- Metal profile gates, do-it-yourself installation

- From the materials you will need to purchase:

- For work, we will use the following tool:

- Advantages and disadvantages of metal frame houses

- Skin selection

- Win-win option - corrugated board

- Wood is out of fashion and time

- metal finish

- Swing gate design

- Wrought iron swing gates

- Advantages and disadvantages

- Calculation and necessary tools

- How to sheathe the frame of the gate

- Sheathing from corrugated board

- wood paneling

- Forged elements

- The main issues in the manufacture of gates

- Manufacturing sequence

- Making a gate with your own hands: stages of work, photo

- frame welding

- Installation of a gate from a metal profile

- Installation of a lock on a gate and metal profile gate

- Swing gate improvement

- Standard design schemes

Metal profile gates, do-it-yourself installation

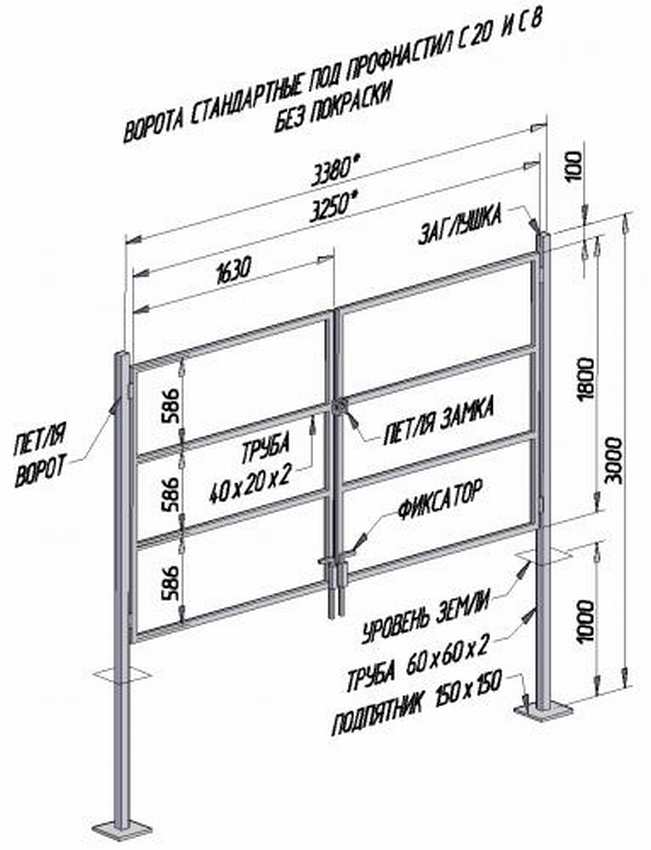

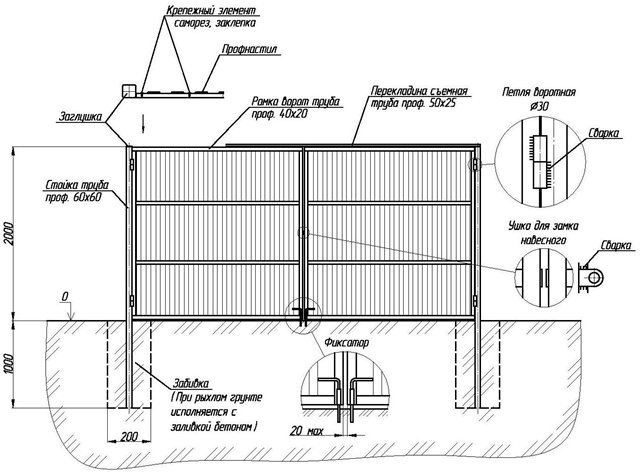

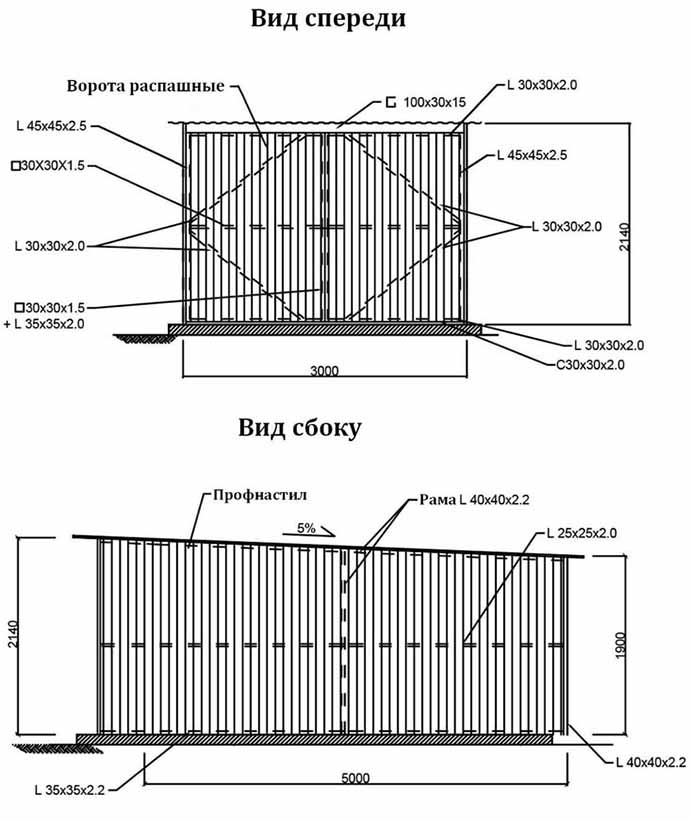

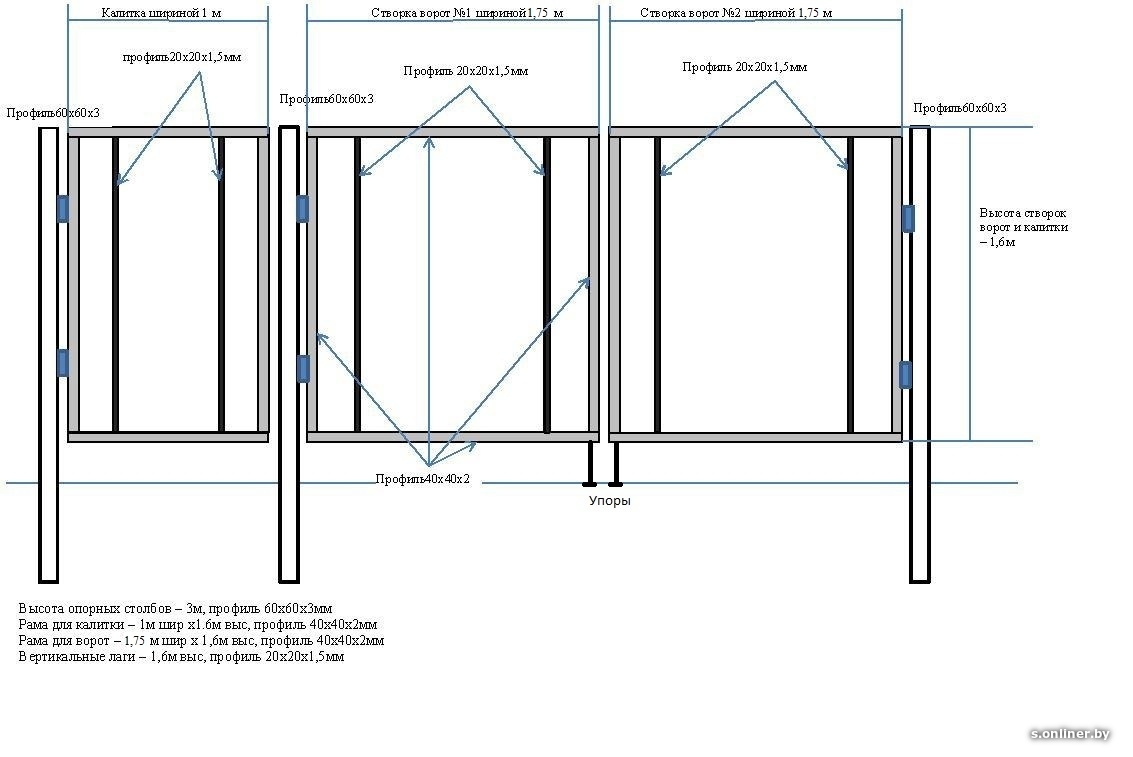

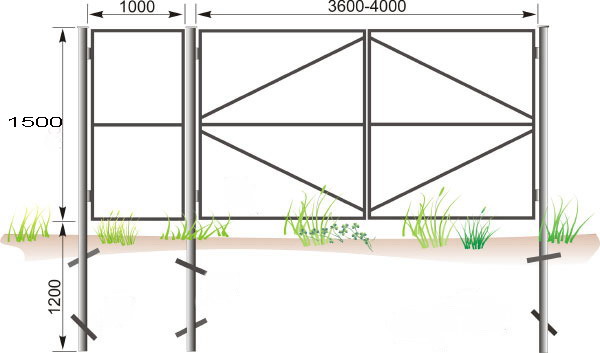

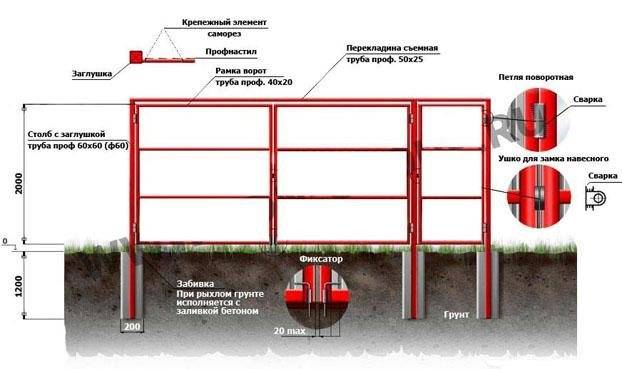

Gates from a metal profile are quite common, we will talk about them, and we will also give detailed instructions on how to properly install a gate from a metal profile with your own hands. Before proceeding with the installation of the gate, it is necessary to decide how they will look and draw up an approximate drawing.

Installation calculations

It will help to calculate the volume and type of materials that will be needed when setting the gate.

From the materials you will need to purchase:

- a metal profile of a round or square section, with a diameter of at least 100mm, we will need it to organize the pillars. Tip when calculating the length of the profile: to the height of the gate, add the depth to which it will be concreted and the height of the gap between the gate leaves and the ground;

- corner or square profile, which will be used to make the frame and stiffeners of the gate. Tip: the corner is lighter and more practical than a square profile;

- anti-corrosion liquid, which will be used to process the materials used - primer and paint;

- gate hinges, and of course, a lock.

Mounting materials

For work, we will use the following tool:

- plumb line and kapron thread;

- semi-automatic welding;

- to install and fix the pillars, you will need a drill and a sledgehammer;

- metal scissors and grinder.

Mounting tools

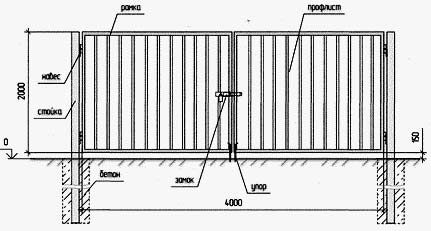

Installation of the gate begins with the marking and installation of pillars. When installing them, the size and weight of the structure should be taken into account, the larger and heavier it is, the stronger the pillars should be installed. For ordinary gates, as a rule, two hinges per side are used. To increase the overall reliability of the structure, you can install three curtains on one gate leaf. This will not greatly affect their cost, but it will increase their reliability and durability.

At a pre-selected place, we apply markings under the pillars, at the points of which we dig holes twice as large in diameter as the pipe itself and the depth of which should be at least 1 meter. We take the pipe and, with the direct help of the grinder, cut off the required length, taking into account the depth of digging and the required gap between the gate and the ground.The next step is to install them in a pit and fill them with rubble and pour concrete. Tip: the poles should be installed strictly perpendicular to the ground, if you do not follow this recommendation, you can get crooked gates, this defect will not be able to be corrected in the future.

