- Production casing replacement

- Important information about the well filter

- Possible breakdowns and their causes

- Harbingers of well failure

- How to determine the cause of a breakdown

- 2.3 Iron removal by ion exchange (iron up to 20 mg/l and in combination with manganese, hardness and organic matter)

- Causes of water well failures

- Limestone wells and artesian wells

- sand wells

- The subtleties of the diagnosis

- Well flushing techniques

- gelling

- Ultrasound resuscitation

- Flushing as a breakage prevention

- Well flushing with one pump

- Submersible Pump Selection

- Work production technology

- When is the best time to drill a new well?

- Pulled up the cork from the bottom

- Four ways to clean a well

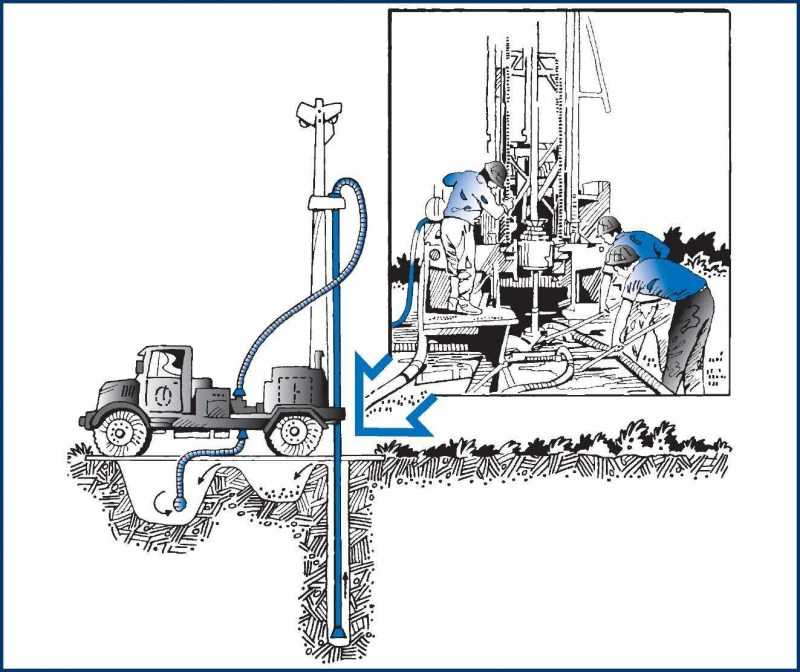

- Method #1 - flushing with a pump

- Method # 2 - cleaning with a vibration pump

- Method # 3 - using a bailer

- Method # 4 - flushing with two pumps

- Do not use a vibrating pump in wells

- How effective is preventive flushing

Production casing replacement

One of the most unpleasant breakdowns is the wear of the production pipe. Its replacement is a complex and time-consuming process that requires considerable financial investments. It is best to entrust the work to professional drillers. For self-fulfillment, it is desirable to have the appropriate skills, because.replacing a pipe is even more difficult than installing a new one when drilling a well.

It is easiest to work if the casing and production structures consist of two pipes of different diameters. In this case, only the production pipe is changed, without touching the casing. If everything is done carefully, the performance of the well will be restored.

It is better not to start repairing a well with asbestos-cement pipes, because. the material is destroyed under additional loads. This is the case when it is worth immediately starting the construction of a new hydraulic structure. But it is quite possible to replace a metal pipe, even if the material is very rusty.

Image gallery

Photo from

Extraction of casing pipes or columns with a filter are produced in the reverse order to that in which the installation was carried out

In order to make it convenient to unscrew the pipes without the risk of dropping them back into the well, you will need a clamp

To pull the casing, you need a loop, clinging to which the pipe is pulled out of the working. It is better to pull by connecting it to the hydraulics of the drilling machine

If the top link of the casing is cracked or unscrewed, or the pump is stuck at this level, it is better to dig the hole to the place of the accident so as not to completely displace the pipe in the hole

Well casing replacement

Collar for holding the extracted barrel

Loop for pulling the pipe out of the barrel

Excavation of the upper link of the casing

To dismantle the pipe, it is captured with a loop loop or a special clamp and pulled out using any available lifting mechanism - a railway jack, a truck crane, etc. The main thing is that the device provides the necessary force for lifting.

