- materials

- The distance from the wall to the toilet is the optimal layout

- Bathroom redevelopment

- External sewerage device

- Timing

- Outlet Options

- How to remove an old toilet

- Reasons for moving the toilet

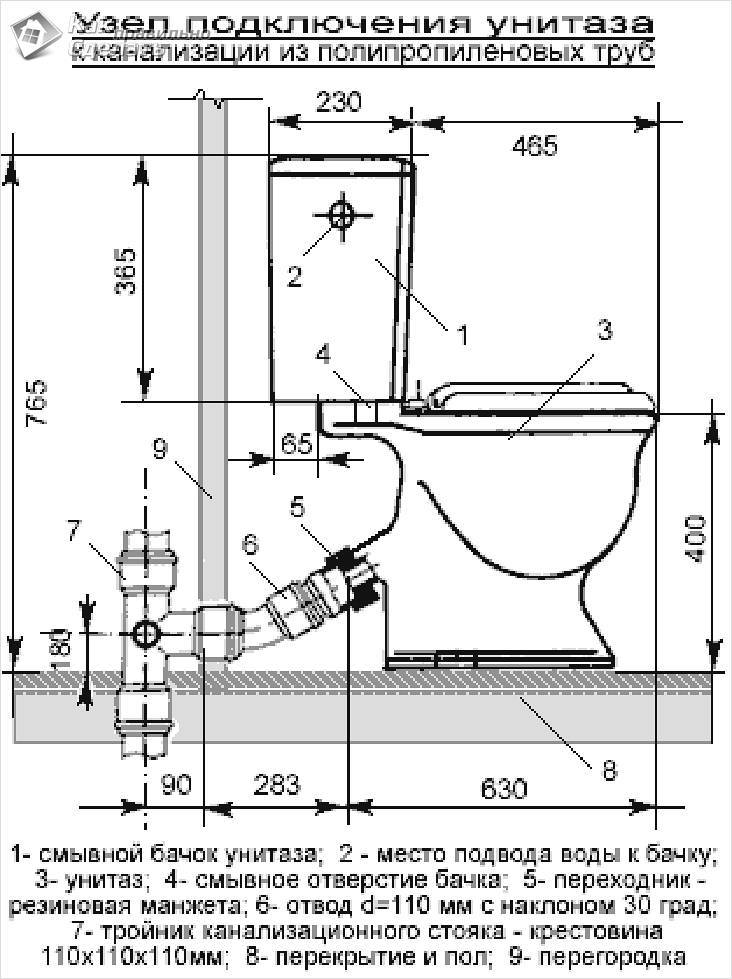

- Rules for installing appliances with an angled and horizontal outlet

- General rules for the operation of drainage systems

- Do-it-yourself procedure for installing a drainage well

- For storm sewers

- For a septic tank

- Use of corrugated pipe

- Water supply and sewerage security zone

- Is it possible to move the kitchen to the room

- SanPin: cesspool operation

materials

The materials used in sewerage systems are subject to increased requirements due to the aggressiveness of the environment of the transferred effluents. Pipelines are usually used from the following materials:

- cast iron;

- PE (polyethylene);

- PP (polypropylene);

- PVC (polyvinyl chloride);

- PVC-U (non-plasticized polyvinyl chloride);

- Fiberglass (based on polyester or epoxy resins reinforced with fiberglass);

- reinforced concrete (on external networks with a diameter of 150 mm or more) - used mainly for collectors of large diameters.

Less commonly used:

- glass pipes;

- wooden pipes;

- ceramic pipes;

- asbestos pipes.

Wells for various purposes are constructed from prefabricated or monolithic reinforced concrete, various durable plastics.