For the mortar, we use cement grade 300, which should be diluted in a ratio of 1 to 3. We constantly stir the dry mixture until smooth and then slowly introduce water, until the mortar comes to a liquid state, it must fill all cavities and voids when pouring. Their presence will seriously impair the strength of the structure. Concrete for complete drying and final setting requires at least a day.

Many people arrange a brickwork box around metal pipes, which not only looks good, but is also able to strengthen the structure. For him, the solution is prepared according to the same principle as for pouring, the only difference is that it must be thick, not liquid.

Advantages and disadvantages of metal frame houses

The frame house has many advantages:

- Short construction time. An average house on a frame from a professional pipe is being built in just two months.

- A team of four people is enough to build a house, which is economically beneficial for the customer.

- The cost of construction is lower than with traditional technologies, with the exception of the construction of wooden frame houses.

- You don't need a strong foundation. The design is lightweight, so you can save on the construction of the base.

- For the same reason, building on a frame does not shrink as much as monolithic and brick buildings.

- A metal frame is stronger and more durable than a wooden frame.

The disadvantages and difficulties in the construction of metal frame buildings include the following:

The frame from the professional pipe must be professionally and correctly calculated

It is important to correctly calculate the loads on load-bearing and other beams and columns, which is impossible to do without special knowledge. Therefore, it is necessary to involve experienced specialists in the design of residential buildings, significant in area of buildings.

Hence the difficulty in determining the optimal pipe cross-section and material thickness, the economic justification for the cost of acquiring elements of metal structures

Buying pipes with an excessive margin of safety, the consumer overpays extra money. Saving money by buying pipes of a smaller section and wall thickness than necessary will lead to irreparable errors in the construction of the entire building.

Skin selection

A finishing material is mounted on a fully designed and prepared frame. The sequence of actions directly depends on the choice of products that will act as a leaf for the sashes. In most cases, a coating is used that is similar to an already built fence, otherwise it is unlikely that a single and complete picture will be obtained.

But with the right combination of materials, you can create an unusual architectural creation. An example is a brick fence of strict classical forms with a gate and gates made of forged metal.

Win-win option - corrugated board

Metal products are the strongest and most durable. For this purpose, it is worth purchasing galvanized sheets, pre-painted. They are customizable and simply mounted on the frame. For the logical conclusion of the picture, it is worth using forged details, these can be platbands, bolts.Made in elegant forms, they always look presentable, decorating the look of an ordinary metal profile.