When the pipe is removed from the shaft, a new one is installed - metal or plastic. Do not use asbestos cement. The material is impractical and potentially hazardous to health. This is confirmed by data from the World Health Organization.

New pipes can be connected with threads or nipples. You should choose high-quality connecting elements with a special anti-corrosion coating. If plastic pipes are chosen, then a strong nippleless connection is provided here. When choosing pipes, you should not save. This is fraught with new breakdowns.

When replacing a production string, a new pipe is selected based on well depth, future loads, material durability, and chemical resistance.

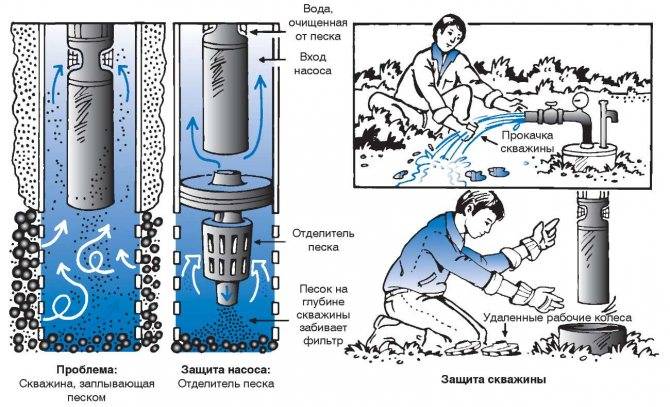

Important information about the well filter

When cleaning the well, it is important to be careful, otherwise you can accidentally destroy the filter, especially if water hammer is used. If chemical filter cleaning has been used, the water quality will inevitably deteriorate. Don't worry

This is a temporary phenomenon.

Don't worry. This is a temporary phenomenon.

Gradually, the well will be cleaned of chemistry, and the water will again become of high quality. So that the reagents do not have a negative impact on health, you should pump water from the well for 12 hours and refuse to use it for domestic purposes for a couple of days. You also need to put good filters in the house and do not use unfiltered water for drinking and cooking until it is purified.

When cleaning the well filter, substances are used that are used in the food industry, so it is generally accepted that they are safe. However, you should always keep in mind the quantity.The concentration of chemicals in the water after cleaning is too high

Reasonable precautions must be taken to avoid poisoning. The initial purification of groundwater from mineral particles is carried out by a well filter

It is arranged along the entire thickness of the aquifer plus half a meter above and below (+)

The initial purification of ground water from mineral particles is carried out by a well filter. It is arranged along the entire thickness of the aquifer plus half a meter above and below (+)

In addition to chemical filter cleaning, mechanical cleaning can be used. This method is safe and does not affect the quality of the water. To clean the filter from deposits, a metal device is used that looks like a regular bottle brush, but much larger.

Simultaneously with the ruff, you can also use cleaning by pumping water. But you should always be aware of the risks. The filter may not withstand the additional pressure and collapse. It is better not to experiment unless absolutely necessary.

Possible breakdowns and their causes

Over time, the state of the well may not change for the better, up to a complete failure.

However, there are not so many reasons for this, here are the most common ones:

- Changing positions of the aquifer;

- siltation;

- Errors made during the installation and design of the device;

- Depreciation of equipment;

- Breakage of the pump;

- Pipe breakage;

- Depressurization of some elements of the aquifer system, etc.

Harbingers of well failure

Wells, as a rule, do not fail suddenly.

This process is accompanied by a number of characteristic signs that home owners need to pay attention to:

- A noticeable decrease in the amount of water, i.e.decrease in debit;

- The appearance of unwanted impurities in the water;

- Turbidity of water.

If these symptoms appeared after a long time after the start of water production, then, most likely, silting of the source occurs. In this case, it is necessary to immediately clean the well, otherwise the equipment will break down.

Aquifer system device

How to determine the cause of a breakdown

To avoid unnecessary expenses, it is necessary to correctly diagnose:

If water is completely absent in the entire system, then most likely the automatic control unit or pump has failed.

If there is poor pressure in the system, then the reason, as a rule, is hidden in the water distribution equipment

It is necessary to make sure that the hydraulic tank is tight, and also check the joints of the pipeline, it is possible that leaks will be found there.

If no problems are found in the water distribution equipment, then attention should be paid to the condition of the well. It is necessary to inspect the pit and the caisson - it should not accumulate ice in winter or water at positive temperatures.

