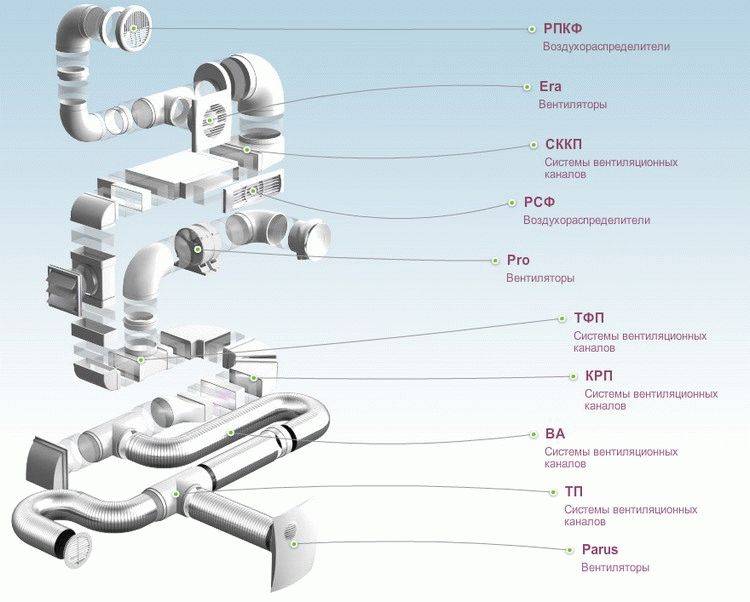

- The physical basis of the ventilation system

- Pros and cons, scope

- Where to use

- Advantages and disadvantages

- Tees and connectors

- Installation of the ventilation system

- Types of mechanical ventilation systems

- Comparison of round and rectangular section

- Implementation options for the ventilation system

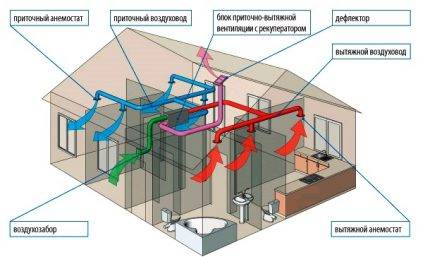

- General exchange ventilation

- Supply and exhaust ventilation with recuperation

- Air handling units

- Other Options

- Air exchange is the key to a healthy microclimate

- What are air ducts for?

- Plastic air ducts: what materials are made of

- Aerodynamic calculation of the duct

- The main types of air ducts and their characteristics

- Conclusions and useful video on the topic

The physical basis of the ventilation system

The supply and exhaust ventilation system is a multifunctional complex for ultra-fast processing of the gas-air mixture. Although this is a system of forced transportation of gas, it is based on quite understandable physical processes.

To create the effect of natural convection of air flows, heat sources are placed as low as possible, and exhaust elements in the ceiling or under it

The very word "ventilation" is closely related to the concept of convection. It is one of the key elements in the movement of air masses.

Convection is the phenomenon of circulation of thermal energy between cold and warm gas flows. Exists natural and forced convection.

A bit of school physics to understand the essence of what is happening. The temperature in the room is determined by the air temperature. Molecules are carriers of thermal energy.

Air is a multimolecular gas mixture that consists of nitrogen (78%), oxygen (21%) and other impurities (1%).

Being in a closed space (room), we have a temperature inhomogeneity relative to height. This is due to the heterogeneity of the concentration of molecules.

Given the uniformity of gas pressure in a closed space (room), according to the basic equation of molecular kinetic theory: the pressure is proportional to the product of the concentration of molecules and their average temperature.

If the pressure is the same everywhere, then the product of the concentration of molecules and the temperature in the upper part of the room will be equivalent to the same product of concentration and temperature:

p=nkT, ntop*Ttop=nbottom*Tbottom,ntop/nbottom=Tbottom/Ttop

The lower the temperature, the greater the concentration of molecules, and hence the greater the total mass of the gas. Therefore, they say that warm air is “lighter” and cold air is “heavier”.

