- Heat pumps and ducted air conditioners

- The latest heating systems

- The principle of operation and types of air heating

- How it works?

- 1 Air heating at home - there are many advantages, but few disadvantages

- Steam heating

- Features of direct-flow heating system

- How to connect a solid fuel boiler

- How the scheme works

- Way to reduce the cost of strapping

Heat pumps and ducted air conditioners

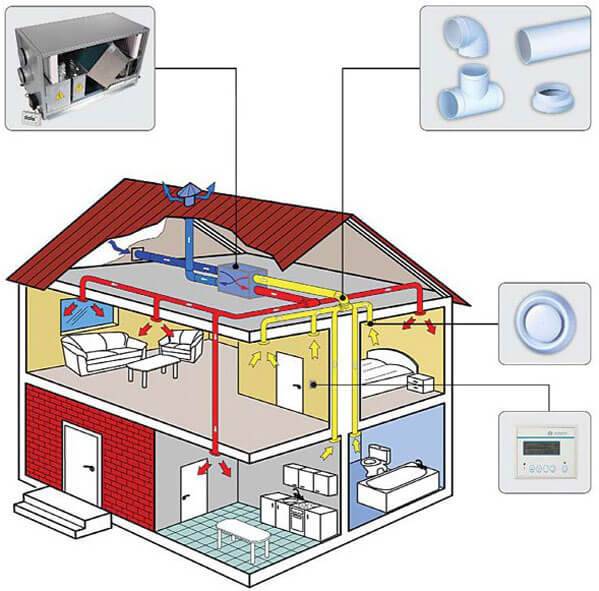

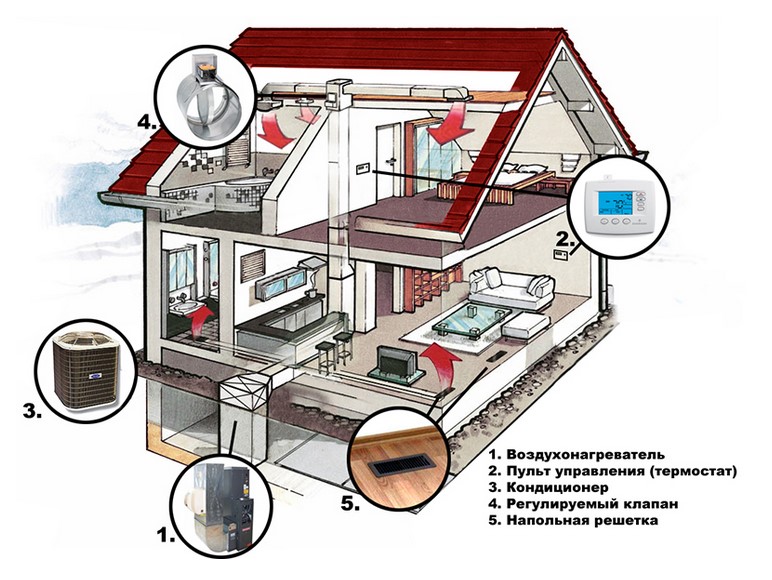

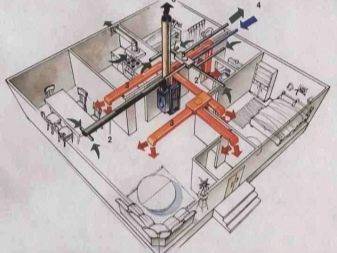

Sometimes you can find combined climate control systems, which include components such as:

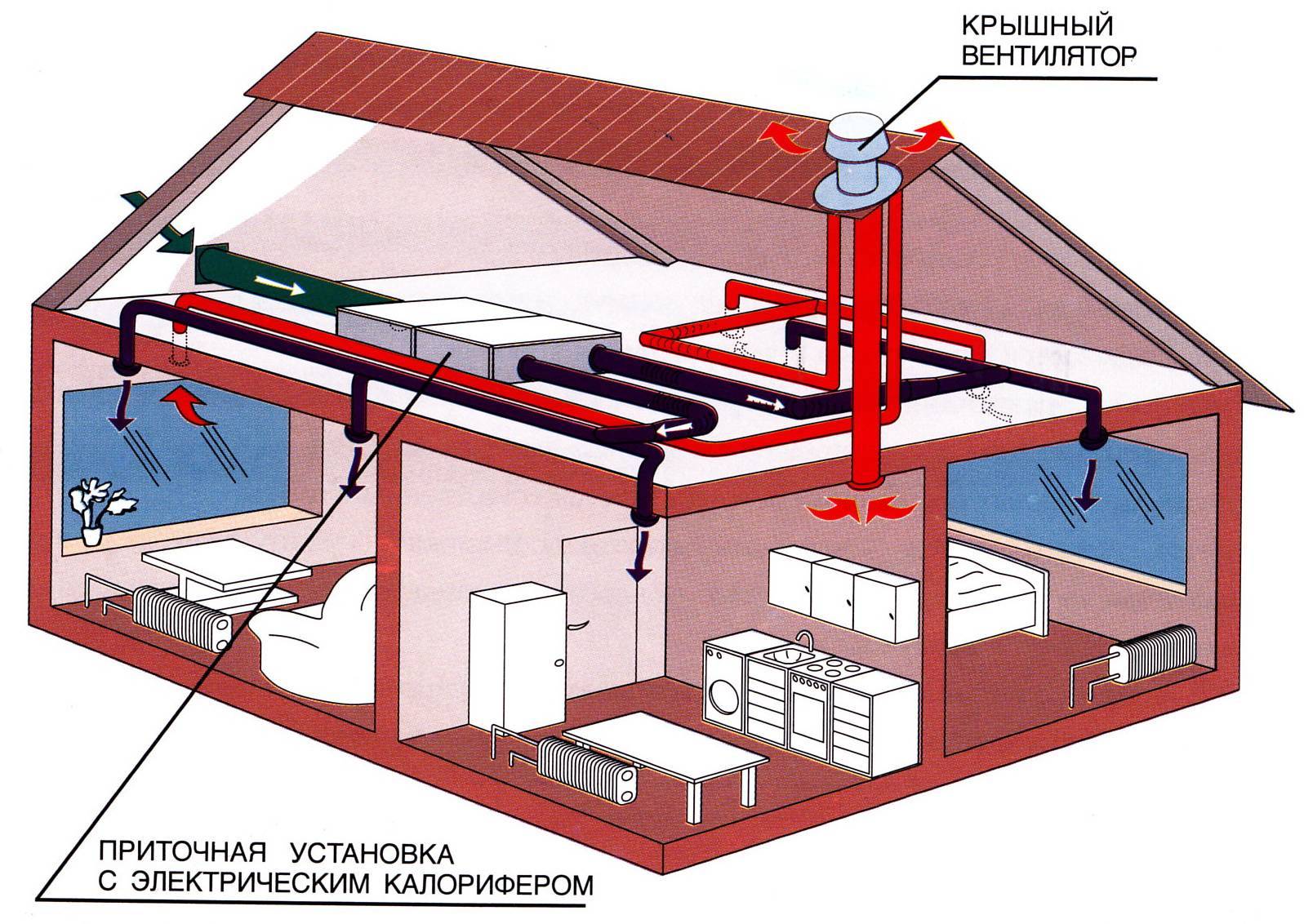

- Ducted air conditioner, which, depending on the weather, is able to heat, cool and dehumidify the air.

- Dust filter.

- An ultraviolet filter that disinfects the air.

- Supply and exhaust ventilation system.

Duct air conditioners

Duct air conditioners

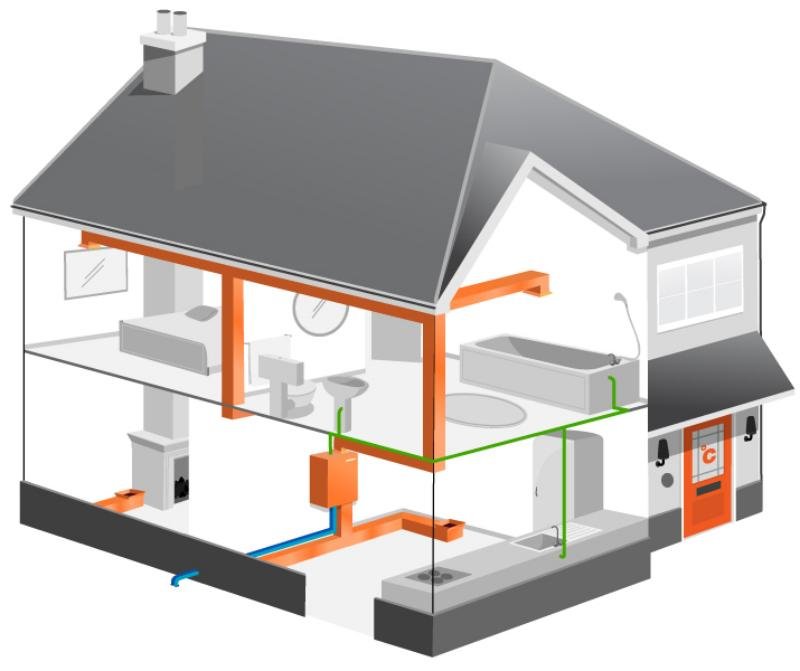

In this case, the source of thermal energy is electrical energy. Studying the reviews, it can be noted that such a scheme of work is very convenient. After all, you have only one control unit that controls absolutely all the characteristics from one point. Compared with the traditional system, where the fan is somewhere in the attic, air conditioners are in the rooms, and air heating through pipes is somewhere else, then such a system seems more thoughtful and improved.