A bent casing can indicate a serious problem.

If no problems were found at this stage, then further diagnostics can be carried out according to the condition of the incoming water:

- If clean water comes in, but in a small amount, then most likely the filter needs to be cleaned.

- The admixture of silt or sand usually indicates the destruction of the filter and siltation of the wellbore of the production string.

2.3 Iron removal by ion exchange (iron up to 20 mg/l and in combination with manganese, hardness and organic matter)

Ion exchange technology for iron removal has a number of significant advantages compared to other methods:

— Simple design makes it easy to operate, no need for labor-intensive maintenance, it is only necessary to regularly change the ion exchange resin cartridges in the unit.

- Versatility - it is used for iron removal not only from well water, but also successfully treats wastewater on an industrial scale. Installations for iron removal in domestic conditions, as well as for production facilities, are identical in principle of operation and structural design and differ only in the size of working tanks and the composition of active reagents.

- High efficiency - the maximum level of water purification from iron, as well as other harmful impurities that have the ability to exchange ions.

As a rule, the ion exchange method is resorted to in case of a simultaneous need to reduce the hardness and the iron content in the water. This technology is especially effective at high mineral salt content (100-200 mg/l).

Ion exchange filters use the ability of ion exchangers (ion exchange materials) to replace negatively or positively charged ions in water by the same number of ion exchanger ions. Ion exchangers are almost water-insoluble compounds of organic or inorganic origin, containing an active anion or cation. Cations replace positively charged salt particles, and anions replace negatively charged ones. Synthetic ion-exchange resins are used as ion exchangers to remove iron and soften water.

Cation exchangers remove almost all divalent metals from water, replacing them with sodium anions.

The design of the ion-exchange filter for deferrization of water from a well consists of:

- a cylinder with a filter load (ion-exchange resin),

- electronically controlled water supply valve,

- containers for regenerating solution.

Scheme of operation of the ion-exchange filter: water comes from the source and flows through the ion-exchange resin that fills the filter, during which the ions of heavy metals and hardness salts are replaced by ions of the filter material. The degasser then removes oxygen and carbon dioxide from the water. Purified water goes to the consumer channel.

One of the advantages of the method is that it is a reversible process and a mechanism for regeneration of the filter media is provided. This is usually done with alkaline or acidic solutions, thus prolonging the lifetime of the plant.

Despite the high efficiency of ion exchange technology for removing iron, there are several points that limit its use:

- Cannot be used to purify water containing trivalent iron, as the filter resin quickly becomes contaminated and becomes unusable.

- The presence of oxygen and other oxidizing substances in water is also unacceptable, as it leads to the formation of iron in solid form.

- The pH value should be no more than 6.5 in view of the above points.

- It is recommended to use an ion-exchange filter where an increased concentration of iron is observed in combination with excessive hardness, otherwise it will be irrational.

Rice. 4 Ion exchange filter

Ion exchange plants can be used in any field. For domestic use, there are compact filters that also work on the basis of ionic resin.For industrial production, equipment is on a larger scale. To increase productivity, you can install several ionic columns. Most often this is provided in industrial production. The bottom line is that two or three columns with ion loading are installed. They can work both simultaneously and in turn. With variable device filtering, regeneration also starts in turn. That is, first, a supply of ionic resin is produced in the first column, it goes to regeneration, and the second one is turned on. When the second flush time comes up, the first one is activated again. When installing three or more ion plants, they can also work several at a time. They are connected by a control unit. It is installed on each column separately or combines everything at once. It is this element that monitors the sequence of equipment operation and the beginning of the regeneration mode.

The ionic method allows not only to remove iron impurities, but also to soften the water at the same time. The ionic resin allows iron impurities to be removed without prior oxidation. At the same time, the cost of operating the system will remain the same. Ionic resin requires only regeneration with saline. And it is desirable to automate the system.

Causes of water well failures

The choice of a contractor who is ready to take up the work on the construction of a well must be approached with the utmost care.

Unskilled actions and mistakes made during drilling operations will lead to the depletion of the well after a few months.

The statement that repairing an old well is easier than creating a new one is not always true.Sometimes, the restoration of the working capacity of a hydraulic structure takes a long time, and as a result, the price for well repair increases significantly.