Proper ventilation combined with the effect of convection are able to maintain the set temperature and humidity in the room during periods of automatic shutdown of the main heating

Proper ventilation combined with the effect of convection are able to maintain the set temperature and humidity in the room during periods of automatic shutdown of the main heating

In connection with the foregoing, the basic principle of arranging ventilation becomes clear: the air supply (inflow) is usually equipped from the bottom of the room, and the outlet (exhaust) is from above. This is an axiom that must be taken into account when designing a ventilation system.

Pros and cons, scope

Plastic air ducts are perceived negatively by many, as they are not sure that plastic does not emit harmful substances during operation. It may be that low-quality plastic is unsafe, but even in household appliances there are so many plastic parts that this consideration seems irrelevant. For example, in a kitchen hood with filters, most of the components are made of plastic. And here the most difficult operating conditions are elevated temperature, a large amount of fat, evaporation of chemically active substances.

Even the open laying of plastic pipes does not spoil the appearance

In general, experts recommend putting plastic on exhaust ventilation ducts. There are no restrictions here. But for the inflow - you need heat-resistant ones, made of special plastic. Especially if the inflow is heated or recuperated.

Where to use

Another reason for not recommending the use of plastic air ducts is problems with the fire department. There were cases that they did not sign permission to use gas equipment if the ventilation was made of plastic. But it was a frame house, and there the requirements are different. If in doubt, it is best to check with your local fire inspector. In general, there are recommendations in regulatory documents.

Extract from SNiP 41-01-2003

According to SNiP 41-01-2003 clause 7.11, plastic air ducts can be used in low-rise residential, public, administrative and residential and industrial buildings of category D. They cannot be laid in basements, undergrounds, attics and technical floors, in rooms with standardized fire safety conditions.

Advantages and disadvantages

Plastic air ducts have both adherents and opponents. Their main disadvantages:

- Flammability. Everything is clear here. Only metal air ducts do not spread fire. Although not all plastics burn and propagate flame, such “reduced” flammability materials are expensive. Therefore, plastic air ducts are allowed only in one-story houses.

-

The accumulation of static charge, which leads to the accumulation of dust (it can flare up again). In fact, much more dust accumulates in corrugated areas. To reduce its amount, it is necessary to install a plastic duct after the completion of "dusty" construction work and install filters that catch most of the dust. In addition, plastic ventilation pipes are treated with a special compound. It forms a film on the surface that prevents the accumulation of static charge.

- With poor workmanship, thin walls or a large cross section, gaps may form at the joints due to changes in geometry. This can be fixed, but there is such a drawback.

These are the disadvantages of using plastic air ducts. More than enough advantages:

- Easy installation. The presence of fittings and fittings allows you to create a system of any configuration. Plastic is easy to cut, weighs little.

- Due to ideally smooth walls, the air encounters less resistance.

- Easier to seal. For reliability, the joints can be smeared with sealant.

- Modern plastic air ducts are joined using butt locks without overlaps, which reduces resistance to air movement.

- Low noise level. With a capacity of up to 100 cubic meters / min, the air movement is almost silent.

-

Not subject to corrosion.

In general, a plastic duct is not the ideal solution, but the ease of installation and good performance outweigh the disadvantages. In general, experts recommend putting plastic on exhaust ventilation ducts. There are no restrictions here. But for the inflow - you need heat-resistant ones, made of special plastic. Especially if the inflow is heated or recuperated.

Also, when choosing, it is worth proceeding from the operating conditions. For example, it makes sense to use a plastic air duct for an exhaust ventilation duct from wet rooms, since galvanized ones are susceptible to corrosion, and stainless ones are very expensive.

