- The specifics of the operation of boilers with two circuits

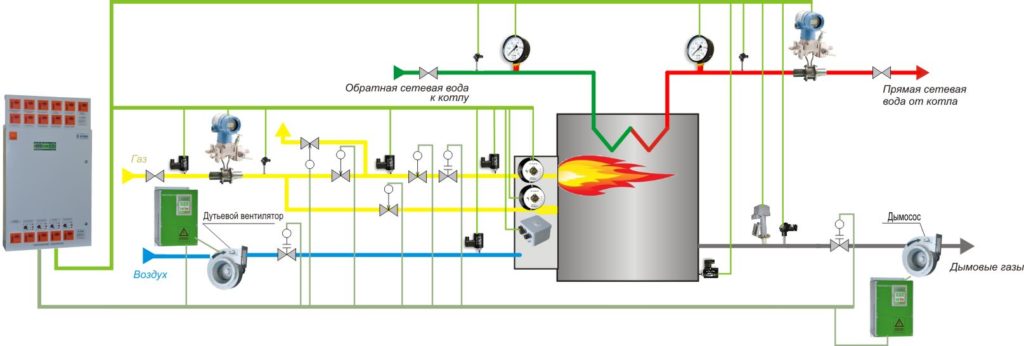

- Heating water supply boiler room

- Heating installation

- Water supply: >

- Boiler room: >

- Synchronous and asynchronous system

- How to remove air pockets

- How the boiler is controlled

- Advantages of remote control

- How to start a gas combi boiler after an emergency stop

- Working with a long-burning boiler

- Gas boiler timing. On time

- UPS installation rules for a gas boiler

- Other criteria

- pivot table

- What does the law say?

- What are the manufacturers saying?

- If we discard discontent, is THAT justified?

- When is maintenance carried out and how long does it take?

- How to save on maintenance?

- Gas burners as part of a double-circuit boiler

- The principle of operation of the boiler

- The choice of fuel for a solid fuel boiler

- Should you choose a convection or condensing boiler?

- The Importance of Boiler Maintenance

- Conclusions and useful video on the topic

- Conclusions and useful video on the topic

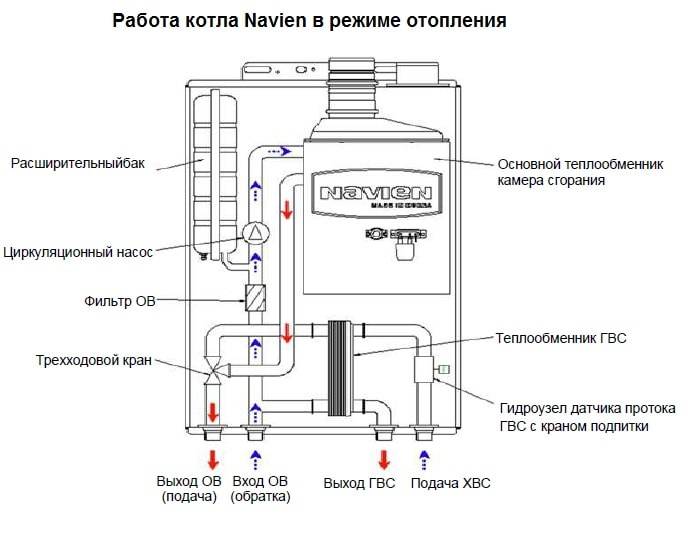

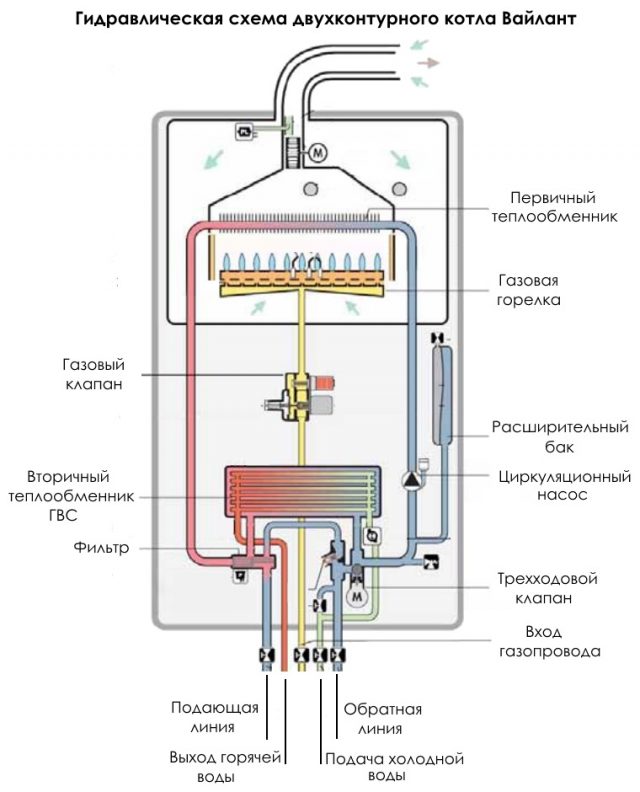

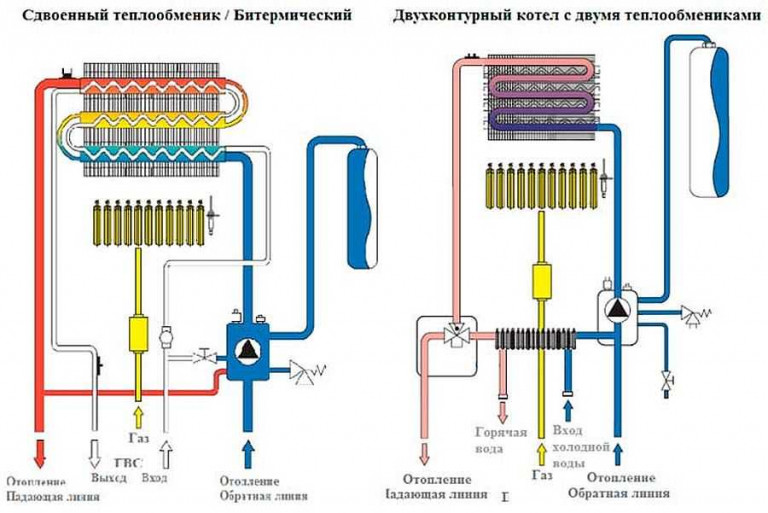

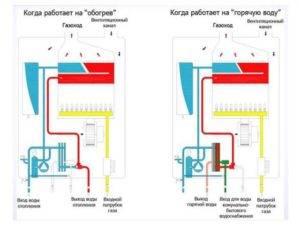

The specifics of the operation of boilers with two circuits

Those who think that both circuits in such a system heat up at the same time at once are mistaken, in fact, everything works in a completely different way. In normal operation, such equipment operates on an ongoing basis only to heat the coolant circulating in the system.How often it will turn on and how intense the flame seems to be during the operation depends on the temperature sensor that controls these processes. Together with the burner, the pump starts, but only if the circulation of the coolant in a natural way does not have any effect on the operation of the heating system. After the temperature of the latter reaches the desired level, a signal is sent from the sensor that the burner activity should be reduced. After that, the boiler operates only in passive mode until the temperature indicator reaches the programmed level. Next, the sensor sends a signal to the automation, which, in turn, starts the valve responsible for supplying fuel.

