamps are made of metal or dense sealed material. Clamps are comparable in strength to welding. Lining designs:

- wide and narrow in the form of split rings with holes for bolts;

- in the form of a metal bracket that fixes the hermetic gasket;

- complex geometry for fastening to a wall or two pipelines between themselves.

Clamps to eliminate leaks are made from improvised materials. Fix on the pipe with tape or wire.

There are many ways of mechanical connection. You can always choose something suitable for the situation. And the welding machine for the time of installation of the pipeline or metal structures can be left out.

How to connect without threading and welding

Next, you can learn how to connect metal pipes without welding and threading. Speaking of connecting metal pipes, this method cannot be bypassed, because it is very popular during installation work.

Let's talk about flange connections. To perform it, they take special fittings, which are called flanges. These parts are equipped with a rubber gasket. The joint itself is performed in the following sequence:

- A cut is made in the fastening area. It is performed clearly perpendicular, and there should be no burrs. The end chamfer is not needed here.

- A flange is put on the prepared cut.

- After that, a rubber gasket is inserted, which should extend 10 cm beyond the edges of the cut.

- A flange is put on the gasket. After that, it is fastened to the counterpart of the flange on the second metal pipe.

- Do not overtighten the bolts while tightening the flanges.

The next connection option is a coupling. This method makes it possible to produce a reliable, highly sealed joint.

Installation work is carried out in the following sequence:

- Metal pipes prepared for fastening are cut off at the end parts. The cut on them should be done perpendicularly and make sure that it runs smoothly.

- A coupling is applied to the connection area. The center of the connecting element must be located exactly in the pipe joint area.

- Markings are made on the pipes with a marker, it will indicate the position of the fitting.

- Silicone grease covers the end parts of the connection.

- One pipe is inserted into the connecting piece according to the mark indicator. After that, the second is put in the same axial line with the first, and only after that it is attached with a coupling. When dressing, the mark affixed with a marker will be a guideline.

Watch the video

How to crash into a plastic water pipe

Do you have plastic communication systems in your private house and do they need modernization or repair? It is not difficult to install plastic on your own, thanks to the features of this material, right? But how to crash into a plastic pipe when it is under pressure? And is it possible do it yourself?

We will tell you the answers to your questions - the article discusses several ways to tie into a pipe to organize a branch from an existing pipeline. Starting with the simplest - shut off the pipeline for a while and insert a tee in the right place, having previously cut out the section.

Following the recommendations given in the videos, you can do most of the work on your own, without involving qualified specialists.

Method # 3 - crimp collar (pad)

In addition to the electric-welded saddle, there is its simpler counterpart - the clamp. It consists of two separate parts that are bolted together.

One for lining the top of the plastic pipe, and the second from the bottom to pull the top. A sealing gasket is additionally inserted between them to prevent leakage.

Inset scheme. The number of tightening bolts and the dimensions of the clamping collar depend on the diameter of the pipeline into which the tapping is made.

Typically, the top and bottom overlay parts exactly repeat the dimensions of the pipe. But there are also universal clamps, in which the top is made small, and instead of the bottom there is a metal strip for the screed.

Outwardly, they resemble repair analogues for connecting with a hose or closing fistulas. Only in the upper part they have a branch pipe for connecting a branch.

Clamps for tapping into a plastic pipe are:

- with stopcock;

- with built-in cutter and protective valve;

- with a flanged or threaded metal end;

- with plastic end for soldering or gluing.

To perform a tie-in, the clamp is put on the pipe and fixed on it with nuts or bolts, depending on the design. After that, drilling is performed through the existing outlet pipe. And then the branch itself is connected from the highway.

Drilling a pipe without installing collar or saddle, Not recommended. You can make a mistake with the drill diameter and drilling point. It is best to do this through the branch pipe of the fitting already installed for the branch.

So the drill will definitely be slightly smaller in size than the internal section of the embedded bend and will be installed exactly where it is needed.

The nuances of work on the water supply under pressure

For tapping into the pressure pipeline, electric-welded saddles and clamps with a built-in cutter are used. It is located in a special hermetic housing of the nozzle.

To drill plastic, it is often enough to turn it with a hex wrench. But there are also models for a drill.

The presence of a sealed branch with a cutter inside ensures that there is no splashing of water at the time of drilling a pipe under pressure

Some of these designs have a built-in valve.Then, after drilling is completed, the cutter rises, the valve closes, and the nozzle with the drill is removed. Instead, a drain pipe is installed.

The use of overlays with an internal cutter allows you to crash into any water pipes

It doesn't matter if they are under pressure or not. But such nozzles are much more expensive than conventional clamps and saddles.

They greatly simplify the tie-in process, but they will have to be spent. At the same time, in terms of the tightness of the resulting joint, they do not exceed and are not inferior to standard solutions.

Conclusions and useful video on the topic

There are many nuances in connecting a branch to a plastic pipeline. There are different types of plastics, and fittings in design, and tie-in methods.

To avoid gross mistakes, we recommend that you watch the videos below on this topic.

Insertion into a pipe from HDPE under pressure with a saddle with a cutter:

Features of mounting an electric welded saddle:

The nuances of tie-in to a polyethylene water pipe:

Crashing into existing plastic plumbing is rare. But sometimes you need to change pipes, install water meters, or simply connect additional plumbing. To do this, there are several different types of fittings and tie-in technologies.

For any case, there is an optimal option so that the installation can be carried out independently. It is obligatory to entrust these works to professional plumbers only in a situation of connection to a common water supply, where preliminary approvals are required.

How to embed your knee in plastic plumbing

Install bends in LDPE lines without welding

It is important that the diameter of the branch is lower than the main pipe.The order of installation depends on the possibility of restricting the transport of the working medium.

If it is possible to shut off the supply of the product, you can embed clamp elbows, saddles, overhead care and similar products with your own hands.

The incision is carried out in several stages:

- they clean the area with a scraper, while partial removal of the upper dirty layer is possible without a critical effect on the wall thickness;

- treated with napkins or cleaning agents;

- drill a hole of the desired diameter;

- fasten reinforcement with clamps or clamping bolts, organize a secondary channel.