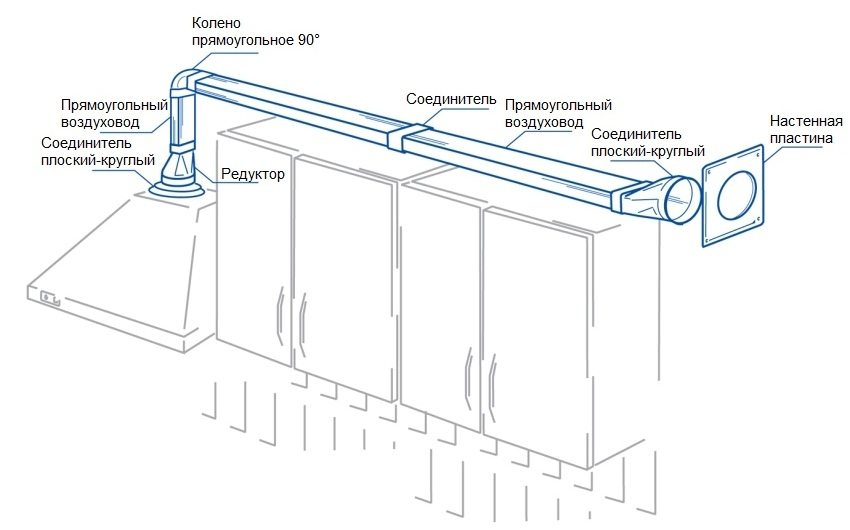

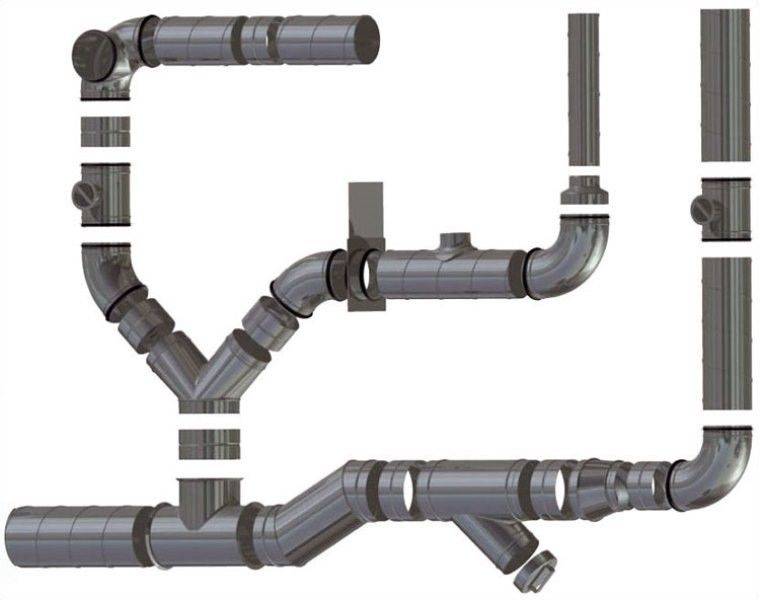

Tees and connectors

For the installation of plastic air ducts, a wide range of connecting elements is used. The assembly process is similar to working with a large-sized constructor. There are two main connection methods:

- For flange connection, special elements are used - flanges, which are attached to sections of the ventilation duct with the help of self-tapping screws or rivets. Sealing is achieved with rubber sealing elements.

- Wafer connection is provided by special couplings, where two elbows of a plastic pipe are simply inserted.

The connecting elements can have various shapes, depending on the sizes and configurations of pipes they must connect and on the functions they perform.

Here are the most common groups:

- Knees and bends. They are used in those areas where it is necessary to rotate the channel by 90 ° or 45 ° in a horizontal or vertical plane.

- Adapters.They help connect a rectangular box to a round pipe or vice versa.

- Confusers. They are placed when you need to connect a wide pipe with a narrower one.

- Diffusers connect a small section box with a larger one.

- Tees and crosses. They are used in those places where it is necessary to branch from the duct or vice versa, to reduce two channels into one.

Thanks to this variety, even an unskilled installer can easily assemble a ventilation duct of the desired configuration.