Wood is out of fashion and time

Practice shows that this natural material always looks win-win. Moreover, over time, its appearance only improves. However, such sheathing can deteriorate due to insufficient resistance to external factors, rotting.

The treatment of wooden structures with antiseptic solutions and impregnations will help prevent such undesirable processes. Wooden sheathing, if necessary, can be easily replaced with other finishing material for the gate.

metal finish

The prepared and installed frame is often sheathed with elegant forged elements, reinforcing bars. Using a welding machine and mastering elementary cutting skills, you can create the most unusual designs with ornate mesh patterns, smooth lines. Completeness of such a product will give a monochromatic colorful finish.

This is interesting: products from a professional pipe.

Metal finish has a number of nuances

Metal finish has a number of nuances

Usually a metal profile or a tree is fixed on both sides of the gate. If one-sided sheathing is provided, the material used is fixed on the outside of the wings. Holes and screws are masked with plugs, which also prevent corrosion.

The metal profile frame is not designed for colossal loads. If the sheathing is made of profiled sheet, it should have a minimum thickness and a small wave height.

Having decided which profile pipe to make the gate from, having prepared a plan for the planned work and acquiring the necessary materials, tools, you can get to work.It is not difficult to make a structure on your own and in a short time, the main thing is to follow the step-by-step instructions and follow all the instructions.

Swing gate design

Whatever materials appear, no matter how the fashion for finishing the gate changes, the basic principle of their arrangement remains unchanged. Structural device:

poles (racks). In fact, they are not gates, but they are supports for their fastening;

swing gate frame. In its manufacture, wood or metal can be used. The latter is more popular because gives the frame greater rigidity;

finishing (facing) material for sheathing;

loops;

latches and locks.

So, we have decided what a swing gate is and what features they differ in.

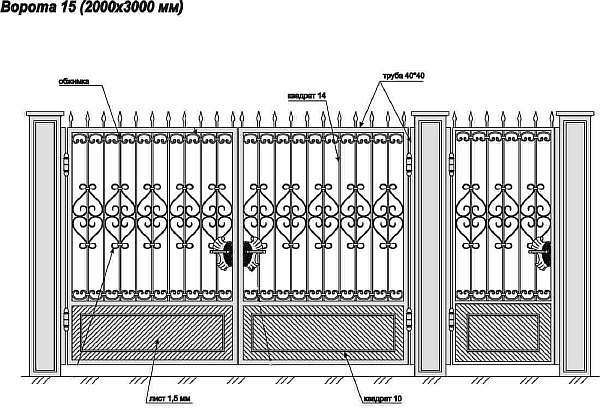

Wrought iron swing gates

Forged structures - decoration of fences made of metal. Despite the huge number of models of modern devices that provide unhindered entry into the territory of a personal plot, it is the swing construction that is in high demand and deserves the trust of owners of private houses located within the city or outside it.

swing gate

It is swing structures that are installed in most cases. Such devices may be:

- Completely transparent, made from individual rods, curved in an intricate pattern.

- Partially or completely deaf, preventing outsiders from seeing what is behind the openwork fence.

Advantages and disadvantages

To achieve this goal, masters create structures in two ways:

- cold forging;

- hot.

cold forging

hot forging

The main advantages of forged gate leaves are a high level of strength and resistance to mechanical damage. In the course of work, specialists with particular accuracy carry out calculations, the level of load on the supporting structure

It is also important that such products:

- universal;

- exclusive;

- can have any shape;

- compatible with all building materials that were used in the construction of the fence.

However, there are certain disadvantages that make you think about the degree of need for work related to the installation and installation of openwork gates. Among them:

- Big weight.

- The need for careful preparation and high-quality installation of supports that have to withstand significant weight.

Despite all the existing difficulties, the installation of the gate attracts many homeowners due to the ability to create various compositions, decorate the entrance to the territory not only with simple drawings, but also with complex ornaments, equip the structure with automation, install video surveillance and an intercom system.

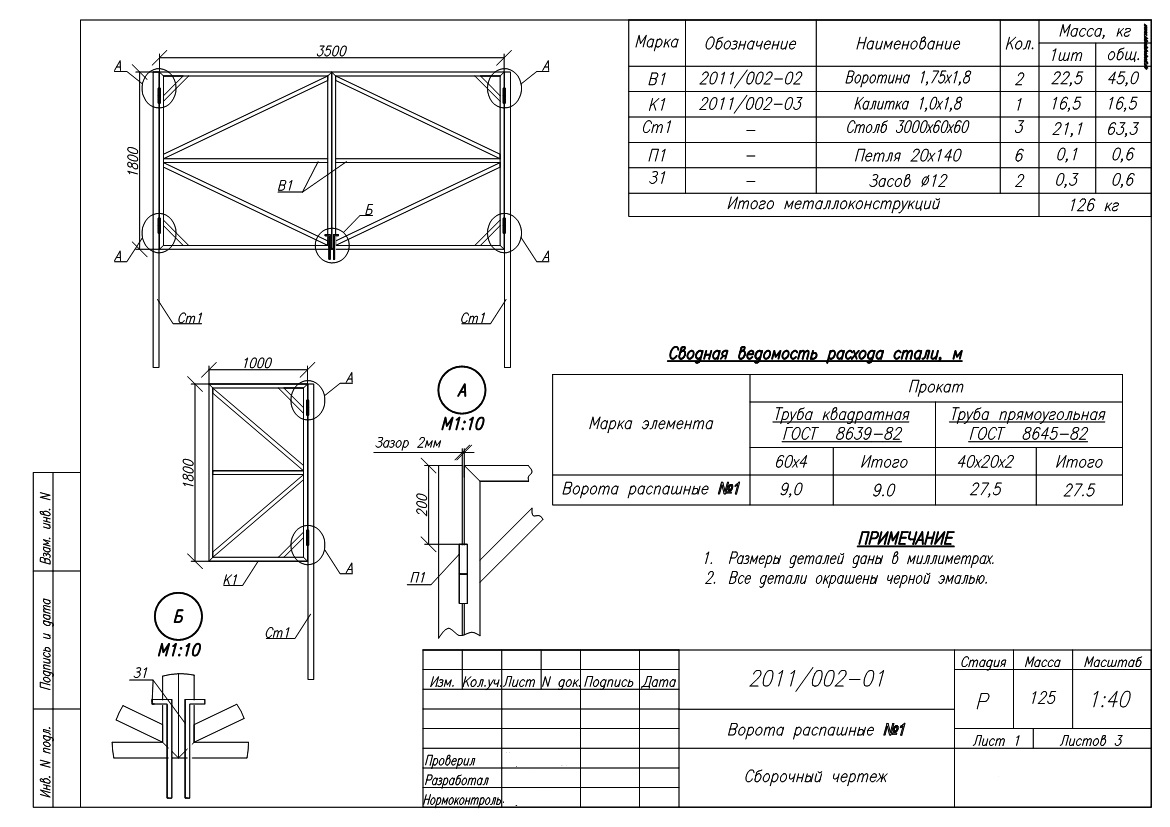

Calculation and necessary tools

Having decided on the size of the profile pipe and having correctly developed the drawing, you can begin to determine the need for materials, purchase purchased components, prepare tools and equipment for construction.