It is enough to first familiarize yourself with certain intricacies of the functioning of gas boilers equipped with two circuits in order to understand what benefits can be obtained from their operation. Moreover, the purchase of such heating systems allows you not to purchase additional equipment that may be required in any other case in order to provide the house with hot water. Even if one circuit fails, the second can be operated further, replacing one circuit will still cost much less than repairing the entire heating installation.

A double-circuit boiler may well be operated in the summer, when there is no need for heating and it is only necessary to provide heating of water intended for domestic needs. In this way, you can really save money, since buying two units at the same time, each of which operates autonomously, will cost much more.

Read also:

Heating water supply boiler room

Heating installation

DESIGN PRESTIGE LLC >

We provide services for the installation of heating systems, water supply for private country houses, cottages, organizations. We carry out the supply of equipment for work with discounts.

Heating: >

Installation, design, service repair. Heating by type: autonomous, water, private, wood, individual, gas, natural.

Water supply: >

Boiler room: >

For private houses and industrial enterprises. We will install the boiler, distribution modules for heating circuits, install automation elements for temperature control.

All work is done on a turnkey basis.

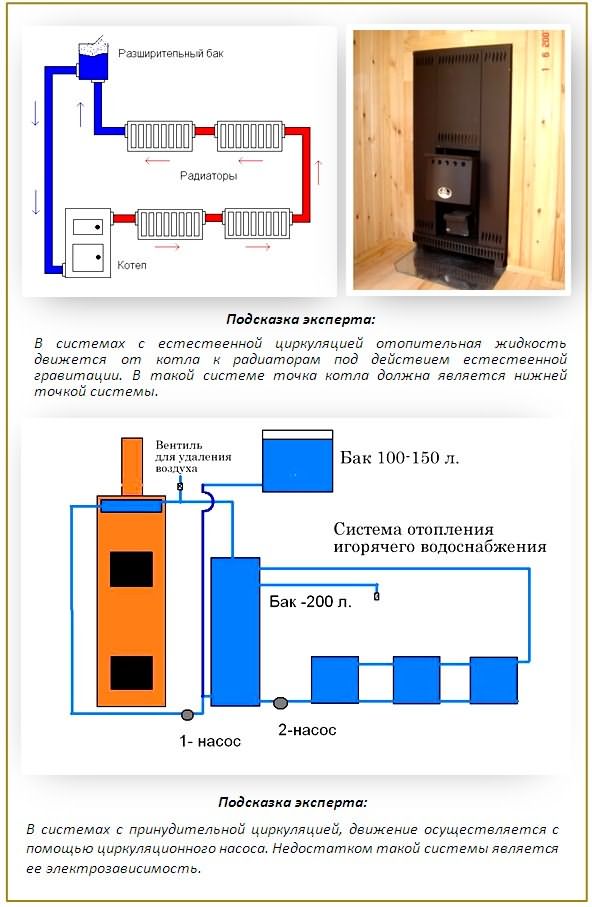

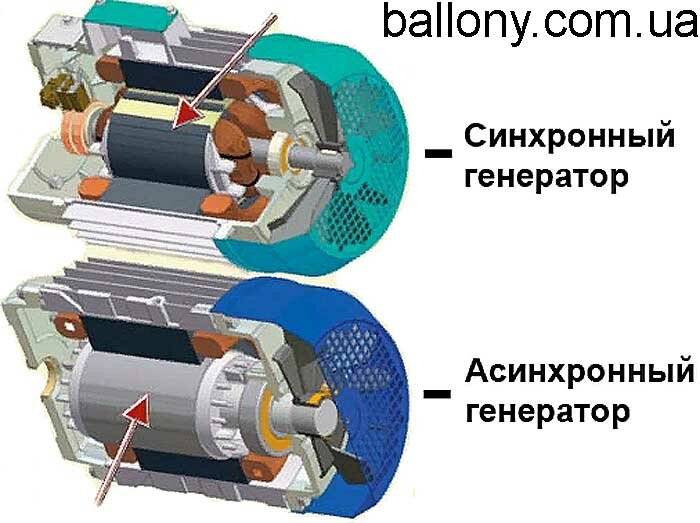

Synchronous and asynchronous system

To make the right choice, you should know their distinctive characteristics. They are set out in the following table:

Characteristics Synchronous Asynchronous Voltage and frequency Stable and high-precision holding Variation in a significant spectrum Electrical overloads High vulnerability to them when starting in standard mode. Resistance to them in starting in a similar mode.

Synchronous models are purchased when a scrupulously accurate current value is required, and the voltage in the network often changes over a wide range.

Devices of the second category are a good budget option and protect the heating network from power surges. This is especially true in domestic conditions. But for this it is recommended to supplement the devices with uninterruptible power supplies (IBS).

How to remove air pockets

Diagram of the correct location of the boiler and chimney.