The distance from the wall to the toilet is the optimal layout

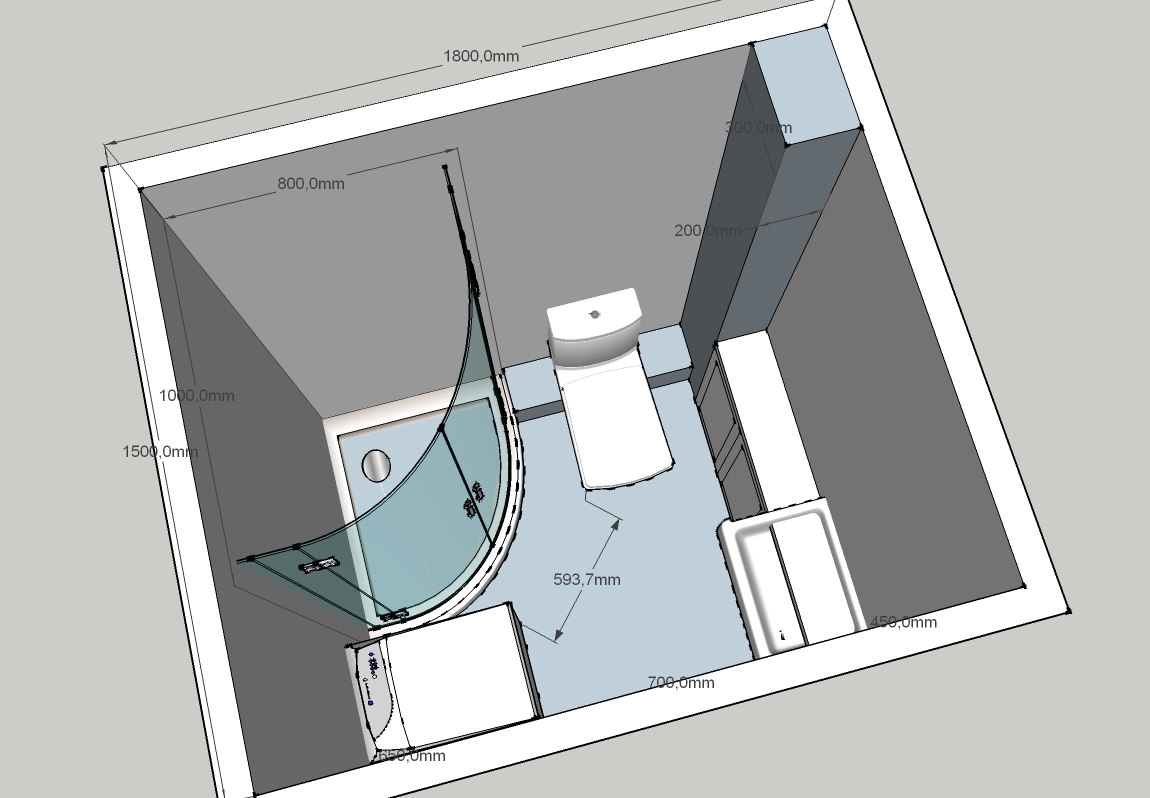

During the repair of the toilet and bathroom, when replacing plumbing, the problem of the correct layout of the bathroom appears. One of the most important convenience parameters is the distance between the toilet and the wall, because if it is chosen incorrectly, it will be uncomfortable to use the device.

We will consider regulatory requirements and find out what specific basic distances the instruction defines.

Bathroom redevelopment

Separate toilet seat

Let's start with a more simple case, when the toilet is separated from the bathroom. It is simpler due to the fact that in such a toilet, in most cases, there is one device. In a large configuration, it is possible to add a bidet, if the size of the room allows.

We will immediately announce the norms for the distance from the wall to the toilet, adopted in SNiP 2.08.01-89 * "Residential buildings":

Note! Official norms are mandatory for public and private construction of facilities. The owners of the apartments will be able not to make them and place the devices at their discretion, since their operation and maintenance is carried out by them. be directed to state that these standards are relevant in the case when the toilet is spacious enough, and you do not understand where it is better to put this or that device

But in most post-Soviet apartments, such a nuisance does not appear, since the dimensions of the toilet are minimal, and the toilet is placed in the middle of the cubicle near the back wall

be directed to state that these standards are relevant in the case when the toilet is spacious enough, and you do not understand where it is better to put this or that device. But in most post-Soviet apartments, such a nuisance does not appear, since the dimensions of the toilet are minimal, and the toilet is placed in the middle of the cubicle near the back wall.

Note! Most of the toilet cubicles of the Soviet era have dimensions in which the installation of a compact exactly in the middle of the room near the back wall gives the very minimum distances to the side walls and the front door. Combined bathroom. Combined bathroom

Combined bathroom

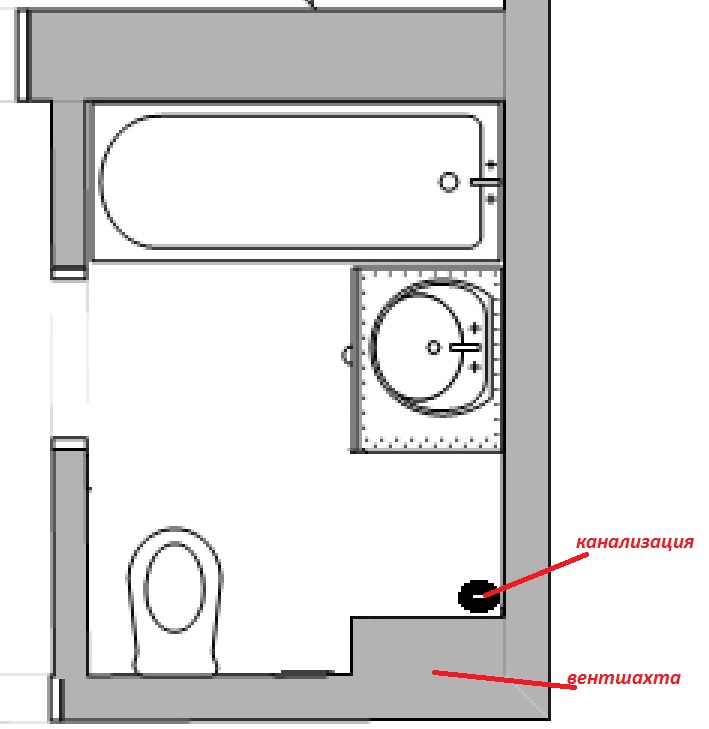

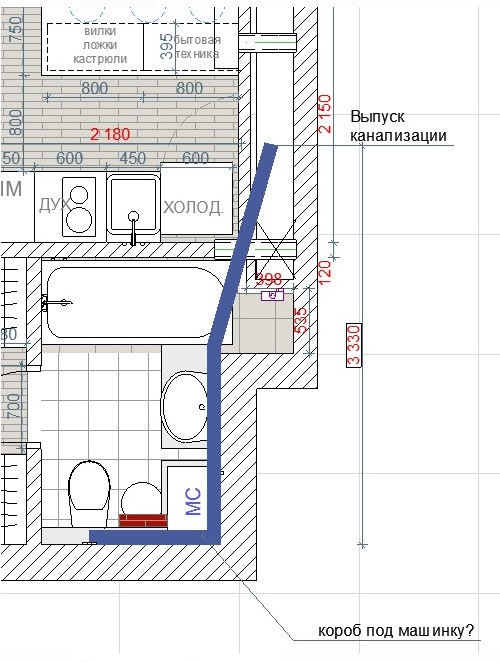

If the toilet and bathroom are in the same room, the task is slightly complicated by the fact that you need to rationally place a couple of plumbing fixtures in a rather small room.