How to connect metal-plastic pipes correctly read: here

Installation of the ventilation system

When installing ventilation systems, the following are taken into account: the area of \u200b\u200bthe room, the number of people, the thickness of walls and partitions, excess heat (warm floor, computer, radiators), the presence of double-glazed windows, the sunny side.

Installation of the ventilation system is best done at the construction stage. Entrance openings are made under the ceilings, the channel is laid up to 0.5 m to the roof ridge. The optimal channel width is 2.5 bricks.

The cross sections of air ducts in the ventilation of premises are calculated in accordance with the current SNiPs. Average cross-sectional dimensions of residential air ducts for apartments, houses per 1 sq.m. – 5.4 sq.m. section, utility rooms - 18 sq.m.

Ventilation controllers are installed for forced ventilation in attic rooms or basements. Also, the controllers of the ventilation system can be connected to dispatching, the "smart home" system.

Lattices are mounted outdoors or indoors. Diffusers with multidirectional cell blades, nozzles and fans are installed in bathrooms, kitchens, and in smoke exhaust systems.

Ventilation is brought out with the help of gratings on a plasterboard or cassette ceiling, walls; on the floor in the form of strips.

Installation of ventilation video:

Types of mechanical ventilation systems

Before engaging in the construction of an artificial air exchange system, it is important to familiarize yourself with the main types of ventilation and their application for specific premises. Depending on the purpose, the following types of ventilation systems are distinguished:

Depending on the purpose, the following types of ventilation systems are distinguished:

- Supply. Provides a forced flow of outdoor air into the room, while the incoming air masses can not only be heated or cooled, but also cleaned of micro-pollution.

- Exhaust. It is intended for fast and effective removal of the polluted air from the room. Such exhaust ventilation is often installed in the ceiling of the bathroom or kitchen, where the highest concentration of odors and moisture is observed.

- Supply and exhaust. Combined ventilation, providing simultaneous air inflow and outflow by artificial means. The most efficient are units with a heat exchanger, which allow to utilize the heat of the exhaust air and give it to the incoming flow.

If the first two systems are installed only in specific rooms (kitchen, toilet), then supply and exhaust ventilation is intended to serve all rooms in an apartment or house.

Installation of supply and exhaust ventilation in a private house allows you to minimize the costs of operating the units, because, in addition to ventilation, the system performs the functions of a heater, air conditioner and air cleaner

Each system has its own features of installation and operation, which should be carefully studied before drafting the ventilation of a room or building.

For example, it makes no sense to install a supply and exhaust system in a small apartment with one room, if you can choose a budget option - forced ventilation.