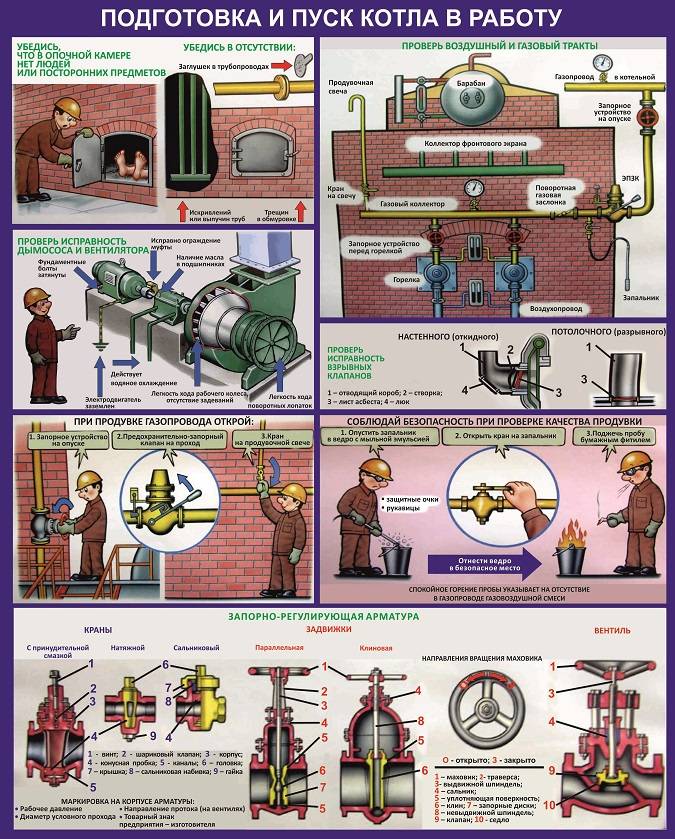

Simply connecting the system by filling it with water is not enough. It will not work or its efficiency will become extremely low. To carry out a full-fledged first start-up of the equipment, it is necessary to drain all the air that has accumulated in it from the system. A modern gas boiler may have a special system for automatically venting air when filling, but the efficiency of such systems is low. This means that manual venting of the main and other systems is required during connection. Only then can you start.

Removal of air locks during connection is carried out not only at the circulation pump, boiler, but also in all heating radiators. In this case, it is recommended to start the process with radiators. Especially for this, they are equipped with the so-called Mayevsky cranes, which you just need to open by substituting a basin under them. At first, a slight whistle will be heard - this is the air gradually leaving the system. If the plugs are removed, then water begins to flow. If the batteries are freed from air masses, then the valves must be closed. Such a simple procedure is carried out with each radiator, it must be checked and cleaned of plugs. When air is removed from all radiators, the pressure gauge needle will be set to the desired value. Before as gas boiler turn on, it is necessary to add a coolant to the system, that is, feed it with liquid.

Next, you need to completely remove all air plugs from the circulation pump, which requires disassembly of some parts of the boiler. This work is simple, you just need to remove the front panel of the boiler, and then find a cylindrical part that has a cover in the middle of the body, it has a slot for a screwdriver.The boiler must be started, that is, turn on the power, set the heating regulator to the required operating position. After that, a faint hum will be heard - this will earn the circulation pump. You can hear gurgling, other sounds. Using a screwdriver, the cover in the found part must be slightly unscrewed, this should be done until water flows. As soon as the liquid begins to seep, the cap must be screwed back. This procedure needs to be carried out 2-3 times, after which the air pockets will completely leave the system, and the sounds and gurgling will disappear, the pump will start to work quietly. Immediately after this, the electric ignition of the equipment will work, the gas boiler will start its work on its own.

The pressure in the heating system must be equalized by adding water to the required level. The system gradually warms up, begins to enter normal operating mode. Connection and first start-up for any heating equipment is a complex and demanding process. From properly performed preparation, start-up, adjustment of the system depends on how efficient the heating will be.

How the boiler is controlled

In order to ensure stable and safe operation of such heating equipment, it is better to choose automation. It controls the temperature of the water in individual components, maintains the temperature of the coolant at the proper level and is responsible for the competent principle of operation of the double-circuit boiler. In the event of potentially dangerous situations, the boiler automatically turns off - a similar manifestation is demonstrated if there is:

- reduction of pressure in the gas system;

- maximum heating of the coolant;

- lack of traction.

In those gas boilers that are on the market today, predominantly “smart” control is used, the software of which allows you to select one of the available operating modes.

Advantages of remote control

Not all users of household appliances are supporters of new technologies. Many are quite satisfied with the usual mechanical control - simple, affordable, without unnecessary "bells and whistles".

But before drawing final conclusions, we suggest considering the advantages of "smart" equipment, which not only makes life easier and more comfortable, but also allows you to significantly reduce costs.

Driving gas boiler at a distance, you can save from 20 to 50% of your total home heating costs by simply changing the operating mode or choosing the right program

Driving gas boiler at a distance, you can save from 20 to 50% of your total home heating costs by simply changing the operating mode or choosing the right program

The main advantage of remote control of a gas boiler is hidden in the method itself: you do not need to be constantly present in the house, “communication” with the equipment occurs at any distance.

Moreover, it is two-way - you send commands to the unit that it executes and, in turn, notifies you of the current parameters and instantly signals failures and irregularities in operation.

The possibilities for programming heating equipment are limited, but still quite wide. Today, having gas boiler with remote control, you can schedule the heating mode while at work, at a party and even on a long trip

The possibilities for programming heating equipment are limited, but still quite wide. Today, having gas boiler with remote control, you can schedule the heating mode while at work, at a party and even on a long trip

Users who have successfully "tested" the remote control system highlight the following advantages:

- Increasing the service life of the boiler due to the optimal choice of mode, reducing the number of shutdowns / on/off, in general - more careful use.

- A long-term absence no longer threatens to return to a cold cottage - you can set the desired temperature on the way home.

- If outdoor weather sensors are installed, you don’t even have to intervene in the operation of the boiler during a thaw or frost - the temperature will be automatically adjusted.

- At a distance, you can choose a more comfortable "night" mode for sleep.

- If an emergency occurs or any part fails, you will know about it right away.

Of course, much depends on the nuances of installation and the complexity of the heating system.

The advantage is that from a smartphone you can manage not only the simplest, but also an extensive network - with radiator or convector heating, a "warm floor" system.

In free sale, you can find equipment for climatic zoning, which will allow you to adjust the comfortable temperature by room: in the bedroom or kitchen - lower, in the living room or nursery - higher

In free sale, you can find equipment for climatic zoning, which will allow you to adjust the comfortable temperature by room: in the bedroom or kitchen - lower, in the living room or nursery - higher

Some functions of the system are launched automatically, that is, you do not even need to select the mode on the phone - the equipment will automatically switch according to the signals from the sensors.