Additional troubles may lead to the need to install household appliances - a washing machine, boiler, etc. Along with this, the most acceptable layout option involves not only rational and ergonomic, but also harmonious placement of all objects from the standpoint of design.

This is another feature of modernity: people want to live comfortably and beautifully, and this, as we know, cannot be forbidden.

If the bathroom is large, then you need to divide its premises into territories: the territory of the shower or bath, the territory of the washbasin, the territory of the toilet, etc. But in most Soviet and many modern apartments, there is no expanse, and the task is to fulfill the minimum requirements for the distance between adjacent devices, devices and walls and the presence of passages.

Quite often, a compact and a bidet, and from time to time a washbasin, are placed in a line against the wall.In this case, there should be a gap of at least 20 cm between adjacent devices, preferably 30 cm. This refers to the distance from edge to edge.

If there is a sink next to the toilet, along with this, the approach to it is carried out from the side of the device, then you need to remember about the space for tilting: during washing, the person leans towards the sink and moves back a little. The minimum space for this should be at least 70 cm.

Note! The dimensions of the distances to the side walls are accepted without transformations - 38 - 45 cm from the middle axis of the bowl to the wall. Similarly, the requirement for the distance in front of the toilet does not change - it forms at least 53 cm, for comfortable use - 76 cm. Here it is possible to make adjustments only in the huge direction

Here it is possible to make adjustments only in a huge direction.

For combined bathrooms, the issue of saving space is very relevant. One example of such savings is a toilet with a tank in the wall. Do-it-yourself installation of this model is complicated, but the use of modern installations and kits with frames simplifies this task.

When redeveloping bathrooms and latrines, you should take into account the distances between adjacent devices, and do not forget about the indents from the wall (see also the article “Bidet toilet bowl: purpose and design features”).

External sewerage device

In most cases, due to the lack of main water supply and sewerage, autonomous sewage systems are used. Let's consider them below.

The simplest type of autonomous collection and removal of sewage is an outdoor latrine with a cesspool device.Collection and treatment of wastewater should be carried out in a filter trench with gravel-sand backfill, located at a distance of no closer than 4 m from the borders of the neighboring site and at least 6 m from the house.

Such a solution, of course, does not provide comfortable conditions and has a lot of disadvantages, but in implementation it is the most economical.

Filter trench for collecting and discharging wastewater

Most developers arrange a septic tank on their site, which allows them to provide amenities no worse than in a city apartment. A septic tank is a sewage treatment plant. Modern solutions are based on wastewater treatment using active aeration: sedimentation and decomposition of suspended particles, biological treatment and filtration, including in soils through the use of soil absorption capacity.

The basis of the septic tank is the principle of ground cleaning.

Scheme of the filter well

All drains pass through a septic tank, where coarse particles are first deposited, and then through a distribution well they are sent to a prepared soil filter, consisting of two layers - crushed stone and sand.

The septic tank is installed underground on the site. Such a system prevents the spread of odor. Flowing drains do not fall into wells, do not pollute surface and ground water.

A septic tank can be designed to service both one individual house and several. It serves for preliminary treatment of wastewater and their partial disposal. With permanent residence in a country house, it will be necessary to pump out water from the septic tank and take it to specialized treatment plants.According to sanitary standards, the process of water purification should last three days. For this, the volume of the septic tank is calculated with an excess of three times the daily volume of wastewater. When installing, it is necessary to install a soil filter - a system of trenches with crushed stone.

The following designs are currently in use:

- prefabricated, usually PVC;

- prefabricated septic tanks erected on the site, usually metal, reinforced concrete, brick

metal septic tank

Consider a factory-made PVC septic tank device.

The structure is installed in the pit on a prepared base in such a way that there is a distance of at least 25 cm on each side between the walls of the septic tank and the slopes of the pit, and the cover is 20 cm above ground level. The base is made of monolithic concrete 100 mm thick, reinforced with a road mesh, to which the structure is attached with anchor bolts. The septic tank is mounted strictly horizontally.

When setting the mark of the cover relative to the ground level, the possibility of further planning and adding soil to the site should be taken into account. After that, backfill the pit.

Similarly, a prefabricated septic tank is being erected on the site. The material for the chambers of such treatment facilities is brick, reinforced concrete or metal. When installing a prefabricated septic tank, it is necessary to compact the soil, make a sand bed 100 mm thick with the addition of cement in a ratio of 1:10.

A metal septic tank consists of two separate tanks, which are connected to each other and have a hatch for pumping water. The elements of the septic tank are welded together; to protect against corrosion, they are covered with bituminous mastic. A metal septic tank is also installed on reinforced concrete.