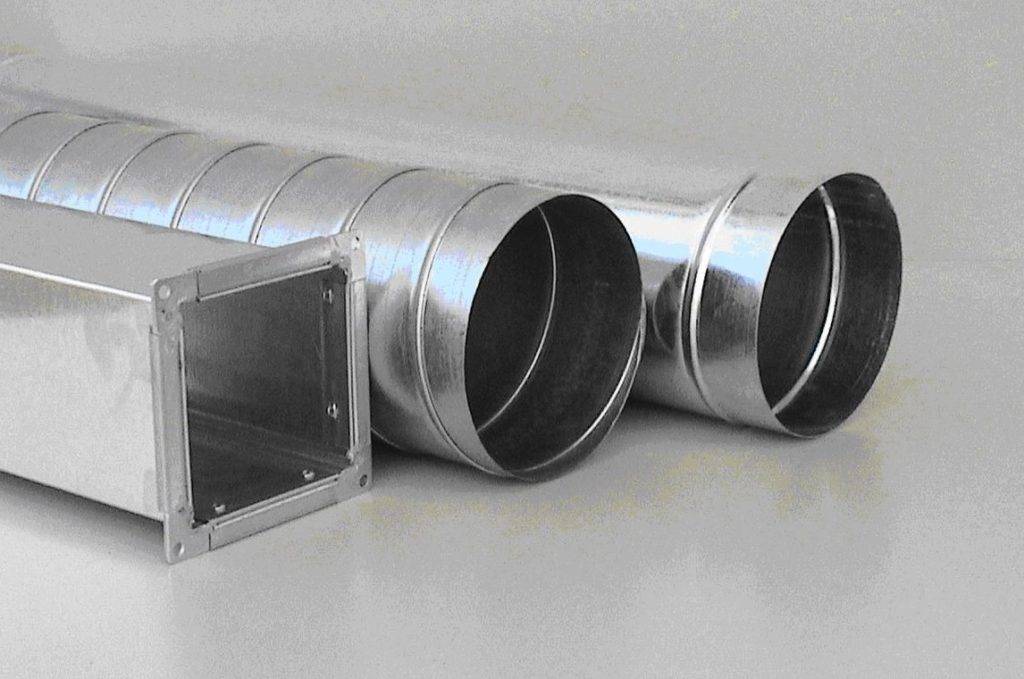

Comparison of round and rectangular section

Many people wonder what shape of pipe to choose: round or rectangular? If we evaluate the throughput, round products win - the air masses meet less resistance, which means that the circulation is faster.

In rectangular pipes, the corners remain unused, therefore reinforcement with an increased cross-sectional area is selected. However, such a line takes up less space - wide and flat models are easier to hide behind a false ceiling or above cabinets.

Oval pipe combines the strengths of rectangular and round ducts: good throughput and the ability to "hide" the ventilation system

Also, the cross section is an important parameter that is used when calculating the area of the air ducts necessary for arranging the ventilation system. Correctly performed calculations will allow you to purchase the required amount of material without overpaying for extra pipes.

Implementation options for the ventilation system

The implementation of high-quality ventilation and air conditioning systems in public spaces is a guarantee of comfort and well-being of people. There are several basic technical solutions for these engineering systems.

General exchange ventilation

The exhaust part of the ventilation system is needed to eliminate polluted air, excess moisture and heat from the room.

Its correct operation depends on a constant supply of air.For this, forced ventilation is needed, supplying fresh air from outside the room.

Within one floor, the air ducts are bred along the ceiling, later, when the system is fully assembled, they can be hidden behind the false ceiling

Within one floor, the air ducts are bred along the ceiling, later, when the system is fully assembled, they can be hidden behind the false ceiling

Type-setting exhaust ventilation consists of: an external grille, a fan, an automation unit, air ducts, exhaust hoods (kitchens, laboratories), an internal grille or exhaust diffusers.

For forced ventilation the following components are needed: an external grille, a filter, an air heater, a silencer, humidity, temperature, frost sensors, a fan, air ducts, internal wall or ceiling grilles, supply diffusers.

This type of ventilation is used most often in public buildings. Several branches of general ventilation are mounted in the building, which do not communicate with each other.

The advantage of stacked ventilation is separate air purification in different rooms, the ability to adjust the power of the air flow in each office. But such an engineering solution also has a number of disadvantages. The main one is bulkiness. In buildings where it is not possible to hide the air ducts behind a false ceiling, there are problems with the aesthetics of this design.

In the case when the ventilation is interfloor, vertical air ducts are mounted by building up from above or building up from below.

In cases where the installation of a false ceiling is not possible, the air ducts cannot be hidden behind it. The ventilation system is laid in an open way, the air ducts are decorated in accordance with the interior of the establishment

In cases where the installation of a false ceiling is not possible, the air ducts cannot be hidden behind it. The ventilation system is laid in an open way, the air ducts are decorated in accordance with the interior of the establishment

Some bars and restaurants use air ducts as part of their decor. In this case, stainless air ducts are usually used.In general, neatly mounted ventilation fits into the interior of the establishment.

To suppress noise, the air ducts are covered with insulating material, which effectively prevents the propagation of sounds between individual rooms and practically reduces the air noise in the air ducts themselves.

Such a ventilation system is suitable for buildings with a large number of separate rooms.