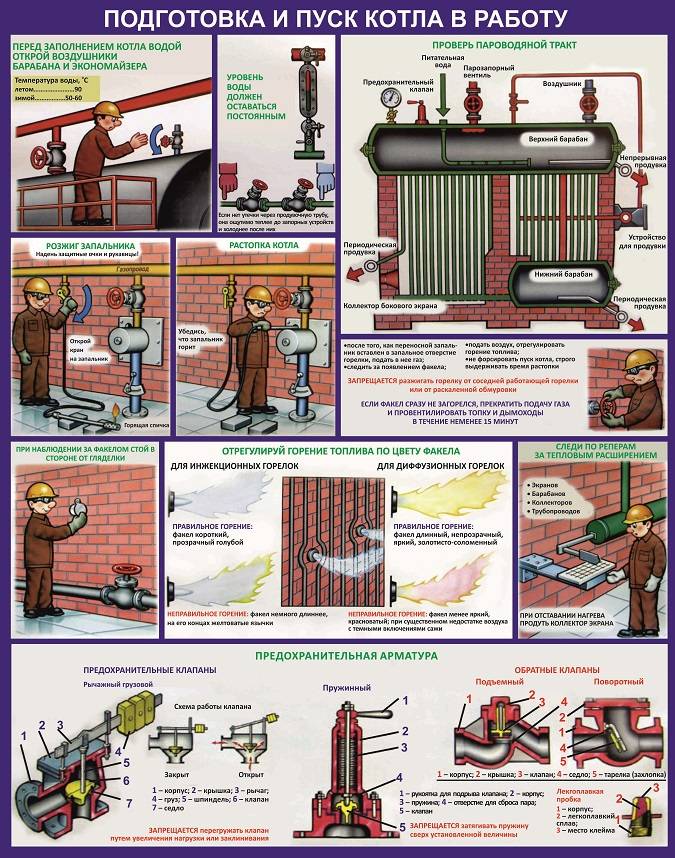

How to start a gas combi boiler after an emergency stop

Good afternoon. I am contacting you with a problem. We have a double-circuit boiler with a coaxial system in our house. During the repair of the heating system, all the water was drained. At that moment, the wife decided to wash the dishes and turned on the tap with hot water. The boiler, of course, reacted, and as a result, an emergency shutdown of the device occurred. The alarm sensor has tripped. When the pipes were repaired and the system filled with water, the boiler failed to start. The emergency light was on, but the heating system did not start.We cannot invite specialists, since the nearest service is 100 km away. Help start the boiler correctly. Boiler brand - Viessmann.

To start the heating system after emergency stop gas boiler, you need to fill the radiators and pipes with water. Before that, look in the technical passport of the boiler, what is its minimum and maximum working water pressure in the system, and fill in the boundary of these figures. The pressure level should be checked on the sensor, which is installed on the front panel of the device (it can be from below, on the side, depending on the brand).

Next, check the gas connection. Are all connecting hoses in place, is the gas supply cock not closed.

If everything is in order, press the "network" button on the boiler to start the system.