A generalized list of materials for the manufacture of gates includes:

- profile section pipes corresponding to the drawing dimensions;

- sheathing material that will be attached to the canvases, for example, a profile sheet, polycarbonate, wood or metal;

- hanging loops for connecting canvases with support pillars or a roller mechanism for sliding gates;

- lock and elements for fixing the canvases (staples, hecks, latches);

- fasteners designed to fix the finishing material;

- decorative details (for example, forged elements), if they are provided for by the drawing;

- primer for corrosion protection and pre-painting of metal structures;

- enamel for exterior work, intended for final finishing and ensuring the presentation of the product.

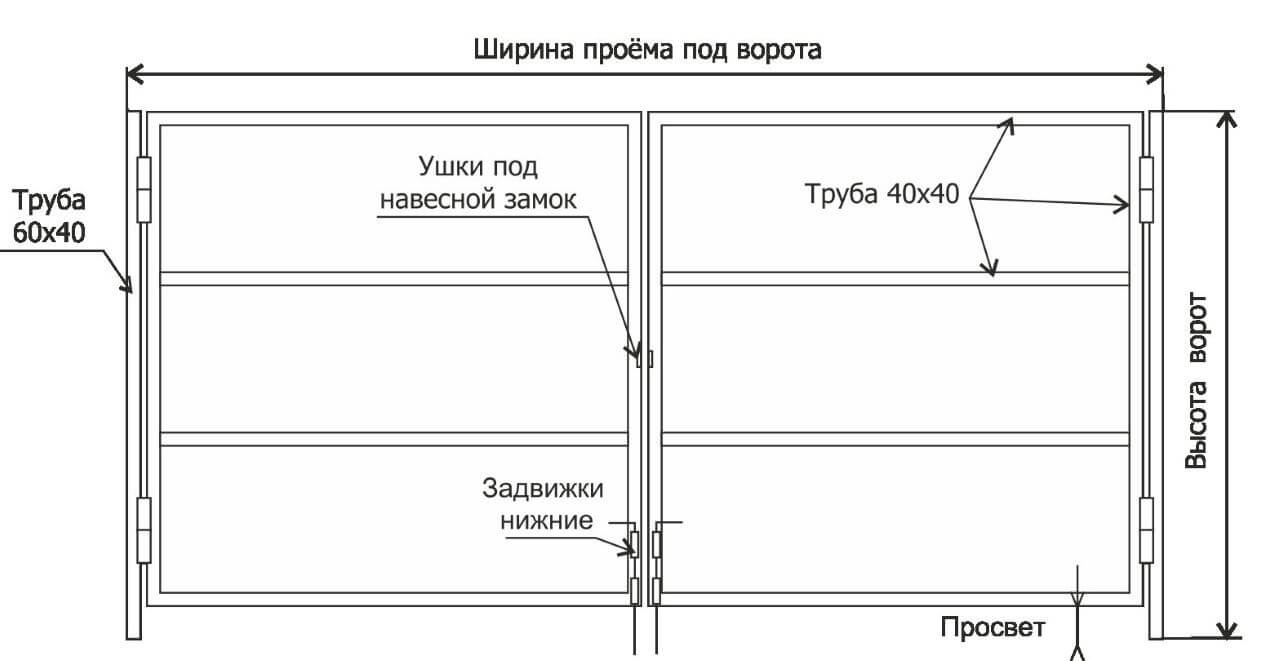

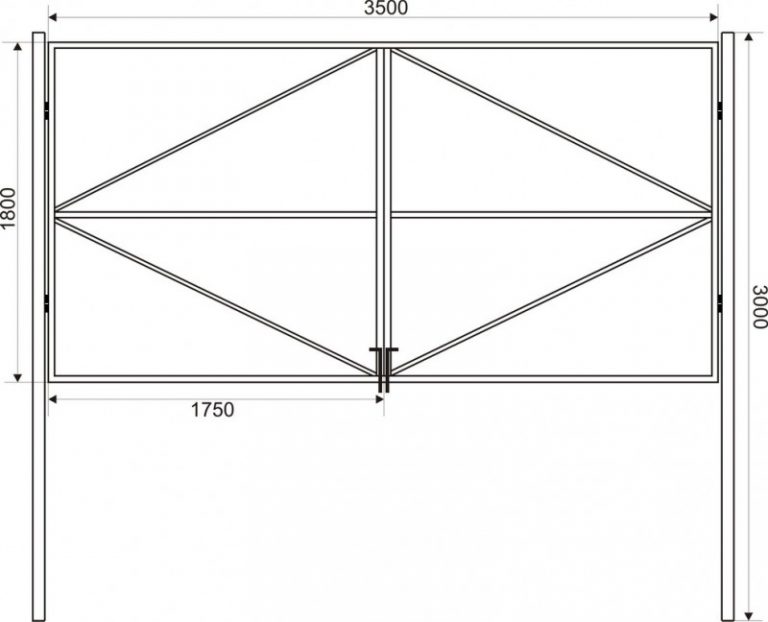

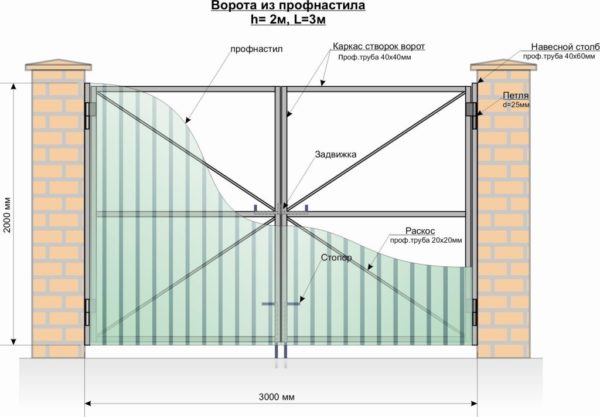

On the example of a swing gate with two wings, we will calculate the need for materials.

The determination of the need for materials is carried out according to the sketch with dimensions

For the gate shown in the sketch, you will need:

- a pipe with a profile section of 40x60 mm for the manufacture of support posts that are not concreted, but are attached to the poles at the entrance. The total need for a pipe measuring 40x60 mm is four meters (two racks of 2 meters each);

- corrugated pipe 40x40 for the manufacture of two frames. Knowing the dimensions of one sash 1.5x2 meters, it is easy to calculate the perimeter and add to it one horizontal jumper located in the middle of the sash, equal to 1.5 meters: 1.5 + 2 + 1.5 + 2 + 1.5 = 8.5 meters . For two canvases, 8.5x2 \u003d 17 meters of pipe will be required;

- a square pipe with a section of 20x20 mm for the manufacture of braces that give rigidity to the canvases. Using the Pythagorean theorem, it is easy to calculate the length of the hypotenuse of a triangle with legs of 1 and 1.5 meters. The square root of the sum of the squares of the legs is 1.8 meters. For four braces, 1.8x4 + 7.2 meters of a profile pipe will be required;

- corner scarves, which is a right-angled triangle made of steel 2–2.5 mm thick with sides of 10 cm. Each leaf will need 4 scarves to ensure the rigidity of the corner zones;

- corrugated board for sewing the frame of the gate. It will take 2 sheets measuring 1.5x2 meters;

How to sheathe the frame of the gate

Upon completion of the installation of the frame, the finishing of the sashes follows. Sheathing technology depends on the material used. It is advisable to use the same sheathing as the fence. Otherwise, the gate will not fit into the overall picture of the fence.