Supply and exhaust ventilation with recuperation

This ventilation system differs from the previous version by the presence of a heat exchanger - a surface-type heat exchanger. It is installed at the intersection of the supply and exhaust branches of ventilation.

The air removed from the room leaves heat on the heat exchanger plates. The air that enters through the supply system is heated by its ceramic plates.

The recuperator in the ventilation system heats fresh air to a comfortable temperature. This energy-efficient fixture allows you to save about 20-30% of heat

The recuperator in the ventilation system heats fresh air to a comfortable temperature. This energy-efficient fixture allows you to save about 20-30% of heat

Non-return valves in the heat exchanger housing prevent air from escaping between the ventilation branches.

Recuperation allows you to significantly save on heating. This advantage of the heat exchanger is especially noticeable in a large room: a conference room, a cinema, an assembly hall.

Air handling units

The use of an air handling unit discourages many building owners due to the high price of the unit itself. It is an all-in-one device - the main elements are placed in the case.

Some models are equipped with an air cooler.Unfortunately, it is difficult to use it for conditioning a large number of cabinets for various purposes. This is due to the inability to set an individual temperature regime for each individual room.

The use of ventilation units will eliminate noise and unnecessary hassle with the arrangement of ventilation and guarantee a minimum of hassle with the maintenance of the ventilation system

The use of ventilation units will eliminate noise and unnecessary hassle with the arrangement of ventilation and guarantee a minimum of hassle with the maintenance of the ventilation system

Air handling units - the easiest option organization of the ventilation system. A fairly compact device does not take up much space in the ventilation chamber.

Due to the fact that the fans are located inside a well-insulated housing, the noise level from the air handling unit is lower. Maintenance of installations is much cheaper than stacked systems. Their disadvantage is the need to install additional ventilation equipment in bathrooms, smoking rooms, and server rooms.

Other Options

Another important parameter is the stiffness of the duct walls. Three groups can be distinguished here:

- Rigid ducts. This is the vast majority of products in this market niche at present. They are available in both round and rectangular sections. External insulation for this type is most often mineral wool.

- Flexible ventilation. These are corrugated designs of their PVC polymer. The main advantage is light weight and the ability to give the ventilation line almost any shape. However, there are some drawbacks: this is one of the noisiest options, and in addition, the relief surface of the sleeve reduces the air flow rate.

- Semi-rigid structures are an intermediate link between the first two types.It has sufficient strength and relatively low weight. The disadvantage is the reduced air flow rate, which makes semi-rigid ducts unsuitable for use in branched networks.

There is no need to dwell on only one type of air duct when designing a ventilation system. It is possible to combine elements of different stiffness, based on the specifics of the place where each section is laid.

Air exchange is the key to a healthy microclimate

For normal operation of the apartment, a single air exchange per hour is sufficient. Compliance with this norm is ensured by laying natural ventilation ducts.

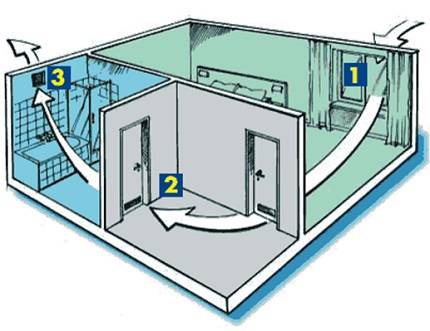

The supply of fresh air during unorganized air exchange is carried out through leaks in window frames, slotted openings in door structures, vents and vapor-permeable wall material.

After the installation of sealed double-glazed windows, the ventilation scheme fails - the air supply channel to the apartment is blocked, the pressure difference is reduced and the exhaust vapors stagnate in the room.

Scheme of natural circulation: 1 - air inflow through the slots of window frames, 2 - movement of the air flow through the gaps of the threshold, 3 - removal of exhaust air through ventilation ducts. Natural circulation is based on the difference in temperature and pressure inside and outside the building

- Deterioration of air quality composition. At home, there is a lack of oxygen, due to an excess of carbon dioxide, the air becomes stale. "Heavy" atmosphere causes discomfort, headaches and fatigue.