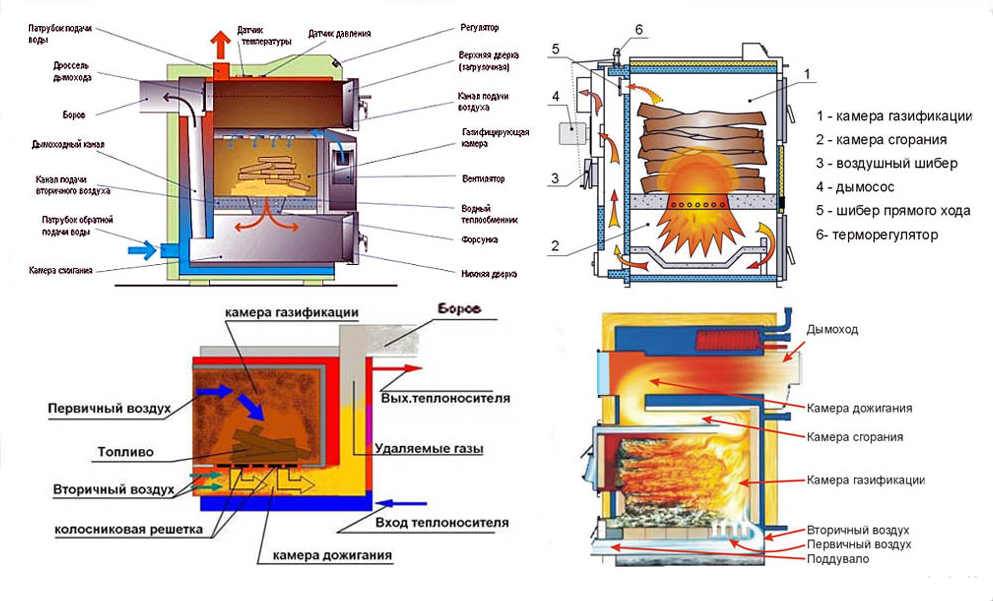

Working with a long-burning boiler

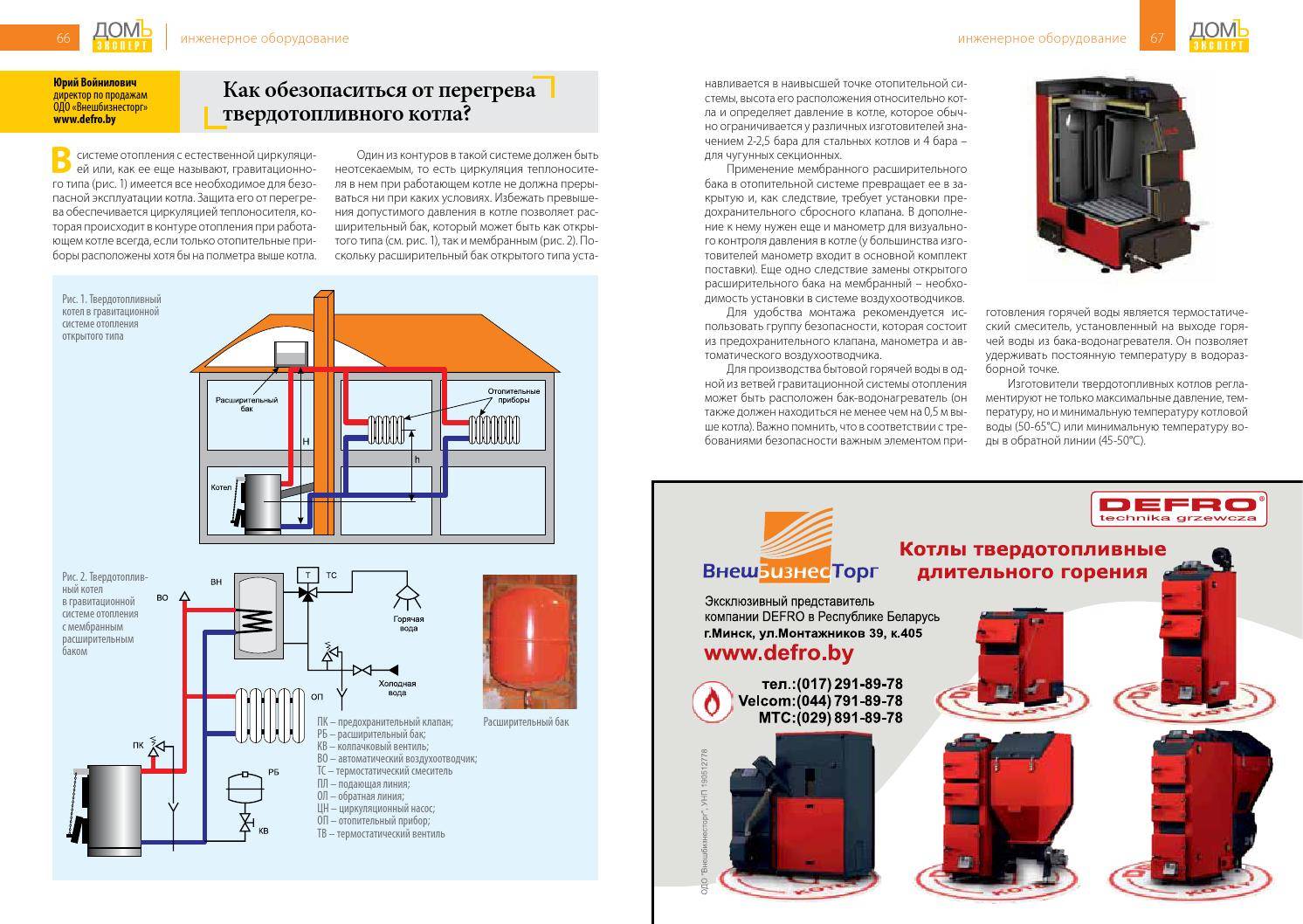

The question of how to heat a long-burning solid fuel boiler is multivariate, since the boiler can heat both by burning through and by a layer. This feature allows you to significantly increase the operating time of the unit with just one load.

The implementation of loading and kindling the device is quite simple:

- firewood is laid up in the firebox;

- chips and paper are added through the loading door;

- paper is set on fire, you must wait until the wood chips light up;

- when the door is closed, the control unit can be turned on.

If all the steps were performed correctly, then the top layer will begin to gradually flare up, during the operation of the unit, all the filling will burn out from top to bottom.

In some cases, when the entire system has not fully warmed up, a small amount of barely visible condensate may appear on the walls of the heat exchanger. Sometimes this liquid can leak out of the hatches, forming small puddles on the floor.Mostly this situation is temporary. The boiler, which has good circulation, after heating the system no longer emits condensate.

Immediately after turning on the control system, it is better to leave the solid propellant apparatus in high temperature mode. In this case, the room and the unit itself will warm up faster, after which the temperature can be reduced.

Gas boiler timing. On time

what is 17 kilowatts of heat carriers? it should be in liters

17 kilowatts of coolants? This parameter is the loss of OK and in double-circuit, the flow rate for heating DHW.

The on/off time depends on the temperature of the coolant and the internal temperature in the room.

Clocking the boiler, in principle, does not interfere with its operation, but the less often it turns off, the better. The boiler must be adjusted to the system or immediately select the boiler power for the heating system. You can reduce the power by going to the engineering menu or invite a specialist so as not to break firewood yourself.

from domestic conditions and from the weather and from the sensitivity of the boiler ....

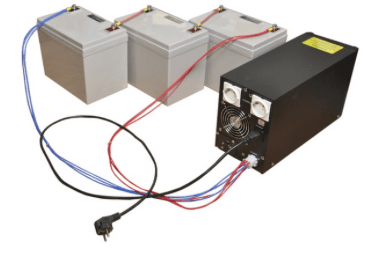

UPS installation rules for a gas boiler

Do not place the UPS near the cold water supply pipes of double-circuit boilers (condensation forms on them), as well as near the heating pipes, so as not to impair the cooling efficiency of the inverter. Batteries should also not be exposed to low or excessively high temperatures.

Do not use the UPS in conjunction with lead-acid batteries, unless it is directly indicated in the instruction manual for this uninterruptible power supply. The difference in charge current characteristics between lead acid and gel batteries may cause the UPS charger to malfunction.

When used in the heating system of a phase-dependent gas boiler in conjunction with a UPS, its output is connected to the load through an isolating transformer. This is due to the fact that when the inverter is running, both of its outputs are phases with respect to ground, while a phase-dependent boiler requires a well-defined phase and neutral supply. For this, an isolation transformer is used, one of the terminals of the secondary winding of which is grounded.

Other criteria

Having resolved the issues with the main technical points, pay attention to the following:

- Duration of work without pauses. Ordinary household models are not able to work 24/7. After all, their engine needs breaks for cooling. More massive and powerful units withstand from 12 to 16 hours. Compact versions, weighing less than 10 kg, work without rest for 3-5 hours.

- Launch method. There are only two options: manual and automatic. The second guarantees complete autonomy of the heating network. But only expensive and powerful devices have this option.

- Noise indicators. They are due to the functional speed of the engine, the ability to control them and the presence of sound insulation. Almost all low power generators have a special casing that isolates the sound.

pivot table

In the following table, you can get acquainted with 9 popular and efficient UPSs on the market, which are divided into 3 subgroups. From the names, you can understand that the main factor is the necessary uptime.

We also took into account the heated area of the house: the larger it is, the higher the power consumption of the boiler and pumps.Each subgroup includes models for houses up to 100 sq.m (power consumption of boilers and pumps - 100-150 and 30-50 W) and for 100-200 sq.m. (150-200 and 60-100 W).

| Group 1: UPS for short (up to 2 hours) and rare (2-4 times a year) outages | ||

|---|---|---|

| 1. |

Ideal for: a boiler in a small house up to 100 sq.m with a stable mains voltage of 220 V | 11000₽ |

| 2. |

Ideal for: boilers without external circulation pumps in a small house up to 100 sqm | 10800₽ |

| 3. |

Ideal for: connection of boilers and pumps in houses 100-200 sq.m. | 12900₽ |

| Group 2: UPS for long (from 2 hours) and frequent (from 5 times a year) outages | ||

| 4. |

Ideal for: sensitive boilers and pumps in 100-200 sqm houses with unstable voltage | 16800₽ |

| 5. |

Ideal for: boilers and pumps in houses 100-200 sq.m with stable voltage | 12900₽ |

| 6. |

Ideal for: Boilers with built-in pump in houses up to 100 sqm | 10325₽ |

| UPS to work together with an electricity generator | ||

| 7. |

Ideal for: uninterrupted power supply of boilers and pumps with unstable voltage | 19350₽ |

| 8. |

Ideal for: Boilers with extra low voltage and high noise requirements | 17700₽ |

| 9. |

Ideal for: Expensive boilers with sensitive electronics | 21600₽ |

And now let's take a better look at the characteristics of the models, study customer reviews and watch video reviews.

What does the law say?