Scheme of a metal septic tank

The construction of a brick septic tank is carried out on a cement-sand mortar. Wall thickness - 250–380 mm.

Septic tank with brick walls

A septic tank with monolithic reinforced concrete walls is placed directly on the site. To do this, they arrange a formwork into which a reinforcing mesh is installed and concrete is poured. Wall thickness - not less than 150 mm.

Septic tank with concrete walls

Timing

After receiving permission for redevelopment, the owners of the apartment are given 45 days to prepare all the necessary documents.

If you contact a good company with experienced qualified specialists, then this period will be significantly reduced.

The approval procedure can be slightly shortened if you turn to intermediaries for help. Their services are paid, but the entire approval process will fall on their shoulders, and the apartment owners will not need to waste their time.

- Permission from the administration can be obtained within 30 days from the date of application.

- For registration of papers in the BTI and Rosreestr, you will have to spend about 3 more weeks.

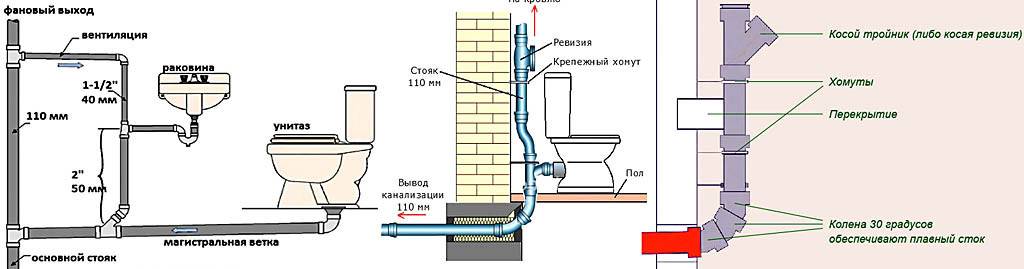

Outlet Options

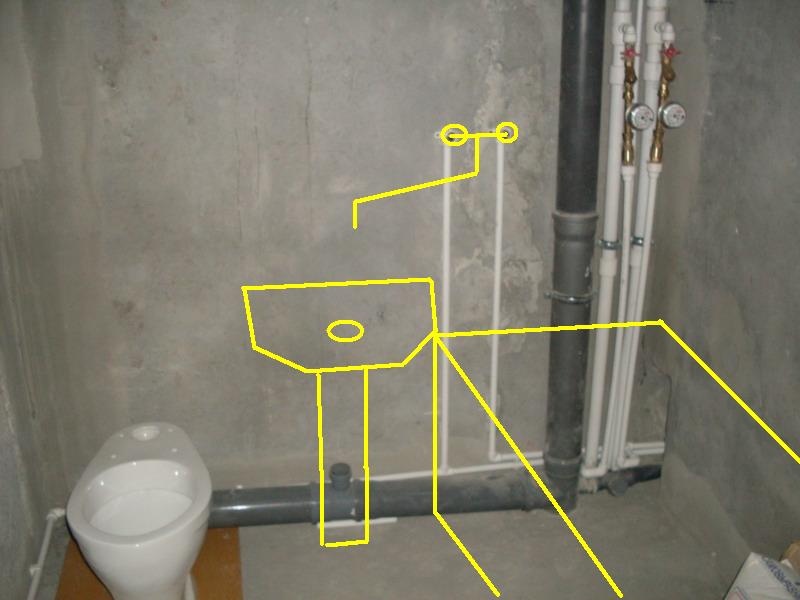

In modern stores and supermarkets you can find a large number of plumbing equipment. Together with each high-quality model, special connecting elements are included in the kit, with the help of which the installation and further connection of the entire system is carried out.

The choice of device depends on which version of the outlet pipe is in the room being repaired. This information should be obtained before you begin to connect the toilet to the sewer pipe.

- Vertical water outlet. These models have an outlet that is perpendicular to the floor.Most often, this option is used in private homes.

- Horizontal pipe arrangement (parallel to the floor).

- The drain is located at an oblique angle to the floor. To avoid errors in the calculation, you will need to know the angle of the drain.