In addition, with such a combined system, you can save the interior of the premises.Indeed, in this case, only ventilation grilles will be visible, since air heating, as seen in the photo, does not require the installation of wiring and radiators.

Warm air outlet for air heating system

Warm air outlet for air heating system

Of course, there are several disadvantages of this kind of scheme. The cost of the finished system is quite high. For example, if we take Chinese ducted air conditioners with a heat output of 15 kWh for heating, they will cost about 70,000 rubles.

The outdoor unit, which takes heat from the atmospheric air, can operate at a temperature not lower than -15 - -25 degrees Celsius. And with a drop in temperature outside, the efficiency of the system will only decrease.

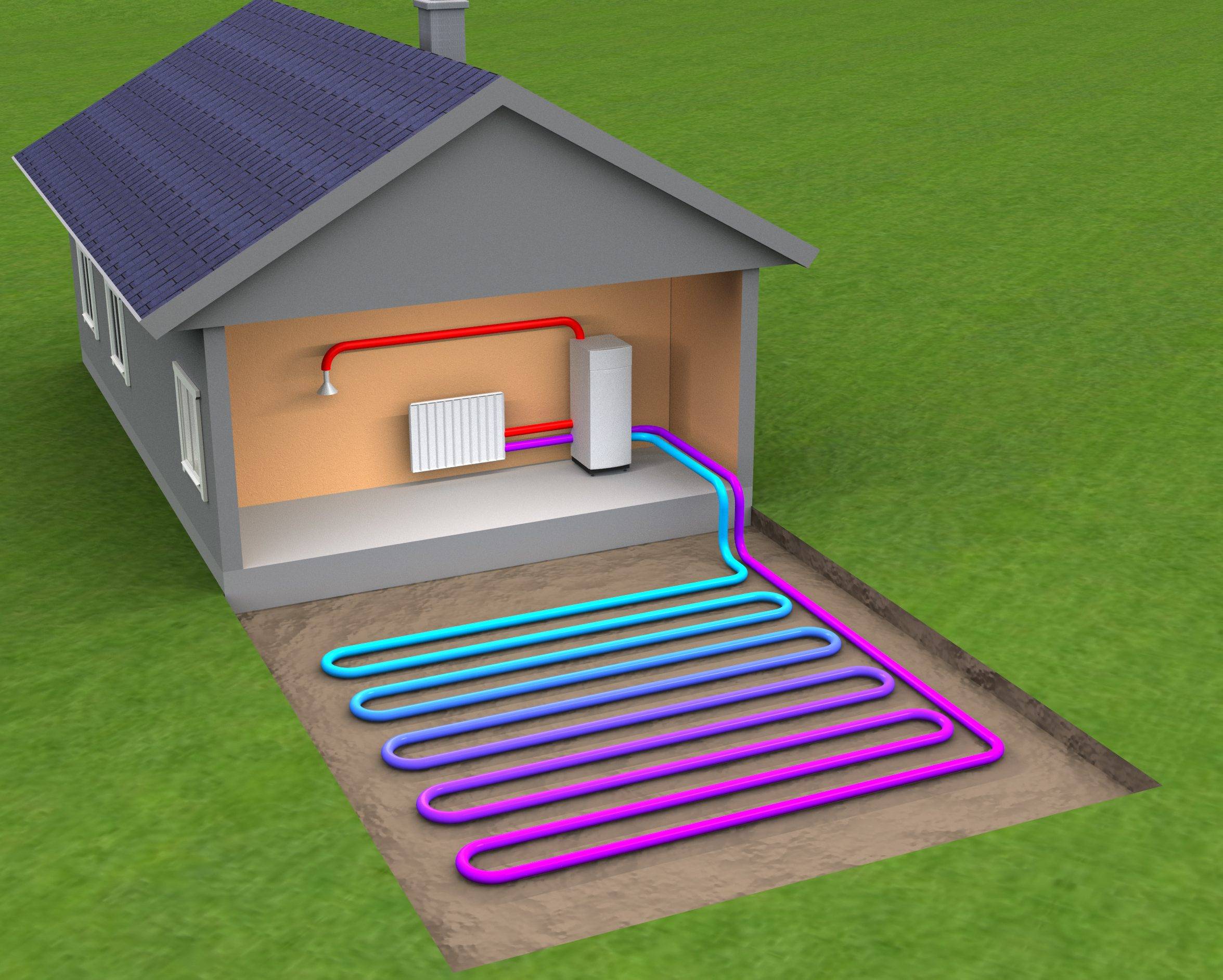

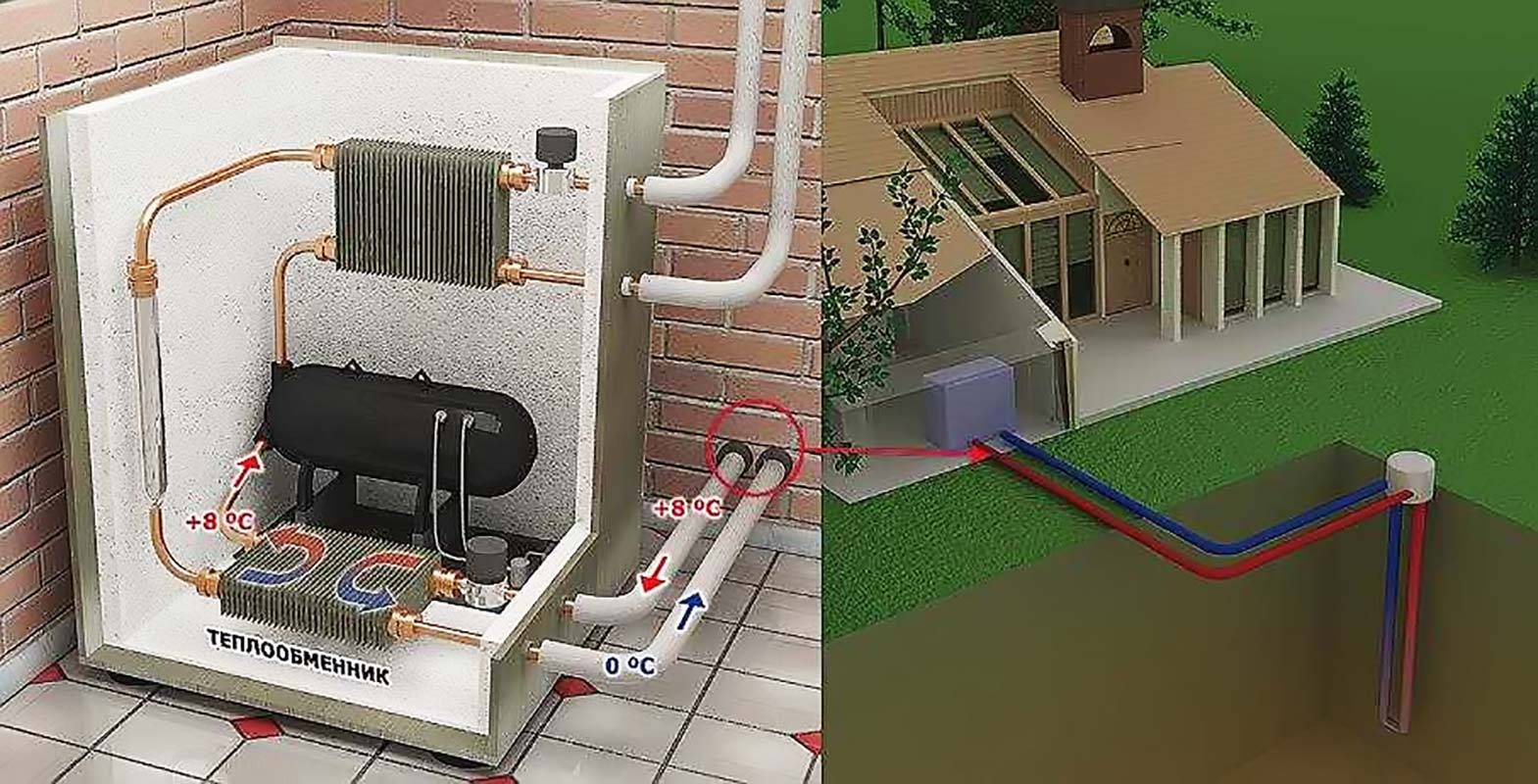

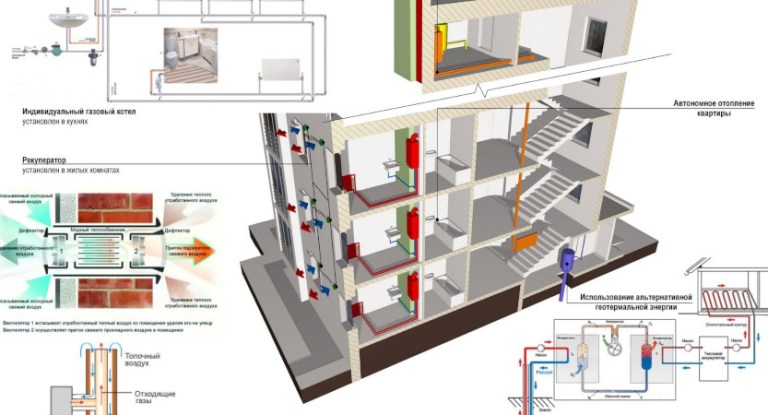

An alternative to such a system is a geothermal heat pump. So, if in winter the air cools down to a very low temperature regime, then below the freezing depth the earth is constantly warmed up to 8-12 degrees. A heat exchanger with a sufficient area is immersed in the ground - and you will have an almost endless resource of heat that needs to be pumped into your home.

The latest heating systems