To date, all owners who have entered into a gas supply agreement are required to annually carry out maintenance of gas equipment. The consumer must provide the gas service with documents confirming the conclusion contracts for technical service with the respective company.

It is noteworthy that in Europe there is no practice of maintenance of boilers - this is an exclusively Russian norm.

Who can carry out maintenance?

Both legal entities and individual entrepreneurs can provide services. The list of approved organizations is published in the register State Housing Inspectorate by your region. Specialists of authorized companies and firms are trained at special plants, in our case - UKK Mosoblgaz.

What happens if maintenance is not carried out?

Everything that is in the apartment (house) is the responsibility of the consumer. That is, it is the consumer who is obliged to find an organization for maintenance, conclude an agreement with it and send the necessary documents to Mosoblgaz or Mosgaz.

If the regulatory authorities do not receive the necessary papers from you, then you may face a fine, and in the future - turning off the gas supply. Cut off the pipe and put a plug on it.

What are the manufacturers saying?

Some manufacturers recommend maintenance, others say nothing about it.

Will the boiler be removed from the warranty if a service company gets into it?

If the service is carried out by specialists, the guarantee will not be removed - according to the law. Moreover, some manufacturers can increase its duration if you carry out maintenance in a timely manner. Information about this is contained in the warranty card, carefully study it.

I want to install a new boiler in the house - which one to choose?

If we discard discontent, is THAT justified?

If the customer and contractor do not treat the need for service as a mere formality, then it definitely makes sense.

First of all, it is the diagnosis of possible problems. You can assess the condition of the boiler and other components before the heating season so that you do not find yourself without heat at an unexpected moment.

Over time, the operation of the heating system may deteriorate:

- The boiler often turns on and off.

- Everything works, but the batteries are cold.

- The pressure drops in the system.

- The extractor doesn't work.

During maintenance, the operation of all boiler components is checked and scheduled work is carried out:

- Testing the wiring.

- Clean internal parts, filter.

- Set up the burner.

- Check the pump.

Regular maintenance helps to play it safe and identify possible problems in advance.

If something happened to the boiler, then quickly replacing it during the heating season will be problematic.

If problems arise in the winter, you will have to urgently look for specialists. Winter is a “hot” season for companies, queues for orders are long and prices are high. The heating operation will stop until the boiler is repaired or replaced. If you have carried out maintenance, you are calm for the entire heating season.

The question is rather how you feel more comfortable: play it safe and feel calm, or hope that the boiler will work as long as possible without intervention, and the gas services will not remember you.

When is maintenance carried out and how long does it take?

By law, maintenance of a gas boiler is carried out at least once a year. In the contract with the contractor, a list of services is indicated, and after maintenance, an act is issued. The procedure lasts from 2 to 4 hours - everything is done within one working day. Work can be carried out at any time of the year, but it is better to do it in advance, before the start of the heating season.

During maintenance, the boiler is disassembled. If it is in operation, then it is advisable to turn it off a few hours before the arrival of the master - so that the system has time to cool down.

Energobyt Service → Services:Maintenance of boilers

How to save on maintenance?

It is best to wait for the period of special offers. From April to June, service companies have the lowest workload, so prices may be lower at this time.

Once again the most important:

Gas burners as part of a double-circuit boiler

Gas boiler burner is responsible for obtaining the required amount of heat, which can ensure the correct operation of the heating system in each room of the heated facility. Also, the water is heated to the desired temperature and already hot is supplied in the proper volume. You can get thermal energy by burning the corresponding volumes of fuel. To do this, the burner is placed in the combustion chamber, where, in addition to gas, air is also injected to help maintain the flame.

Depending on the selected mode, the burners can be conditionally divided into single-level, multi-level and simulated ones. In the first variant, the equipment operates only in two modes - "start" and "stop", is highly economical, inexpensive and has a simple design. Two-level burners can operate both at full and at partial power.Its advantages can be fully appreciated, starting in spring, when there is no need for heating, and therefore there is no point in operating the device at full strength. The modulating burner is considered the most expensive, with its help you can adjust and regulate the power of the boiler. The latter is economical and lasts quite a long time.

Depending on the selected mode, the burners can be conditionally divided into single-level, multi-level and simulated ones. In the first variant, the equipment operates only in two modes - "start" and "stop", is highly economical, inexpensive and has a simple design. Two-level burners can operate both at full and at partial power.Its advantages can be fully appreciated, starting in spring, when there is no need for heating, and therefore there is no point in operating the device at full strength. The modulating burner is considered the most expensive, with its help you can adjust and regulate the power of the boiler. The latter is economical and lasts quite a long time.

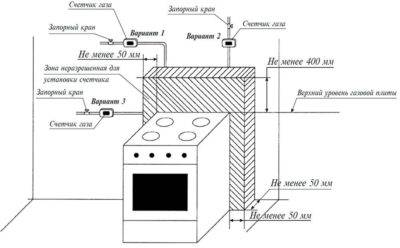

Structurally, the burners are open and closed. In the first case, the air, without which full combustion of fuel is impossible, is supplied from the room where the boiler is located. Such a system is equipped with a chimney, with its help natural draft is provided.

Atmospheric heating boilers are equipped with a conventional metal pipe, while turbocharged models are equipped with a coaxial chimney. They can be installed vertically, but often they are located at an angle - this option is connected to a common shaft, through which smoke and combustion products are fully removed.

Particularly noteworthy are turbocharged models of gas boilers, in which closed-type combustion chambers are installed. Oxygen is forced into them, and therefore they are considered more reliable and do not pose any danger during operation, which makes them in demand in residential premises. In addition to the chimney, they require a special channel - it is through it that oxygen will be supplied to the chamber.

Turbocharged boilers require coaxial pipes in order to remove smoke and draw in fresh air from the street. In some models, there are two such elements; in addition, they are equipped with a pipe for air supply.

All of these models are necessarily equipped with fans that promote smoke, as well as automation and a multi-level protection system.