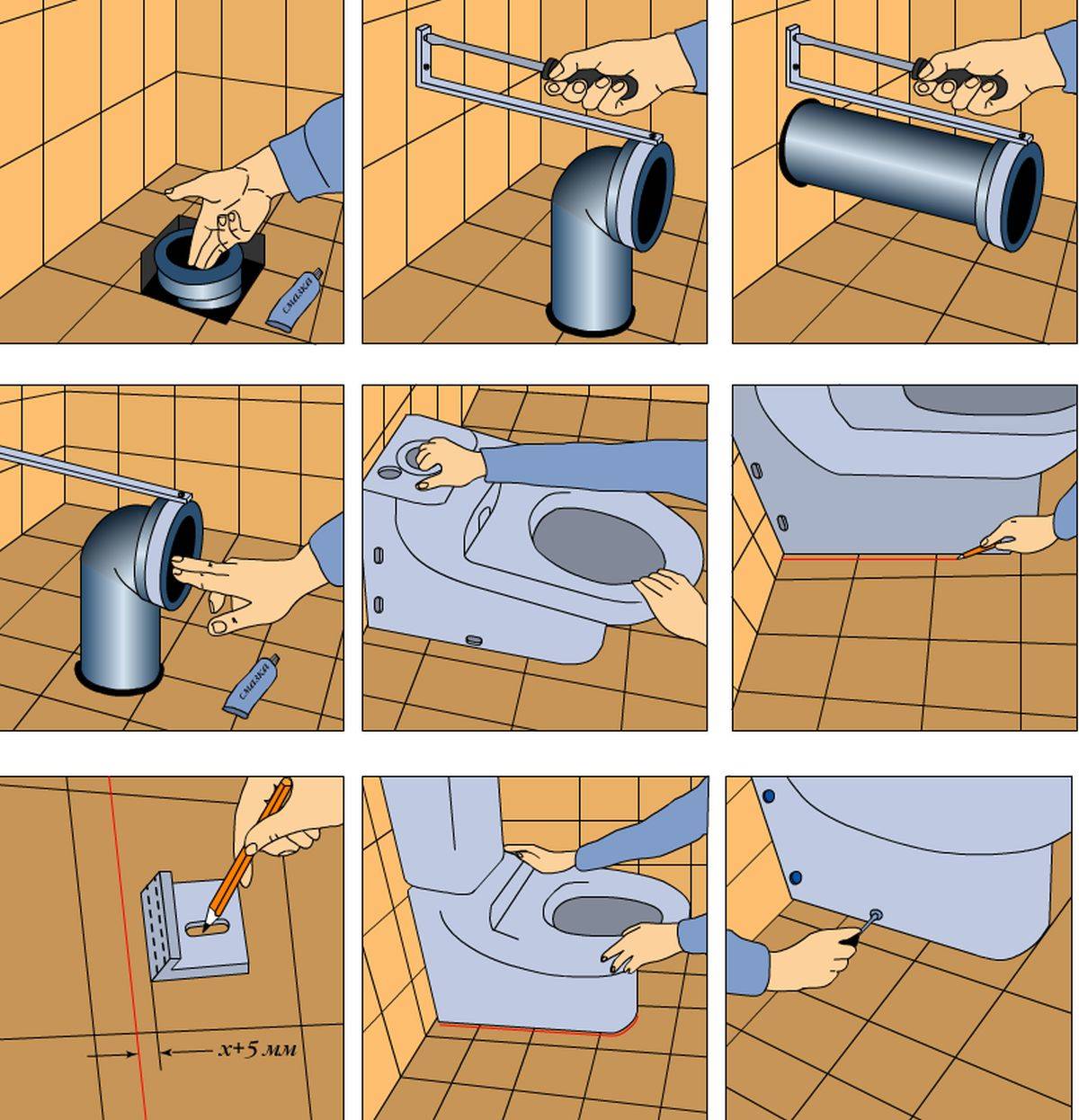

How to remove an old toilet

After the tank is turned off, proceed to dismantle the plumbing fixture. Previously, the outlet of the old toilet bowl is disconnected from the outlet pipe of the sewer riser. The method of dismantling depends on which method was used for fastening. This may be connecting the toilet to the sewer with a corrugation or a coupling. In any case, there should not be any difficulties with their dismantling.

On the sides of the base of the toilet there are two holes from which you need to unscrew the bolts. After the equipment is disconnected, it is set aside and the condition of the mortgage board is checked. If it is damaged or rotted, it should be replaced. To do this, the old board is removed and thrown away. The niche is thoroughly cleaned, expanded if necessary, filled with cement mixture and a new board is pressed into it, corresponding to the size of the "leg" and the base of the toilet bowl.

In the event that the floor in the bathroom is tiled, it is worth putting a rag under both the old and the new plumbing fixtures (so as not to scratch the coating).