At the cottage

At the cottage

To fill the sash frame from the profile, material of various variations is used:

- forged items;

- sheet metal (galvanized);

- profiled sheets;

- edged and tongue-and-groove boards treated with primers, antiseptics or paints and varnishes.

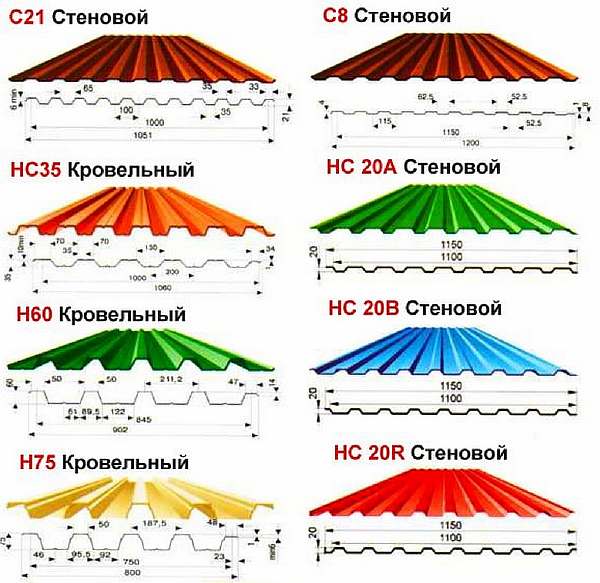

Sheathing from corrugated board

This is the most practical option for finishing this design. The material is low cost and easy to install. It can be combined with forged elements (bolts, platbands). Often, sheets are purchased with a painted and galvanized coating. The corrugated board is attached to the sash frame with self-tapping screws.

Types of profiled sheet

Types of profiled sheet

wood paneling

She wins in presentable appearance, but loses in strength. Wood is subject to decay and mechanical damage. To improve strength and extend the life of the lumber used, it is treated with flame retardants and anti-fungal agents.

Forged elements

Often, the sheathing of the structure frame is made of forging elements made of metal that is heated to forging temperature and amenable to high-temperature pressure treatment. The implementation of original design solutions is possible by cutting and welding such products.

Wrought iron doors

Wrought iron doors

If you have a welding machine and a blowtorch, you can forge a pattern on the sash from metal yourself. However, it is easier to buy ready-made forging elements, but they will cost much more.For example, the price for 1 m2 of finished products will be at least 1 thousand rubles.

The main issues in the manufacture of gates

Each owner can be engaged in the manufacture of gates from a profile pipe. The main thing is to have the necessary tools and initial skills in handling specialized equipment. In the absence of a welding machine, you can order the manufacture of the main elements to a professional and assemble the structure yourself.

To achieve the desired result, several conditions must be met:

- Good luck with the gate design.

- Make a good drawing.

- Choose the right metal.

- Purchase the appropriate hardware.

Gates on a metal frame can be used to enter the garage and the yard. The ideal option is a single execution of the entire structure. A simple but neat design will look harmonious only when different gates are similar and painted in the same color. Gates of different designs look aesthetically pleasing (some of the sliding type, others of the hinged type), but having the same type of finish. When closed, even structurally different gates can look the same.

It is quite difficult to make a gate from a profile pipe on your own, since the process involves the transportation of metal, its cutting and welding. A separate stage is the digging of pillars

Particular attention should be paid to the gate: it should open autonomously from the entrance gate, as it is used much more often

Manufacturing sequence

In practice, there are 3 main ways to properly weld garage doors:

- Before the end of the construction of the garage, the frame of the doors is prepared separately in the form of a single piece. After that, they are transported to the construction site and mounted in the opening.Then the metal frame is lined with building material.

- In the finished garage, doors are made according to the dimensions of the opening, a frame is installed and canvases are fixed.

- According to the already made opening, all parts of the structure are welded in stages right on the spot.

Before processing

Before processing

In this case, high accuracy of preliminary calculations and measurements is not required, it is not required to withstand the diagonals of the structure up to a millimeter, and it is not necessary to transport massive metal products.

If the work is done correctly, the welded product will stand securely and work without breakage for a long time.