Limestone wells and artesian wells

The first sign of a well failure is an admixture of sand in the water. These are the consequences of an error made during the installation of casing pipes. You can identify violations and problematic components by performing geological logging - one of the types of well survey.

Incorrect or insufficient aquifer clipping can cause reddish or white water to appear. Water is stained with impurities of clay and limestone particles, destroyed to the state of flour, which have fallen into the water.

Advice!

Another two of the most common causes of limestone and sandstone well workovers are misplaced perforations in the filter string and stuck submersible pumps in the wellbore.

None of these consequences can be eliminated without the intervention of qualified specialists with sufficient knowledge, experience and appropriate technological equipment.

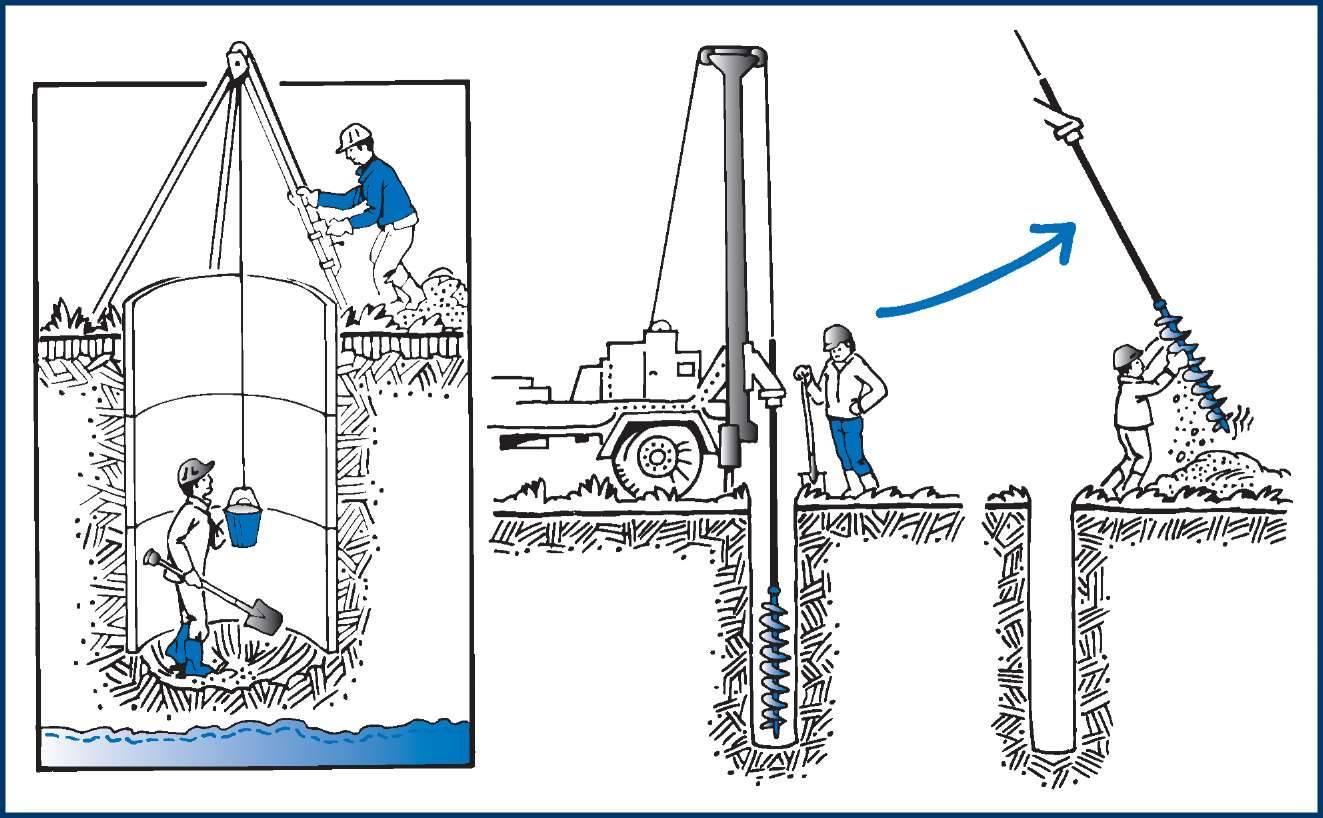

sand wells

It is believed that one of the most difficult works in terms of production is water wells for Quaternary deposits in sands, that is, drilled for water in sandy soil.