An example of a fairly affordable and at the same time effective system, suitable for both a country house and an apartment, is an electric underfloor heating. Having incurred relatively small expenses for the installation of such heating, it is possible to provide a home with heat and not buy any boilers. The only drawback is the cost of electricity. But given that modern floor heating is quite economical, yes, if you have a multi-tariff meter, this option may be acceptable.

For reference.When installing an electric floor heating, 2 types of heaters are used: a thin polymer film with coated carbon elements or a heating cable.

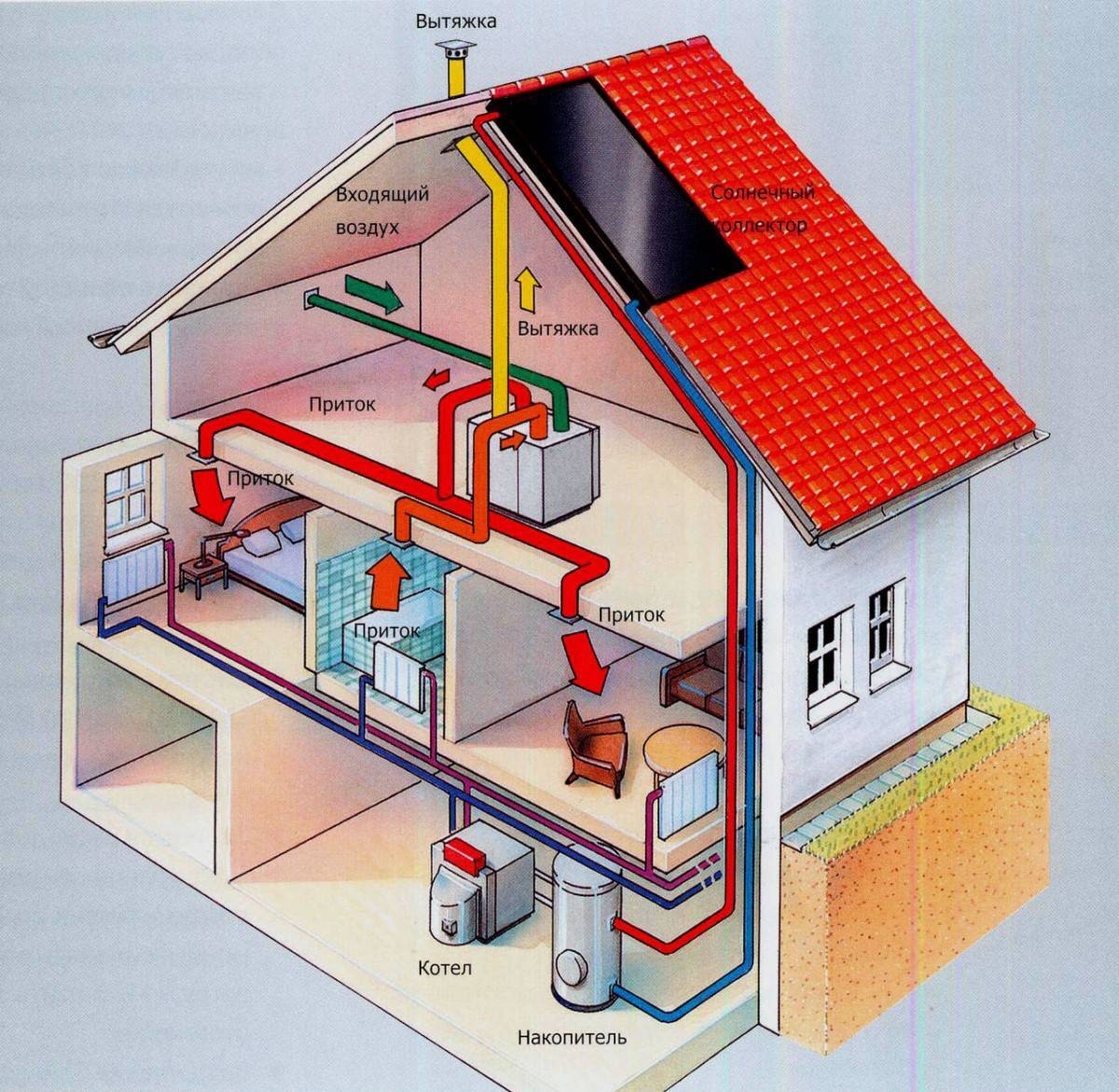

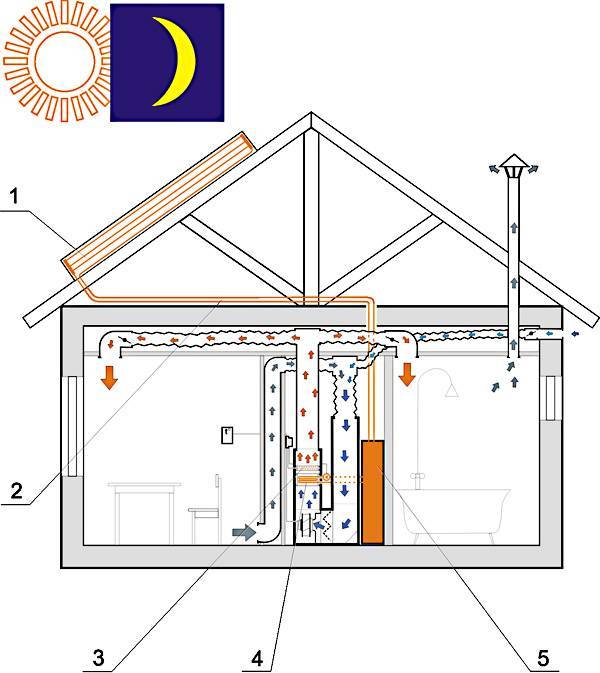

In the southern regions with high solar activity, another modern heating system performs well. These are water solar collectors installed on the roof of buildings or other open places. In them, with minimal losses, water is heated directly from the sun, after which it is fed into the house. One problem - the collectors are absolutely useless at night, as well as in the northern regions.

Various solar systems that take heat from the earth, water and air and transfer it to a private house are installations in which the most modern heating technologies are implemented. Consuming only 3-5 kW of electricity, these units are able to "pump" from the outside 5-10 times more heat, hence the name - heat pumps. Further, with the help of this thermal energy, you can heat the coolant or air - at your discretion.

An example of an air heat pump is a conventional air conditioner, the principle of operation is the same for them. Only the solar system equally well heats a country house in winter and cools in summer.