It is necessary to weld the frame correctly

It is necessary to weld the frame correctly

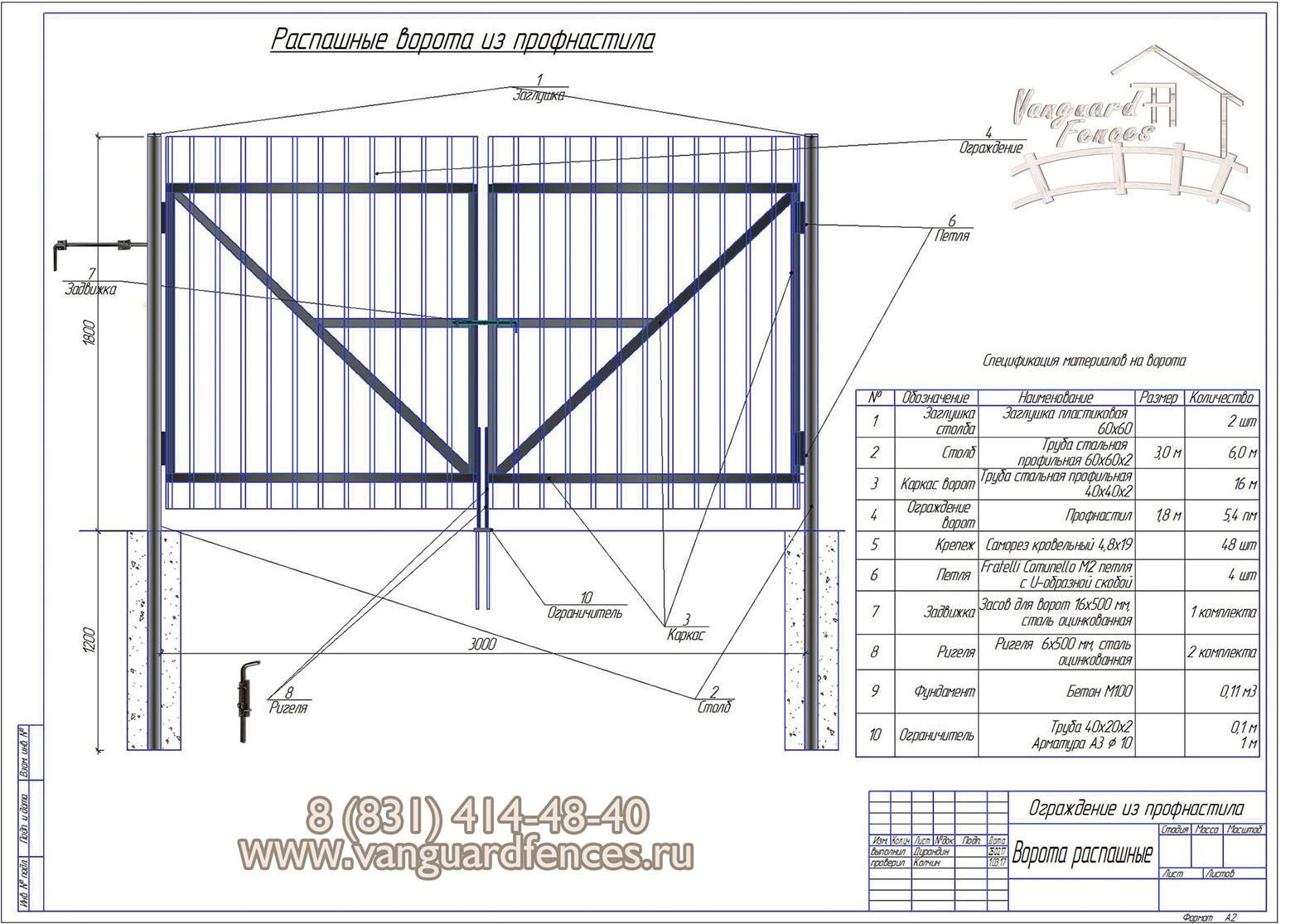

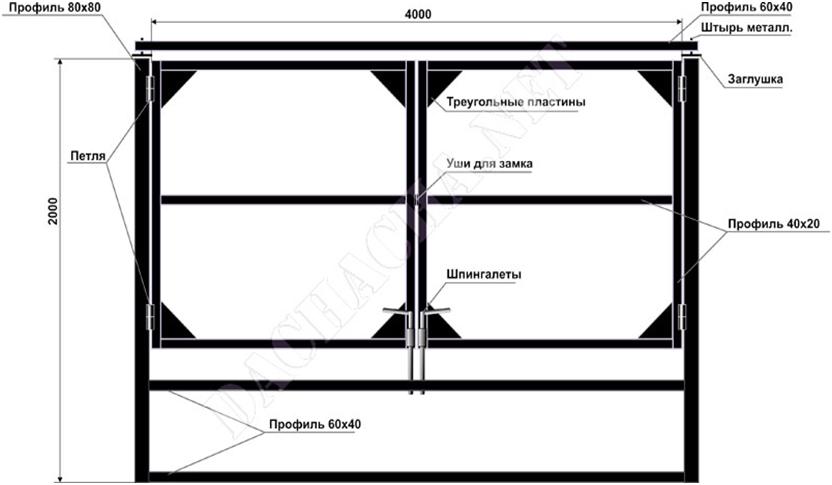

Making a gate with your own hands: stages of work, photo

While the foundation is gaining the necessary strength, you can begin to assemble the gate.

frame welding

To make a frame with your own hands, you need to prepare:

- profile pipe 60x30 or 40x40;

- corrugated board for cross members;

- welding machine;

- a composition that protects the metal from corrosion;

- paint;

- metal cutting tool.

According to the scheme prepared in advance, blanks are cut from the pipe, the edges of which must be made at an angle of 45 degrees. Previously, the profile pipe should be cleaned of rust with a metal brush.

To give the structure greater rigidity and facilitate the installation of the lock, two crossbars are inserted between the large sides of the frame, along its height.

To make the corners of the frame straight, it is recommended to fix its blanks in a home-made jig, which you can do yourself:

- A sheet is cut out of a sheet of thick plywood, the dimensions of which should be 50 mm larger than the dimensions of the future gate.

- Clamps will press the frame elements to the canvas, which should be twice as many as welds.

Having measured the diagonals of the frame and checked all the corners, first the crossbars and then the clamps are installed between its lower and upper jumpers. It is necessary to ensure that the clamps are located at a small distance from the welding site.

Once again, carefully checking the parallelism of the sides, you can start welding. Clamps will need to be removed only after all the seams have cooled.

The welded frame is treated with an anti-corrosion compound and loops are welded to it with a continuous seam. After the frame is painted, its manufacture can be considered complete.

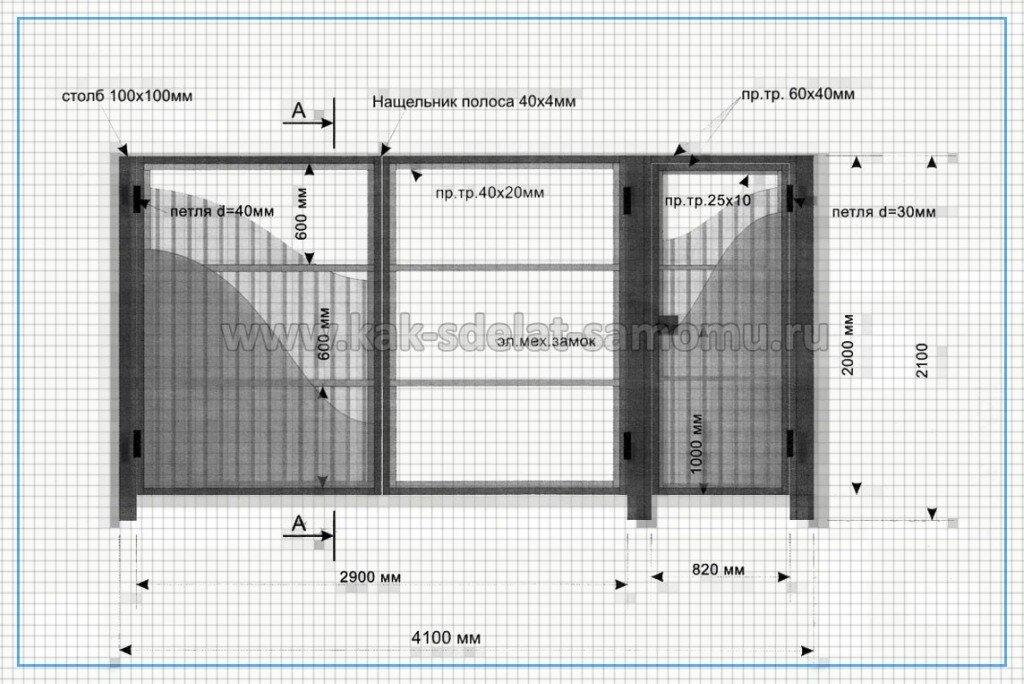

Installation of a gate from a metal profile

With the help of electric welding, the hinges are attached to the intended places of the support posts and, after checking for opening and closing, are scalded with a continuous seam. A properly installed frame will not spontaneously open and close.

Further, according to the measured standards, a metal profile is cut out and attached to the frame using self-tapping screws. A lock is cut into the finished structure.

Installation of a lock on a gate and metal profile gate

The choice of lock should be based on the direction in which the gate or gate opens. If it opens outward, then you need to purchase a mortise lock. If the canvas opens inward, then the lock can be both overhead and mortise.

The handle and lock are installed at a height of approximately 90 cm.

- Slots are made along the long sides of the castle marked on the canvas with the help of a grinder.

- Holes are drilled along the marked strip of short sides with a drill, which should be located as close to each other as possible.

- Using a file, the hole is brought to the desired shape.

- Round holes are cut with a metal burr for the core.

- Holes for mounting screws are drilled, and the lock is installed on the gate or gate.

Now it is necessary to cut the second part of the castle into the support post. To do this, the lock is closed and the place where the locking element will go is marked.

If there is no receiving block in the lock, then a hole is simply drilled in the support, which is brought to the desired shape with a file. For a lock with a receiving block, you will additionally need to drill holes for fasteners.

Swing gate improvement

Earlier, we considered the scheme of standard swing gates. But given modern realities, constantly manually opening them is not very convenient. Therefore, this process can be automated. At the same time, you won’t have to come up with something new, since there are linear electric drives on sale.