Drilling wells in the Leningrad region in areas dominated by sandy soils has its own technological features. The arrangement of sand wells requires a particularly careful approach to the drilling process and the choice of pumping equipment.

Otherwise, the following problems are inevitable:

- low water flow rate in a sand well when using a centrifugal pump, which is not recommended for operation in wells of this type;

- sand impurities in the water resulting from filter failures;

- occurrence of corrosive processes and failure of pumping equipment.

At this causes the malfunction wells can be very different, and in order to start restoration work, it is required to carry out diagnostics using special equipment.

The subtleties of the diagnosis

To eliminate the breakdown, you need to clearly understand its cause. If it is planned to repair the well by hand, then if the diagnosis is incorrect, the owner will only lose time. If he turns to professionals, then also money. Therefore, you should not rush and carefully consider the diagnosis.

First of all, you need to make sure that the problem is really in the hydraulic structure itself, and not in the water distribution system. To do this, the pump is disconnected from the water supply, connected to a regular hose and put into operation.

If the water comes with good pressure, then everything is fine with the well and pumping equipment. The source of trouble should be sought in the water distribution system. If the pressure is weak or the water does not flow at all, and the pump is idling, you really need to resuscitate the well with your own hands or call in specialists.

To check the pump, you will have to get it and temporarily connect another one. If no changes occur, then equipment failure can be ruled out. In this case, you will have to clean the well or deal with malfunctions in the operation of the production string.

In case of suspicion of a breakdown of the submersible pump, it is removed from the well and another unit is installed in its place. If it pumps better, then the reason is a violation in the pump

In the case of self-diagnosis, you have to act by the method of elimination, checking each node in turn. It is impossible to explore the wellbore with special equipment, you will have to call the employees of the drilling company.

In order to clean the well, filter or replace the production pipe, you should also resort to the help of drillers. If it is simply silted, then it is possible to restore performance. In serious cases, professionals should be hired. And even in this case, there is no full guarantee that the productivity of the well will be restored.

Well flushing techniques

Methods of resuscitation: hydraulic, vibration and with the help of reagents.