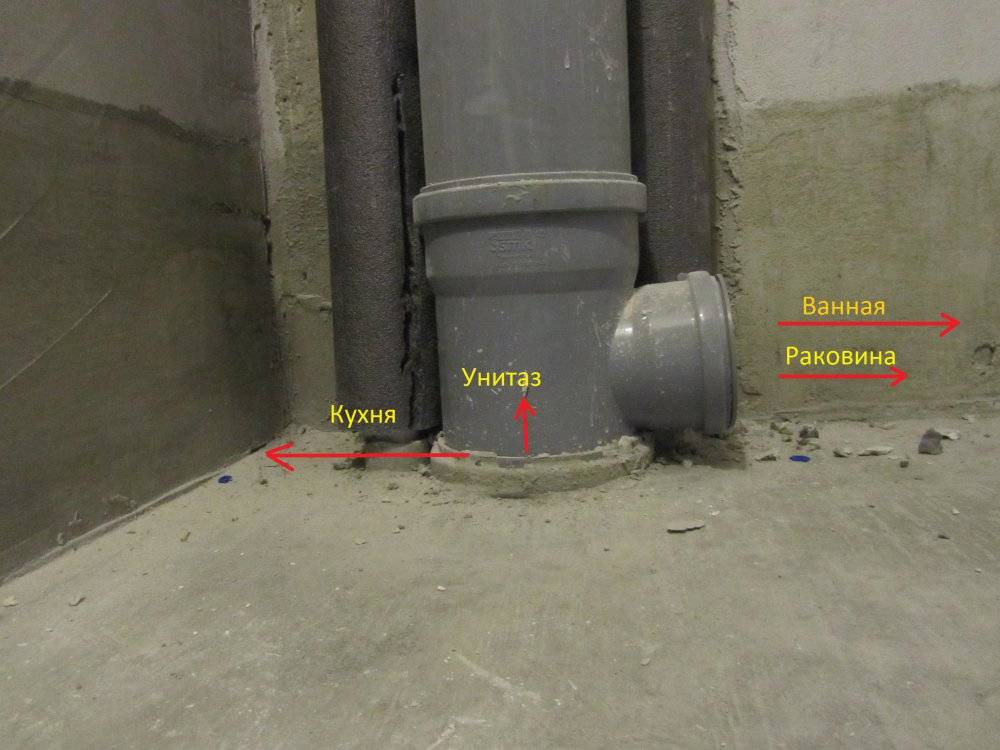

Reasons for moving the toilet

Before proceeding with the process of dismantling the old toilet and installing a new one, consider the main reasons for its transfer.

- Changing the layout of the bathroom. In this case, all operations are coordinated, at a minimum, with the Housing Inspection, the State Sanitary and Epidemiological Supervision, the State Fire Supervision, and the Architectural and Planning Department. Only after obtaining permission, redevelopment of the restroom is carried out.When moving a wall, the old location of the device can cause discomfort, which is why it becomes necessary to move it.

- Replacing the old device with a new one, which has a much larger size. If, due to the dimensions of the updated design, it cannot be installed in the previous location, the product should be relocated.

- Buying new furniture for the bathroom.

Remember, regardless of motivation, the old toilet should be removed whole, the sewer should be redone, and only after that proceed with installing the device at another point in the restroom. For this purpose, often, use a long flexible eyeliner.

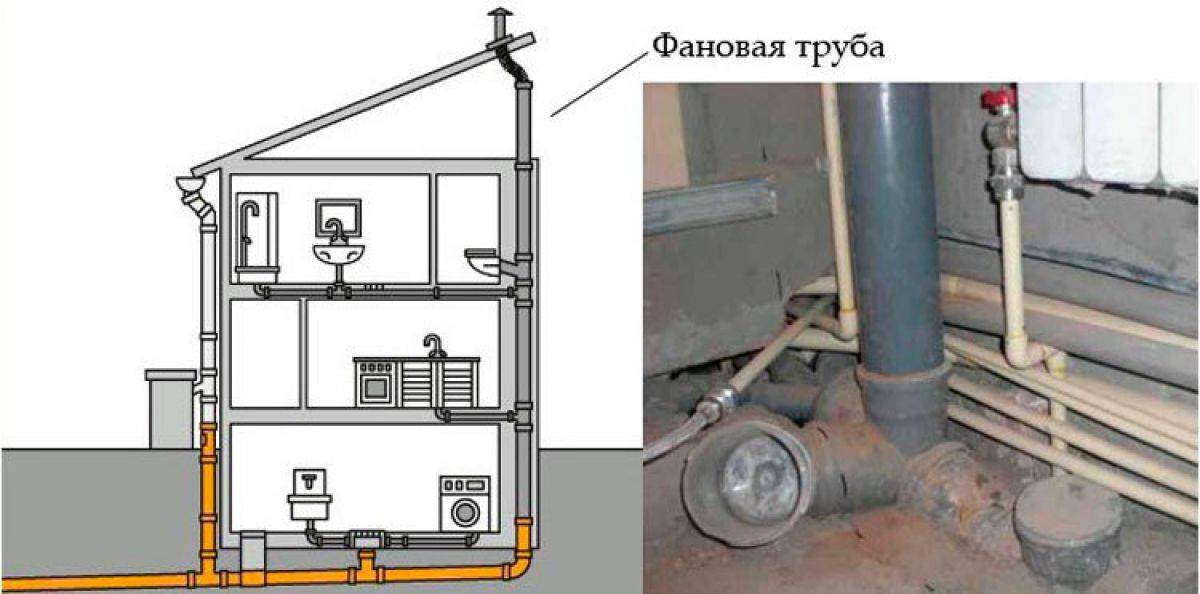

Rules for installing appliances with an angled and horizontal outlet

Because the toilets with horizontal outlet or oblique are used most often, consider the scheme of their connection in more detail. If the outlet of the bowl and the socket of the pipe are aligned, plastic pipes are used for connection. In case of small inconsistencies, eccentric cuffs are used. Minor misalignments are usually caused by the toilet being misaligned when attached to a board or tile. In case of serious deviations, corrugation is used.

Previously, as already mentioned, the toilet is installed (with an oblique outlet or with a horizontal one) on a mortgage board. Next, proceed to the actual connection. The release itself is smeared with red lead and wrapped with a resin strand in such a way that its end 0.5-1 cm long remains outside. If you fill it inside, in the future it can become an additional cause of blockages. Next, a connecting element is put on top - a corrugation or a coupling.Their opposite end is coated with sealant and inserted into the socket of the sewer pipe.

General rules for the operation of drainage systems

Sewer complexes consist of pipelines, manholes. All elements must be kept in good condition, their technical parameters must be maintained at the calculated level. Together with water supply sites, wastewater disposal is the most important part of the city's supply tools.