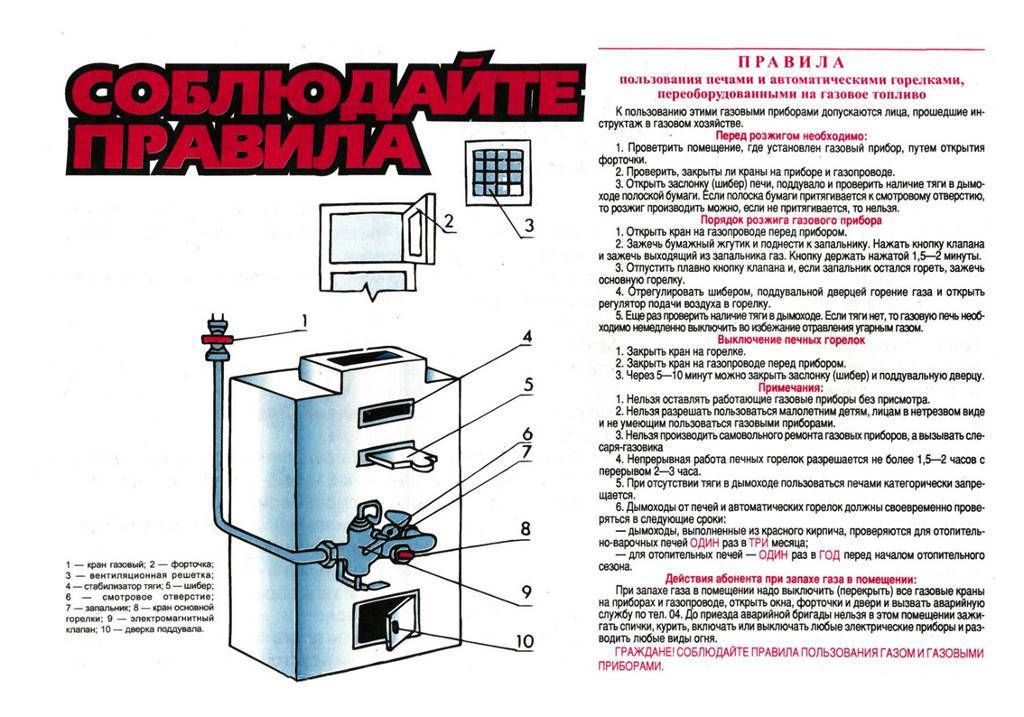

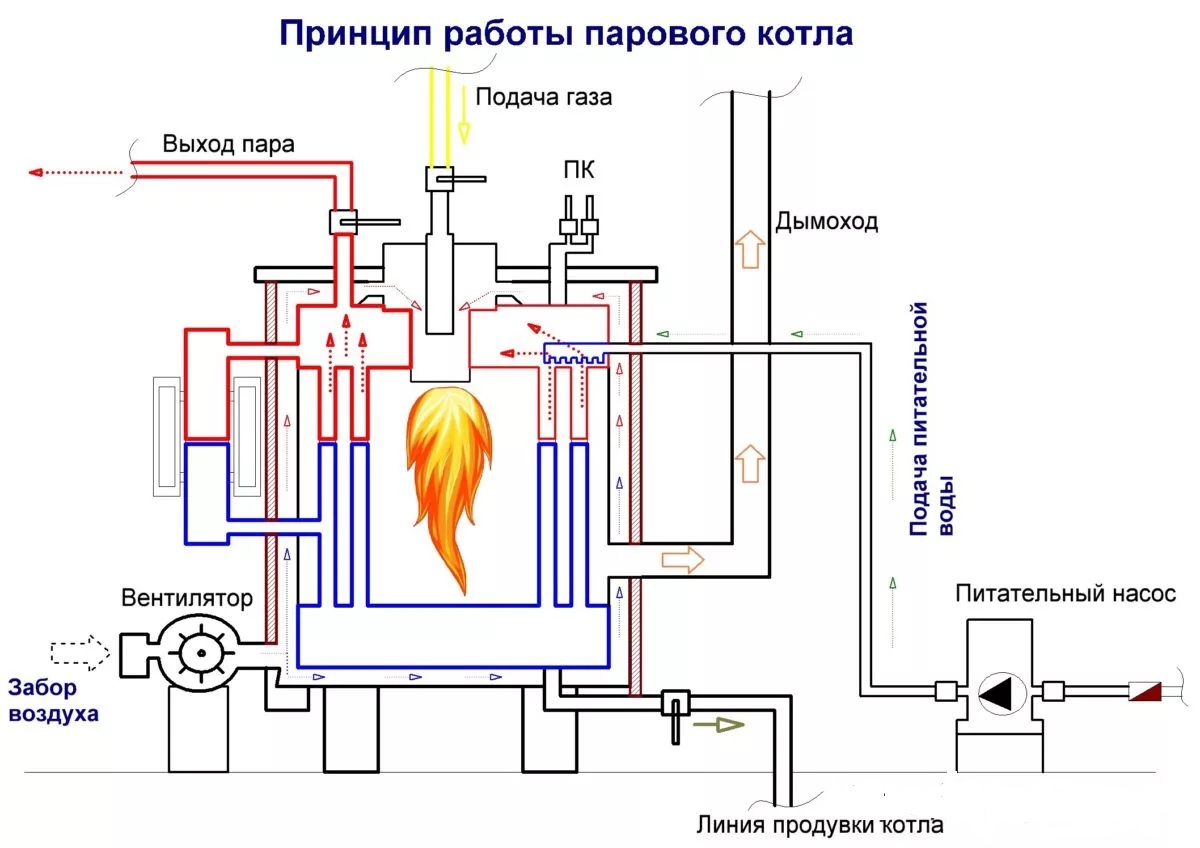

The principle of operation of the boiler

Gas is used not only for space heating, but also for heating water. For this, either water columns or double-circuit boilers are used. The equipment that is used today is equipped with highly effective security systems - they keep the gas combustion process under control. But, nevertheless, there are mandatory rules for the use of gas equipment and their observance can become a guarantee of safety.