- Stagnation of unpleasant odors. In a "canned" apartment, the aromas that accompany a person's life are retained for a long time.Exhaust appliances in the kitchen or in the bathroom cease to function fully.

- High humidity. A clear sign of a problem is condensation on the windows and wet corners on the walls. Subsequently, black dots can be found on the surfaces - the first manifestations of mold. In such conditions, the decoration of the room is saturated with moisture and gradually collapses.

If you do not take care of the unhindered and regular supply of street air in time, then the likelihood of allergic and viral diseases increases.

The unrenewable musty atmosphere stimulates the development of pathogenic fungi, parasitic mites and bacteria. Older people and small children react very quickly to air deterioration.

Restoring the intensity of air flow solves these problems.

Regardless of the chosen method of organizing supply ventilation, it is necessary to ensure the following air exchange standards per resident:

- bedroom, children's room and living room - 30 cubic meters / h;

- kitchen - 60-90 cubic meters / h;

- bathroom - 25-50 cubic meters / h.

The air supply requirements for the kitchen depend on the type of stove installed. The exact norms for the bathroom are determined based on the joint or separate use of the toilet and bathroom.

The parameters are relevant if the maximum concentration of harmful components in the atmosphere does not exceed the established normative indicators for settlements

If the room is not used for permanent housing, then the minimum air exchange rate for residential and non-residential rooms is reduced by 0.2 h-1 and 0.5 h-1, respectively.

Full information on performing calculations for the device and modernization of ventilation is given in this article.We encourage you to read the helpful information.

What are air ducts for?

The term "air ducts" means specially made channels for ventilation, thanks to which air masses are supplied in a certain direction. Through such devices, oxygen enters the living or industrial premises, CO is removed2 and other pollution.

In such systems, it is usually possible to adjust the intensity of the flow of air masses and their pressure using valves.

Various types of devices designed for air circulation are successfully used in residential buildings, in industrial spaces, as well as in public buildings.

There are two ways to solve the problem of air circulation:

- Option number 1. In this case, they are limited to natural or forced ventilation, providing one exhaust duct to remove used air. The arrival of a new one is carried out through technological openings and / or doors, windows.

- Option number 2. A more complex and efficient design is considered to be a supply and exhaust system, which involves laying two channels located separately from each other. Fresh air flows through one of them, and used air is removed from the other.

Often, in one ventilation communication, several types of air ducts are used, which make up a complex network with various branches, shafts, sleeves.

Plastic air ducts: what materials are made of

The word "plastic" hides a whole group of materials with different properties and performance characteristics.Ventilation ducts are made from the following plastics:

- PVC (polyvinyl chloride). It has a wide operating temperature range from -30°С to +70°С. PVC air ducts can be installed in unheated rooms.

-

PVDF (fluoroplastic). acid-resistant material with a wide temperature range - from -40°С to +140°С.

- PP (polypropylene). Differs in the increased resistance to chemical influences (transfers acids, alkalis, organic chemistry).

- HDPE (low pressure polyethylene). This material is characterized by increased flexibility, it is more difficult to damage it mechanically, but does not tolerate low temperatures.

When choosing plastic air ducts, you should focus on the characteristics of plastics. For example, for connecting a kitchen hood it is better to use polypropylene ducts. If the exhaust air temperature is high, PVC or PVDF ducts are suitable. Polyethylene boxes are quite suitable for distributing ventilation in residential and other technical premises.

Aerodynamic calculation of the duct

To determine the size of the duct in the section, you need a draft version of the air network. First, calculate the cross-sectional area.

For a round pipe, the diameter is found from the formula:

D = √4S/π

If the section is rectangular, its area is found by multiplying the length of the side by the width: S \u003d A x B.

Having calculated the cross section and applying the formula S = L / 3600V, they find the volume of air replacement L in mᶾ / h.