Rules for the operation of sewer networks

are required to comply with the following requirements:

- ensure constant monitoring of the integrity, condition of pipelines, tanks;

- remove blockages immediately;

- carry out preventive maintenance, prevent subsidence, destruction or deformation of pipes, wells, and other elements. Problem components are subject to dismantling with replacement;

- constantly carry out planned, emergency repairs of all sections, lines;

- renew used parts, assemblies;

- supervise the observance by subscribers of the rules of use;

- supervise the construction of new lines, conduct acceptance tests;

- display all work and actions in the reporting documentation;

- constantly study the operation of equipment, develop new methods of use, development.

Technical operation of sewerage systems

consists of maintenance or repair of two main parts:

- internal sewerage. These are pipelines and fittings located inside buildings, structures, MKD;

- the outer part of the sewer. This is a vast, branched accumulation of underground pipelines. The gravity principle of wastewater movement puts forward increased requirements for their condition and capabilities.

The condition of the external areas is necessary

constantly control.In particular, it is necessary to inspect lines, wells

Important

detect subsidence, blurred or destroyed areas in time. Besides,

periodic inspection of inspection and revision wells is required for

detection of blockages or deformations

Any violation of the integrity of the elements threatens

the formation of a complex blockage that will stop the operation of this line. Sewer operation

networks requires a quick response to any disruption, which

forces to organize round-the-clock work of emergency services.

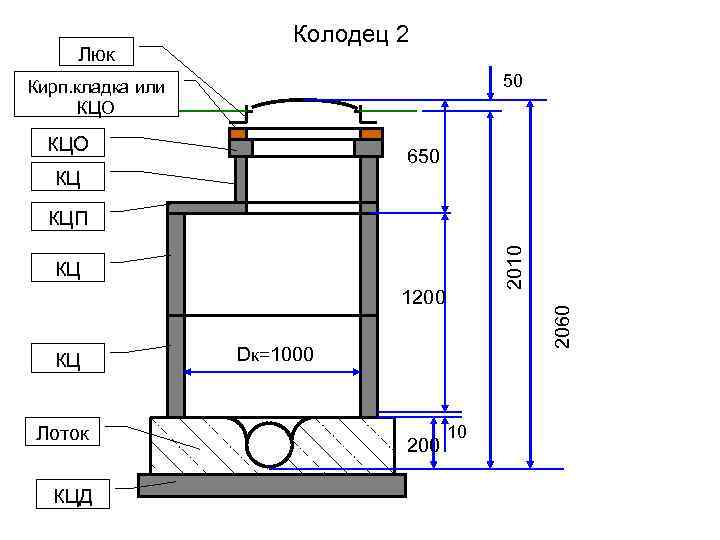

Do-it-yourself procedure for installing a drainage well

Regardless of the purpose of the well, the sequence of work on its installation can be considered typical, and yet there are some nuances.

For storm sewers

Since the sequence of installation work is the same for all types of drainage wells, we will consider it using the example of a reinforced concrete well for storm sewers.

For the prompt execution of installation work, it is necessary to prepare in advance:

- reinforced concrete rings;

- a concrete slab for the device of the bottom of the tank or components necessary for the device of a concrete screed;

- bituminous mastic or liquid glass for sealing joints;

- rammer and trowel.

In addition, it is necessary to provide for the possibility of arrival of heavy lifting equipment.

The sequence of operations is as follows:

The marking of the main elements of the system is being carried out and earthworks are being carried out (digging trenches and a foundation pit for a well).

At the bottom of the pit, a sand cushion is arranged, which is carefully rammed. For greater efficiency, sand is spilled with water.

A reinforced concrete slab is laid on the compacted sand layer or a reinforced concrete screed is poured, the thickness of which must be at least 100 mm

In the process of performing these works, it is extremely important to achieve the horizontalness of the concrete base.

Holes for pipes are formed in reinforced concrete rings in pre-marked places. The outer surface of the rings is abundantly covered with bituminous mastic or liquid glass.

Using a hoist, the support ring is slowly raised and lowered onto the concrete base.

If it is necessary to install several rings, cement mortar is applied to the upper end of the previous one and only after that the next ring is installed.

Pipes are installed in pre-prepared holes, and the remaining cracks and gaps are sealed with cement mortar

After the solution has completely dried, the installation sites of the nozzles are treated with bituminous mastic or liquid glass. In addition, the bottom of the mine must also be covered with mastic.

The last ring is covered with a concrete slab with a hole in which the neck of the well is installed. The neck installed in this way is covered with a hatch or a special grate.

The gap between the outer surface of the rings and the ground is half filled with sand and rammed. The rest of the space is covered with earth to the very surface. After the poured soil has finally settled, a blind area of cement mortar is equipped around the perimeter.

Important! Before starting the operation of the drainage well, it is necessary to make sure that it is tight. To do this, the pipes overlap and fill the tank with water.

If the water level does not drop within 3-4 days, the well is ready for operation.

For a septic tank

Grouting drainage wells have some similarities with a conventional cesspool. They also do not have a bottom and, after filtration, allow them to freely go into the soil.

Wells for a septic tank are quite simple, so they can be assembled on their own from improvised materials. The sequence of installation work is as follows.

- Dig a hole, the volume of which exceeds the volume of the future septic tank.

- Install a set of concrete rings, a set of tires or a large plastic barrel without a bottom into the pit, in other words, form the side walls of the well. In addition to the materials listed above, you can use brick, laying it, leaving special drainage windows.

- Cover the bottom of the well with crushed stone or coarse sand.