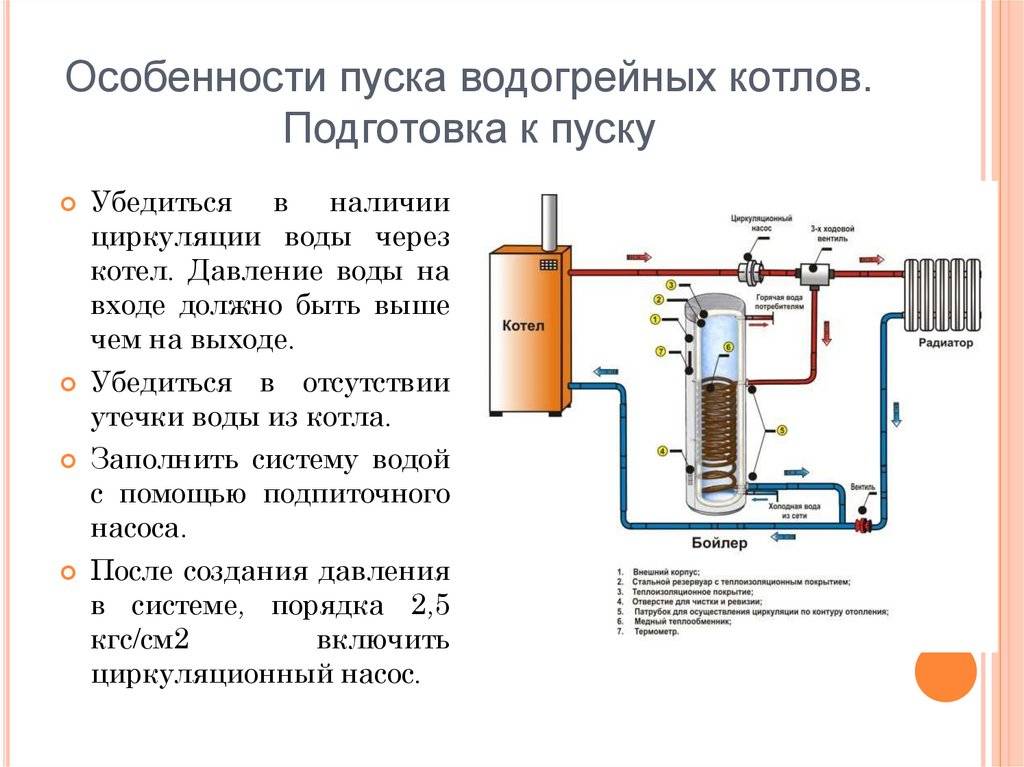

Before putting the equipment into operation, the user must ensure:

- In the presence of the required amount of working fluid in the heating system.

- That the burner, safety valve, are in working order.

- Measuring instruments show correct data.

- The operating temperature of the boiler device should not fall below 65 degrees. This may lead to condensation.

The choice of fuel for a solid fuel boiler

Many users of solid fuel boilers are very careful about the choice of fuel. This is not at all surprising, since the quality of the unit depends on this product. Moreover, it must be bought in large quantities, not only because of the cold climate, but also because the long-burning device provides for refueling with large quantities of raw materials.

The most popular today are the following types of gas stations:

Not knowing what is the best way to heat a solid fuel boiler, you should pay attention to briquettes and pellets, which are easy to use and have a long burning time.But when using them, there is also a significant minus - a high price, which is a derivative of the difficulty of manufacturing these products. But heating with coal is beneficial from all sides - its combustible effect is quite long, and when burned, it does not emit any harmful substances

No less pleased with the low price of the material

But heating with coal is beneficial from all sides - its combustible effect is quite long, and when burned, it does not emit any harmful substances. No less pleased with the low price of the material.

The method of loading firewood as an attachment to this product is extremely popular because, after burning firewood, black fuel remains active for a long time, increasing the time to the need for a new refueling. Although none of the heating methods can be called correct, each user selects the option that suits him.

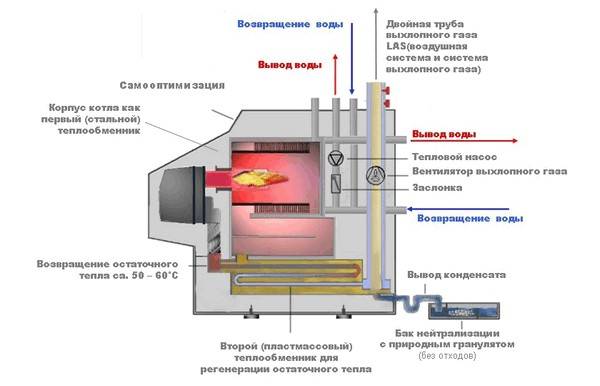

Should you choose a convection or condensing boiler?

Condensing boilers are about 15-20% more economical than convection boilers (under certain operating conditions), but they are also more expensive, on average, by 30-50%. They can be recommended in cases where it is expected that the boiler will be used intensively - for example, all year round, and not just in summer. Condensing boilers are best combined with heating systems such as underfloor heating, as the desired efficiency is achieved only at low temperatures (below 60°C). When used with a classic radiator heating system, it is mandatory to use weather-compensated regulation on the boiler controller.

The Importance of Boiler Maintenance

Above were listed effective methods that can solve such a problem as reducing boiler gas consumption. But all of them have an unpleasant feature. The reason is that the described procedures are used when the heating unit, and with it the entire heating system, has become less efficient. Which leads to an increase in fuel (gas) consumption and a decrease in the comfort of living.

And such a disadvantage can only be eliminated with the help of maintenance. The main feature of which is the ability to prevent an increase in gas consumption, as well as to prevent premature wear of structural elements of any gas boiler. Which allows you to save even more.

Do not reduce gas consumption using illegal methods. Since as a punishment you can get a fine of up to a million rubles and with a possible restriction of freedom (Article 158 of the Criminal Code). And this, if there are no consequences in the form of harm to health, the lives of other people

Do not reduce gas consumption using illegal methods. Since as a punishment you can get a fine of up to a million rubles and with a possible restriction of freedom (Article 158 of the Criminal Code). And this, if there are no consequences in the form of harm to health, the lives of other people

This procedure is a complex of various works, namely:

- control;

- verification.

Which allow timely detection of signs of all problems leading to a decrease in the efficiency of boilers. The only exception is the clogging of the heat exchanger channels, since it cannot be visually identified. Therefore, in this case, you just need to combine cleaning work with maintenance (at the right frequency).

Maintenance must be carried out at least once a year before the start of the heating season. But it is more practical to carry out maintenance up to 3 times every 12 months:

- before the start of seasonal operation;

- during its operation;

- after the end of the heating season.

An important advantage of boiler maintenance is that a significant part of the work can be done by the owner himself. Since all that is needed for this is to have a certain set of knowledge and practical experience.

Conclusions and useful video on the topic

How to pressurize the expansion tank:

How to start a gas boiler:

Putting a gas boiler into operation is a responsible and difficult job. In order for the device and the heating system to work for a long time, a number of important requirements must be met. After combining the system into a single whole, it is necessary to check its tightness. If water seeps through the pipe connections, the pressure will constantly drop.

The gas pipe connection also needs to be checked for leaks. When turning on the boiler, it is necessary to strictly observe the safety precautions, since working with gas equipment involves an increased risk.

Conclusions and useful video on the topic

The first video material will allow you to better understand the reasons that lead to excessive consumption of energy by the boiler.

The following video shows how to reduce the consumption of "blue" fuel to a minimum.

It is quite possible to reduce gas consumption by a household boiler, and in many cases this can be done quickly and without financial costs. But it should be remembered that the most effective method is regular maintenance.

In addition, when performing any work on gas equipment, one should not forget about safety measures.

Would you like to supplement our material with useful comments or tell us your secrets to reduce gas consumption? Or do you still have questions about reducing fuel consumption by a gas boiler? Add your comments, ask for advice from our experts and other site visitors - the feedback block is located below the article.