It is a well-known fact that the more efficient an innovation in a heating system is, the more expensive it is, although it requires lower operating costs. Conversely, high-tech electric heating systems that are cheap to install make us pay later for the electricity we use. Heat pumps are so expensive that they are not available to most citizens of the post-Soviet space.

The second reason why homeowners gravitate towards traditional systems is the direct dependence of modern heating equipment on the availability of electricity.For residents of remote areas, this fact plays a big role, because they prefer to build brick ovens and heat the house with wood.

The principle of operation and types of air heating

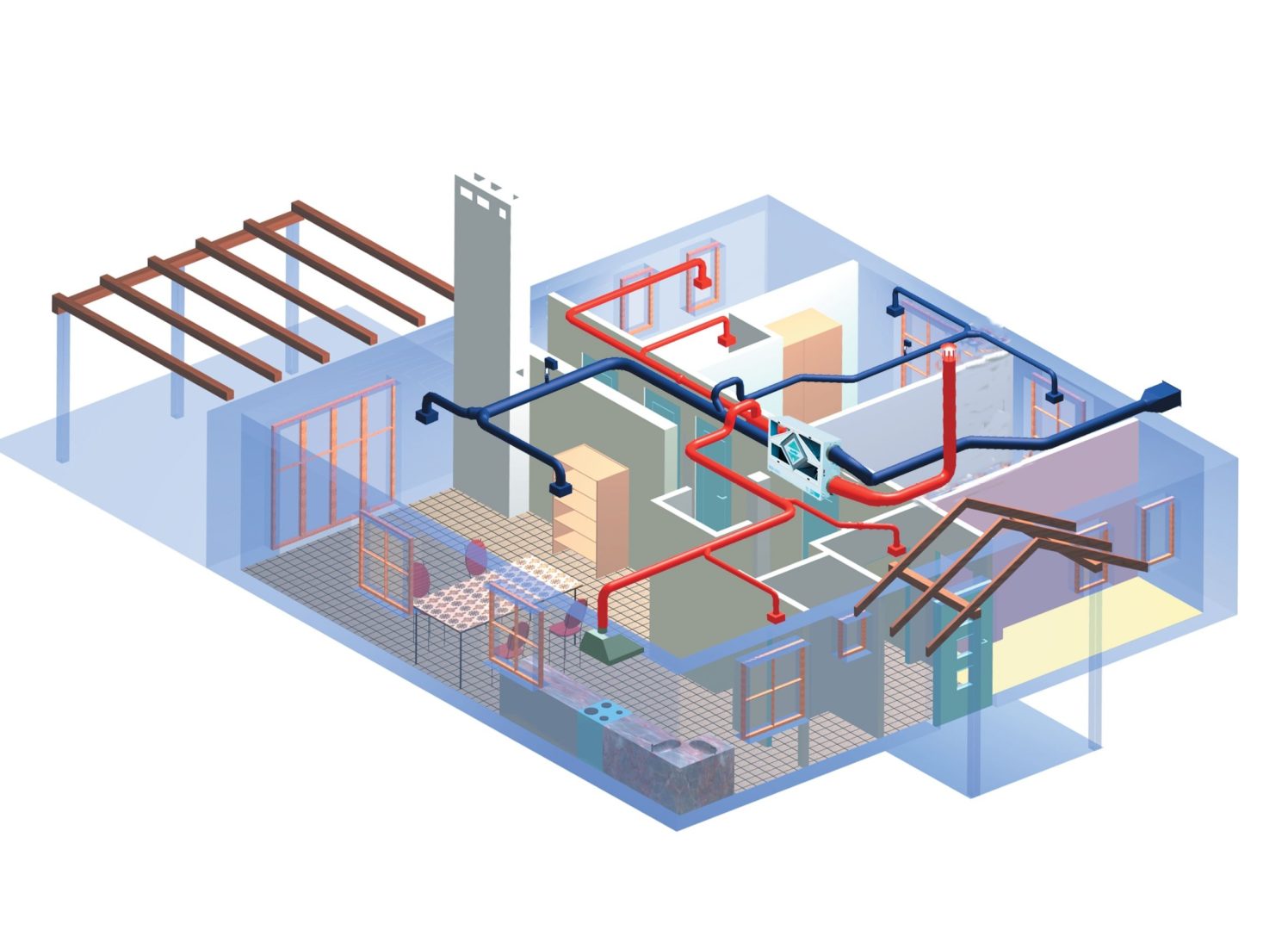

You need to know that there are two different types of air-type heating, each of which can be used in practice.