The set of automated equipment also includes a control unit. electromagnetic locking mechanism and signal lamp. Connection of swing automatic corrugated board gate runs into a typical AC outlet. In the photo you can see how all the elements complement the overall appearance of the structure.

Depending on which direction the doors will open, two options for installing an automatic structure can be distinguished: external and internal. But regardless of the opening method, the installation of automation is the same. If we consider the system control unit, then it can have a left-hand or right-hand placement.

Due to the design features of the automated drive, it is necessary to provide a mounting gap from the gate leaves to the bearing support.If this has not been done in advance, then when opening the sashes internally, you need to carefully prepare and arrange places for their fastening.

Independent production of swing gates from a profiled sheet is an economical and reliable way to protect your backyard from unwanted guests. At the same time, the entire system can be automated, which will significantly improve the functionality and practicality of using the gate.

Some examples of finished gates

Acquaintance with the house begins with the gate. In fact, this is the business card of the owners. Therefore, their appearance should by definition be solid and beautiful. But, at the same time, their main purpose is to ensure the safety and security of private country houses and cottages.

How to connect these two destinations together? How to make swing gates for summer cottages beautiful, reliable and functional. What types of swing gates are there and which is better to choose. How to make and install. About all this detailed step-by-step instructions in our article.

Do-it-yourself swing gates – manufacturing

Do-it-yourself swing gates – manufacturing

Before proceeding to the description of the gate device process, we will focus on their pros and cons.

Benefits of swing gates:

- simple design;

- relatively low price;

- undemanding in maintenance;

- long service life;

- strength;

- ease of operation;

- unlimited choice of design solutions and shapes;

- no need for concreting the site. For example, under rollers for sliding gates;

- the ability to install automation.

- the need to provide quite a lot of space for opening and closing;

- the need to take into account the wind load in the region.

Simple arithmetic shows that swing gates have much more advantages.And the shortcomings are eliminated or not critical. The long history of their existence only confirms the reliability of the system.