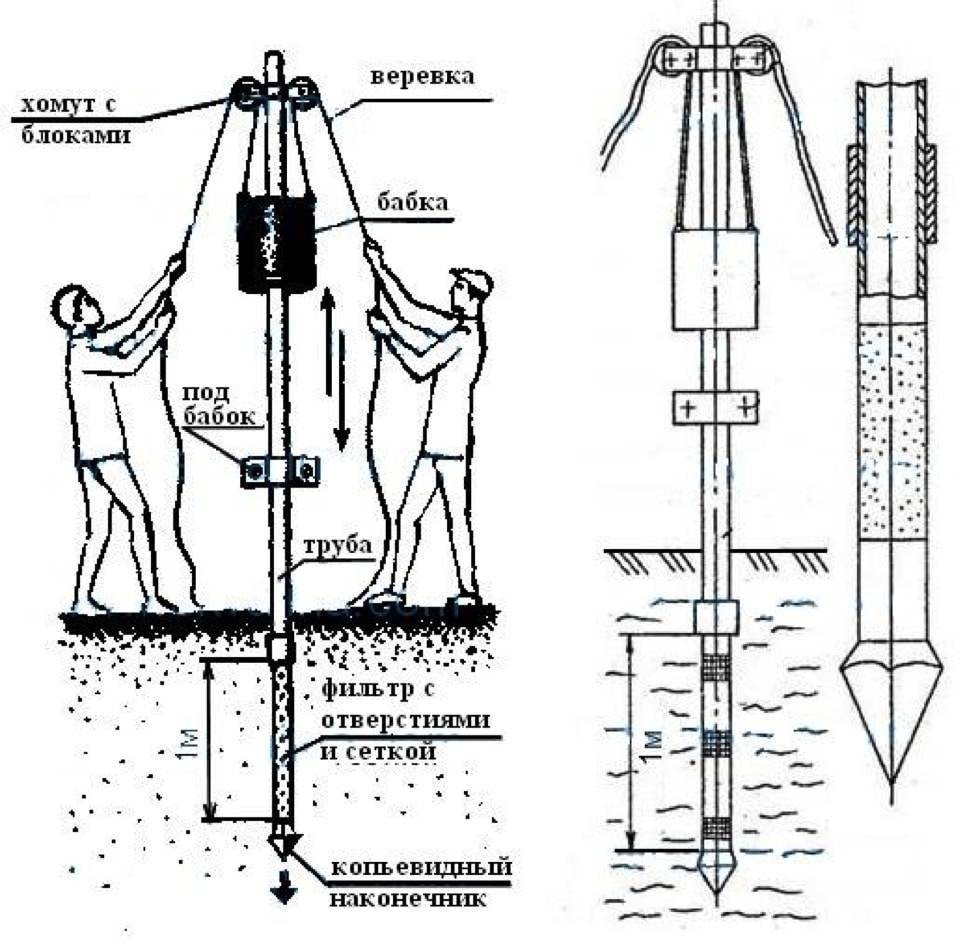

gelling

The way to remove the cork from the sand by gelling is considered the simplest. The bailer, a steel pipe of smaller diameter than the main ones, is lowered into well to the bottom. Its length is from one to three meters, at the end there are baking powder and a check valve. Several times it needs to be raised half a meter and thrown down. The device is filled with sand and pulled up. Sand and silt are extracted to the maximum extent. Then everything is pumped with a pump until clean water comes out.

Ultrasound resuscitation

Acoustic well resuscitation is very effective. Under the action of ultrasonic waves, pressure is created in the water. The precipitate is separated from the filter by the impact of the wave. the cohesive forces between the metal and sediment particles are broken.An ultrasonic projectile converts ultrasonic vibrations into mechanical ones. Frequency from 1 to 20 kHz. Cleaning of the colmatant can be carried out by the acoustic-reagent method. Here comes both chemical and sound processing. The reagent is supplied through a hose. The result will be an increase in water supply by 2.5 times.

Flushing as a breakage prevention

Often you can find a recommendation to flush the well to prevent silting. Usually such advice is given by drilling specialists. Many well owners have a suspicion that they are simply tied to a certain company that will deal with their water supply system after the arrangement.

Are preventive flushes really needed or is it still a trick? If the well is constantly working, then there is no particular need for such an event. But for a structure that is used only seasonally or temporarily, it is advisable to periodically flush to avoid sedimentation of sand and silt.

Sometimes regular flushes can indeed prevent a well from being repaired or rehabilitated, but more often than not, they are not needed. Extra flushing will not hurt in case of difficulties with putting the well into operation after construction or a long downtime.

If the well is built in a country house and is used only during the summer season, it must be washed before operation and closed for the winter with the onset of cold weather

Well flushing with one pump

This is the easiest way to flush., for the implementation of which you need:

- submersible pump;

- delivery hose;

- cable.

The flushing of the well in this case is carried out due to the pumped out water, which will carry away pollution with it.The duration of such pumping can be from 12 hours to several days, depending on the degree of contamination. You can stop cleaning when the water extracted from the well does not become clean.

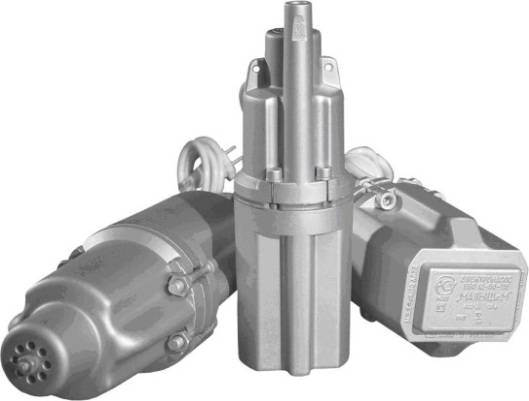

Submersible Pump Selection

Well flushing will be effective only if the right submersible pump is selected.

Pump requirements:

- optimal power;

- low price.

When flushing a well after drilling, the pump experiences heavy loads, pumping cubic meters of polluted water. Therefore, the probability of pump failure is very high.

In other words, it is recommended to use a pump that is “not a pity” to flush the well. It can be a very cheap model or an old pump that has worked out its time and needs to be replaced for a long time.

For flushing most wells, it is enough to use an inexpensive medium-power pump of the Russian-made “Kid” type.