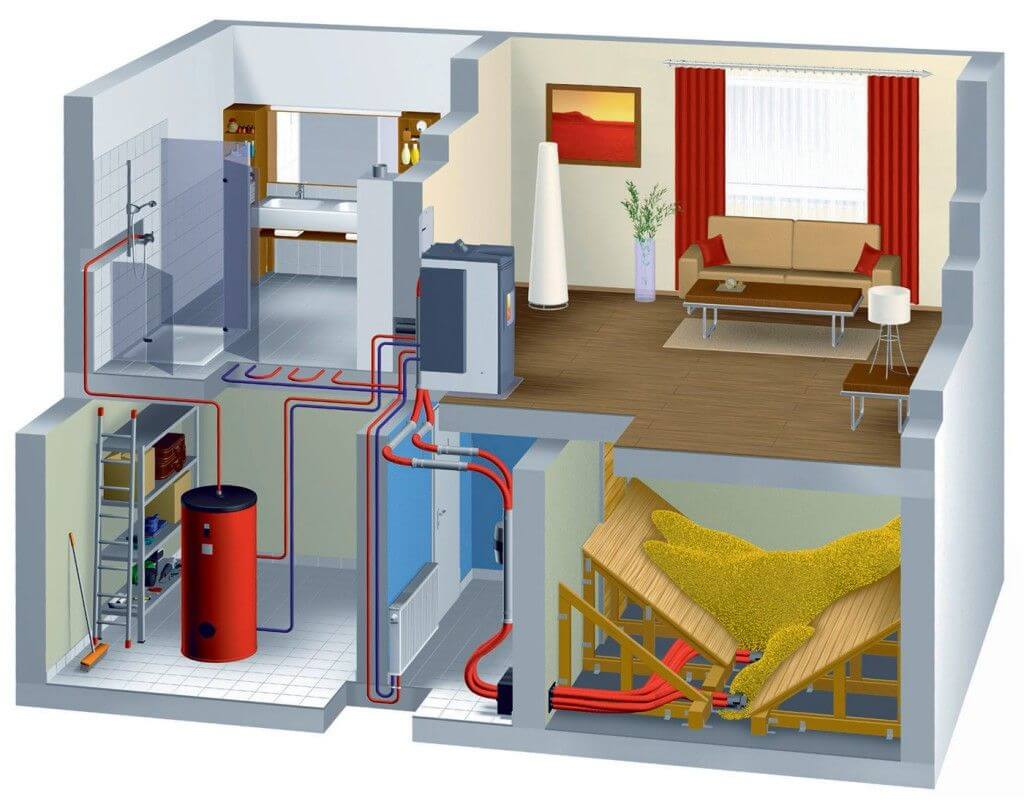

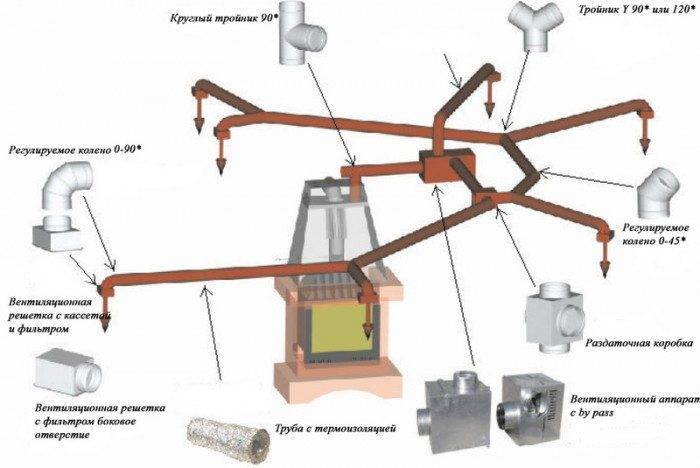

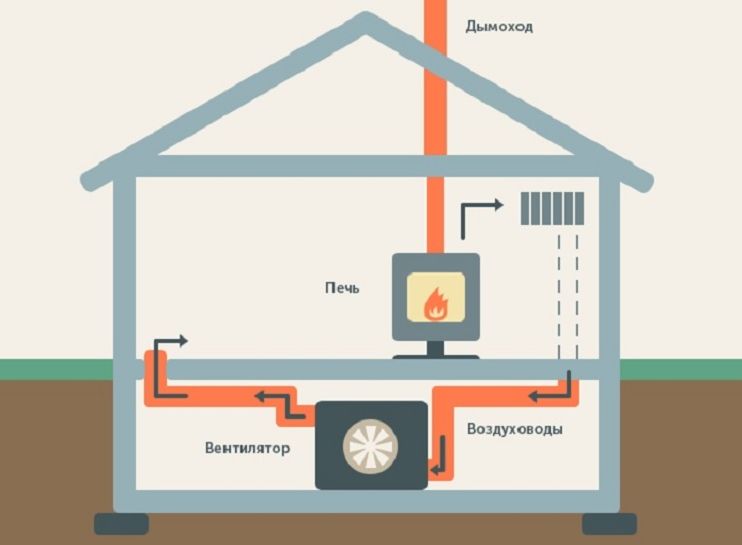

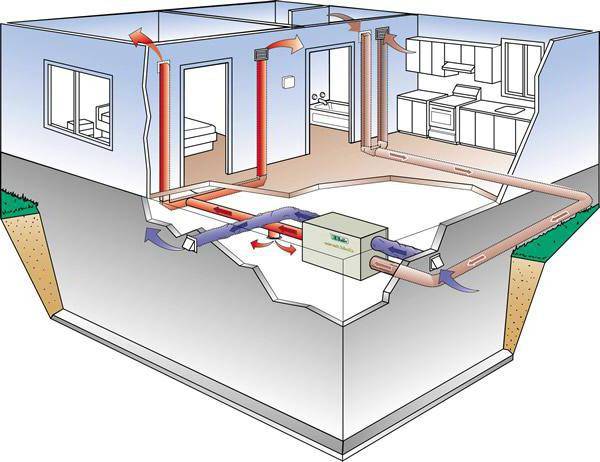

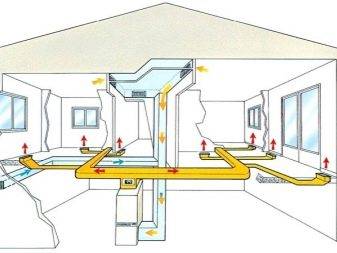

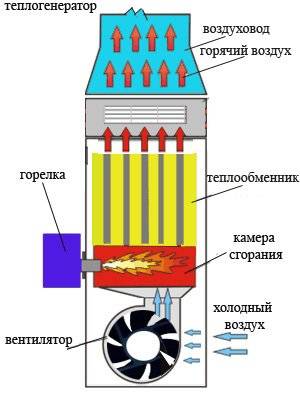

The first is implemented in systems with a heater. It is essentially similar to heating with a liquid heat carrier, with the difference that heated air is used instead of a liquid. The duct heater heats the air that moves through special pipes to heated rooms.

Air ducts filled with hot air heat the room. Such systems are little used today, since channels are inevitably damaged during operation. From the alternation of heating with cooling, the air ducts either expand or narrow, which weakens the joints, and cracks appear in the walls.

This leads to a violation of the air distribution process and, as a result, to uneven heating of the premises, which is undesirable. An open air heating system is considered more practical.

The air heating device has a lot in common with the traditional water type and less commonly used steam. The main difference is the absence of standard heating devices - radiators.

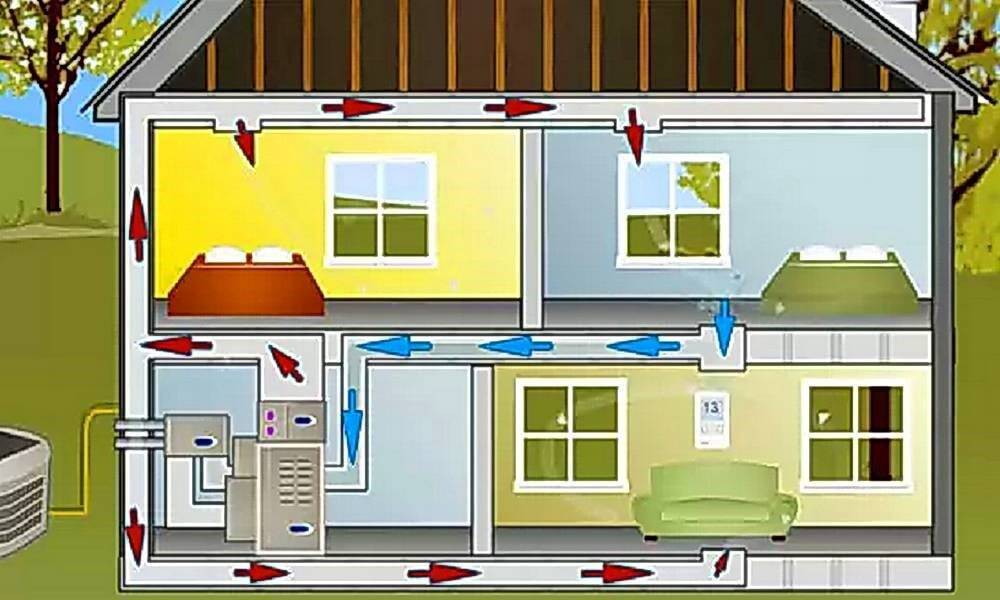

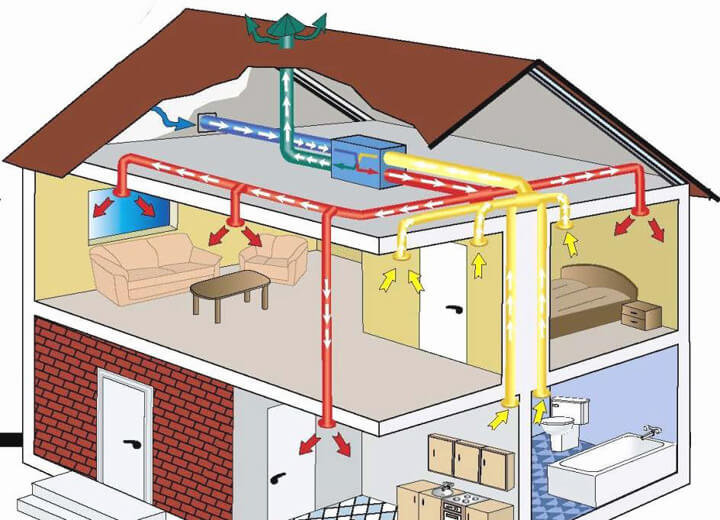

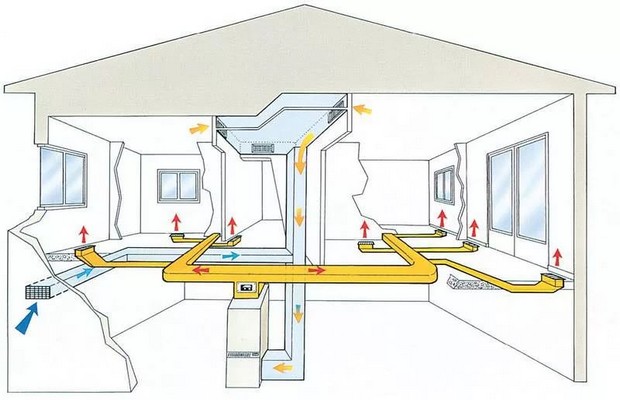

The principle of its operation is as follows. The heat generator heats the air, which is supplied through a pipe system to the heated rooms. Here it goes outside and mixes with the air present in the room, thereby raising the temperature in it.

The cooled air is sent down, where it enters special pipes and through them again enters the heat generator for heating.