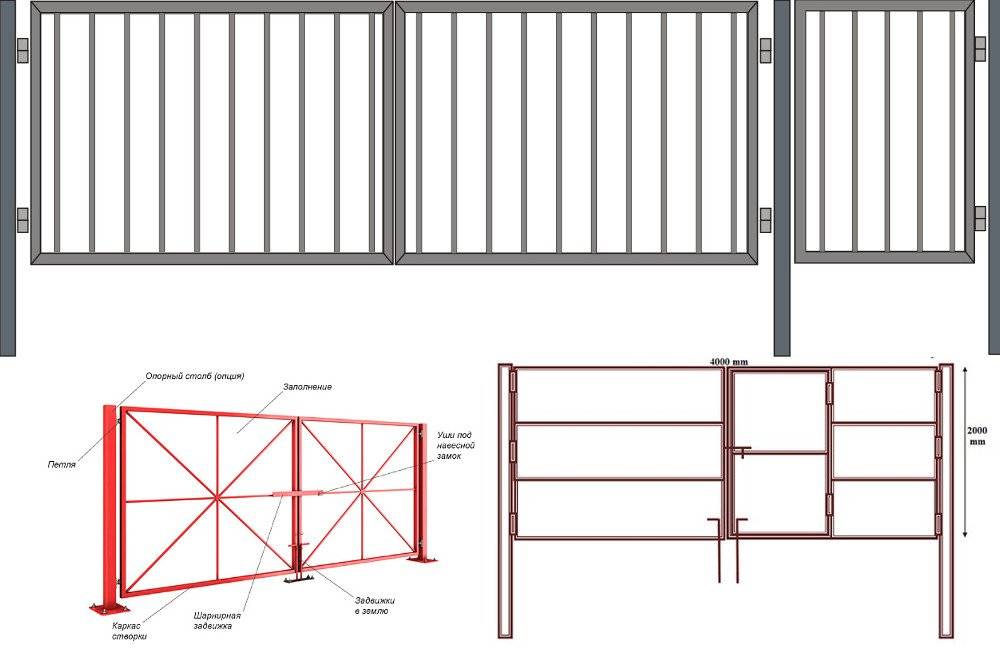

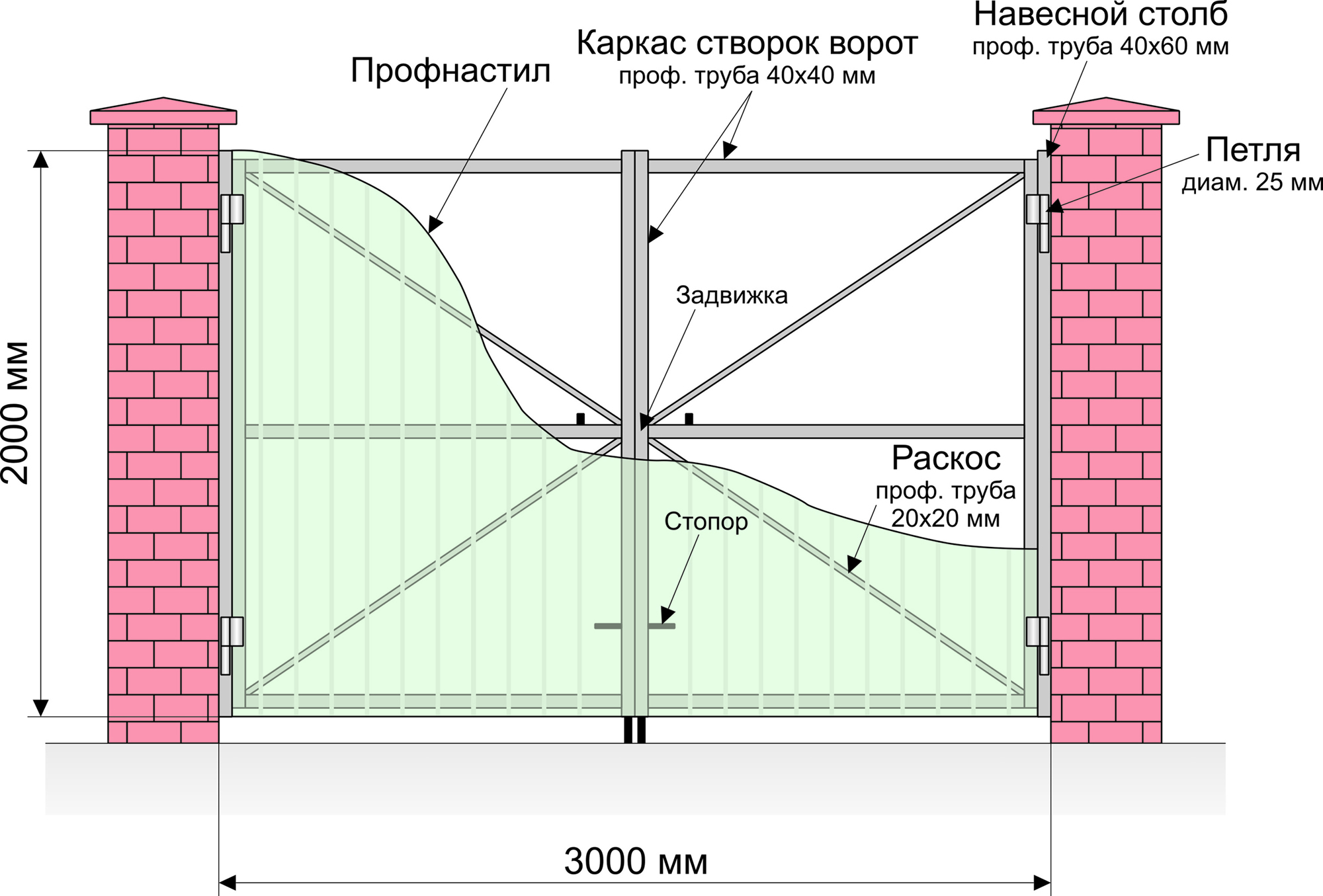

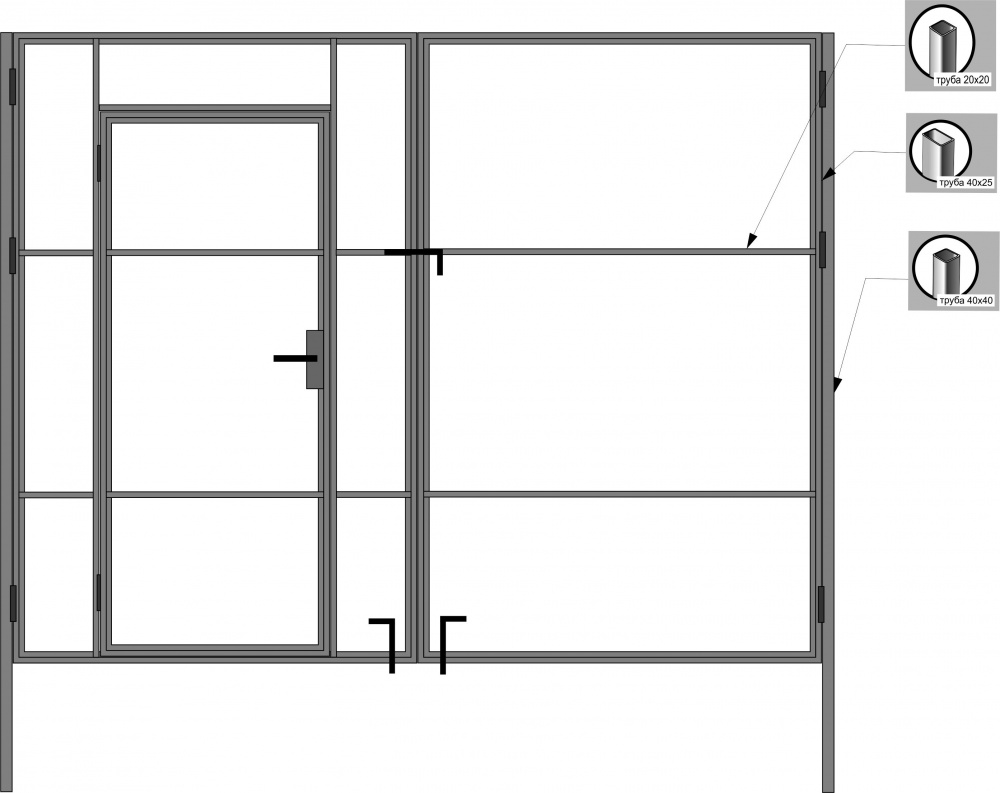

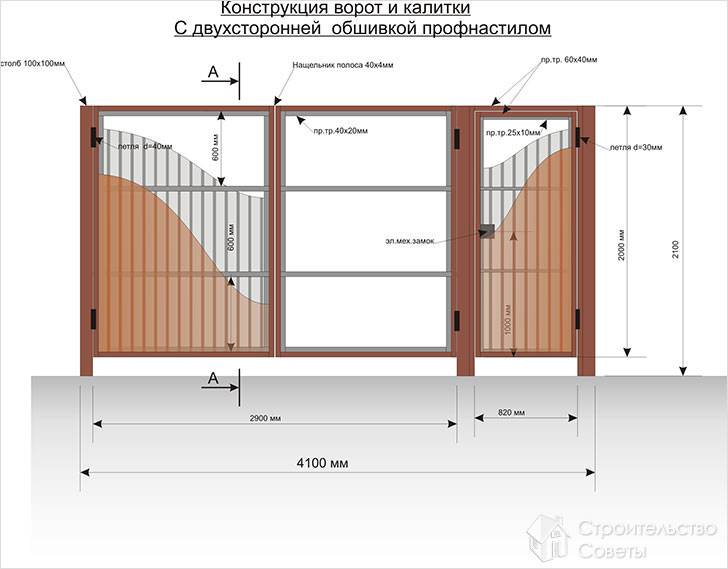

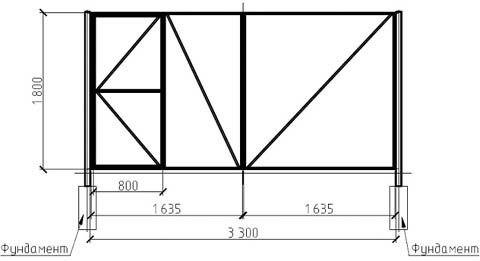

Standard design schemes

Regardless of the materials used, the design of the wicket - like the gate - consists of a frame and flooring. If we are talking about a gate made of metal, then the frame is metal, and the filling of the plane can be metal or from other building materials.

Mandatory elements of a gate from a pipe or other type of metal profile:

- base for installation - supports fixed in the ground, to which the structure is attached by a canopy. The masonry of the enclosing wall, existing fence supports, gates can act as a base;

- rectangular or figured (with a complex configuration) frame with additional reinforcing elements - braces;

- filling gaps in the frame. It can be compound or integral. For a metal frame, filling is usually chosen from a solid metal panel (corrugated board, flat sheet) or wooden boards.

The standard design also includes locking elements. For metal gates, a metal box is usually used, inside of which the lock and / or latch mechanism is hidden. If you do not want to install relatively complex mechanisms, let's install a conventional deadbolt. For its fastening, reinforcement of the frame is provided at the place of fastening and the place of landing of the locking bracket.

Below are typical drawings of a gate from a pipe.

With one support and incomplete overlapping of the opening. The support post is buried in the ground and concreted

With two supports and a rigid frame with braces. Covering the opening by 95%, the supports are fixed on the prepared base (concrete, stone)

Built into swing gates, the frame is partially integrated with the gate frame. Supports are concreted in the ground

With straight frame elements, complementing the basic design of swing gates

Given the above schemes, the basic structures can be divided into two groups:

- separately located gates, can be based on the supporting pillars of the fence, located next to the gate or at a distance from them;

- integrated with the gate structure. In this case, the gate may have common supports with the gate or be part of one of the gate wings.

Read also: What seals are put on water meters

In appearance, design and partially construction, models with solid and lattice (partial) filling of the frame are distinguished. Any sufficiently strong and practical materials are suitable for complete filling: wood, metal, polymers (including polycarbonate), less often glass. Lattice structures are divided into products with a rectangular or figured frame. The simplest option is a chain-link mesh fixed on the frame or analogues. The appearance of forged and welded art products is limited only by the imagination of the master.

Lattice products can be supplemented with transparent or opaque sheet filling of the frame.