Such pumps are less sensitive to silt and sand than centrifugal pumps.

The principle of washing with a vibration pump is as follows: after connecting the device to the power supply, a magnetic field is formed inside its case, which constantly increases and then weakens.

The created reciprocating movements (vibration) lead to a change in pressure, due to which water is pumped.

The advantages of submersible vibration pumps include:

- low cost;

- ease of use;

- no heating during operation.

Disadvantages of this type of pumps:

- cannot work stably with “jumping” voltage in the mains;

- low power compared to centrifugal pumps.

Of course, the use of a more powerful centrifugal or screw pump will make it possible to clean the well much faster.

However, the cost of even the simplest submersible pumps of these types is several times higher than that of a vibration pump. And given that, with a high degree of probability, the pump will be unsuitable for well operation in the future, the use of vibration submersible equipment will be the most acceptable option.

When choosing a pump for flushing, consider its dimensions and the possibility of narrowing the well target, otherwise the pump may simply not go down to the required depth.

Recommendations for choosing a pump for cleaning wells are given in this article.

Work production technology

A step-by-step instruction for flushing a well after drilling is as follows:

- The submersible pump is securely tied to the cable to prevent it from being sucked into the silt. It is not recommended to use the rope or cord that comes with the kit, because. their strength is not always enough to pull the pump out of the silt “trap”.

- The pump descends to the very bottom of the well and rises several times in a row. This is done to shake up the sediment at the bottom.

- At a certain height, the pump is suspended and connected to the mains. The location of the pump is determined above the bottom of the source by 60-80 cm. In no case should the operating pump be lowered to the very bottom!

- The pump pumps the well until the water is clear.

In order for the pump to wear out less, it is necessary to periodically remove it to the surface and rinse it with clean water. The frequency of flushing is every 5-6 hours.

Advantages of the well flushing method with one pump: simplicity and high efficiency.This method is also used for pumping a well put into operation or an already used source of water intake.

The disadvantages of this method include the fact that in most cases a long time is required for flushing, and there is also a risk of breakdown of pumping equipment. This method is advisable to apply on sandy and sandy soils.

To improve the quality and speed of washing, you can use a more high-performance centrifugal type submersible pump.

Fecal and drainage pumps also do an excellent job of flushing shallow workings, passing particles with fractions up to 30-40 mm through themselves when pumping.

The selected submersible pump must be located inside the well in a strictly vertical or position, this is achieved by using a rigid cable.

When is the best time to drill a new well?

If failures become frequent, the supply system is intermittent, and the rate is steadily declining, it is worth considering creating a new permanent source. There are a number of violations that cannot be eliminated, and most of them are associated with the arrangement of the filter:

- improper installation (past the aquifer);

- when selecting the mesh, the fraction of water-bearing sand was not taken into account;

- no gravel barrier installed;

- installation of a low-quality mesh that allows sanding.

If the design of the shaft does not allow the replacement of internal mechanisms, the listed factors automatically become the reason for conservation of the source. You can put in additional meshes or do weekly resuscitation, but performance will still constantly drop.

In these cases, it is easier to make a new well than to reanimate the old one:

- Stem displacement. Occurs if the pipes were clogged incorrectly;

- The ground layer has been depleted. Sometimes from prolonged use the water disappears;

- Asbestos pipes were used in the construction. Over time, they become brittle and cannot be removed for replacement.

Keep in mind that the Abyssinian version is installed for a limited period - up to 7 years, so it is also customary not to repair it, but to close it after the expiration of its service life. Each recovery attempt will only extend the work by 2-3 months.

Remember that the old well must be sealed so that contaminants do not enter the source.

Pulled up the cork from the bottom

A sand well should ensure the inflow of fresh water exclusively through a strainer. To prevent the ingress of water, and with it foreign mechanical inclusions into the pipe, the bottom of the sandy well is sealed in a special way. Part of the sump is usually covered with rubble. Such a plug is enough for the well to produce a debit corresponding to the passport characteristics.

It happens that the customer either poorly studied the technical documentation regulating the operation of the well, or unnecessarily counted on the decency and competence of pumping equipment dealers, or simply relied on "maybe". As a result, a pump is purchased that is not suitable for a particular well. The pump, whose power significantly exceeds the well's passport characteristics in terms of productivity, will soon put the well out of action. This is due to the fact that with each turn on of the pump, water hammer occurs over and over again.The pump draws sand and other mechanical fractions through the aforementioned plug. Over time, the filter becomes clogged with sand, its functionality decreases, along with this, the debit also decreases.