Air velocity in the duct in the area of the supply grill, it is recommended to take in the range from 2 to 2.5 m / s for offices and housing and from 2.5 to 6 m / s in production.

In the main air ducts - from 3.5 to 6 in the first case, from 3.5 to 5 - in the second and from 6 to 11 m / s - in the third.If the speed exceeds these figures, the noise level will increase above the standard value. Coefficient 3600 coordinates seconds and hours.

Using tabular values will simplify the calculation process. Sometimes, in order to reduce noise in the system, pipes with a cross section that exceeds the calculated value are used. From an economic point of view, such a decision is irrational. Volumetric channels cost more and steal space

From the table, based on air flow rate, you can take the approximate flow of air mass.

You may also find detailed information on calculating the area of ducts with calculation examples discussed in our other article useful.

The main types of air ducts and their characteristics

The rules for the installation of ventilation ducts, depending on the design features of the building, provide for the use of various types of ducts, which are classified according to different types of bases.

By design:

- built-in air ducts (ventilation shafts);

- external air ducts.

Built-in ventilation shafts are arranged inside the brick or concrete walls of the house. The main condition for their normal operation is a smooth inner surface of the channel, on which there are no influxes of the solution and other obstacles for the free circulation of air. A technological opening is provided in the lower part of the shaft, with the help of which the ventilation ducts are periodically cleaned.

External air ducts are made in the form of attached and / or hanging boxes, assembled from pipes and fittings of various shapes and sizes.The choice of a specific type of such air ducts depends on the design features of the building and the overall design of individual rooms.

According to the material of manufacture:

- metal air ducts made of galvanized or stainless steel, as well as of various aluminum alloys;

- plastic pipes made of high-tech polypropylene;

- flexible air ducts made of polymer materials or corrugated aluminum-polymer sheet with steel wire reinforcement.

Metal air ducts for ventilation have the greatest strength and fire resistance, sufficiently high anti-corrosion, ease of installation and durability of use.

At the same time, pipes made of stainless steel and aluminum alloys are relatively expensive, so the most popular among consumers belongs to more practical and cheap air ducts made of galvanized steel.

Plastic air ducts are made of polypropylene, which is highly durable and environmentally friendly. Their main advantages are: low weight and cost, high anti-corrosion properties, wear resistance and tightness, ease of installation and repair, long service life. The main disadvantage is low resistance to mechanical shock loads and high temperatures.

Flexible air ducts are used in ventilation systems in conjunction with conventional rigid air pipes and their fittings. They have a significant aerodynamic resistance to the movement of air flow and increased noise during operation compared to conventional smooth pipes.

According to the shape of the internal section channel:

- round;

- rectangular.

Circular air ducts are most widely used in the construction of various types of ventilation systems, as they have the lowest aerodynamic air resistance, convenience and practicality in manufacturing and installation. Docking of pipes and their fittings is carried out using nipple connections or external couplings, which ensure high tightness of the air ducts.

Rectangular air ducts are able to harmoniously and conveniently fit into the interior of almost any room, especially with a low ceiling height. However, they have worse aerodynamic properties and are more labor intensive when manufacturing and installation compared to round pipes. The pipes are connected to each other and to the fittings of the system using flanges, latches, mounting brackets and rails.

The modern range of products offered by manufacturers allows you to choose any air ducts for ventilation, the price of which depends on the material of manufacture and overall dimensions.

Conclusions and useful video on the topic

The video tells and demonstrates the features of the design and installation of PVV in a private house:

Another illustrative example of a ready-made ventilation solution for a private 1-storey wooden house:

p> Summarizing the above information, we note that supply and exhaust ventilation is easy to design, available for purchase and installation system.

Ventilation in conjunction with the heating system allows you to organize the balance of fresh and warm air in the room.

Have you been doing ventilation in your country house? Or do you know the secrets of designing and installing a ventilation system in an apartment? Please share your experience - leave your comments on this article.