- To ensure intensive drainage, special drainage holes are made in the side walls of the well at a height of 500 to 800 mm.

- Using sewer pipes, connect the septic tank to the well and connect additional ventilation. Otherwise, "airing" of the system is possible.

- Carefully seal the entrance to the septic tank.

- Cover the space between the outer surface of the tank and the walls of the pit with sand and soil.

On this work on septic tank drainage equipment can be considered completed.

Important! Drainage wells should be buried below the level of clay, in addition, the level of groundwater at the site of the well should be at least 2 m.

The construction of drainage wells is not particularly difficult, but requires accurate technical documentation.Properly installed wells significantly increase the efficiency of the drainage system as a whole.

Use of corrugated pipe

Connecting a toilet bowl to a sewer pipe with a corrugation is the most common method that is used when installing the sewer system of a sanitary unit. The difference between a corrugated pipe and other connection options is that errors are not so clearly visible and less expressively affect the quality of the functioning of the sewer.

Note! The use of a corrugated pipe is justified if the toilet is higher than the sewer pipe and its outlet cannot be connected to the riser using other methods. To make the connection, you need to prepare the following tools and materials:

To make the connection, you need to prepare the following tools and materials:

- corrugated pipe;

- cuffs for sealing, one for a plumbing fixture, the second for a socket of a sewer pipe;

- silicone hermetic seal.

Corrugated pipe for toilet bowl

One end of the corrugated pipe must be lubricated with sealant, installed in the socket of the pipe and fixed with a cuff. The other end is connected to the toilet.

Note! To check how good the seal is, it is necessary to pour some water into the toilet bowl after the drying time of the sealant has elapsed. If everything is done correctly, nothing will leak during the check.

Only now you can proceed to install the bowl legs. To perform this work, you will need cement mortar or special dowels.

If everything is done correctly, nothing will leak during the check. Only now you can proceed to install the bowl legs.To perform this work, you will need a cement mortar or special dowels.

Water supply and sewerage security zone

City water supply and sewerage facilities are objects of particular importance in the life support of the city. For network facilities of water supply and sewerage on street driveways, etc.

open territories, as well as subscribers located in the territories, the following security zone is established:

For network facilities of water supply and sewerage on street passages and other open areas, as well as subscribers located on the territories, the following security zone is established:

- for networks with a diameter of less than 600 mm - a 10-meter zone, 5 m each on both sides of the outer wall of the pipelines or from the protruding parts of the building, structure;

- for mains with a diameter of more than 1000 mm - a 20-50-meter zone on both sides of the pipeline wall or from the protruding parts of the building, structure, depending on the soil and the purpose of the pipeline. The water supply must run outside the facility at a distance of at least 5 m from the fence.

Is it possible to move the kitchen to the room

First of all, it is necessary to deal with all legislative and domestic nuances. The transfer of the kitchen in a new building is considered redevelopment. And if you live in an apartment building, then your freedom to rearrange and redevelop is seriously limited. It is necessary to reckon with the requirements of a number of legislative acts and not violate the rights of other residents. Therefore, the owner of the apartment is required to obtain permission for redevelopment from the local authorities. For St. Petersburg, these are regional interdepartmental commissions created under the administrations of the city's districts.

In case of ignoring the law, according to Art.7.21 of the Code of Administrative Offenses of the Russian Federation, you are threatened with a fine of one thousand to two thousand five hundred rubles, and you will also not be able to dispose of your apartment, for example, to sell it. Moreover, you will be obliged to return the premises to their previous appearance, which will require a lot of expenses.

Theoretically, you can move the kitchen even to another room, even to the hallway or utility room. In practice, you will not always be allowed to carry out the transfer.

SanPin: cesspool operation

The pit latrine code also specifies standards for effluent management. Regardless of the type of garbage drain, it must be cleaned 2 times a year with sterilizing mixtures. This is done after the sewage cleaning, so that it is possible for some to completely neutralize the action of pathogenic bacteria.

For sterilization, a special acid-based chemical solution, gentle compounds or home-made mixtures are used. It is strictly forbidden to use pure lime chloride. When mixed with water or other chemicals, it releases a hazardous gas. It is odorless, but can cause severe poisoning and burns of the upper respiratory tract.

Mixtures for sterilization

Mixtures for sterilization

For home self-service, a mixture is used, which includes:

- Bleaching powder;

- Creolin;

- Naphtalizol and some other compounds.

Cleaning is carried out every two weeks, and the cesspool is inspected every season. The pit can be cleaned independently, with the help of a cesspool machine, or cleaned with bioactivators.

- With self-cleaning, a drainage or fecal pump is installed in the tank, which pumps the waste into the tank for further disposal.After draining the drain, its walls are cleaned of growths and silt with iron brushes, the pit itself is washed with clean water;

-

In the sewer cleaning, the work is carried out by a special machine, which is equipped with a tank and a pump. The hose from the pump is lowered into the drain and pumped out. In order to be able to carry out machine cleaning, the depth of the tank must be less than 3 meters;

- Bioactivators are considered the most convenient. With constant use, they solve the problem of the need for sewage cleaning, soil contamination, unpleasant odors, etc. Here, active microorganisms are placed in the drain, which process waste into products that are safe for the environment. Many owners of private houses further use these liquid products as fertilizers. Instead of biological activators, chemical reagents can be used, but they corrode plastic and metal.