Four ways to clean a well

If during the diagnosis it turned out that the problems arose due to silt, then the well can be cleaned independently. To do this, it is washed with water or blown with a compressor.

The easiest option is to pump water. The process takes a lot of time and effort, but the result is worth it. If the filter is not destroyed, but simply contaminated, then it is quite possible to completely restore the productivity of the source.

Method #1 - flushing with a pump

You will have to stock up on clean water in advance. If your own well works poorly, this can become a whole problem, you will need to turn to neighbors for help. Water will require a large container and pump, and finding them can also be difficult.

If these issues are resolved, then you can get to work. The hose is connected to the pump and lowered to the bottom of the well

It is important that it reaches not just to the mirror of water, but almost to the very bottom.

The pump is turned on for pumping water, and it lifts silt and sand from the filter. The wellbore quickly overflows with water, and it begins to gush uncontrollably. Pollution particles are thrown out with water.

This is one of the fastest and most reliable ways to clean a silty source. If you can’t do the restoration of the well with your own hands, then you can turn to hydrogeologists and sewers. The former will calculate the required water hammer power, while the latter will help with a large volume tank to remove excess water.

Method # 2 - cleaning with a vibration pump

shallow the well can be cleared of silt and sand with a vibration pump. Small-diameter equipment is often used, for example, devices of the Malysh brand. The pump is lowered into the shaft to the level of the filter, the well is turned on and gently rocked.

The device will lift solid particles, and they, along with water, will come to the surface. Such flushing of the well may take several days, but it will be effective only if the pollution is not severe.

During well cleaning, the working parts of the pump may become clogged with dirt, and the electric motor may overheat. Therefore, it is advisable to take breaks and clean the device from contamination.

The advantage of this method is its simplicity and low cost. Everything can be done by hand, no complicated equipment is required.

Method # 3 - using a bailer

This method is only suitable for shallow wells - no more than 30 m. Assistants, a winch and a bailer are required for work. It is a piece of metal pipe with a mesh top and a washer bottom. The bailer is attached to a long strong cable.

The device is lowered to the very bottom of the well, after which it is raised by about half a meter and sharply lowered again. After several such manipulations, the bailer is removed from the well and cleaned of sand. Usually it is recruited about 0.5 kg.

Not all well owners consider this method of cleaning effective, but most still agree that the bailer helps to cope with silting. The main advantage of cleaning with a bailer is cheapness. If you make a device with your own hands, you can remove the sand almost for free.

Method # 4 - flushing with two pumps

The method is similar to flushing with a pump, but has some differences.Two pumps are required - submersible and surface. Not far from the well, a large water tank (from 200 cubic meters) should be installed, and in it - a home-made filter made from a bucket with a mesh or a women's stocking. A hole is made on the side and bottom of the tank through which water will be pumped using a surface pump.

With the help of a deep pump, contaminated water is pumped into the tank, passing through a filter. The surface pump takes the purified water from the tank and pumps it back into the well. The bucket is periodically freed from sand and silt. The procedure is carried out until clean water without impurities flows from the well.

Do not use a vibrating pump in wells

You should never use a vibration pump, because during its operation it can destroy the casing with its vibrations, then the sand will definitely get inside. To this we can add the fact that vibrations destroy the bottom of the well and can completely wash it out.

Do not pay attention to advice from craftsmen, as well as advice from the Internet. All of them quite often advise that you need to add gravel to create a gravel cushion that will not allow sand to pass through.

Such advice can completely leave you without water.

If you have any questions, please call +7 (495) 760-77-73! We will advise you for free and advise you on how to proceed.

How effective is preventive flushing

Well drilling firms advise owners to regularly flush hydraulic structures with water. It is believed that such preventive measures prevent silting. Is it really necessary or do drillers simply acquire regular customers?

If the well is used seasonally or infrequently, regular flushing makes sense. But for structures that work constantly, it is useless. Such wells are flushed daily with pumps. Additional flushing may be necessary if the structure was originally built incorrectly, there are problems or the pump does not cope with the work.