The coolant of air heating systems belongs to the category of secondary, because. before that, it is heated by the primary coolant - steam or water (+)

The coolant of air heating systems belongs to the category of secondary, because. before that, it is heated by the primary coolant - steam or water (+)

According to the radius of action of the heating system with heated air, they are divided into local and central. The former include circuits designed to serve one object (cottage, room, two or more adjacent premises), the latter are apartment buildings, public and industrial facilities

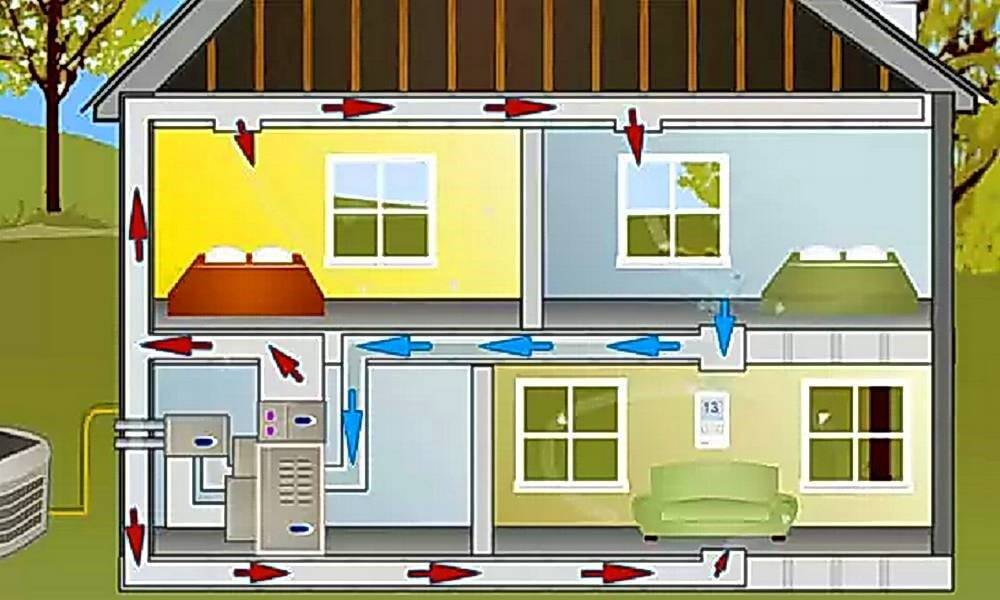

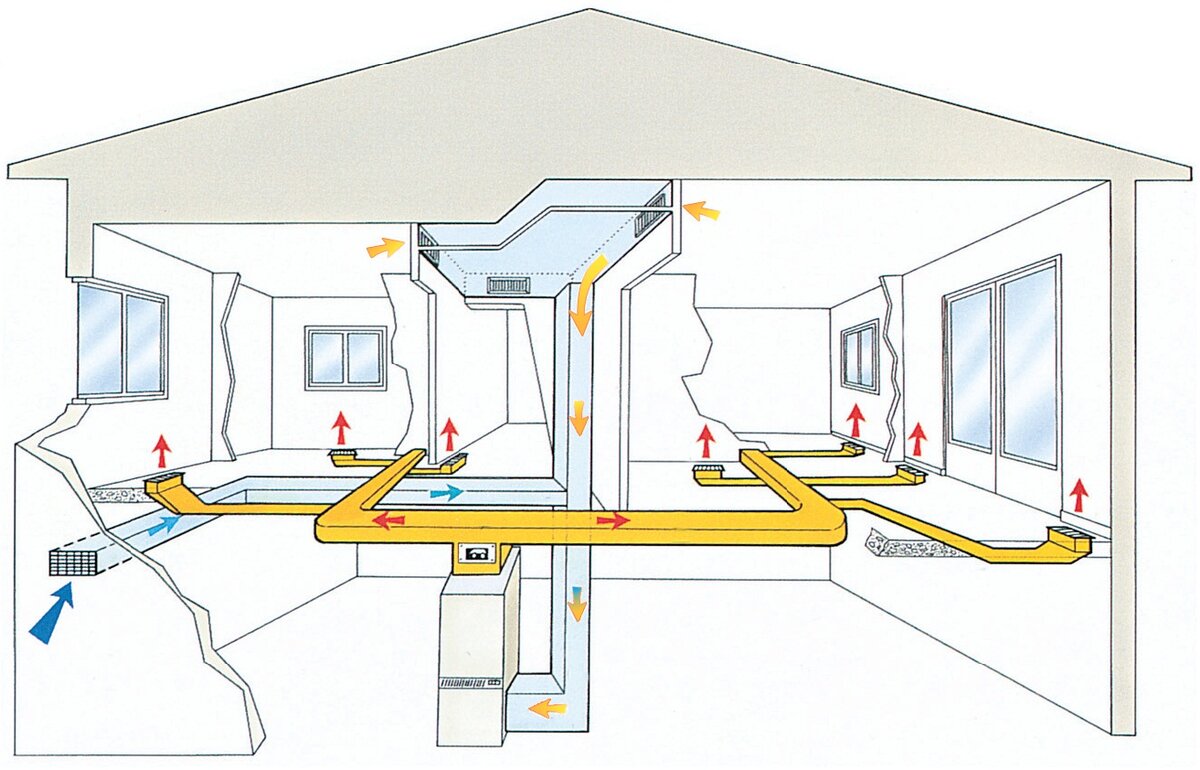

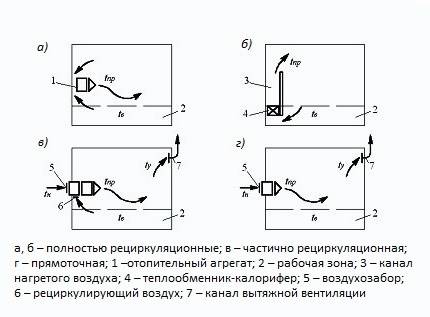

All systems are divided into schemes with complete recirculation of the coolant, with partial recirculation and direct-flow.

Local systems with complete air recirculation are ducted (a) and ductless (b). These are schemes with the natural movement of heated air. If heating is combined with ventilation, then other schemes (c, d) with partial recirculation are used. According to which part of the air is mixed with the air mass in the room without moving through the channels

All central systems belong to the category of direct-flow. For them, the air coolant is heated in the heating center of the building, and then delivered to the premises through air distributors. Central schemes are only channel.

Air once-through systems are too costly for the private sector. They are arranged where ventilation is being constructed that processes an air mass equal in volume to the air mass required for heating.

Central air heating is arranged in industries that produce or use in the manufacture of flammable, toxic, explosive, etc. substances.In the arrangement of country houses, this type is used if transportation of heated air over a long distance is required.

The organization of the scheme for private traders is impractical due to the need to use powerful ventilation equipment.

How it works?

The principle of operation of the air system is based on the use of a heat generator, in the heat exchanger of which the air is heated to optimal values of 50-60C. Then the hot streams are distributed through the duct and moved to the rooms, evenly heating them. The system also has in its design special openings in the form of gratings built into the walls or floor. Through them, the cooled air returns to the heat generator using air ducts. Thus, we can say that such a device acts simultaneously as a heating element, a fan and a heat exchanger.

Air systems often operate using a heat pump or gas burner, but sometimes the air is heated by hot water coming from central communications. The speed of heating rooms, as a rule, depends on their size. Therefore, the air flow can be from 1000 to 4000 m3 per hour, provided that the pressure in the system is at least 150 Pa. In order to minimize heat losses in large rooms, the device is supplemented with auxiliary thermal elements. In addition, it is recommended to install air ducts up to 30 m long, they shorten the path of air passage, maintaining its temperature.

The operational effect of the system is also increased by installing air conditioning units. Thanks to this scheme, in the cold season, the premises will warm up well, and in the summer - cool.This will maintain a constant microclimate that is favorable for living in the house.

1 Air heating at home - there are many advantages, but few disadvantages

Many modern heating systems have quite serious shortcomings. This forces property owners to look for more efficient heating options. In recent years, air systems have begun to gain considerable popularity, which equally heat both large premises (both residential and industrial or administrative), and very small houses with several rooms. This type of heating is characterized by the following advantages:

- 1. There is no need to spend money on the purchase of pipes and radiators, as well as on their installation.

- 2. The efficiency of air systems is approaching 90%.

- 3. The possibility of arranging, within the framework of one project, a combined complex for maintaining the required temperature in a private house (air conditioning plus heating).

- 4. Complete safety of equipment operation. The systems we are considering are equipped with highly sensitive automation. It is she who controls the operation of heating every second. As soon as there is any failure, there is a danger of leakage, the automation switches off the used air installations.

- 5. Low energy consumption, affordable cost and quick payback of installed heating equipment. Air heating for any private house will be truly profitable and economical.

- 6. Aesthetics. The dwelling does not need to be cluttered with radiators and highways connecting them. Due to this, all the free space in the rooms can be used to create chic interiors.

- 7. Easy operation.Starting the system, selecting the required mode of its operation, stopping the equipment and many other processes are carried out in automatic control mode. The probability of making a mistake on the part of a person when using air heating is reduced, in fact, to zero.

In addition, the described type of heating is durable and reliable. If the heating project is drawn up correctly, the installation is completed without errors, and regular maintenance is done on time, the network will last 20–25 years without the slightest accident. We also note the uniquely high rate of air heating. In cases where the temperature in the room was zero or negative, after starting the equipment, it takes a maximum of 30-40 minutes to fully warm up the room.

Air heating at home

The disadvantage of air heating is the need for fairly frequent (and necessarily regular) maintenance. Another disadvantage is the energy dependence of the described complexes. The equipment is powered by electricity. If there is no light in the house, the system will stop. There is only one way to solve this problem - to take care of installing an additional (autonomous) source of electrical power.

Steam heating

the boiler heats the water to the temperature when the water turns into steam.collective and direct.

Advantages of steam heating:

- inexpensive installation and compact dimensions

- no heat loss in heat exchangers

- high heat transfer

- steam, unlike water, does not freeze in pipes

- economy

Disadvantages of steam heating:

- steam gradually destroys the pipes

- it is impossible to smoothly regulate the temperature in the visit

- the surface of the radiators heats up to a high temperature, and if accidentally touched, you can get burned

Stages of preparation for the installation of steam heating:

1st stage: choose a steam boiler. Its power is similar to that of a water boiler. It also runs on natural gas, solid and liquid fuels.

2nd stage: choose the pipes through which the steam will flow. Steel pipes are good for everyone, but they have low anti-corrosion properties. Galvanized and stainless pipelines resist corrosion well, but are quite expensive. Copper pipes have the same drawback, but they are easy to embed in walls, they withstand high temperature and pressure well. Plastic pipes are dangerous to use because they cannot withstand pressure. The main condition, regardless of the pipe material, is to buy factory-made pipes. It is necessary to mount them among themselves in the building, and not on the street.

3rd stage: we make a diagram of the device of the future heating system. The total length of the pipeline with all branches, the material from which it will be made, instrumentation, safety and shutoff valves, the number of tees and transitions are taken into account. Again, all this can be done by employees of the company, where you will buy everything you need.

4th stage: install a steam boiler. The room where it will be placed must be at least 2.2 meters high. The distance from the wall to the boiler must be at least a meter. Walls should be made of brick or lined with fire-resistant tiles. The room must have a window and a ventilation system. The boiler is mounted below the level of the radiators. This will allow the steam to rise up, and the accumulated condensate will automatically drain back into the boiler.Together with the boiler, sensors, valves, fuses and other devices are installed.

5th stage: installation of radiators is carried out. They must be at least 7-knee. They can be attached to the wall with a drill, puncher and screwdrivers. Radiators are mounted in the heating system by means of a threaded connection or welding. Tightness is vital! Otherwise, the radiators will leak steam. Installation of pipes is carried out not earlier than the installation of radiators.

Features of direct-flow heating system

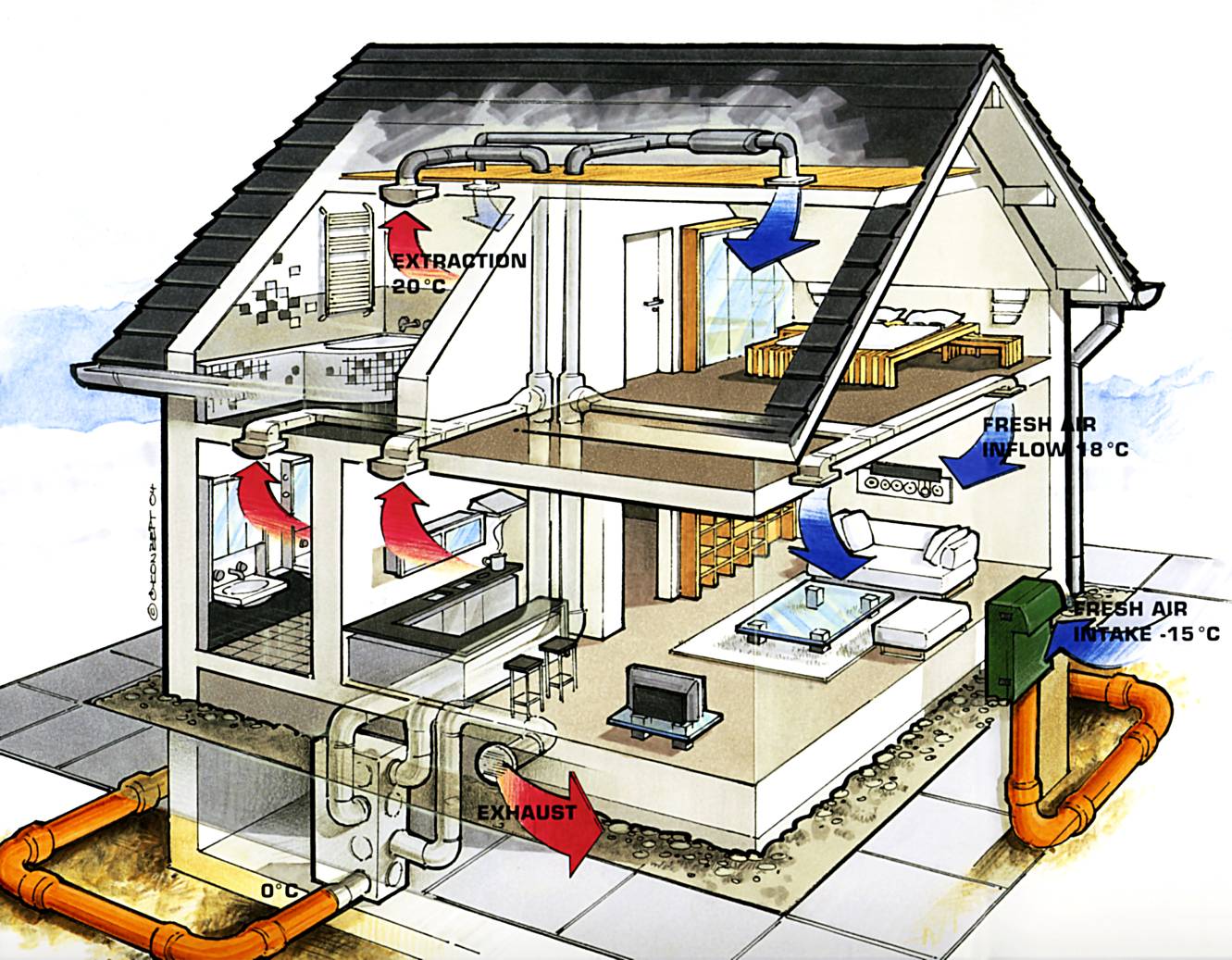

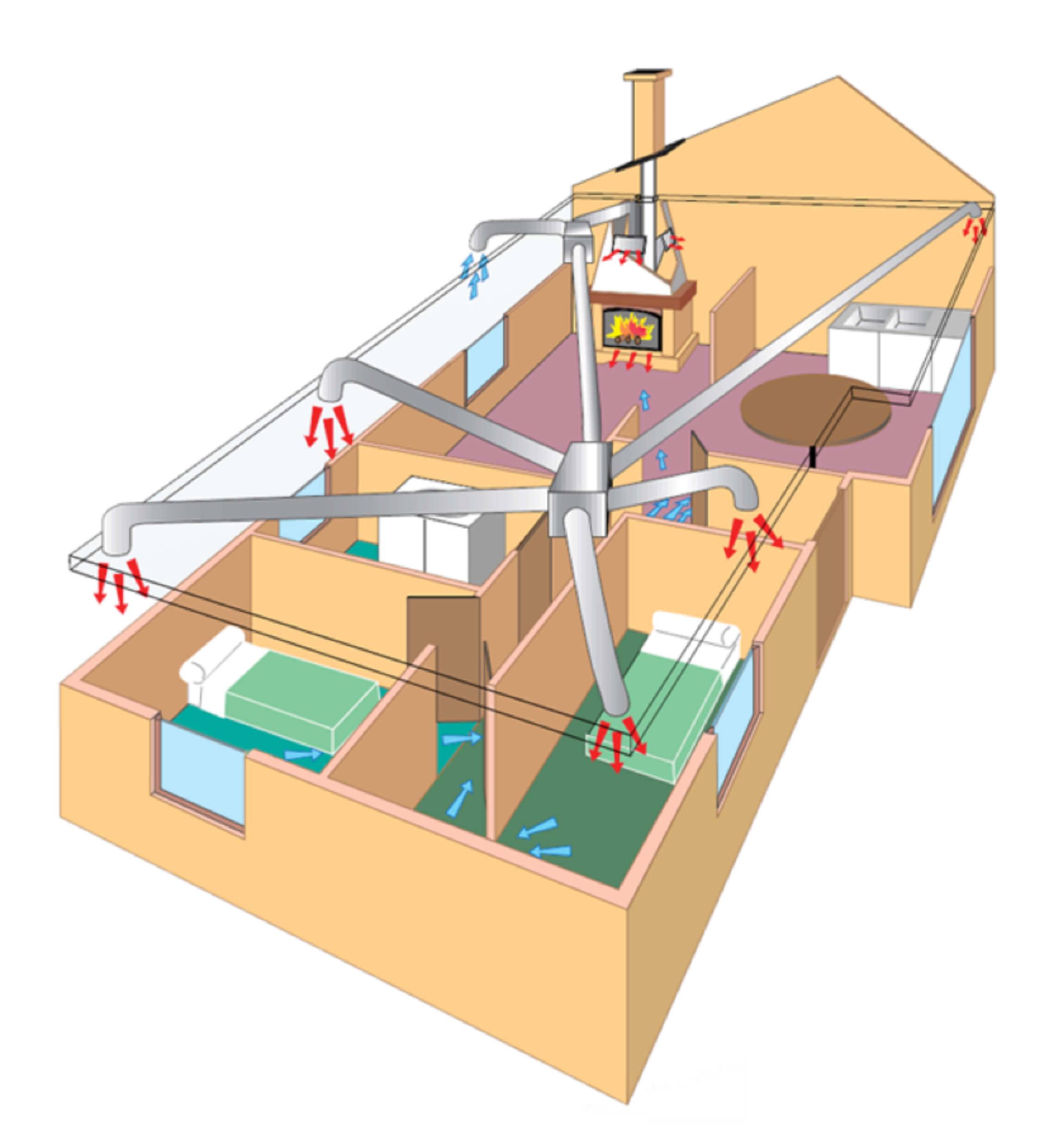

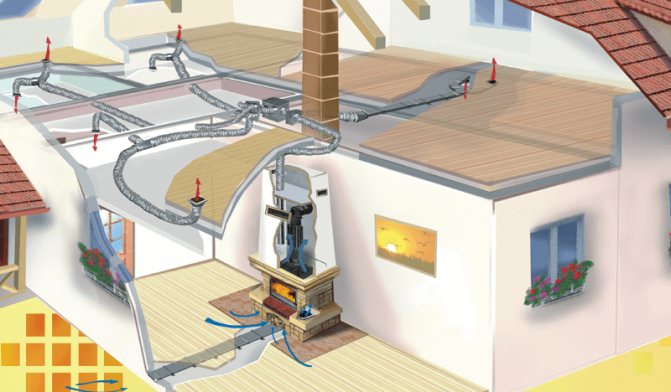

In a direct-flow system, air is taken from the street, heated by a heater and, after being distributed throughout the house, it is again removed to the street through the exhaust ducts. Such a scheme is good in that clean and fresh air constantly enters the premises, and pollution, unpleasant odors and excess humidity are irrevocably removed.

But along with them, a substantial part of the heat also flies out into the pipe, which leads to excessive fuel consumption. To get rid of this shortcoming, systems with recuperation are used, in which the heat of the air removed through the exhaust air in a special heat exchanger is transferred to the newly incoming fresh air.

How to connect a solid fuel boiler

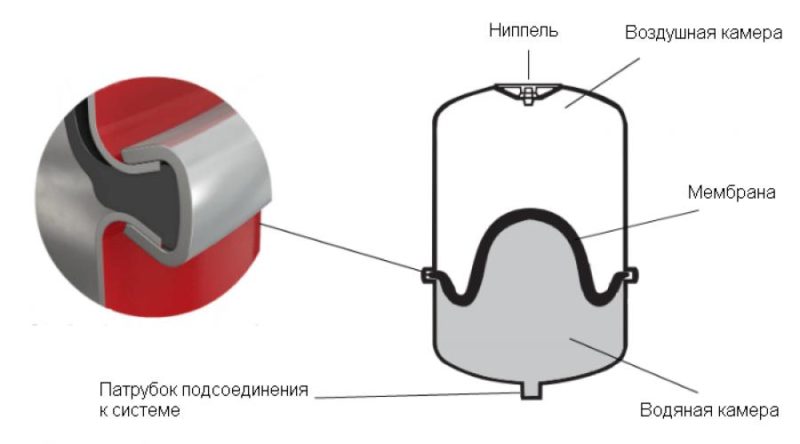

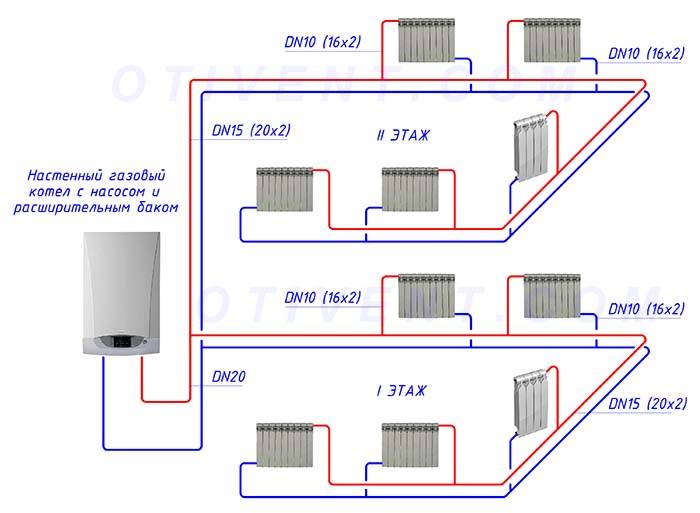

The canonical scheme for connecting a solid fuel boiler contains two main elements that allow it to function reliably in the heating system of a private house. This is a safety group and a mixing unit based on a three-way valve with a thermal head and a temperature sensor, shown in the figure:

Note. The expansion tank is conventionally not shown here, since it can be located in different places in different heating systems.

The presented diagram shows how to connect the unit correctly and should always accompany any solid fuel boiler, preferably even a pellet one. You can find various general heating schemes anywhere - with a heat accumulator, an indirect heating boiler or a hydraulic arrow, on which this unit is not shown, but it must be there. More about this in the video:

The task of the safety group, installed directly at the outlet of the solid fuel boiler inlet pipe, is to automatically relieve the pressure in the network when it rises above the set value (usually 3 bar). This is done by a safety valve, and in addition to it, the element is equipped with an automatic air vent and a pressure gauge. The first releases the air that appears in the coolant, the second serves to control pressure.

Attention! On the section of the pipeline between the safety group and the boiler, it is not allowed to install any shut-off valves

How the scheme works

The mixing unit, which protects the heat generator from condensate and temperature extremes, operates according to the following algorithm, starting from kindling:

- Firewood is just flaring up, the pump is on, the valve on the side of the heating system is closed. The coolant circulates in a small circle through the bypass.

- When the temperature in the return pipeline rises to 50-55 °C, where the remote-type overhead sensor is located, the thermal head, at its command, begins to press the three-way valve stem.

- The valve slowly opens and cold water gradually enters the boiler, mixing with hot water from the bypass.

- As all the radiators warm up, the overall temperature rises and then the valve closes the bypass completely, passing all the coolant through the unit heat exchanger.

This piping scheme is the simplest and most reliable, you can safely install it yourself and thus ensure the safe operation of the solid fuel boiler. Regarding this, there are a couple of recommendations, especially when tying a wood-burning heater in a private house with polypropylene or other polymer pipes:

- Make a section of the pipe from the boiler to the safety group from metal, and then lay plastic.

- Thick-walled polypropylene does not conduct heat well, which is why the overhead sensor will frankly lie, and the three-way valve will be late. For the unit to work correctly, the area between the pump and the heat generator, where the copper bulb stands, must also be metal.

Another point is the installation location of the circulation pump. It is best for him to stand where he is shown in the diagram - on the return line in front of the wood-burning boiler. In general, you can put the pump on the supply, but remember what was said above: in an emergency, steam may appear in the supply pipe. The pump cannot pump gases, therefore, if steam enters it, the circulation of the coolant will stop. This will accelerate the possible explosion of the boiler, because it will not be cooled by the water flowing from the return.

Way to reduce the cost of strapping

The condensate protection scheme can be reduced in cost by installing a three-way mixing valve of a simplified design that does not require the connection of an attached temperature sensor and a thermal head. A thermostatic element is already installed in it, set to a fixed mixture temperature of 55 or 60 ° C, as shown in the figure:

Special 3-way valve for solid fuel heating units HERZ-Teplomix

Note. Similar valves that maintain a fixed temperature of mixed water at the outlet and are designed for installation in the primary circuit of a solid fuel boiler are produced by many well-known brands - Herz Armaturen, Danfoss, Regulus and others.

The installation of such an element definitely allows you to save on piping a TT boiler. But at the same time, the possibility of changing the temperature of the coolant with the help of a thermal head is lost, and its deviation at the outlet can reach 1–2 °C. In most cases, these shortcomings are not significant.